-

1/2″ VCR Gasket Stainless Steel Porous Filter for Semiconductor Industry Ultra-High Pur...

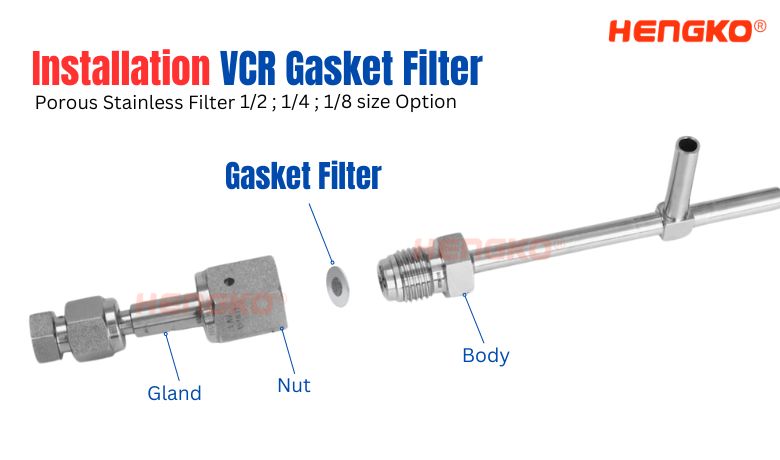

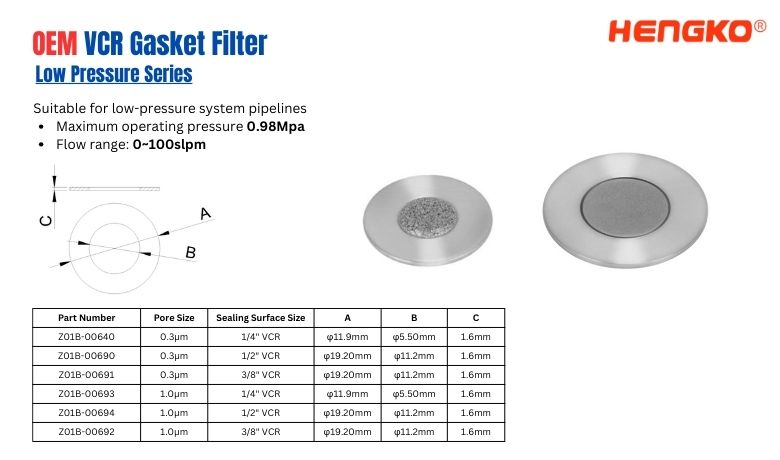

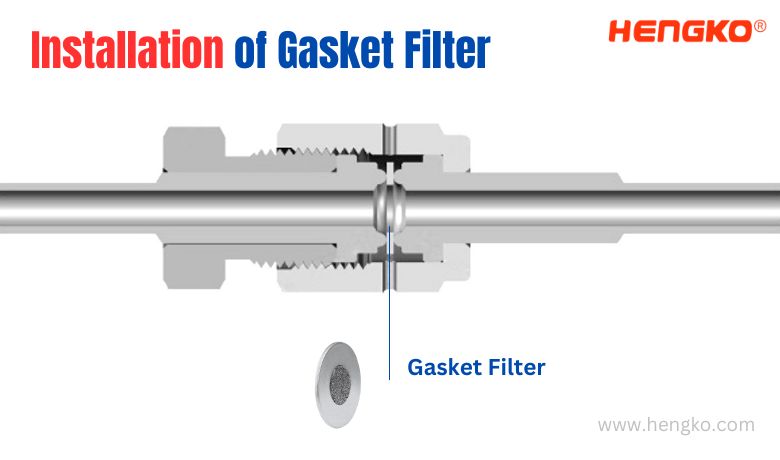

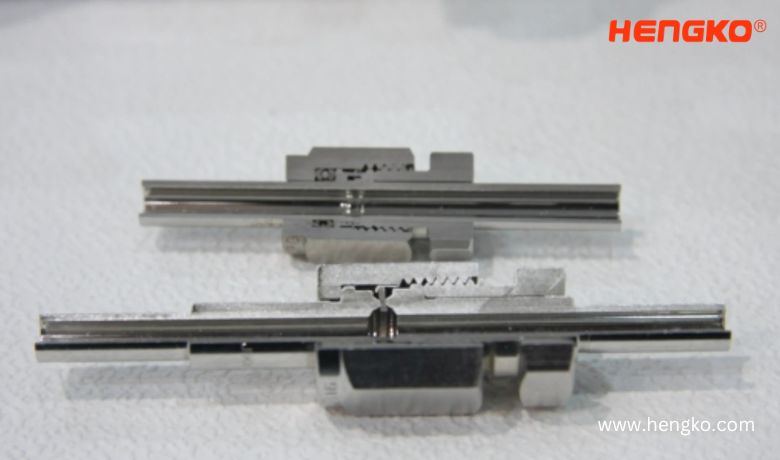

What Is a VCR Gasket Filter? A VCR Gasket Filter is a high-purity sealing gasket integrated with a sintered stainless-steel micro-porous filter, designed ...

View Detail -

1/2″ VCR Gasket with Fine Porous Sintered Metal Filter for Semiconductor Industry

Porous Metal Gasket Filter for Semiconductor Applications A Reliable Solution for Protecting Precision Gas Systems: 1.) Designed specifically for sem...

View Detail -

Robust 3/8″ VCR Gasket with Fine Porous Sintered Filter for Critical Semiconductor ss 4...

Porous Metal Gasket Filter for Semiconductor Applications A Reliable Solution for Protecting Precision Gas Systems: 1.) Designed specifically for sem...

View Detail -

High Pressure 1/2″ VCR Gasket Porous Stainless Steel Filter for Semiconductor Industry

Porous Metal Gasket Filter for Semiconductor Applications A Reliable Solution for Protecting Precision Gas Systems: 1.) Designed specifically for sem...

View Detail -

High Pressure 1/4″ VCR Metal Gasket Porous Filter for Semiconductor Industry

Porous Metal Gasket Filter for Semiconductor Applications A Reliable Solution for Protecting Precision Gas Systems: 1.) Designed specifically for sem...

View Detail -

VCR Metal Gasket Porous Filter for Semiconductor Gas Industry High Pressure Pipeline an...

VCR metal gasket porous filter for semiconductor gas systems —ideal for high & low pressure pipelines, ensuring purity, safety, and reliable perf...

View Detail -

1/4″ Stainless Steel VCR Gasket Filter for Precision Sealing in High-Pressure Systems

Porous Metal Gasket Filter for Semiconductor Applications A Reliable Solution for Protecting Precision Gas Systems: 1.) Designed specifically for sem...

View Detail -

1/4″ Stainless Steel VCR Gasket Filter for High-Pressure Gas Sealing in Semiconductor A...

Porous Metal Gasket Filter for Semiconductor Applications A Reliable Solution for Protecting Precision Gas Systems: 1.) Designed specifically for sem...

View Detail -

1/8″ Stainless Steel VCR Gasket Filter for Vacuum Coupling,Ideal for Semiconductor Manu...

Porous Metal Gasket Filter for Semiconductor Applications A Reliable Solution for Protecting Precision Gas Systems: 1.) Designed specifically for sem...

View Detail -

1/8″ Stainless Steel VCR Gasket Silver-Plated, Nonretained For Semiconductor

Porous Metal Gasket Filter for Semiconductor Applications A Reliable Solution for Protecting Precision Gas Systems: 1.) Designed specifically for sem...

View Detail

Benefits of Porous Sintered VCR Gasket Filter

There are many benefits for the sintered porous VCR Gasket for Semiconductor Industry, please

check some points we list , hope you can understand more features of our VCR Gaskets.

*High Filtration Efficiency:

Made from premium sintered stainless steel, effectively filtering out particles in gas and liquid streams,

ensuring system cleanliness.

*Superior Corrosion Resistance:

Ideal for filtering corrosive gases and liquids, prolonging equipment lifespan.

*High-Temperature Tolerance:

Capable of stable operation in high-temperature environments, ensuring reliable equipment performance.

*Customizable Design:

Tailored VCR gasket filters available in various sizes, pore sizes, and shapes to suit specific application needs.

*Long-Lasting and Reliable:

Built with durable materials to ensure long-term, efficient performance in harsh environments.

Types of VCR Gasket and Why Use it ?

VCR gaskets are essential components used in vacuum and high-pressure systems to provide a reliable, leak-tight seal.

They come in various types depending on the material, application, and sealing requirements.

Here are the common types of VCR gaskets:

1. Stainless Steel VCR Gasket

*Material: Typically made from 316L or 304 stainless steel.

*Applications: Ideal for high-temperature and high-pressure environments such as semiconductor,

chemical processing, and pharmaceutical industries.

*Benefits: Excellent corrosion resistance, durability, and mechanical strength.

2. Copper VCR Gasket

*Material: Made from pure copper.

*Applications: Commonly used in vacuum and high-vacuum systems, as well as in cryogenic

and ultra-high-purity applications.

*Benefits: Soft material allows for excellent sealing performance, especially in high-vacuum conditions.

Also provides good thermal conductivity.

3. Nickel VCR Gasket

*Material: Manufactured from nickel.

