Superior Filtration and Reliable High-Pressure Flow Control for Semiconductor Processes

Description

The Diffuser Filter is a cutting-edge solution specifically designed for rapid venting applications in vacuum chambers

used in semiconductor manufacturing processes.

Combining the flow characteristics of a diffuser with the particle interception capabilities of a high-efficiency filter,

this product ensures unmatched performance and reliability.

Key Features:

Ultra-High Filtration Precision:

Achieves filtration accuracy of up to 0.003μm, effectively capturing even the smallest particles to protect sensitive semiconductor environments.

Innovative 316L Stainless Steel Construction:

Crafted entirely from 316L stainless steel, this unique design ensures exceptional durability, corrosion resistance, and superior filtration efficiency.

Turbulence-Free Design:

Engineered to minimize turbulence, preventing any disturbance to the process chamber environment.

This feature safeguards against particle resuspension or wafer surface contamination, maintaining the

integrity of the production process.

Customizable and Flexible:

Tailored to fit various installation spaces, the filter adapts seamlessly to diverse system requirements,

providing a versatile solution for semiconductor manufacturing needs.

![]()

Product Feature

▶ Sintered Stainless Steel Media for Rapid Venting

Ensures efficient and swift exhaust processes in vacuum chambers.

▶ Full 316L Stainless Steel Construction

Guarantees exceptional durability, corrosion resistance, and reliability.

▶ Reduces Turbulence During Chamber Exhaust

Minimizes disturbances in the process chamber, maintaining environmental stability.

▶ Compatible with a Wide Range of Process Gases

Offers versatility for various semiconductor manufacturing applications.

▶ Manufactured, Tested, and Packaged in Cleanroom Environments

Ensures strict compliance with the highest cleanliness standards.

▶ 100% Integrity Testing

Every unit undergoes thorough testing to ensure flawless filtration performance.

▶ 100% Helium Leak Detection Passed

Validates absolute sealing and reliability in high-pressure environments.

▶ High-Temperature, High-Pressure, and Corrosion Resistant

Built to withstand the most demanding operational conditions.

▶ Prevents Particle Contamination

Enhances product quality by reducing the risk of defects and improving yield rates.

▶ Customizable Design

Adaptable to various installation spaces, providing tailored solutions for diverse requirements.

This feature-rich diffuser filter is designed to meet the rigorous demands of semiconductor manufacturing,

ensuring performance, reliability, and adaptability in every application.

Datasheet

Technical Parameters

| Parameter | Specification | Parameter | Specification |

|---|---|---|---|

| Filter Material | 316L Sintered Stainless Steel | Housing Material | 316L Stainless Steel |

| Surface Treatment | Inner Surface: Ra ≤ 32μm | Filtration Accuracy | ≥ 0.003μm |

| Maximum Inlet Pressure | 4 bar | Maximum Operating Differential Pressure | 5 bar |

| Maximum Operating Temperature | 400℃ | Downstream Cleanliness | ≤ 0.03 particles/liter @ >0.01μm rated flow |

