Stainless Steel Sintered Metal Filters – Applications of Filtration in the Pharmaceutical Industry

Filtration through sintered metal filters is used in pharmaceutical manufacturing to remove unwanted material from the formulated bulk solution. The primary purpose of filtration is to create a sterile final product.

Filtration through sintered metal filters is used in pharmaceutical manufacturing to remove unwanted material from the formulated bulk solution. The primary purpose of filtration is to create a sterile final product.

Different microns (0.2-100um) can match different degrees of filtration requirements. HENGKO sintered metal filters can be easily applied to a large variety of pharmaceutical needs, and because of this flexibility, it is widely used within the industry.

Compared to surface filtration, depth filtration also retains particulate matter farther down from the surface. It is primarily used for clarification of solutions. Among the most common filters used in in-depth filtration is sintered filters. Recent developments in sintered metal filters: In the past, the industry depended heavily on the use of electrostatic precipitators, cyclones, and disposable filters. But recently, these are being replaced by metal sintered filters. These filters can be cleaned in situ, and as the filter cake (the layer of filtered material at the membrane) forms, the screen becomes more efficient.

Which Sintered filter is right for you?

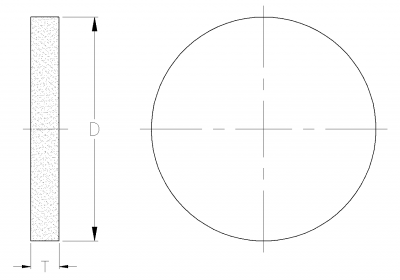

Discs HENGKO porous 316L SS discs

| Discs | D,mm | T,mm |

| Smallest standard size | 1 | 2 |

| Lrgest standard size | 100 | 150 |

(* For reference only, please consult our customer service for more accurate requirements)

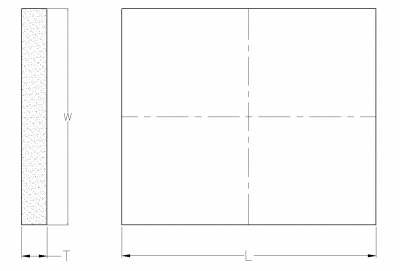

Sheets HENGKO porous 316L SS porous metal sheets

| Sheets | W,mm | T,mm | L,mm |

| Smallest standard size | 1 | 2 | 2 |

| Lrgest standard size | 100 | 450 | 800 |

(* For reference only, please consult our customer service for more accurate requirements)

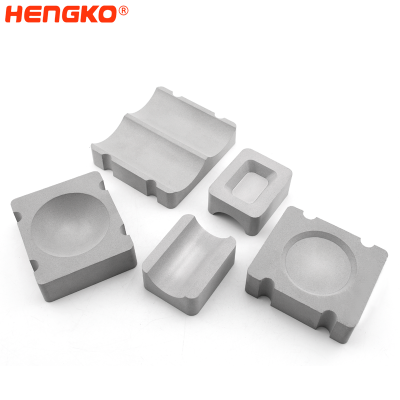

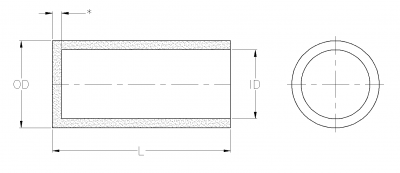

Cups HENGKO porous 316L sintered stainless steel cups

| Cups | OD,mm | ID,mm | L,mm |

| Smallest standard size | 4.0 | 1 | 2 |

| Lrgest standard size | 220 | 210 | 1000 |

(* For reference only, please consult our customer service for more accurate requirements)

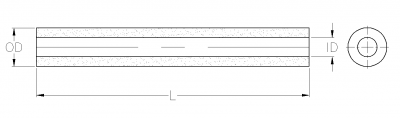

Tubes HENGKO porous 316L SS sintered porous metal tubes

| Tubes | OD,mm | ID,mm | L,mm |

| Smallest standard size | 4.0 | 1 | 2 |

| Lrgest standard size | 220 | 210 | 800 |

(* For reference only, please consult our customer service for more accurate requirements)

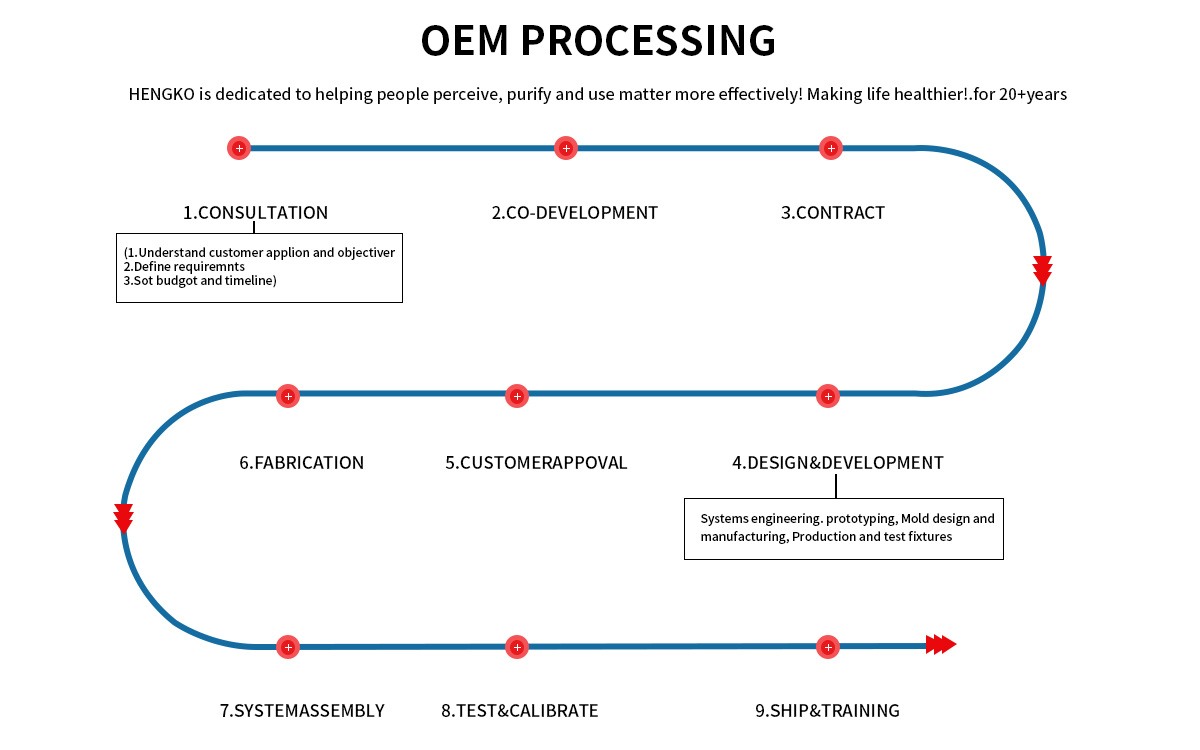

Can't find a product that meets your needs? Contact our sales staff for OEM/ODM customization services!