-

Isihlungi Sesibaso Sethusi Sekhwalithi Ephezulu

Imininingwane Yomkhiqizo Sethula Isihlungi sethu Sesibaso Esiphezulu Nge-Sintered Bronze Fuel Element - ikhambi eliphelele kunoma ubani odinga ikhwalithi ephezulu...

Buka imininingwane -

I-Sintered Copper Bronze Grounding Plate

I-Deters Electrolysis kanye ne-Galvanic CorrosionYehlisa Ukuphazanyiswa kwe-RF futhi Ithuthukisa Ukusebenza Kwe-Electronics Ukwamukela okungcono kakhulu kwamadivayisi akho e-GPS, isimo sezulu ...

Buka imininingwane -

I-Porous Metal Sintered Mini Cylinder

Izinsimbi ezinama-porous zingenye yezinto eziningi ezifanele ukukhiqiza ama-bearings. Izinzuzo ze-Sintered Mini Cylinder Powdered metals zinenani elikhulu...

Buka imininingwane -

Isihlungi Esine-Acid Ne-Alkali Esiqinile Kakhudlwana esingu-316L Isihlungi Sensimbi Engenasici Esingenazimbobo...

Chaza umkhiqizo we-HENGKO isihlungi se-biomedical senziwe nge-316L yensimbi eyimpushana efakwe endaweni yokushisa ephezulu, ene-porosity efanayo engu-0.2-0.5 um, ukugqwala ukumelana...

Buka imininingwane -

I-CEMS Online Smoke Analyzer Gas Sampling Probe 44.5mm*121mm i-Unique Probe Design

Chaza uMkhiqizo * Ukuhlukaniswa kothuli ngesikhathi senqubo * Ngokugxilisa uthuli ngaphezu kuka-3g/m3 * Indawo enkulu esebenzayo * Impilo ende * Ukucindezela okuhlukile okuphansi...

Buka imininingwane -

Ishubhu yesihlungi sensimbi enezimbotshana zokuphatha okushisayo kanye namakhemikhali akhethekile | HENGKO

Amashubhu okuhlunga ensimbi engenasici e-HENGKO enziwa ngokufaka i-sintering 316L powder material noma i-multilayer stainless stainless wire mesh emazingeni okushisa aphezulu. Bake ba...

Buka imininingwane -

316L SS insimbi engagqwali izihlungi sintered, ngokwezifiso microporous nickel monel inco...

Izinto zensimbi ze-HENGKO ezinama-porous zikhiqizwa ngokwelashwa okushisa okuqinile kwe-multilayer yensimbi engagqwali wire mesh noma 316L powder emazingeni okushisa aphezulu. Ngoba...

Buka imininingwane -

Uhlobo lwekhandlela I-Sintered 316L yesihlungi se-mesh cartridge esisebenziseka kabusha

I-HENGKO inikela ngeqoqo elibanzi lama-cartridges ensimbi engenasici enzelwe ukusetshenziswa ezinhlobonhlobo zezimboni, kufaka phakathi amakhemikhali e-petrochemicals...

Buka imininingwane -

I-Anti-corrosion Microns Powder Porous Sintered Metal Filter Cartridge For Filtration System

I-HENGKO idala amashubhu okuhlunga anezimbotshana anikeza ukuguquguquka ekwakhiweni njengoba engaba yizigodi noma ayimpumputhe anogqinsi oluncane lodonga oluyi-1mm. Le mikhiqizo c...

Buka imininingwane -

imidiya yesihlungi esinezimbotshana zensimbi, i-porosity 0.2 μm ~ 100 micron titanium mon...

Kwa-HENGKO, inqubo yokudala izinto zabo zensimbi ezinezimbobo ihilela ukwelapha ukushisa okungu-316L okuyimpushana noma i-multilayer yensimbi engagqwali enemeshi endaweni ephezulu...

Buka imininingwane -

Isihlungi se-cartridge yensimbi engenazimbobo yensimbi yokucindezela okuphezulu kokuhlanza umoya okuqinile ...

I-HENGKO ikhiqiza izinto zayo zensimbi ezinama-porous ngokuphatha ukushisa okungu-316L okuyimpushana impahla noma i-multilayer insimbi engenasici yocingo enezikhala emazingeni okushisa aphakeme. Yabo...

Buka imininingwane -

Abanekhono 0.2 kuya 120 microns micro porosity zethusi inconel monel 316 316L insimbi engagqwali ...

Insimbi enezimbotshana idalwa ngokucindezela insimbi eyimpushana ibe yizimo ezihlukahlukene, ezibe sezihlanganiswa ne-sinter ukuze kwakhiwe isakhiwo esiqinile nesingenasici. Lokhu okuhlukahlukene ...

Buka imininingwane -

Izihlungi Ze-Bronze Ezihlanganisiwe ezine-OEM Specific Shape Yokuhlunga

I-HENGKO inganikeza amakhasimende ithuba lokukhiqiza izihlungi kanye nezingxenye zethusi ezinama-porous ezinobunjwa obuthile. Ngasinye salezi zinhlelo zokusebenza ezikhethekile r...

Buka imininingwane -

I-5 10 20 90 120 microns sintered metal porous bronze insimbi engagqwali 316L multi-purpose ...

I-HENGKO ikhiqiza izinto zokuhlunga ngenani elibanzi lezinto, osayizi, nokufakwa ukuze kucaciswe kalula ngezici kanye nokucushwa...

Buka imininingwane -

Amandla afanayo anezimbotshana zensimbi ezinezimbotshana zesihlungi se-micron fluidizers zethusi zethusi ifilimu yethusi...

Amashidi okuhlunga okujulile asetshenziselwa ukususa izinhlayiya oketshezini. Lokhu kusho ukuthi uketshezi lungacaca-, lucolise noma luhlungwe olwenziwa yinyumba. Amashidi okuhlunga alungele ...

Buka imininingwane -

isihlungi somoya esine-sintered medium spheric bronze filter element

I-HENGKO SINTERED BRONZE OIL FILTER isetshenziswa ku-sparging, ukuvikela izinzwa, igesi, nokuhlunga uketshezi, ukudambisa, ukuphatha inqwaba nokunye okusetshenziselwa i-solu...

Buka imininingwane -

Ukulawula ukugeleza nokusabalalisa uketshezi ipuleti/ishidi lesihlungi esine-sintered, impushana enezimbotshana ezimbotshana...

Amashidi okuhlunga okujulile asetshenziselwa ukususa izinhlayiya oketshezini. Lokhu kusho ukuthi uketshezi lungacaca-, lucolise noma luhlungwe olwenziwa yinyumba. Amashidi okuhlunga alungele ...

Buka imininingwane -

Isihlungi sethusi esinezimbotshana zensimbi esinezimbotshana ze-uniaxial ezinomkhawulo owodwa ovaliwe one-hex.

Incazelo Yomkhiqizo I-HENGKO ikhiqiza izinto zokuhlunga ngenani elibanzi lezinto, osayizi, nokufakwa ukuze kucaciswe kalula nge-charac...

Buka imininingwane -

Amapuleti/ishidi lokuhlunga lethusi elinezimbotshana elinezimbotshana lokugeleza nokulawula umsindo

Amashidi okuhlunga okujulile asetshenziselwa ukususa izinhlayiya oketshezini. Lokhu kusho ukuthi uketshezi lungacaca-, lucolise noma luhlungwe olwenziwa yinyumba. Amashidi okuhlunga alungele ...

Buka imininingwane -

Uwoyela owuketshezi wamakhemikhali ezokwelapha namagesi angu-3um-90 microns powder porous all-metal steam sint...

Amashubhu wesihlungi se-HENGKO angaba yizimbotshana noma angaboni futhi abe nobukhulu obuncane bodonga obungu-1 mm. Zenziwe nge-isostatic compaction of powder in a mo flexible...

Buka imininingwane

Yini Isihlungi Sensimbi Ye-Sintered Powder kanye nezici Eziyinhloko

Izihlungi zensimbi eziyimpushana ziwuhlobo lwesihlungi esenziwe ngokushisisa, noma ukufudumeza, ingxube yezimpushana zensimbi

baze bahlangane ukuze bakhe isakhiwo esiqinile. Le nqubo idala i-porous material engabamba

ukungcola nokunye ukungcola, okwenza kube isihlungi esisebenzayo sezinhlelo zokusebenza ezahlukene.

1.High Porosity

Enye yezinzuzo eziyinhloko zezihlungi zensimbi ze-sintered powder yizoi-porosity ephezulu. Izimbotshana kusihlungi

mancane kakhulu, ngokuvamile asukela kusayizi ukusuka ku-0.2 kuya ku-10 microns, okuwavumela ukuthi asuse ngempumelelo

anhlobonhlobo ukungcola okuvela oketshezini namagesi. Kubenza balungele ukusetshenziswa ezimotweni,

i-aerospace, nezimboni zezokwelapha, lapho ukuhlanzeka nokuhlanzeka kubalulekile.

2.Ukuqina

Enye inzuzo yezihlungi ze-sintered zensimbi ze-powder yizoukuqina. Inqubo ye-sintering yakha a

isakhiwo esiqinile, esiqinile esimelana nokuguga, okuvumela isihlungi ukuthi simelane nezingcindezi eziphezulu kanye

amazinga okushisa ngaphandle kokukhubazeka noma ukuphuka. Kubenza bafanelekele ukusetshenziswa ezindaweni ezinzima,

njengasezinjinini noma kweminye imishini esebenza kahle kakhulu.

3. Ukuhlanza Kalula

Enye yezinselelo zokusebenzisa izihlungi zensimbi ze-sintered powder ukuthi zingabaokunzima ukuhlanza nokusebenzisa kabusha.

Ngenxa yokuthi ama-pores mancane kakhulu, ukususa ukungcola okuvalelekile kusihlungi kungaba nzima, kukwenze

kudingekile ukufaka isihlungi esikhundleni sokusihlanza. Kungaba eqolo, ikakhulukazi izicelo lapho

isihlungi sisetshenziswa njalo. uqinisekile futhi unendlela ethile yokuhlanza.

Naphezu kwalokhu mkhawulo, izihlungi zensimbi ye-sintered powder zisetshenziswa kabanzi ngenxa yokusebenza kahle kwazo nokuqina.

Ziyingxenye ebalulekile ezinqubweni eziningi zezimboni nezokukhiqiza, ezisiza ukuqinisekisa ukuthi

ubumsulwa kanye nekhwalithi yoketshezi namagesi. Ngekhono labo lokucupha uhla olubanzi lokungcola kanye nokumelana

izindawo ezidingayo, izihlungi zensimbi ze-sintered ziyithuluzi elibalulekile lokugcina ukusebenza

kanye nokwethembeka kwemishini nemishini.

Kungani HENGKO Sintered Powder Metal Izihlungi

Nikeza Izixazululo Ezivelele Zokuhlunga

Izinhlobo zethu zezixazululo ze-sintered metal filter metal zivelele ezinhlobonhlobo zezicelo ezidinga kakhulu;

i-porous sinterIzakhiwo eziyingqayizivele zensimbi zisetshenziswa emishinini ehlukahlukene yokucindezela okuphezulu kwenhlawulo kanye

ukusatshalaliswa okufanayo kwamagesi kuketshezi.

Izihlungi zensimbi eziyimpushana ezinezimbotshana, ngokuvamile ngezixhumi zendawo ezinkulu ezithuthukisiwe, zisetshenziselwa ukuhlukanisa

okuqinile okuvela emifudlaneni yegesi phakathiizinqubo ezahlukene. Izici Eziyinhloko zimi kanje:

1. Ukumelana nezinga lokushisa eliphezulu, Ukuzinza kwe-Thermal kufika ku-950°C

2. Ifanele ingcindezi ephezulu yokuhluka

3. Ukumelana nokugqwala okuphezulu

4. Isixhumi esihlanganisiwe se-sinter esiyingqayizivele

5. Isakhiwo esizisekelayo esinamandla amakhulu emishini

6. Ukusebenza kahle kwe-back pulse

7. Akukho Welding of abezindaba porous

8. Ukuguquguquka kwedizayini, izimo ezihlukahlukene ezitholakalayo, nokwenza ngendlela oyifisayo

9. Ngaphezu kuka-10,000 izinhlobonhlobo ezijwayelekile nezingokwezifiso zosayizi/izimo ezitholakalayo

10. Okubalulekile Ekusatshalalisweni kwegesi/uketshezi olulinganayo

11. Adopt Food-class 316L kanye 304L insimbi engagqwali noma ithusi

12. Izinto Ezihlanzeka Kalula Nezisebenziseka Kabusha

EYETHU Ezobuchwepheshe

Njengomkhiqizi wekhwalithi ephezulu wemikhiqizo yokuhlunga yensimbi ene-porous, i-HENGKO inikeza izixazululo zobuchwepheshe besimanje.

ngezinga lokushisa eliphezulu kanye nezindawo ezonakalisayo.

Imvamisa izinto zokuhlunga zensimbi eziyimpushana zenziwe ngensimbi engagqwali, ithusi, ama-alloys asekelwe ku-nickel, ne-titanium futhi

zishiselwe ngaphandle komthungo ngama-alloy athile ukuze wenze ngendlela oyifisayo umumo ohlukile ngesixhumi esinentambo noma umlomo wombhobho womoya.

Ukuhlunga okuchazwe ngokusatshalaliswa kosayizi wembotshana oqondile.

Inketho Yezinto Zokusebenza

I-HENGKO itholakala ngezinhlobonhlobo zezinto.

Isixazululo se-powder metal senza umklamo wokuthunga kanye nezidingoizimfuneko inqubo ngayinye lula.

Izinto ezitholakalayo:

1. Insimbi Engagqwali (okujwayelekile 316L),

2. Hastelloy,

3. Ikhoneli,

4. Imali,

5. Ithusi,

6. I-Titanium

7. Ama-Special Alloys ngesicelo.

Izinhlelo zokusebenza

1. Ukuhlunga Kwegesi

Sihlinzeka ngemikhiqizo eminingi nezisombululo zokuhlunga amagesi ashisayo ezinhlelweni zemboni, namazinga okushisa okusebenza

ngokuvamile ingaphezu kuka-750°C isikhathi eside. Lezi zihlungi zivame ukusebenza kumasistimu afakwe ukuzihlanza okuzenzakalelayo

amakhono, kanye nezinto zokuhlunga kumele zikwazi ukukhiqiza kabusha ngokugcwele kumjikelezo ngamunye. ngakhoizihlungi zensimbi eziyimpushana

kuyisinqumo esingcono kakhulu, futhi zonke izici zingahlangana; ngaleyo ndlela, izihlungi zethu ze-porous melt zisetshenziswa ngokwandayo kumagesi amaningi

izimboni zokuhlunga.

2. Ukubhuqa

Imishini eminingi enengcindezi ephezulu idinga izinto zokuhlunga, njengokuthintana noketshezi lwegesi oludingekayo ukuze kuphenduleke: ukuhlubula, ukuxuba,

noma ukusabalalisa. Kwezinye izinhlelo zokusebenza eziningi, sikusiza ukuthi ukhulise ukusebenza kahle kwenqubo ngokuncoma nokuklama okungcono kakhulu

isisombululo esifanele esisekelwe ezinhlobonhlobo ezinkulu zamayunithi we-sparger atholakalayo.

3. Ukuhlunga Okuwuketshezi

Futhi sinikezela ngezinto ezidizayinelwe ngokwezifiso zesihlungi ezincibilikayo ezizisekelayo kuze kufike ekusebenzeni kahle kwesihlungi esingu-0.1µm oketshezini. I

izihlungi zensimbi eziyimpushana ezihlanganisiwe zingaklanywa ngesemishi elikabili, kanye namabanga amabili empushana axhumeke ku-sinter anikezwayo

Ukukhishwa okungaguquki nokulinganayo nokuthuthukisa ukugeleza ngokuqhathaniswa nezihlungi eziklanywe ngokujwayelekile. The sintered

I-porous disc iyisihlungi esiphelele sezinqubo ezibandakanya i-catalyst. Izinto zethu zesihlungi se-sintered metal metal zine-a

impilo yonke edlula izixazululo eziningi eziqhudelanayo ngenxa yokungabi bikho kwedizayini yokushisela enoxhumano "oluqinile-oluqinile".

4. Fluidizing

Sinikeza ukwenza ngendlela oyifisayo imishini yokugcwalisa i-fluidizing yezinhlelo zezimboni ezintsha nezikhona ngokulawula ngokudidayo okuhlukile

imiklamo yokukhiqiza isisefo ukuze kuqinisekiswe ukusatshalaliswa kwegesi okuphelele okuholela ekugelezeni okuphelele noma ukuxutshwa kwabaningi

abezindaba ezahlukene, kuhlanganise ithusi, insimbi engagqwali, futhi polyethylene. Ngaphezu kwalokho, ngoba fluidizing Izigaxa ezenziwe

izinto zensimbi ezizinzile zivame ukuzenzela, singakwazi ukuhlinzeka ngezihlungi ezinama-flange axhumayo

njengoba kudingeka.

Uzakwethu

Kuze kube manje i-HENGKO inezinkulungwane zezinkampani ezisebenza embonini eminingi ezihlanganisa ikhemistri namafutha, ukudla, ezokwelashwa njll

Futhi ama-laboray amaningi ezinkampani kanye nenyuvesi yomhlinzeki wesikhathi eside wozakwethu. Ngethemba ukuthi uzoba ngomunye wabo,

xhumana nathi namuhla uma unentshisekelo.

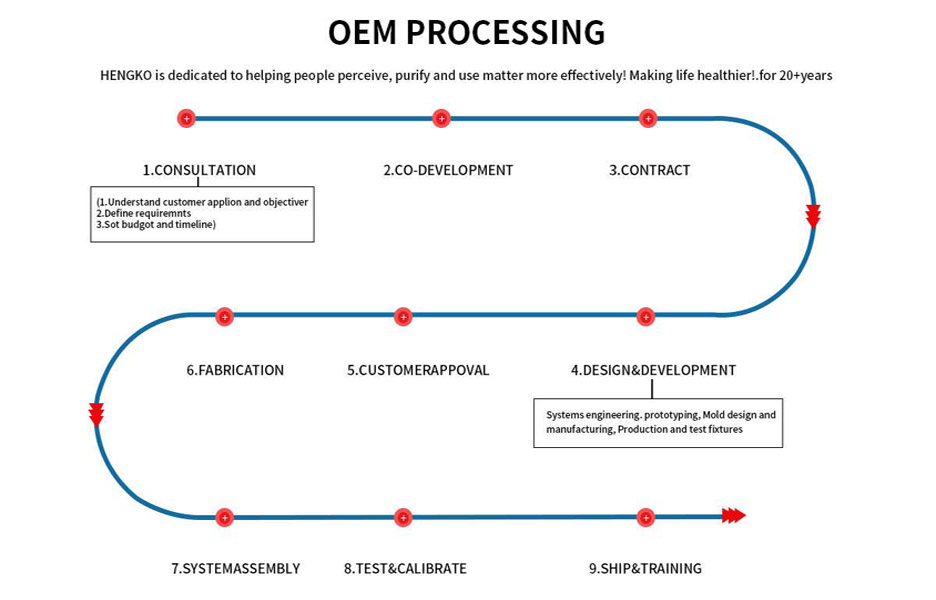

Ungazenza kanjani ngokwezifiso izihlungi ze-Sintered Metal Metal From HENGKO

Lapho UnakhoIsihlungi Sedizayini Esikhethekile Sintered Meltkumaphrojekthi akho futhi awukwazi ukuthola Isihlungi esifanayo noma esifanayo

imikhiqizo, Siyakwamukelaukuze uxhumane no-HENGKO ukuze basebenzisane ukuze bathole isisombululo esingcono kakhulu, futhi nansi inqubo ye

Isihlungi se-OEM Porous MeltSicela uyihlole futhiXhumana nathikhuluma ngemininingwane eyengeziwe.

I-HENGKO Izinikele Ekusizeni Abantu Babone, Bahlanze futhi Basebenzise Izinto Ngempumelelo Kakhudlwana! Ukwenza Impilo Iphile Kahle Ngaphezu kweminyaka engama-20.

1.Ukubonisana futhi Xhumana HENGKO

2.Ukuthuthukiswa ngokubambisana

3.Yenza Inkontileka

4.Idizayini Nokuthuthukiswa

5.Ikhasimende ligunyaziwe

6. Ukukhiqiza/Ukukhiqiza Okuningi

7. Umhlangano Wesistimu

8. Hlola & Linganisa

9. Ukuthumela ngomkhumbi

Ngakho yini imboni yakho? futhi ingabe unayo imibuzo mayelana nezihlungi zensimbi futhi udinga ukuthi sibhekane noma senze ngendlela oyifisayo

izihlungi ezikhethekile zensimbi ezinezimbotshanangomshini wakho nomshini? Sicela uzizwe ukhululekile ukusithumelela uphenyo, Ithimba lethu le-R&D lizokwenza

ukwazi ukukunikeza izimpendulo ezisheshayo nezigculisayo.

FAQ

1. Yini i-sintering in powder metallurgy?

I-Sintering isetshenziswa ku-powder metallurgy ukuguqula izimpushana zensimbi zibe into eqinile, enezimbotshana. Le nqubo ihilela

ukushisisa izimpushana zensimbi ezingeni lokushisa elingaphansi nje kwendawo yokuncibilika, okubangela ukuba izinhlayiya zihlangane

ndawonye futhi bakhe isakhiwo esiqinile.

Inqubo ye-sintering ivame ukusetshenziswa ekukhiqizeni izingxenye zensimbi nezingxenye, njengama-bearings, amagiya,

nezihlungi. Inikeza izinzuzo ezimbalwa kunezinye izindlela zokukhiqiza, njengokuphonsa noma ukufoja, okuhlanganisa

izindleko eziphansi, ukuguquguquka okukhulu komklamo, kanye nekhono lokudala izimo eziyinkimbinkimbi nezakhiwo.

Ngesikhathi senqubo ye-sintering, ama-powders ensimbi afakwa esikhunjeni noma afe, okunquma ukuma kwe-

ingxenye eqediwe. Isikhunta sibe sesifakwa esithandweni, lapho sishiswa khona kuze kube sezingeni lokushisa elingaphansi nje kokuncibilika

pamafutha ensimbi. Njengoba izimpushana zensimbi zifudumala, ziqala ukuhlangana ndawonye futhi zakhe isakhiwo esiqinile.

Njengoba i-metal powders sinter, izimbotshana phakathi kwezinhlayiya ziba zincane futhi zibe zincane. Kwakha imbobo

impahla eqinile futhi ehlala isikhathi eside kodwa futhi inendawo ephakeme, okwenza ilungele izinhlelo zokusebenza ezinjalo

njengokwesekwa kokuhlunga kanye ne-catalyst. Ingakwazi ukulawula ubukhulu nokusabalalisa kwama-pores ngokulungisa i-sintering

izinga lokushisa nesikhathi kanye nokwakheka kwezimpushana zensimbi.

Uma inqubo yokucwilisa isiqediwe, okuqinile, okunezimbotshana kuyasuswa esikhunjeni futhi kuvunyelwe

kupholile. Ingxenye eqediwe ingase ifakwe ngomshini noma icutshungulwe ukuze kwakhiwe umumo nosayizi oyifunayo.

I-Sintering iyinqubo eguquguqukayo engakha izingxenye eziningi zensimbi nezingxenye. Inikeza izinzuzo eziningi,

okuhlanganisa izindleko eziphansi, ukuguquguquka komklamo, kanye nekhono lokudala izimo eziyinkimbinkimbi nezakhiwo. Ngenxa yalokho,

i-sintering isetshenziswa kabanzi ekukhiqizeni izingxenye zensimbi nezingxenye zezimoto, i-aerospace, kanye

izimboni zezokwelapha.

2. Kungani i-sintering ibalulekile ku-powder metallurgy?

I-Sintering iyinqubo ebalulekile ku-powder metallurgy ngoba ihlanganisa izinhlayiya kumpushana wensimbi

yakha into eqinile, ehlangene. Kwenziwa ngokushisisa impushana ezingeni lokushisa elingaphansi kwendawo yayo yokuncibilika,

okubangela ukuthi izinhlayiya zihlangane ngokusabalalisa.

I-Sintering ibalulekile ngezizathu ezimbalwa:

1. Ivumela ukudala izingxenye ezinobunjwa obuyinkimbinkimbi okungaba nzima noma okungenakwenzeka ukukhiqiza

ngokusebenzisa ezinye izindlela zokukhiqiza.

2. Ingasebenzisa ukukhiqiza izingxenye ezinezakhiwo ezithuthukisiwe zemishini, njengamandla amakhulu

nobulukhuni.

3. I-Sintering ingakha izinto ezinama-porous ezine-porosity elawulwayo, ewusizo ezinhlelweni zokusebenza

njengezihlungi nama-catalysts.

Inqubo ye-sintering ngokuvamile ihilela ukushisa impushana ekushiseni okungaba ngu-80-90%.

indawo yayo yokuncibilika ngaphansi kwezimo zomfutho ophezulu kanye nomoya olawulwayo. Kubangela i

izinhlayiya ukuze zisakaze komunye nomunye, zenze inqwaba eqinile. Inqubo ye-sintering ingalawulwa

ukukhiqiza izinhlobonhlobo zama-microstructures kanye nezakhiwo zemishini, kuye ngohlelo oluthile.

Enye yezinzuzo ezibalulekile ze-powder metallurgy ukuthi ivumela ukwakhiwa kwezingxenye ezinobunjwa obuyinkimbinkimbi

nokubekezelelana okuqondile. Kungenxa yokuthi impushana yensimbi ingakhiwa ibe yinoma yisiphi isimo ngokusebenzisa amasu ahlukahlukene,

njengokucindezela nokucupha. Lokhu kuvumelana nezimo kuvumela abakhiqizi ukuthi bakhiqize izingxenye ezinejometri eyinkimbinkimbi

kanye nobukhulu obunembile, okungenakwenzeka ngezinye izindlela zokukhiqiza.

Sengiphetha, i-sintering iyinqubo ebalulekile ku-powder metallurgy ngoba ivumela ukudalwa kwezingxenye

enezimo eziyinkimbinkimbi, izakhiwo ezithuthukisiwe zemishini, kanye ne-porosity elawulwayo. Kuyisinyathelo esibalulekile kumpushana

inqubo ye-metallurgy futhi yenza abakhiqizi bakwazi ukukhiqiza izingxenye eziphezulu zezinhlelo zokusebenza ezihlukahlukene.

Ngakho-ke uma usenayo Noma Yimuphi Imibuzo Futhi Unentshisekelo Yezihlungi Zensimbi Ze-Sintered Powder, wamukelekile

xhumana nathi nge-imeyilika@hengko.com futhi ungathumela umbuzo ngokulandela ifomu lokubuza, sizokuthumela

emuva ngaphakathi 24-Amahora.