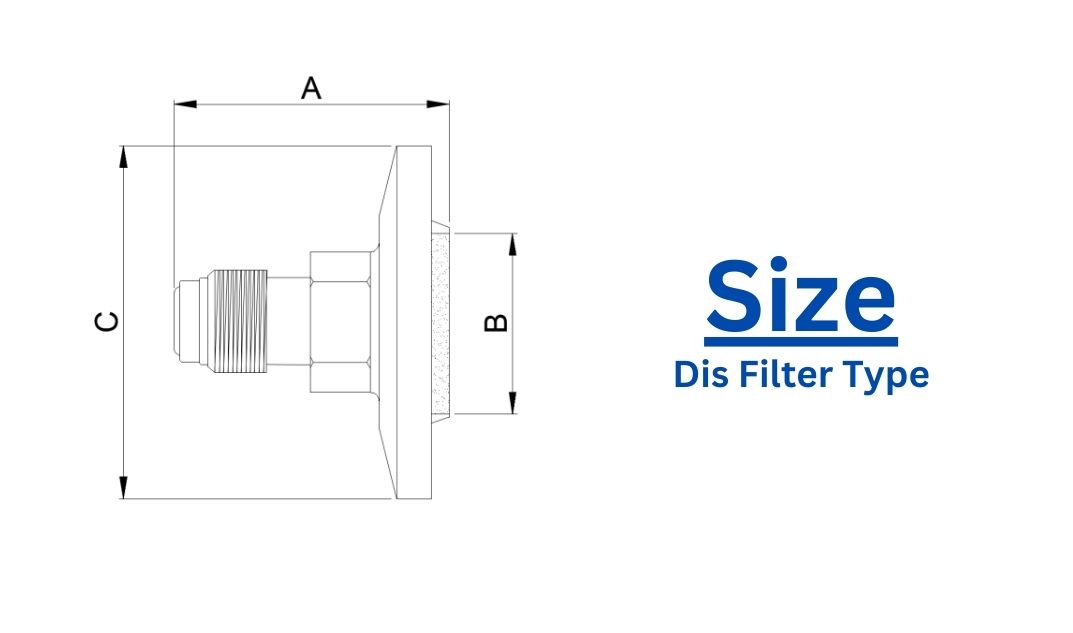

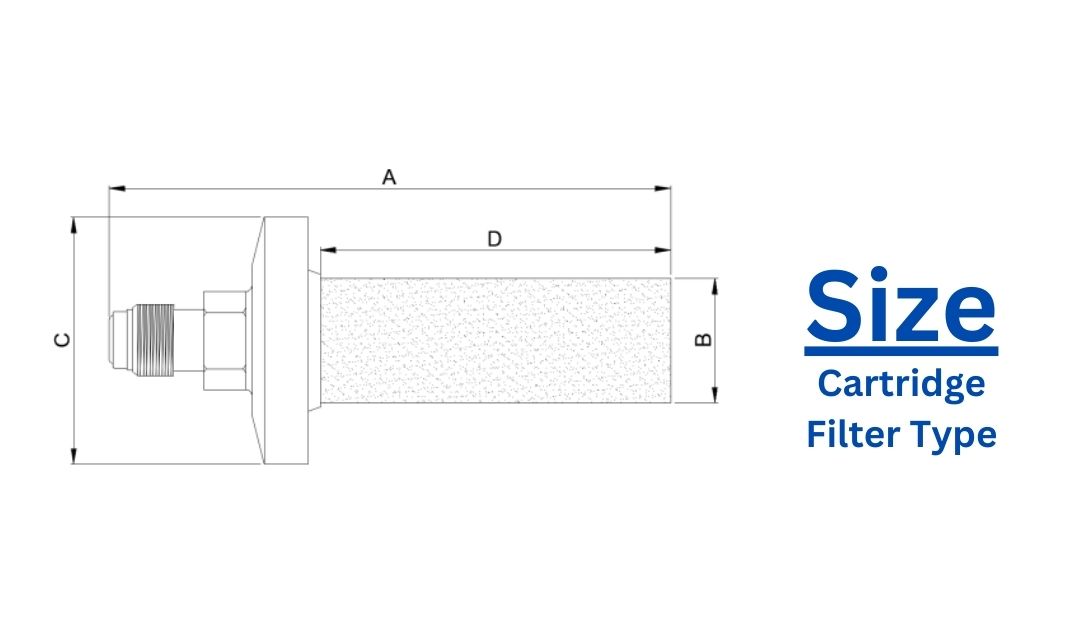

Size

Here’s the part number you can order and size details :

Product Information Table for Disc filter type

| Product Model | Inlet Specification | Outlet Specification | Total Length (A) | Filter Element OD (φB) | Housing OD (φC) |

|---|---|---|---|---|---|

| Z01B-00639 | 1/4’’ VCR | ISO NW40 Vacuum Flange | 42mm (1.64’’) | Φ39mm (1.53’’) | Φ55mm (2.16’’) |

| Z01B-00695 | 1/4’’ VCR | ISO NW50 Vacuum Flange | 42mm (1.64’’) | Φ52mm (2.05’’) | Φ75mm (2.95’’) |

Product Information Table for Cartridge filter type

| Product Model | Inlet Specification | Outlet Specification | Total Length (A) | Filter Element OD (φB) | Housing OD (φC) | Filter Tube Length (D) |

|---|---|---|---|---|---|---|

| Z01B-00697 | 1/4’’ VCR | ISO NW16 Vacuum Flange | 81mm (3.18’’) | Φ16mm (0.64’’) | Φ30mm (1.18’’) | 44mm (1.74’’) |

| Z01B-00501 | 1/4’’ VCR | ISO NW16 Vacuum Flange | 104mm (4.08’’) | Φ16mm (0.64’’) | Φ30mm (1.18’’) | 67mm (2.64’’) |

| Z01B-00698 | 1/4’’ VCR | ISO NW16 Vacuum Flange | 135mm (5.30’’) | Φ16mm (0.64’’) | Φ30mm (1.18’’) | 98mm (3.86’’) |

| Z01B-00699 | 1/4’’ VCR | ISO NW25 Vacuum Flange | 81mm (3.18’’) | Φ16mm (0.64’’) | Φ40mm (1.58’’) | 44mm (1.74’’) |

| Z01B-00700 | 1/4’’ VCR | ISO NW25 Vacuum Flange | 104mm (4.08’’) | Φ16mm (0.64’’) | Φ40mm (1.58’’) | 67mm (2.64’’) |

| Z01B-00701 | 1/4’’ VCR | ISO NW40 Vacuum Flange | 104mm (4.08’’) | Φ16mm (0.64’’) | Φ55mm (2.16’’) | 67mm (2.64’’) |

Typical Applications

Ideal for use in:

*Vacuum chambers requiring rapid and precise gas venting.

*High-sensitivity semiconductor manufacturing environments.

*Processes where turbulence minimization and particle control are critical.

With its advanced design and outstanding performance, the Diffuser Filter is the perfect choice for

optimizing filtration and flow control in semiconductor applications.

Contact us today to learn how this innovative product can elevate your production

*Filters high-pressure gases for cooling and process applications, especially in high-temperature settings.

*Enhances efficiency and reduces equipment wear by preventing contamination in gas cooling and flow systems.

These filters are essential in any application requiring clean, consistent gas flow, enhancing equipment protection,

process efficiency, and final product quality across industries.

![]()

Send your message to us: