-

Ukucocwa kwe-Biopharmaceutical kunye nokuhluza ipleyiti yokucoca i-porous 10um 20um 50um

Ipleyiti yokucoca enemingxuma luhlobo olutsha lwesixhobo sokuhluza esinezingxobo esiphakamileyo esenziwe ngentsimbi engatyiwayo ngumgubo ngokusefa, ukubumba, i-sinterin...

Jonga iinkcukacha -

Umlomo obanzi wengqayi yomenzi wengqayi enentsimbi engatyiwa sintered filter disc yobushushu obuphezulu...

Utshintsho oluncinci, iinzuzo ezinkulu! Sigcina udongwe lwe-bentonite ngaphakathi kwengqayi kwaye sibhaka kwi-oven vacuum ukususa umswakama. Nokuba isiciko eludongweni uyaphuma o...

Jonga iinkcukacha -

NW16 KF16 Flange-Centering O-Ring ngeFine Filter

ISO-KF kunye neNW-Sintered Metal Filtering Ring NW-16、NW-25、NW-40、NW-50 Umboneleli Ngecebo lokucoca elicikizekileyo (isihluzo sesinyithi esinobukroti okanye khetha umnatha wocingo f...

Jonga iinkcukacha -

I-NW50 KF50 iVacuum Flange iringi yokuPhakamisa ngeSintered Metal Filter, intsimbi engatyiwa, 50 ...

I-NW50 KF50 i-Centreing ring nge-Sintered Metal Filter, insimbi engenasici, i-50 ISO-KF Imveliso yemveliso: insimbi engenasici 304,316 Indlela yokufakela: sebenzisa nge-clam...

Jonga iinkcukacha -

I-NW25 KF25 KF iRingi yokuZinzisa kwisiSihluzo seMetal esiSintered

NW25 KF25 KF Centreing Ring to Sintered Metal Filter • NW16 (KF16, QF16) Series• Viton (Fluorocarbon, FKM) O-Ring• Viton: 200°C Ubuninzi• 0.2 µm Ubungakanani bePore• F...

Jonga iinkcukacha -

I-Monocrystalline silicon yoxinzelelo loxinzelelo lwe-sintered metal porous filter disc

Ukusebenzisa i-crystal silicon piezoresistive iteknoloji yoxinzelelo lwenzwa yoxinzelelo, inkqubo yenkqubo yokulinganisa inqanaba lolwelo usetyenziso lwe-sintered filter disc material:...

Jonga iinkcukacha -

Isihluzo sesinyithi esinezingxobo se-ozone kunye nomoya emanzini

Inkqubo yokuvelisa ubukhulu obukhulu (80-300 mm) iidiski ze-stained stainless kunye ne-corrosion-resistant steels ichazwe. Iimpawu ze...

Jonga iinkcukacha -

I-Sintered metal filter ye-disc ene-porous 20 micron yokuhlanjululwa kwegesi kunye nohlalutyo

Ukufezekisa ukwahlulwa kweGesi/Iziqina ezingenakuthelekiswa nanto kunye neeDiskhi zeSintered Steel Filter ye-HENGKO! Iinkqubo zethu zokucoca, ezine-sintered stainless ...

Jonga iinkcukacha -

Sintered metal round deep filter sheets for imveliso yeoli ye-cannabis

Ukuhluzwa Kwimveliso yeemveliso ze-cannabinoid ezizinzile ukuhluzwa linyathelo elibalulekileyo. Ukususa i-wax, amafutha kunye neoli kwi-winterization ezininzi ...

Jonga iinkcukacha -

Sintered metal Gas / Solids Venturi Blowback (GSV) GSP filter OEM Iinkonzo OEM

Isihluzo seSintered seMethali eseSiko/i-Solids Venturi Blowback (GSV) Isihluzi se-GSP Sezihluzi zentsimbi ezi-Sintered zisetyenziselwe ukuhluza irhasi eshushu kwizityalo ezahlukeneyo kwi-che...

Jonga iinkcukacha -

I-Stainless Steel Porous Metal Sheets SS316 Isihluzi sokusasazwa kwegesi yeHydrogen

I-Stainless Steel Porous Metal Sheets SS316 Isihluzo sokuDibaniswa kwerhasi yeHydrogen Ukuvula ukuguquguquka kwezinto eziNyenziwe ngeSintered Metal nge-HENGKO! Imeta yethu sintered...

Jonga iinkcukacha -

HENGKO Ukucoca iBanga leBakteria yeMedia 0.2 5um Isihluzi seMedia esinePorous...

Ukwazisa iHENGKO's Sterilizing Gradeing Metal Filter for Medical and Life Science Filter! Isihluzi sentsimbi esandula kuphuhliswa kaHENGKO si...

Jonga iinkcukacha -

Isihluzi seMetal enePorous Sintered Stainless Steel Disc Filter yokuVeliswa komsonto weFayibha / iP...

Izihluzi zesinyithi ze-Porous ze-HENGKO ziyilo lokucoca isinyithi se-porous sinika ubomi obandisiweyo kunye nokusebenza kuhluzo lwe-polymer spin pack. Isihluzo si-sintered,...

Jonga iinkcukacha -

I-47mm ye-Porous Disc Filter 316L SS iSintered Metal Filter yoVavanyo lweSikali seBhentshi yaseLabhoratri

Isihluzi se-bench-top ye-HENGKO (i-47mm yokuvavanya i-disc filter), yethu i-47mm ye-disc filter, yindlela elula, engabizi kakhulu yokwenza ulwahlulo olululwelo kunye ne-gas-slid nge-e...

Jonga iinkcukacha -

Imboni yeStainless Steel Powder Sintered Metal Filter Media kuKhuseleko loMlilo

Fumana amava ngoKhuseleko olungenakuthelekiswa nanto kunye nokuSebenza kunye neZindlu zoVavanyo lwegesi ye-HENGKO! Xa kuziwa ekukhuseleni izinzwa zakho zegesi kunye nokuqinisekisa indawo engqongileyo ekhuselekileyo...

Jonga iinkcukacha -

Sintered Stainless Steel Sanitary Tri Clamp Filter Disc eneViton O-Ring frit Gasket f...

E-HENGKO® sizama ukunceda abathengi bethu ukuba bakhe umgangatho ophezulu, ukhuselekile, kunye nokusebenza okuchanekileyo kokulungiswa kwe-hemp. Ezona zixhobo zibalaseleyo ze-CBD zikhupha esizifumanayo...

Jonga iinkcukacha -

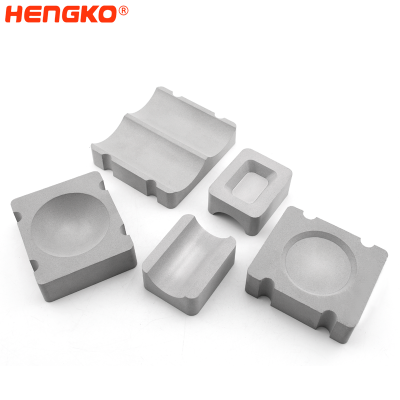

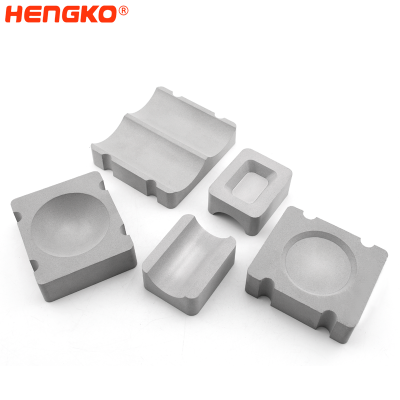

Umenzi weSihluzi seDiskhi esinePorous Metal eSintered kwi-line yoMenzi-HENGKO

I-HENGKO yenza iiwasha ezisecaleni zeVenus, iKitty, iKlasi, kunye neembiza zikaMusa Moka. Iphakheji ibandakanya iwasha kunye nepleyiti yokucoca ikofu. Idayamitha yeGasketNceda...

Jonga iinkcukacha -

Sintered metal stainless steel 316L bronze porous air filtration filter cylinder / ikhandlela

Ukwazisa izihluzi zekhandlela ze-HENGKO: Izisombululo eziLungisiweyo kwiiMfuno zakho zokuHlufa kwimizi-mveliso! Iimpawu zeMveliso:-UHluzo oluLungileyo: Izihluzi zethu zekhandlela zi ...

Jonga iinkcukacha -

Micron replacement sintered steel stainless steel porous metal filter disc

Ukwazisa iHENGKO's High-Stainless Steel Sintered Porous Metal Filters I-HENGKO ngumvelisi okhokelayo wentsimbi engatyiwa sintered metal porous f...

Jonga iinkcukacha -

D6.1 * H1.6 20um sintered metal esinezingxobo icwecwe disc stainless steel

Ukwazisa i-HENGKO's Sintered Filtered Disc: Vula Amandla oHluzo oluchanekileyo! Ngaba ujonge idiski yokucoca i-sintered ebonelela ngokuhlukileyo...

Jonga iinkcukacha

Iimpawu eziphambili:

I-Sintered Stainless Steel Filter Disc iyaqhayisaamandla aphezulu oomatshini, ukuqina okulungileyo, kwayeiplastiki,

njengoukuxhathisa okubalaseleyo to i-oxidationkwayeumhlwa. Ayifuni i-skeleton eyongezelelweyo

ukhuseleko lwenkxaso, ukwenza ukufakela kunye nokusetyenziswa okulula kwaye kulula ukuyigcina. Le diski yokucoca ingaba

sintered nge 304 okanye316izindlu, ezibotshelelweyo, kunye noomatshini ukuhlangabezana neemfuno ezithile zeprojekthi.

Sintered steel stainless filter discs ngamacandelo aguquguqukayo asetyenziswa kumashishini ahlukeneyo ngeenjongo zokuhluza. Ezi diski ziveliswa ngenkqubo ebizwa ngokuba yi-sintering, apho amasuntswana ensimbi engenasici adityaniswe kwaye afudunyezwe ukuze enze i-porous structure. Nazi ezinye iifitsha kunye nemisebenzi ye-sintered steel stainless filter discs:

Iimbonakalo:

1. Izinto zentsimbi engatyiwayo:Iidiski zokucoca i-Sintered zenziwe ngentsimbi ekumgangatho ophezulu, enika ukuxhathisa okugqwesileyo kunye nokuqina.

2. Ulwakhiwo lwePorous:Inkqubo ye-sintering idala isakhiwo se-porous kunye nobukhulu obufanayo be-pore, okuvumela ukuhluzwa okusebenzayo kunye nokwahlula amaqhekeza.

3. Uluhlu olubanzi loBubungakanani bePore:Ezi diski zokuhluza zifumaneka kuluhlu olubanzi lweesayizi zepore, zizenza zilungele ukuhluza izinto ezahlukeneyo ukusuka kwi-coarse ukuya kumasuntswana amahle.

4. UFanelo oluPhezulu lokuHlunga:Ukuhanjiswa kobungakanani obufanayo kunye nokulawulwa kwepore kuqinisekisa ukusebenza kakuhle kokucoca ngelixa ugcina ukuhla koxinzelelo oluphantsi.

5. Ukumelana neeKhemikhali kunye neThermal:I-Sintered steel stainless filter discs inokumelana noluhlu olubanzi lweemeko zeekhemikhali kunye ne-thermal, zizenza zilungele izicelo ezahlukeneyo.

6. Ukucoca kulula kwaye kuphinde kusetyenziswe:Ezi diski zokucoca zinokucocwa ngokulula kwaye ziphinde zisetyenziswe, ukunciphisa imfuno yokutshintshwa rhoqo kunye nokunciphisa inkunkuma.

7. Iimilo kunye nobukhulu obunokwenziwa ngokwezifiso:Abavelisi banikezela ngenketho yokwenza ngokwezifiso iimilo kunye nobukhulu ukuze zilungele izixhobo ezithile zokucoca kunye nokusetyenziswa.

8. Ubungqongqo kunye nozinzo:Inkqubo ye-sintering inikezela iidiski zokucoca ngokuqina kwesakhiwo kunye nokuzinza, ukuqinisekisa ukuba zigcina imilo kunye nokusebenza kwazo ngexesha lokusetyenziswa.

Imisebenzi:

1. Uhluzo:Umsebenzi ophambili we-sintered steel stainless filter discs kukucoca ngokufanelekileyo kunye nokususa ukungcola, ukungcola, okanye iincinci ezivela kulwelo okanye iigesi.

2. Ukwahlula:Ezi diski zokucoca zingasetyenziselwa ukwahlula izinto ezahlukeneyo ngokusekelwe kubungakanani bamasuntswana, ukuqinisekisa ukuba amacandelo afunekayo agcinwa okanye asuswe kumxube.

3. Ukhuseleko:I-Sintered steel stainless filter discs isetyenziselwa ukukhusela izixhobo ezibuthathaka, iimpompo, kunye nezixhobo kumonakalo owenziwe ngamasuntswana okanye inkunkuma.

4. Ukucoca:Baqeshwe kwiinkqubo zokucoca ukucokisa ulwelo kunye neegesi, ukuqinisekisa iimveliso ezikumgangatho ophezulu.

5. Ukungenisa umoya kunye noLawulo lokuHamba komoya:Iidiski zokucoca kunye ne-porosity elawulwayo zisetyenziselwa ukukhutshwa kwezicelo, ukuvumela ukuhamba komoya okanye igesi ngelixa ukuthintela ukuhamba kwezinto ezingcolileyo.

6. Ulwelo:Kwizicelo ezithile, iidiski zokucoca zinceda kwiinkqubo ze-fluidization, zinceda ukulawula ukuhamba kunye nokusabalalisa kweegesi okanye ulwelo ngokusebenzisa ibhedi yeengqungquthela.

7. Ulawulo lothuli kunye nokuPhuculwa:Iidiski ze-stainless steel stainless steel zisetyenziselwa kwizicwangciso zemizi-mveliso ukulawula ukukhutshwa, ukubamba uthuli kunye ne-particulate matter ukuthobela imimiselo yokusingqongileyo.

8. Inkxaso yeCatalyst:Kwezinye iimeko, ezi diski zokucoca zisebenza njengezakhiwo zenkxaso ye-catalyst kwiinkqubo zeekhemikhali, ukuphucula ukusebenza kakuhle kokuphendula kunye nokuququzelela ukuhlukana emva kokuphendula.

Ezi mpawu kunye nemisebenzi igxininisa ukubaluleka kunye nokuguquguquka kweediski ze-sintered stainless steel filter kwizicelo ezininzi zemizi-mveliso apho ukuhluzwa kunye nokwahlula kudlala indima ebalulekileyo.

Ukuba uneemfuno eziphezulu zendawo yokucoca kunye neemfuno zedatha yokulawula ukuhamba, iqela leenjineli ze-HENGKO

izakuyila izisombululo ezizezonaisihluzo sesinyithi esine-sinteredidiski ukuhlangabezana neemfuno zakho eziphezulu kunye nemigangatho yeeprojekthi.

Kutheni HENGKO Sintered Isihluzi Disc

I-HENGKO ngumvelisi owaziwayo wezihluzi zediskhi zensimbi ezingenazinwebu ezilungiselelwe ukuhlangabezana neemfuno ezahlukeneyo zesicelo.

Iimveliso zethu ziyilwe ngokuyila kunye nokwenza ngokwezifiso ukuqinisekisa ukuba ufumana imveliso egqibeleleyo kwiimfuno zakho.

Siyazingca ngembali yethu yexesha elide yokubonelela ngeemveliso ezikumgangatho ophezulu, ezisetyenziswa ngokuqhelekileyo kuhluzo oluphezulu lwamashishini,

ukudambisa, i-sparger, ukukhuselwa kwenzwa, ukulawulwa koxinzelelo, kunye nezinye izicelo ezininzi. Iimveliso zethu zenzelwe ukuhlangabezana ne-CE

imigangatho kwaye ziyaziwa ngokuzinza kunye nokuphila ixesha elide.

EHENGKO, sibonelela ngenkxaso ebanzi, ukusuka kubunjineli ukuya kwiinkonzo zasemva kwentengiso, siqinisekisa ukuba ufumana uncedo oludingayo.

kuwo wonke umjikelo wobomi bemveliso. Iqela lethu leengcali linamava abanzi kwiikhemikhali ezahlukeneyo, ukutya kunye nesiselo

izicelo, zisenza iqabane eligqibeleleyo kwiimfuno zakho zokuhluza.

✔ PM Umenzi owaziwayo kwishishini kwizihluzi zediskhi zentsimbi engenazinwebu

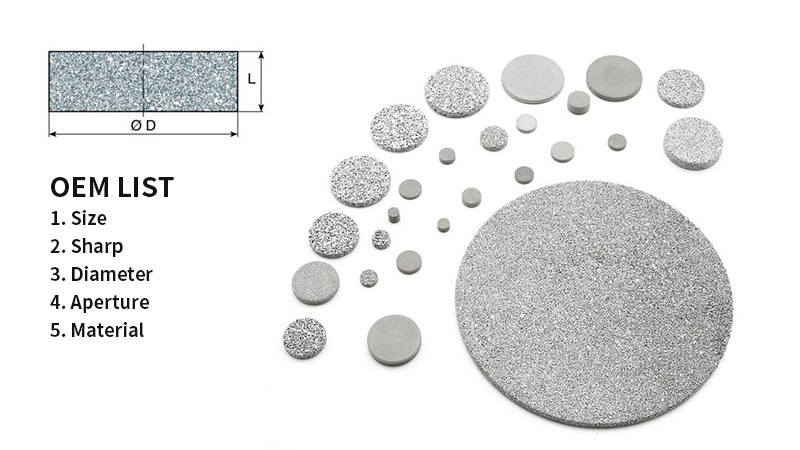

✔ Uyilo olwahlukileyo olulungiselelweyo njengobukhulu obahlukeneyo, izixhobo, iileya kunye neemilo

✔ Iimveliso ezikumgangatho ophezulu ngokungqongqo njengomgangatho we-CE, imilo eZinzile

✔ Inkonzo esuka kubuNjineli ukuya kwinkxaso yentengiso yasemva

✔ Ubuchwephesha bokusetyenziswa ngeendlela ezahlukeneyo kumashishini ekhemikhali, ekutyeni nakwiziselo

Ukusetyenziswa kweDisc yeSihluzo seNsimbi eNgatyiwayo :

Kumava ethu, siye safumanisa ukuba umgubo ovunyiweyo metal sintered icwecwe discs zisebenza kakhulu kwiinkqubo ezahlukeneyo zoshishino.

Ezi diski zokucoca zilungele ukusetyenziswa kwi-distillation, i-absorption, i-evaporation, i-filtration, kunye nezinye iinkqubo kumashishini afana ne-petroleum,

ukucokisa, iikhemikhali, ishishini lokukhanya, amayeza, isinyithi, oomatshini, inqanawa, iteletele yemoto, nokunye. Zisebenza ngokukodwa

ekususeni amathontsi kunye ne-foam engamanzi efakwe kwi-steam okanye igesi, okukhokelela kwimveliso ephezulu.

Ukucoca ulwelo

Iidiski zokucoca intsimbi zisetyenziswa ngokubanzi kwizicelo zokucoca ulwelo. Zingasetyenziselwa ukuhluza amanzi, imichiza, i-oyile, kunye nolunye ulwelo. Umnatha wocingo wenzelwe ukubambisa amasuntswana obungakanani obahlukeneyo, ukuqinisekisa ukuba ulwelo oluhluziweyo alunazingcolisi.

Ukuhluzwa kwegesi

Iidiski zokucoca intsimbi engatyiwayo zinokusetyenziselwa ukucoca igesi. Zidla ngokusetyenziswa kushishino lweemoto ukucoca umoya phambi kokuba ungene enjinini. Zisenokusetyenziswa kwizicwangciso zemizi-mveliso ukucoca iigesi ezifana nenitrogen, ioksijini, kunye nehydrogen.

Ukuhluzwa kokutya kunye nesiselo

Iidiski zokucoca insimbi engenasici zikhuselekile ukuba zisetyenziswe kwizicelo zokuhluza ukutya kunye nesiselo. Zisenokusetyenziswa ukuhluza ulwelo olufana newayini, ibhiya, nencindi yeziqhamo. I-wire mesh yenzelwe ukubambisa iincinci kunye nokungcola, ukuqinisekisa ukuba imveliso ehluziweyo ihlambulukile kwaye ikhuselekile ukuba isetyenziswe.

UHluzo lwezamayeza

Iidiski zokucoca insimbi engenasici ziqhele ukusetyenziswa kwizicelo zokuhluza amayeza. Zingasetyenziselwa ukuhluza ulwelo kunye neegesi kwimveliso yamachiza kunye nezinye iimveliso zamayeza. Umnatha wocingo wenzelwe ukubambisa iibhaktheriya kunye nezinye izinto ezingcolileyo, ukuqinisekisa ukuba imveliso yokugqibela ikhuselekile kwaye iyasebenza.

Ngokuzibophelela kwethu kwiimveliso ezikumgangatho ophezulu, inkxaso yeengcali, kunye noyilo oluyilayo, i-HENGKO yeyona nto uyifunayo

iqabane kuzo zonke iimfuno zakho sintered lokucoca disc.

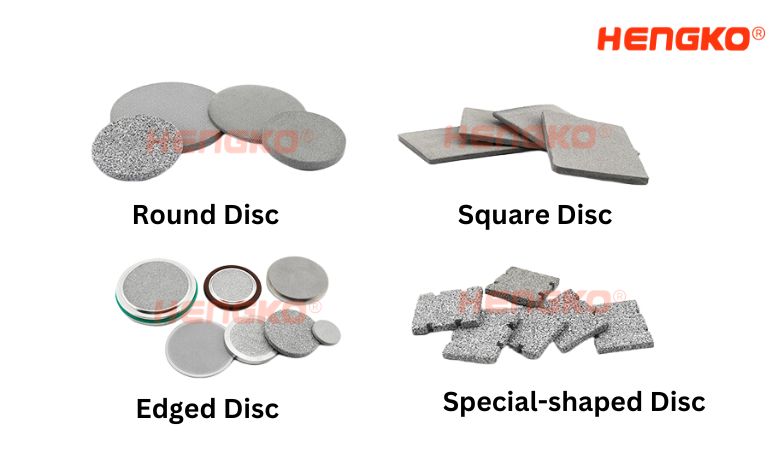

Iindidi zeSintered Metal Filter Disc

Iidiski ze-Sintered metal filters ziza kwiindidi ezahlukeneyo, nganye ilungiselelwe ukuhlangabezana neemfuno ezithile zokuhluza kunye nokusetyenziswa. Ezi ntlobo zahlulwe ngokusekwe kubume bezinto zazo, ubungakanani bepore, kunye nokusetyenziswa okujoliswe kuko. Nazi ezinye iintlobo eziqhelekileyo zeediski ze-sintered metal filter:

1. I-Disc yeStainless Steel Sintered Filtered Disc:Olona hlobo luqhelekileyo, olwenziwe kwinsimbi engenasici, lunikeza ukuxhathisa okugqwesileyo kwe-corrosion kunye nokuqina. Isetyenziswa ngokubanzi kumashishini ahlukeneyo kwizicelo zokuhluza ngokubanzi.

2. Icwecwe leBronzi Sintered Filtered:Iidiski zebronze sintered filter ziyaziwa ngokuba nkulu kwazo kwaye zihlala zisetyenziselwa ukuhluza ulwelo kunye neegesi kwizicelo ezifuna ukuhluzwa kakuhle.

3. I-Nickel Sintered Filter Disc:Iidiski ze-nickel sintered filter zisetyenziswa kwindawo ezinamaqondo obushushu aphezulu kunye neemeko zekhemikhali ezindlongondlongo, ngenxa yokuxhathisa okukhethekileyo kwenickel ekumdleni.

4. Icwecwe leCopper Sintered Filter:Iidiski zokucoca i-copper sintered zifumana isicelo kwiigesi zokucoca kunye nolwelo ngelixa zibonelela ngokuqhuba kakuhle kwe-thermal.

5. I-Titanium Sintered Filter Disc:Iidiski zokucoca i-Titanium sintered zikhethwa kwizicelo apho amandla aphezulu, ubunzima obuphantsi, kunye nokumelana nokugqwesa okugqwesileyo kubalulekile.

6. I-Inconel Sintered Filter Disc:Iidiski zokucoca i-Inconel sintered zisetyenziswa kubushushu obugqithisileyo kunye nemekobume ezonakalisayo, zizenza zilungele imisebenzi ecela umngeni yokuhluza.

7. Idiski yeMonel Sintered Filtered:Iidiski zokucoca i-Monel sintered zixhathisa kakhulu ekudlekeni, zizenza zilungele ukuhluzwa kwiindawo zaselwandle kunye nokusetyenzwa kweekhemikhali.

8. I-Hastelloy Sintered Filter Disc:Iidiski zokucoca i-Hastelloy sintered zisetyenziswa kwizicelo ezifuna ukuchasana noluhlu olubanzi lwemithombo yeendaba ezonakalisayo.

9. IDisc yeTungsten Sintered Filtered:Iidiski ze-Tungsten sintered filter zisetyenziswa kwizicelo zobushushu obuphezulu kunye nokucoca imichiza enobundlobongela.

10. IProsity-graded Sintered Filter Disc:Ezi diski zokucoca zinobukhulu obahlukeneyo bepore ngapha kwediski, evumela ukuhluzwa okuchanekileyo kumacandelo ahlukeneyo.

11. I-Sintered Fiber Metal Filter Disc:Yenziwe kwimicu yetsimbi, olu hlobo lwediski yokucoca lubonelela nge-porosity ephezulu kunye nommandla ongaphezulu, okwenza ukuhluzwa okusebenzayo kwamasuntswana amahle.

12. IDiskhi yesiSihluzo esinaMaleko amaninzi eSintered:Kubandakanya iileya ezininzi ezine-porosities ezahlukeneyo, olu hlobo lwediski lokucoca lubonelela ngomthamo ophuculweyo wokuhluza kunye

ingasetyenziselwa imisebenzi enzima yokuhluza.

Kubalulekile ukukhetha uhlobo olufanelekileyo lwediski ye-sintered metal filter esekelwe kwiimfuno ezithile zesicelo sokuhluza, njengobungakanani besuntswana, ukuhambelana kweekhemikhali, ubushushu kunye neemeko zoxinzelelo. Uhlobo ngalunye lwediski yokucoca lubonelela ngeenzuzo ezizodwa kunye nemida, ngoko ke ukukhetha echanekileyo kuqinisekisa ukusebenza kakuhle kokucoca kunye nokuqina.

Isihluzo sakho seSintered Ubunjineli bezisombululo nguMboneleli ogqwesileyo

Kule minyaka ingama-20+ idlulileyo, i-HENGKO ibonelele ngezisombululo kuhluzo oluninzi oluntsonkothileyo kunye nolawulo lokuhamba

iimfuno kubathengi kuluhlu olubanzi lwamashishini kwihlabathi liphela. Iqela lethu leengcali linokukhawuleza

bonelela ngezisombululo ezilungiselelwe izicelo zakho zobunjineli ezinzima.

Qhagamshelana nathi namhlanje ukuxoxa ngeprojekthi yakho neqela le-HENGKO R&D, kwaye siya kufumana olona chwephesha lubalaseleyo

sintered metal isihluzo diski isisombululo kwiprojekthi yakho kwiveki enye.

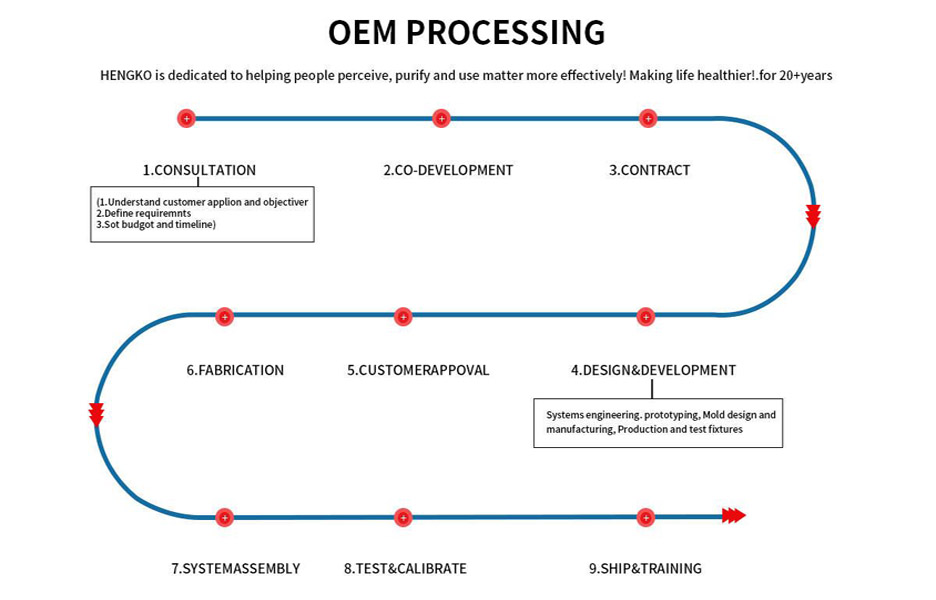

Uyenza njani iDiskhi yesihluzi seNtsimbi yeSintered eStainless

Ukuba unoyilo oluthile lweeprojekthi zakho kwaye awukwazi ukufumana okufanayo okanye imveliso yediskhi yentsimbi engenasici,

wamkelekile ukuba uqhagamshelane HENGKO. Siza kusebenzisana ukufumana esona sisombululo silungileyo. Nantsi inkqubo ye-OEM sintered

idiskhi yesihluzi sensimbi engenasici:

1. Ukubonisana kunye noQhagamshelwano HENGKO

2. UPhuhliso ngokubambisana

3. Yenza iSivumelwano

4. Uyilo noPhuhliso

5. Imvume yoMthengi

6. Ukwenziwa/ Ukuveliswa kobuninzi

7. INdibano yeNkqubo

8. Vavanya kwaye ulinganise

9. Ukuthumela kunye noQeqesho

I-HENGKO izinikele ekuncedeni abantu baqonde, bahlambulule kwaye basebenzise into ngokufanelekileyo, ukwenza ubomi bube nempilo ngaphezulu kweminyaka engama-20.

Nceda ujonge inkqubo kwaye uqhagamshelane nathi ukuze sixoxe ngeenkcukacha ezithe vetshe.

I-HENGKO ngumzi-mveliso onamava obonelela ngobunzulusintered isihluzo sentsimbiizinto zezicelo ezininzi.

Sisebenze namawaka eelebhu, iidyunivesithi, kunye namasebe eR&D eenkampani zophawu kwihlabathi liphela. Iiyunivesithi ezininzi,

ezifana nezi zilandelayo, bebengamaqabane ethu exesha elide. Wamkelekile ukuba uqhagamshelane nathi kwaye usebenze neqela le-HENGKO.

Uya kufumana izisombululo zakho ngokukhawuleza.

Ii-FAQ ezidumileyo malunga neDiskhi yeStainless Steel Filter

1. Yintoni iDiskhi yeSihluzo seNsimbi eStainless?

Kwaziwa njengeiidiski zokucoca intsimbikunye neediski zemesh ezincinci, ezi diski zinemingxuma efanayo yobungakanani bemingxuma emincinci leyo

bamba amasuntswana amancinci kakhulu.

Eqhelekileyo Iidiski zocingo ezinemesh zihlala zisetyenziswa kwiilabhoratri kunye nezicelo zokubhubhudla kwerhasi (sparging).

Zenziwe nge-316L engenasiciintsimbi ngenxa yokugqwesa okugqwesileyo kunye nokuxhathisa kwe-abrasion.

Iidiski zokucoca ezinentsimbi engenastainless zisetyenziselwa ukuhluza kwiinjini zedizili, isihluzo soxinzelelo, ifayibha yemichiza kunye

iplastiki extruder, textile dope filtration, mgodi, amanzi, ukutya, kunye namanye amashishini.Sintered metal 316l stainless

I-disc yokucoca insimbi iququzelela ukuhlolwa okanye ukwahlula into enye kwenye,ikwenza ukuba kwenzeke

susa ungcoliseko olungeyomfuneko kwisiqina okanye kulwelo.

Inkqubo yokwenziwa kweisihluzo sensimbi engenasiciidiski ibandakanya amanyathelo amathathu aphambili.

Inyathelo lokuQala libandakanya ukukhethwa komgangatho ophezulu wocingo lwentsimbi engenasici, ethi emva koko ibethelwe ngenqindi okanye ilukwe.

Kwakhona kufuneka ufumane imathiriyeli efanelekileyo yokusonga idiskhi ye-wire mesh disc.

Kwakhona, khetha ubungakanani obuhlukeneyo bepore ye-316L yomgubo wentsimbi yokuhlanganisa phakathi kunye ne-sintering.

Iidiski zemesh yentsimbi engenakutyiwa zinokuyila kwaye zenze iimilo ezahlukeneyo, ubuchule bokuluka, ukuchaneka kokucoca, kunye

izixhobo zokusonga emphethweni, phakathi kwezinye iimpawu.Ke ungayila olu hlobo lwediski yokucoca isinyithi ukuzalisekisa eyakho

Iimfuno ezifana nesantya sokuqukuqela, ubungakanani bamasuntswana okucoca, imida yendawo ebonakalayo, kunye nolwelo loqhagamshelwano.

Njengomnye weengcaliumboneleli wediski yentsimbi engenasici, Wamkelekile ukuba undwendwele iFactory yethu ubuso ngobuso

ukuthetha iinkcukacha ezininzikwiiprojekthi zakho, sikwanayo nesivumelwano sokungachazi sohluzo oluninzi

iprojekthi kubathengi bethu.

2. Ziziphi iimpawu eziphambili zeSintered Filter Disc?

1. Amandla aphezulu kunye nokuzinza kwesakhelo kubomi obude benkonzo.

2. Ukuxhathisa okugqwesileyo kwi-corrosion, i-asidi, i-alkali, kunye ne-abrasion.

3. Ingasebenzisa ukumelana nobushushu obuphezulu phantsi kobushushu obusuka kwi -200 °C ukuya kuma-600 °C.

4. Iireyithingi ezahlukeneyo zokucoca ukukhetha okanye ukwenza ngokusesikweni kunye nokuchaneka okukhulu kwesihluzi kwizicelo ezahlukeneyo.

5. Umgangatho olungileyo wokubamba ubumdaka.

6. Kulula ukucoca kunye nokusebenziseka kwakhona, ukunciphisa ixesha lokuphumla kunye nokugcina iindleko.

7. Ngokweemfuno ezahlukeneyo zeprojekthi, iSintered Metal Filter Disc inokubunjwa ibe yingqukuva, isikwere,

uxande, umbhoxo, umsesane, kunye nabanye. Uluhlu olulodwa okanye uluhlu oluninzi lunokukhethwa.

Ngoko ukusebenza okuthembekileyo kunye nexesha eliphezulu le-intanethi kunye nokugcinwa okuphantsi; Bonisa newe iteknoloji

kwinqanaba lorhwebo.

3.Zisetyenziselwa ntoni izihluzi zeSintered?

Izihluzi zeSinteredziyilwe kwaye zasetyenziswa njengento entsha yokucoca ukutya, isiselo,

unyango lwamanzi, ukususa uthuli, amayeza, kunye namashishini polymer ngenxa ebalaseleyo

ukusebenza kwezihluzo ze-sintered, kubandakanywa amandla omatshini aphezulu wezihluzo ze-sintered kunye nobubanzi

uluhlu lwamabanga okuhluza.

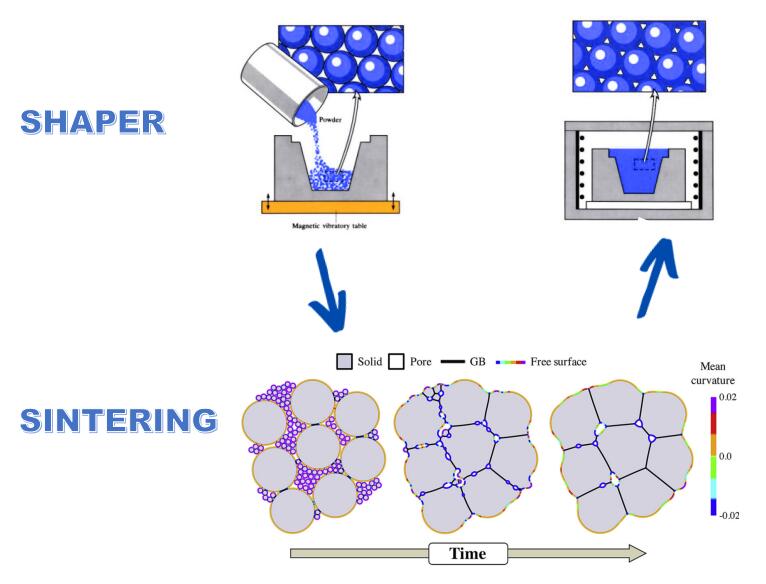

4. Isebenza njani iSinered Filter Disc?

Ngokufutshane, inkqubo yokuvelisa i-sintered filters iqukethe amanyathelo ama-2

1. Ukubumba

2. Ukucula

Nangona kunjalo, ngaphambi kokubunjwa kunye ne-sintering, kufuneka siqinisekise kunye nomthengi uyilo, ubungakanani, i-porosity,

iimfuno zokuhamba, imathiriyeli, kwaye nokuba icebo lokucoca linendlu enemisonto yofakelo olulula.

Amanyathelo okuvelisa i-cartridge e-sintered ngolu hlobo lulandelayo.

5. Loluphi uhlobo lweNtsimbi eNgatyiwayo olusetyenziswa kakhulu kwiDiskhi yeSihluzo?

Amabakala aphambili omgubo wensimbi engenasici afanelekileyo kwimveliso yohlobo lwensimbi engenasici

Sintered filter disc ziquka:

1.) Intsimbi engatyiwa 316, equlethwe yimanganese, isilicon, ikhabhoni,nickel kunye nezinto zechromium.

2.) Intsimbi engenasici316L, Inomlinganiselo ophantsi womxholo wekhabhoni xa kuthelekiswa nentsimbi ye-316.

amabakala okutya kwizicelo ezininzi abandakanya Ukutya kunye noKutya kunye nokuhluzwa kwezonyango njl

3.) Intsimbi ye-stainless 304, Ibandakanya i-nickel kunye neentsimbi ze-chromium ezizii-non-ferrous elements.

4.) I-Stainless steel 304L, Inomlinganiselo ophezulu womxholo wekhabhoni xa kuthelekiswa nentsimbi ye-304.

ngokuqinisekileyo ixabiso liya kuba ngaphantsi kwe-316L, 316, njl

6. Ucoca njani iDisc yeSihluzo socingo olungenaNsimbi olungenaNsimbi?

Kukho iindlela ezininzi zokucoca iidiski zokucoca insimbi engenasici, ngokhetho lwendlela nganye

kuxhomekeke kuhlobo lwakho kunye nenqanaba lokusebenza.

Makhe sijonge ezinye zeendlela eziqhelekileyo zokucoca iidiski zokucoca isinyithi.

1) I-Blowback kunye ne-Backwash Flushing

Yenye yeendlela ezilula zokucoca iidiski zokucoca.

Ukuze ukugungxulwa kwe-backwash kusebenze ngempumelelo, kuxhomekeke ekuhambeni umva kolwelo ukukhupha

kwaye uthwale amasuntswana kude nesakhiwo semidiya.

Ulwelo olusetyenziswayo luqhele ukuhluzwa okanye olunye ulwelo oluhambelana nenkqubo.

I-blowback kunye ne-backwashing technique ixhomekeke kwi-attachment ekhululekileyo yamasuntswana okanye

ngaphakathi kwemingxunya yemesh yokucoca.

Ukusebenzisa irhasi njengomthombo woxinzelelo endaweni yolwelo kuvelisa isiphithiphithi njengoko senziwa

uxinzelelo lunyanzela irhasi/ulwelo umxube ngomnatha wediskhi yokucoca.

2) Gxuma kunye neFlush

Ukucoca iidiski zokucoca insimbi engenasici kubhekiselele ekusebenziseni isisombululo sokucoca.

Kobu buchule, uvumela idiski yokucoca ukuba ifunxe ngokwaneleyo ukwenzela isenzo sokucoca

khulula amasuntswana kwaye uwakhuphele ngaphandle kwesixhobo sokucoca imidiya.

Kwibhubhoratri, unokwenza le nkqubo ekuqhubeni iidiski zokucoca insimbi engenasici okanye ezincinci

amacandelo.

3) Ukujikeleza okujikelezayo

Kule ndlela yokucoca idiski yokucoca i-wire mesh, udinga inkqubo yokucoca ukunceda ukupompa kunye

Jikelezisa isisombululo sokucoca kumnatha wokucoca de ucoceke.

Ukusasazwa ngokuqhelekileyo kwicala elichaseneyo apho i-mesh ye-disc yokucoca yayingcoliswe.

Kufuneka ucoce isisombululo sokucoca phambi kokuba usibuyisele kwimidiya yokucoca.

4) Iibhafu ze-ultrasonic

Obu buchule bufuna izixhobo ezikhethekileyo ezisebenzisa amaza esandi e-ultrasonic ukuze aqalise

amasuntswana kwaye uwasuse kumnatha wokucoca.

Ungasebenzisa iimodeli zaselabhoratri yesi sixhobo ukucoca ngokulula iidiski ezincinci zokucoca intsimbi,

kanti ezinkulu zifuna izixhobo zetanki ezinkulu ezinamagalelo anamandla aphezulu.

Ukucoca kwe-ultrasonic, ngokubambisana nesisombululo esifanelekileyo se-detergent, yindlela efanelekileyo kakhulu

ukucoca iidiski zokucoca, ngakumbi kwimeko yamaqhekeza afakwe ngokunzulu.

5) Ukucoca isithando somlilo

Ikwayindlela elula yokucoca iidiski zokucoca isinyithi ngokutshisa okanye ukutshisa ibhayoloji okanye

iikhompawundi eziphilayo.Isebenza kakhulu ekususeni izinto zepolymer.

Furnace steel stainless steel filter ukucoca idiski ifanelekile kwizinto ezingashiyi uthuthu olushiyekileyo.

Ngaphandle koko, uya kufuna indlela yokucoca eyongezelelweyo yokususa intsalela yomlotha.

6) I-Hydro Blasting

Iindlela zokucoca i-Hydro blasting zihlala zidlula ezinye iindlela zokucoca xa amasuntswana

zithintele ngokugqithisileyo imingxuma yesihluzo semesh.

Unokusebenzisa le ndlela yokucoca, umzekelo, iidiski zokucoca kwiityhubhu ezinqamlezayo.

Ijethi yamanzi yoxinzelelo oluphezulu isusa amaqhekeza abanjwe ngokusebenzisa impembelelo ephezulu yamandla.

Ayingeni nzulu kakhulu kumnatha wokucoca; nangona kunjalo, kwiimeko ezininzi, isithintelo sinokuba kuphela

kumphezulu wemidiya yokucoca.