*Applications: Used in systems exposed to corrosive chemicals or gases, such as in chemical

processing or harsh industrial environments.

*Benefits: High corrosion resistance, especially in the presence of aggressive chemicals

and oxidizing environments.

4. Aluminum VCR Gasket

*Material: Made from aluminum.

*Applications: Common in vacuum and low-pressure systems, particularly where lightweight

and non-magnetic properties are needed.

*Benefits: Lightweight, corrosion-resistant, and provides a good seal in less extreme conditions.

5. PTFE (Teflon) VCR Gasket

*Material: Made from PTFE or Teflon.

*Applications: Suitable for applications involving aggressive chemicals and gases due to

PTFE's excellent chemical resistance.

*Benefits: Non-reactive, corrosion-resistant, and capable of withstanding a wide range of temperatures.

6. Gold-Plated VCR Gasket

*Material: Copper or stainless steel base with a gold-plated surface.

*Applications: Typically used in ultra-high vacuum (UHV) environments requiring high conductivity

and ultra-purity, such as in specialized scientific instruments or semiconductor processes.

*Benefits: Provides superior sealing in UHV conditions, with excellent corrosion resistance and high conductivity.

7. Custom Alloy VCR Gasket

*Material: Customizable alloys such as Inconel, Monel, or other high-performance metals.

*Benefits: Customizable for extreme conditions, offering excellent thermal stability, corrosion resistance, and durability.

These various types of VCR gaskets provide solutions for a wide range of applications, from basic vacuum systems to extreme conditions requiring high resistance to temperature, pressure, or chemical exposure. Each material offers distinct properties that make it suitable for specific industrial or scientific needs.

FAQ on VCR Gasket Filter and VCR Gasket

1. What is a VCR Gasket Filter and how does it differ from a VCR Gasket?

A VCR Gasket Filter is a specialized type of VCR fitting that incorporates a filter element within the gasket.

This filter element is designed to capture and remove contaminants from the fluid flowing through the fitting.

While a VCR Gasket is primarily used for creating a leak-tight seal between two components,

a VCR Gasket Filter serves the dual purpose of sealing and filtering.

2. What are the key advantages of using a VCR Gasket Filter?

*Enhanced fluid purity:

By capturing contaminants, VCR Gasket Filters help to maintain the cleanliness and purity of the fluid

flowing through the system. This is particularly important in applications where high levels of cleanliness

are required, such as in semiconductor manufacturing or pharmaceutical production.

*Reduced system maintenance:

By removing contaminants before they can reach other components, VCR Gasket Filters can help to

reduce the frequency of system maintenance and prevent costly equipment failures.

*Improved system performance:

A clean fluid can lead to better system performance and efficiency. By using a VCR Gasket Filter, you

can help to ensure that your system is operating at its optimal level.

3. What are the common applications for VCR Gasket Filters?

VCR Gasket Filters are widely used in a variety of industries, including:

*Semiconductor manufacturing: Used to filter ultrapure gases and liquids used in wafer fabrication processes.

*Pharmaceutical production: Used to filter sterile fluids and prevent contamination in drug manufacturing.

*Chemical processing: Used to filter corrosive or hazardous chemicals to protect equipment and personnel.

*Vacuum technology: Used to maintain high vacuum levels in various applications, such as research and development.

4. How often should a VCR Gasket Filter be replaced?

The replacement frequency of a VCR Gasket Filter depends on several factors, including the type of fluid being filtered,

the operating conditions, and the desired level of cleanliness. As a general rule, it is recommended to inspect the filter

element regularly and replace it when it becomes visibly dirty or clogged.

5. What are the key considerations when selecting a VCR Gasket Filter?

When selecting a VCR Gasket Filter, it is important to consider the following factors:

*Compatibility with the fluid: The filter element must be compatible with the fluid being filtered to ensure proper

performance and prevent damage to the filter or the system.

*Flow rate:

The filter must be able to handle the required flow rate without causing excessive pressure drop or becoming clogged.

*Particle size:

The filter must be able to capture particles of the desired size to achieve the desired level of filtration.

*Temperature and pressure ratings:

The filter must be rated for the operating temperature and pressure conditions of the system.

Looking for high-quality, customized VCR gaskets for your VCR tube system?

HENGKO is your trusted OEM partner!

With our expertise in manufacturing precision gaskets using a variety of materials like stainless steel,

copper, Hastelloy, and more, we can tailor solutions to meet your specific requirements.

Contact us today to discuss your project needs and discover how our VCR gaskets can enhance the

performance and reliability of your system.

Get in touch now at sales@hengko.com to start your custom OEM VCR gasket solution!