-

Stainless Steel 316 Micro Spargers and Filter in Bioreactors and Fermentors

Product Describe The function of the bioreactor is to provide a suitable environment in which an organism can efficiently produce a target product. * Cell b...

View Detail -

In-tank porous metal spargers or multiple sparger assembly for a large tank, increase g...

Attaches to the tip of the sparger tube, this 316L stainless steel sintered tip is available in a variety of pore sizes. The 5 10 15 50 100 pore frit is the ...

View Detail -

Single Use Bioreactor diffuser sparger for cell culture

In the initial stage of upstream processing in bioprocessing, fermentation is commonly used. Fermentation is defined as the chemical changes caused by microo...

View Detail -

multi – bioreactor sparger for the fermenter sartorius

The Stainless Steel Fermenter|Bioreactor for Your Laboratory A bioreactor is a type of fermentation vessel that is used for the production of various chemica...

View Detail -

Sintered Stainless Steel Sparger Porous Metal Diffuser for Gas Applications

OEM Sintered stainless steel diffuser / sparger, for aerating in liquid. HENGKO’s sintered sparger are unsurpassed in strength, precision and uniformity. Th...

View Detail -

HENGKO OEM Sintered Steel Filter and Sparger

OEM Sintered stainless steel diffuser / sparger, for aerating in liquid. HENGKO’s sintered sparger are unsurpassed in strength, precision and uniformity. The...

View Detail -

Sintered Microsparger in Bioreactor System for Green chemistry industry

The importance of aeration and gas dispersion to achieve good oxygen mass transfer cannot be understated. This is at the heart of the ability of mic...

View Detail -

Replacement Micro-Bubble Porous Sparger Tips for Fermentation / Bioreactor Air Aeration...

Advantages of HENGKO Porous Metal Micro Spargers Due to the low solubility of oxygen in many cell culture mediums, optimizing this critical nutrient can be ...

View Detail -

Sintered Micro Porous Sparger in Benchtop for Bioreactors and Laboratory Fermenter

Every bioreactor sparging system is designed for the introduction of oxygen to feed cell cultures. Meanwhile, the system must remove carbon dioxide to preven...

View Detail -

Quick Change Sparger System for Bioreactors and Fermentors Air Sparger Accessories- Mic...

Stainless steel sparger is to supply enough oxygen to the microbes in submerge culture technique for proper metabolism. Each fermentation process requires a ...

View Detail -

316 L Powder Stainless Steel Metal Frit Spargers Building A Stainless Steel Filtering S...

Product Description This device is particularly good for fermentations that require a large population of yeast. Pilsners (or other beers fermented at low te...

View Detail -

HENGKO sintered porous carbonation stone air sparger bubble diffuser nano oxygen genera...

In bioreactor systems, optimal mass transfer of gases like oxygen or carbon dioxide is difficult to accomplish. Oxygen, in particular, is poorly soluble in w...

View Detail -

Sintered Sparger Tube with Porous Metal Stainless Steel Tank and In-line Spargers Used ...

Introducing the exceptional HENGKO sintered spargers, the ultimate solution to introducing gases into liquids. This innovative product utilizes thousands of...

View Detail -

HENGKO micron small bubble air sparger oxygenation carbanation stone used in acrylic wa...

Product Describe HENGKO air sparger bubble stone is stainless steel 316/316L, food grade, with a beautiful appearance, suitable for hotels, fine dining and o...

View Detail -

Sintered Sparger Stainless Steel Material Quick Change for Bioreactor Systems

In bioreactor systems, optimal mass transfer of gases like oxygen or carbon dioxide is difficult to accomplish. Oxygen, in particular, is poorly soluble in w...

View Detail -

Aeration Stone 20um Sintered Stainless Steel 316L Micro sparger Diffusion Stone Supplier

Hydrogen water is clean, powerful, and with hydron. It helps to purify the blood and gets blood moving. It can prevent many kinds of diseases and improve peo...

View Detail -

Sintered 316l stainless steel bubble hydrogen-rich water generator air sparger

Product Description Hydrogen water is clean, powerful, and with hydron. It helps to purify the blood and gets blood moving. It can prevent many kinds of di...

View Detail -

Stainless Steel Ozone Diffuser Stone Fine Air Sparger for Hydrogen Generator

Hydrogen water is clean, powerful, and with hydron. It helps to purify the blood and gets blood moving. It can prevent many kinds of diseases and improve peo...

View Detail -

Stainless Steel Aeration/Oxygen CO2 Diffusion Stone Micro Sparger for Microalgae Cultiv...

Micro-diffuser for Microalgae Cultivation, Photobioreactors & sintered sparger for microalgae cultivation is used in laboratories for growing algae. HEN...