Isetyenziswa ngokuqhelekileyo kwizityalo, kwaye ngokuqhelekileyo isetyenziselwa ukucoca iityhubhu zokutshintsha ubushushu.

7. Yeyiphi iMiba omele uyithathele ingqalelo xa ukhetha iDiskhi yesihluzi seNsimbi eNgatyiwayo?

Xa ukhetha idiski yokucoca intsimbi echanekileyo ukuze uqinisekise ukusebenza kakuhle kwenkqubo yakho yokucoca,

ngoko ke, kufuneka uqwalasele le miba ilandelayo xa ukhetha icwecwe lensimbi engenasici:

-

Uhlobo lwesihluzi semidiya

Kukho iintlobo ezahlukeneyo zemithombo yeendaba zokucoca, ezinje ngefiber yentsimbi engacwangciswanga, i-photo-etched, kunye ne-sintered

imidiya yokuhluza, nganye ineengenelo zayo kunye nokungalunganga.

Ke ngoko, kuya kufuneka ukhethe idiski yokucoca engenastainless enemidiya elungileyo yokucoca kwizicelo zakho.

-

Uhlobo lweStainless-Steel Esetyenzisiweyo

Intsimbi engenastainless iza kwiindidi ezahlukeneyo, ngohlobo ngalunye luneenzuzo ezilungele iinjongo ezahlukeneyo.

Ngaphambi kokuthenga enye, kubalulekile ukuqiniseka ngeempawu zomntu ngamnye wemathiriyeli esetyenziselwa ukwenza idiski yokucoca.

Ezo mpawu ziquka uxinzelelo, umda wobushushu, kunye nokusabela kwezinye iikhompawundi kunye neemeko.

-

Inombolo yeMesh

Linani lemingxuma nge-intshi nganye yomnatha wokucoca intsimbi.

Ukuba inani lomnatha likhulu, libonisa imingxunya emininzi nge-intshi nganye yomnatha wediski wokucoca.

Kukwabonisa ukuba imingxuma nganye mincinci kwaye ngokuphambeneyo.

-

Ubungakanani beMesh

Ubungakanani bomnatha buchaza ubungakanani bemingxunya nganye kumnatha wediskhi yentsimbi engenakutyiwa.

Ihlala ilinganiswa ngeemilimitha, ii-microns, okanye i-intshi eziqhekekileyo.

-

I-Strand Diameter

Yingqwalaselo ebalulekileyo xa ukhetha idiski yesihluzo sentsimbi.

Xa ucingo lunobubanzi obubanzi be-strand, lubonisa ukuba lunemingxuma emincinci.

Ngamafutshane, ubukhulu bedayamitha ye-strand, kokukhona inani le-mesh lediski ye-sintered filter.

Ububanzi bomtya yipesenti yendawo yonke yomphezulu wemesh yentsimbi engenasici, okt.

ipesenti yendawo evulekileyo.Ngoko ke, ukuba nepesenti enkulu yendawo evulekile ibonisa

ukuba idiski yokucoca inompompolo ophezulu.

-

I-Filament Diameter

Le parameter ichaphazela ukuvuleka komnatha kunye nepesenti yendawo evulekileyo yemesh yokucoca.

-

Ukuhambelana kolwelo

Kuya kufuneka uqinisekise ukuba idiski yentsimbi engenasici ihambelana kakuhle nolwelo ofuna ukuluhluza.

Inceda ukuphepha nakuphi na ukusabela phakathi kwediski yokucoca kunye nolwelo olubandakanyekayo kuba nayiphi na impendulo iya kuthi

ifuthe elibi kumgangatho wenkqubo yokucoca.

8. ls kukho iShape Unyino lweDiskhi yeSihluzo socingo olungenaNsimbi olungenaNsimbi?

Hayi, ungayila njengoko iprojekthi yakho ifuna. Yabelana ngobungakanani bakho, ubungakanani bepore, ulawulo lokuqukuqela njalo njalo kunye

Qhagamshelana nathingeenkcukacha.

9. Zeziphi izinto eziluncedo kwiiDiskhi zeSintered Filtered?

Izinto ezine eziluncedo ezingundoqo zibandakanya:

1.) Ukuqina

Idiski yokucoca intsimbi yeSintered yomelele kakhulu, iyenza ibe lolona khetho lufanelekileyo kwizicelo zakho.

Ihlala ixesha elide kuba ayisebenzi ngeencindi ezininzi.

Iqinisekisa ukuba unesakhono esipheleleyo sediski yakho yentsimbi engenastainless sintered mesh filter.

Ngenxa yokuphila ixesha elide, kuya kunciphisa iindleko zakho zokusebenza kwixesha elide.

2. ) Ukuguquguquka

Stainless steel sintered icwecwe iidiski kukunika inkululeko yokusebenzisa kwizicelo ezahlukeneyo ngenxa

iipropathi ezizodwa zeekhemikhali kunye nezomzimba zeediski zokucoca insimbi engenasici.

Ezi mpawu ziquka ukubola, iasidi kunye nokumelana ne-alkali, uxinzelelo lokusebenza kunye nobushushu,

kunye nokuhambelana nolwelo olwahlukeneyo.

3.) Ukusebenza kakuhle

Uhlobo lwediski ye-sintered filter yensimbi iqinisekisa ukusebenza kakuhle ekusebenzeni kwayo.

Ukusebenza kakuhle kwediski ye-sintered stainless steel filter kuqinisekisa ukuba unokufikelela ngokulula kwinto oyifunayo

inqanaba lokuhluza.

4.) Ukulula kokuCoca

Wire mesh sintered filter discs ezenziwe ngentsimbi engatyiwa kwinqanaba eliphezulu lococeko kuba kulula ukuzicoca.

Ukuzisebenzisa kwizicelo ezithatha ucoceko njengeshishini lokutya kunye nesiselo zenza ukuba kwenzeke.

Ngaphaya koko, inkangeleko yesilivere yentsimbi engatyiwayo inyusa umdla wobuhle bediski yokucoca ngelixa

ukuqinisekisa ucoceko jikelele lwemisebenzi yakho.

Qhagamshelana nathi ukuba ufuna ukuSombulula iiNkcukacha zeDiskhi yeStainless Steel Filter.