View Detail -

Biotech Removable Porous Frit Micro Sparger for Mini Bioreactor System and Fermentors

Stainless steel sparger used as a cell retention device. The device consists of a metal tube and a sintered metal filter with a pore size of 0.5 – 40 µm. The...

View Detail

Types of Sparger

Spargers: Tiny Bubbles, Big Impact

Spargers are the unsung heroes of many industries, silently introducing gas into liquids to achieve amazing things. But not all spargers are created equal! Let's dive into the different types and their unique strengths:

1. Porous Spargers:

These are the workhorses, made from sintered metal, ceramic, or glass. They have a porous structure that allows gas to break into tiny bubbles, increasing surface area for efficient mass transfer and mixing.

* Stone Spargers: Classic and versatile, often used in bioreactors for cell culture and fermentation.

* Membrane Spargers: Fine-tuned for sterile applications, offering high gas purity and low shear stress.

* Microporous Spargers: Tiny pore size for exceptionally fine bubbles, ideal for delicate processes like frothing or aeration.

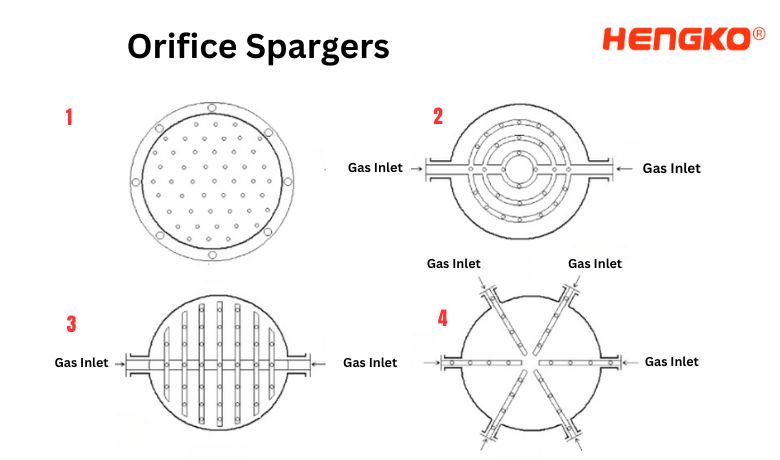

2. Orifice Spargers:

Simple and cost-effective, these use a single hole or multiple orifices to inject gas.

They create larger bubbles but are efficient for low-pressure applications like wastewater treatment.

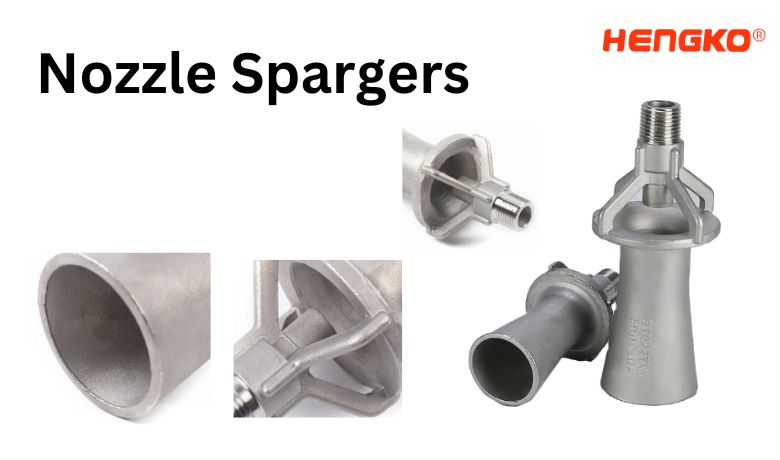

3. Nozzle Spargers:

Offering more control, these use nozzles to direct gas flow. They're perfect for creating specific bubble patterns or achieving high shear for mixing.

* Single Nozzle Spargers: Precise and easy to clean, ideal for situations like gas chromatography.

* Multi-Nozzle Spargers: Offer wider coverage and controlled bubble size, suitable for large tanks or complex mixing needs.

4. Other Spargers:

Beyond the usual suspects, there's a world of innovative designs:

* Bubble Columns: These tall towers use rising gas bubbles to gently mix and aerate liquids.

* Syringe Spargers: Precise and sterile, ideal for introducing small amounts of gas into sensitive environments.

* Surface Aerators: Often used in water treatment, they agitate and oxygenate liquids using rotating impellers or diffusers.

Choosing the right sparger depends on several factors:

* Application: What are you trying to achieve with the gas? Mixing, aeration, filtration, or something else?

* Liquid properties: Viscosity, pressure, and compatibility with the sparger material are crucial considerations.

* Gas type: Different gases require specific pore sizes or flow rates for optimal performance.

* Budget and scale: Simple spargers might be sufficient for small-scale operations, while complex processes might demand advanced features.

Remember, the perfect sparger is a match, not a one-size-fits-all solution. By understanding the types and their strengths,

you can choose the one that empowers your tiny bubbles to make a big impact.

What is a sparger in bioreactor

In the world of bioreactors, the sparger is the unseen hero, the tiny maestro conducting the delicate dance of gas and liquid. It's a device with a crucial mission: infusing the broth with vital gases, like oxygen, and ensuring they mingle evenly with the cellular residents.

Imagine a bioreactor as a bustling city. Cells are the busy citizens, constantly working and needing to breathe. The sparger is like the city's air filtration system, drawing in fresh air (oxygen) and distributing it throughout every nook and cranny.

Here's how it works:

1. Gas enters the sparger:

This could be pure oxygen, air, or even a specific gas mixture, depending on the cells' needs.

2. Tiny bubbles form:

The sparger breaks the gas into a multitude of microscopic bubbles. This is crucial, as more surface area means better gas transfer to the liquid.

3. Bubbles rise and mingle:

The bubbles gently rise through the broth, carrying the precious gas cargo. The sparger's design ensures the bubbles distribute evenly, reaching every corner of the bioreactor.

4. Cells breathe easy:

As the bubbles rise, they come into close contact with the cells. The cells absorb the dissolved gas, like oxygen, to fuel their growth and metabolism.

Different spargers for different bioreactors:

Just like cities have diverse air filtration systems, bioreactors use various spargers:

* Stone spargers:

These are the classic workhorses, made from porous materials like ceramics or metals. They're reliable and versatile, often used for bacterial or fungal cultures.

* Membrane spargers:

These are the tech-savvy siblings, offering sterile environments and even finer bubbles. They're perfect for sensitive cell lines or delicate processes.

* Microporous spargers:

These are the bubble whisperers, creating exceptionally fine bubbles for applications like protein production or shear-sensitive cells.

The sparger's impact goes beyond mere breathing:

* Mixing magic:

The rising bubbles gently stir the broth, preventing cell clumping and ensuring uniform nutrient distribution.

* Shear force:

Some spargers can create a controlled shearing force, which can be beneficial for certain processes like cell fragmentation or mass transfer.

* Waste removal:

Sparging can also help remove unwanted gases like carbon dioxide, keeping the cellular environment healthy.

So, the next time you see a bioreactor humming away, remember the tiny maestro within – the sparger, ensuring the life-giving gas reaches every cellular corner.

What is sparging in brewing

In the brewhouse, sparging is the art of extracting the last drops of deliciousness from your grains. It's like squeezing the final notes from a well-played melody, ensuring you capture every bit of flavor and aroma locked within.

Think of your mash tun as a treasure chest filled with sugary goodness. You've already drained off the first, sweet wave of liquid, the wort. But there's more to be found! Sparging is all about unlocking those hidden reserves, gently coaxing out the remaining sugars without introducing harsh bitterness.

Here's how it unfolds:

* Hot water on the scene:

Fresh, hot water, called sparge water, is slowly sprinkled or poured over the spent grain bed. This creates a gentle flow, washing away the sugar trapped in the grains.

* Sugar whispers:

As the sparge water trickles through, it entices the sugars to join the party. They dissolve and mingle with the water, creating a weaker wort, separate from the initial, stronger brew.

* Layering the flavors:

The sparge water isn't just a sugar grabber; it also washes away some tannins, those astringent fellows that can make your beer bitter. This delicate balance ensures you extract sweetness without bitterness, resulting in a smooth and harmonious brew.

But sparging isn't just a one-size-fits-all approach. Brewers have different techniques up their sleeves, each with its own twist:

* Fly sparging:

A continuous sprinkling of sparge water, like a gentle rain, for maximum sugar extraction.

* Batch sparging:

Adding the sparge water in batches, allowing each soak to release its sugary secrets before moving on.

* Raking and sparging:

Stirring the grains while sparging, like coaxing honey from a beehive, for more efficient sugar release.

No matter the technique, the goal remains the same: maximize your beer's potential without sacrificing its drinkability. A good sparge is like a whispered promise – it ensures that your next sip is just as flavorful and delightful as the first.

So, the next time you raise a glass, remember the unsung hero of the brewhouse – the sparger, the gentle extractor of hidden treasures that makes your beer sing.

What is steam sparging

Steam sparging is a powerful technique used to heat liquids, remove unwanted gases, and even mix ingredients, all thanks to the magic of steam. Imagine a tiny, invisible army of steam bubbles rising through a liquid, working tirelessly to transform it.

Here's how it works:

1. Steam enters the scene: Hot, pressurized steam is injected directly into the liquid through a sparger, a device with tiny holes or a porous structure.

2. Bubble bonanza: As the steam hits the cooler liquid, it condenses, forming a multitude of microscopic bubbles. These bubbles are the key players in the sparging game.

3. Heat transfer: The steam bubbles, much hotter than the liquid, transfer their thermal energy, causing the liquid to heat up rapidly and evenly. This is a much faster and more efficient way to heat liquids compared to traditional methods like immersion heaters.

4. Gas-busting: The rising bubbles also act like tiny vacuum cleaners, scrubbing unwanted gases like oxygen or carbon dioxide from the liquid. This is particularly useful in processes like deoxygenating boiler feedwater or removing CO2 from beer.

5. Mixing mayhem: The gentle turbulence caused by the bubbles can also help mix ingredients in the liquid, ensuring a uniform and consistent mixture. This is beneficial in applications like blending wine or preparing fermentation broths.

Steam sparging isn't just for one-trick ponies, it's a versatile technique with many applications:

* Heating liquids in tanks and vessels: from industrial chemicals to brewing wort.

* Deoxygenating water for boilers: preventing corrosion and explosions.

* Removing CO2 from beer: ensuring a clean and crisp taste.

* Mixing ingredients in food and beverage production: creating smooth and consistent products.

* Wastewater treatment: promoting aeration and improving efficiency.

The beauty of steam sparging lies in its simplicity and effectiveness. It's a gentle yet powerful technique that can be easily adapted to various needs. So next time you see a liquid bubbling away, remember the unseen force at work – the tiny steam bubbles, transforming liquids with their invisible magic.

what temperature should sparge water be

What is the different with air sparger in bioreactor, sparging in brewing steam sparging ?

| Feature | Air Sparger (Bioreactor) | Sparging (Brewing) | Steam Sparging |

|---|---|---|---|

| Function | Introduces oxygen for cell growth | Extracts sugars from grains | Heats, degases, and mixes liquids |

| Gas used | Air or oxygen | Air | Steam (condenses to water) |

| Bubble size | Fine bubbles for efficient gas transfer | Coarse bubbles for gentle extraction | Tiny bubbles for efficient heat transfer and gas removal |

| Mixing | Can gently mix the broth | No mixing | Can mix ingredients depending on sparger design |

| Applications | Aerating fermentation broths in lab and industrial settings | Extracting sugars for beer production | Heating and degassing liquids in various industries (food processing, chemical production, etc.) |

| Benefits | Efficient oxygen transfer, low shear stress, sterile options available | Maximizes sugar extraction, avoids harsh bitterness | Fast heating, efficient degassing, good mixing potential |

| Drawbacks | Can clog with cell debris, requires regular cleaning | May extract unwanted tannins, less control over bubble size | Can be energy-intensive, requires specialized equipment |

Notes:

* Air spargers in bioreactors often come in various designs like stone spargers, membrane spargers, and microporous spargers, each with its own strengths.

* Sparging in brewing can also involve techniques like fly sparging, batch sparging, and raking and sparging for optimal sugar extraction.

* Steam sparging can be combined with other techniques like mechanical agitation for enhanced mixing.

What is a Sparge Pipe ?

A sparge pipe, also known as a sparger, is a versatile tool used in various industries to introduce a gas into a liquid. It's like a hidden conductor, orchestrating the delicate dance of gas and liquid to achieve specific results.

Think of it like a straw, but instead of sucking up liquid, it blows gas into it. This gas can be anything from air and oxygen to more specialized mixtures, depending on the application.

Here's how sparge pipes work their magic:

1. Design Variations:

* Simple pipes: These have holes drilled throughout their length, allowing gas to escape and form bubbles as it enters the liquid.

* Porous pipes: Made from sintered metal or ceramics, these have a porous structure that lets the gas diffuse evenly, creating finer bubbles.

* Nozzles: These have specialized tips that control the gas flow direction and bubble size, ideal for specific mixing or aeration needs.

2. Applications Galore:

* Bioreactors: Sparging oxygen into fermentation broths keeps cells happy and brewing.

* Wastewater treatment: Air sparging helps break down pollutants and improve oxygen levels.

* Beverages: Adding CO2 creates fizzy sodas and frothy beers.

* Chemical reactions: Sparging specific gases can initiate or control reactions.

* Industrial processes: From mixing paints to cleaning tanks, sparging plays a role.

3. Benefits of Using Sparge Pipes:

* Efficient gas distribution: Tiny bubbles maximize gas-liquid contact for better results.

* Controlled mixing: Sparging can gently stir liquids without damaging delicate ingredients.

* Aeration and oxygenation: Vital for biological processes and water treatment.

* Versatility: One tool, many uses, adaptable to diverse needs.

Remember, the sparge pipe may be hidden, but its impact is undeniable. It's the silent hero behind bubbly beverages, thriving cell cultures, and cleaner water. So next time you witness a process involving gas and liquid working in harmony, think of the sparge pipe – the tiny conductor orchestrating the symphony behind the scenes.

Looking for a Custom Metal Porous Sparger for Your System?

Reach out to HENGKO at ka@hengko.com for specialized solutions tailored to your needs.