-

Flashback arrestors for single cylinders custom sintered porous metal stainless steel f...

Product Describe The design concept of this product is to prevent users from accidentally using fire to test whether there is hydrogen. The flame arrester wi...

View Detail -

Sintered Porous Metal Stainless Steel Filter Tube for Fiber Optic Collimator HENGKO

Product Describe porous metal cartridges can be customized for a wide variety of applications and specifications and can be attached to metallic and non-meta...

View Detail -

HENGKO Sintered Filter Cartridge for Process Gas and On-Line Analysis

Gas and Sample Filtration For process Gas and On-Line Analysis The filtration of gases is essential in a vast range of applications, yet only three m...

View Detail -

HENGKO stainless steel filter for VOC dust aerosol generators

Product Describe VOCs come mainly from fuel combustion and transport outdoors; indoors from combustion products such as coal and natural gas, smoke from smo...

View Detail -

Explosion Proof Sintered Filter Gas Sensor Housing for Process and Analytical Gas Appli...

Gas sensor housing are safety devices that allow flow of combustible gases while preventing ignition. The (sintered metal filter media) gas sensor housing pr...

View Detail -

Metallic Sintered Filter for Filtration PM2.5

Metallic Sintered Particulate Filter Replacement metal airstone water dust It prevents dirt and debris from entering and clogging the pump The metallic ...

View Detail -

Sintered Metal Stainless Steel Porous Mesh Filters for in High Pressures Environments

Hengko’s food-grade textile filters are primarily manufactured in the form of cups, threaded cups, discs, and extended area packs. These filters are primaril...

View Detail -

stainless steel 316 sintered metal filter 30-90 microns filter element – space al...

Product Describe HENGKO stainless steel filter elements are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatur...

View Detail -

High-purity sintered porous 316L stainless steel steam filters effective retention of p...

SINTERED METAL FILTERS FOR THE REMOVAL OF PARTICLES High-purity filters and spargers are specially designed to meet strict requirements for the removal of pa...

View Detail -

Porous filters liquid-solid process filters for high temperature & corrosive envir...

HENGKO offers liquid-solid process sintered metal filters for high-temperature & corrosive environments. HENGKO manufactures filter elements in a ...

View Detail -

Custom sintered stainless steel round disc filter for flameproof and fire resistance

Sintered metal materials are a popular choice because these highly engineered materials consist of a uniform, interconnected porosity that can be fabricated ...

View Detail -

OEM sintered stainless steel porous metal fluidizers fluid for material transfer or tra...

HENGKO’s porous metal fluidizers provide an optimum solution for material transfer or transport applications that require strength, elevated temperature tole...

View Detail -

Sintered Metal Fame Arrestors Manufacturer for the Storage and Transportation of Inflam...

Flame Arrestors are safety devices that allow the flow of combustible gases while preventing ignition. The Flame Arrestorprevents the flame from transferring...

View Detail -

3D Printed porous metal filter OEM filtration & flow control designs for medical d...

HENGKO manufactures filter elements in a broad range of materials, sizes, and fittings so they can be easily specified with the characteristics and configura...

View Detail -

Good grade sintered porous metal stainless steel textile filters for polymer filtration

Good-grade sintered metal stainless steel textile filters for polymer filtration Hengko’s food-grade textile filters are primarily manufactured in the form ...

View Detail -

Microns porous stainless steel sintered filters inline reusable washable fuel filter

Captures dirt and grit as small as 40 microns before they can cause damage to the intake system. CNC polished alloy body with the sintered metal internal ele...

View Detail -

Pre-filtration of smoke sampling – sintered stainless steel 304 316 316L filter e...

Product Describe Boost Your Gas Analysis with HENGKO's Gas Sampling Probes! When it comes to accurate and reliable gas analysis, HENGKO has you covered. Our...

View Detail -

Professional manufacturer customized sintered porous metal filter tube used for medical...

HENGKO sintered filters are usually used for purification and filtration of liquid and gas, separation and recovery of solid particles, transpiration cooling...

View Detail -

Sintered metal 316 stainless steel filter medical micro filter tube for liquid and gas ...

Product Describe Porous filter material has been widely used in metallurgical, chemical, pharmaceutical, aerospace, and aviation fields. Porous Metal media...

View Detail -

sintered metal powder stainless steel filter air compressor air filters

HENGKO 5-micron sintered filter cups can be customized to a wide variety of applications and specifications. Cups can be attached to various metallic and non...

View Detail

Types of Stainless Steel Filter

Stainless steel filters come in various forms and designs, tailored to meet the specific needs of different applications. Here are some of the main types of stainless steel filters:

1. Stainless Steel Wire Mesh Filters:

Wire mesh filters are made from woven or welded stainless steel wire. They are popular due to their durability, high filtration accuracy, and corrosion resistance. These are often used in water treatment, petrochemical, and food and beverage industries.

2. Stainless Steel Sintered Filters:

Sintered filters are created by fusing together stainless steel particles using heat and pressure, without actually melting the steel. The result is a filter with high strength and rigidity, as well as excellent permeability and corrosion resistance. These are commonly used in the pharmaceutical, chemical, and petrochemical industries.

3. Stainless Steel Pleated Filters:

Pleated filters have a larger surface area due to their folded or pleated design. This allows them to capture more particles and have a higher flow rate compared to other filter designs. They are typically used in air filtration systems, hydraulic systems, and oil filtration.

4. Stainless Steel Cartridge Filters:

Cartridge filters are cylindrical filters designed for use in filter housings. They can be constructed from a variety of materials, including stainless steel. These are used in water purification systems, beverage production, and chemical filtration.

5. Stainless Steel Disk Filters:

Disk filters are flat, circular filters that are typically used in applications that require a high level of filtration accuracy. They are often found in the electronics industry, particularly in the production of semiconductors.

6. Stainless Steel Cone Filters:

Cone filters, also known as strainer filters, are shaped like a cone to capture particles in a flowing medium. These are commonly used in the automotive and aerospace industries, often for fuel and oil filtration.

7. Stainless Steel Bag Filters:

Bag filters are a type of filter where the fluid is passed through a bag made of stainless steel mesh or felt. These are used in various applications like water treatment, food and beverage processing, and chemical filtration.

8. Stainless Steel Filter Baskets:

Filter baskets are used in applications where large amounts of debris need to be filtered out of a system. These are often found in industrial applications such as paint filtration, chemical processing, or wastewater treatment.

The type of stainless steel filter used will depend on the specific requirements of the process, including the type of material being filtered, the size of the particles to be removed, the flow rate, and the operating temperature and pressure.

Main Special Features of Stainless Steel Filters

Stainless steel filters are a type of filter that is made using kinds of 316L, 316 stainless steel. Stainless steel

is a type of metal that is highly durable and resistant to corrosion, making it an ideal material for use in a filter.

Some of the key features of stainless steel filters include the following:

1. Durability:

Stainless steel filters are extremely durable and can withstand a wide range of temperatures and

conditions without breaking or becoming damaged. This makes them ideal for industrial, commercial, and

residential applications.

2. Corrosion Resistance:

Stainless steel is resistant to corrosion, meaning it won't rust or deteriorate over time

when exposed to water, chemicals, or other substances. This makes stainless steel filters an ideal choice for

applications where the filter may be exposed to corrosive materials.

3. Easy to Clean:

Stainless steel filters are easy to clean and maintain. They can be easily washed with soap

and water and don't require special cleaning solutions or chemicals. This makes them a convenient and

low-maintenance option for use in many different settings.

4. Versatility:

Stainless steel filters are highly versatile and can be used in a wide range of applications,

including water filtration, air filtration, and oil filtration. They can be customized to meet the specific needs

of each application, making them flexible and adaptable options for many different uses.

5. Cost-effective:

Stainless steel filters are relatively inexpensive compared to other filters, making them

a cost-effective option for many applications. They are also long-lasting and durable, so they can

provide good value over the long term.

Why Wholesale Stainless Steel Filter From HENGKO

HENGKO is a leading manufacturer of sintered steel filters, offering customizable designs for various applications. We provide solutions to meet the requirements of different industries, such as petrochemical, fine chemical, water treatment, pulp and paper, auto industry, food and beverage, metalworking, and more.

Here are some key points about HENGKO:

1. With over 20 years of experience, HENGKO is a professional stainless steel filter manufacturer in powder metallurgy.

2. HENGKO manufactures strict CE certification for 316 L and 316 Stainless Steel Powder Filter Material Procurement.

3. We have a professional High-Temperature Sintered Machine and Die Casting Machine at HENGKO.

4. The team at HENGKO includes 5 of over 10 years of experienced engineers and workers in the stainless steel filter industry.

5. To ensure fast manufacturing and shipping, HENGKO stocks stainless steel powder materials.

Main Applications of Stainless Steel Filter

Stainless steel filters are highly durable and resistant to corrosion, making them suitable for a wide range of applications. Here are some of the main uses of stainless steel filters:

1. Water Treatment and Filtration:

Stainless steel filters are commonly used in the filtration and purification of drinking water. They are also used in wastewater treatment to remove harmful substances before the water is discharged back into the environment.

2. Food and Beverage Industry:

They are used in the food and beverage industry for filtering processes such as brewing beer, making wine, and processing dairy products. Stainless steel filters can withstand harsh cleaning chemicals and high temperatures, making them ideal for these applications.

3. Pharmaceutical Industry:

The pharmaceutical industry uses stainless steel filters for sterile processing and filtration of various medicines and other pharmaceutical substances. They are ideal for applications that require a high level of cleanliness and sterility.

4. Chemical Industry:

In the chemical industry, stainless steel filters are used for filtration of chemicals, solvents, and other corrosive substances. They are highly resistant to many chemicals and can operate under high pressure and temperature conditions.

5. Oil and Gas Industry:

Stainless steel filters are used for filtering crude oil and natural gas in the oil and gas industry. They help remove impurities and protect downstream equipment from damage.

6. Petrochemical Industry:

Stainless steel filters are used for the filtration of petrochemicals. They can withstand high temperatures and pressures, making them ideal for this application.

7. Power Generation:

In power plants, stainless steel filters are used for filtering cooling water, lubricating oils, and fuels. They help maintain the efficiency of power generation equipment and reduce the risk of breakdowns.

8. Automotive Industry:

Stainless steel filters are used in the automotive industry to filter engine oil, fuel, and air intake. They help protect the engine and other components from wear and damage.

9. Electronics Manufacturing:

Stainless steel filters are used in the manufacturing of electronics, especially semiconductors. They help ensure the cleanliness of the manufacturing process and the quality of the finished products.

10. HVAC Systems:

Stainless steel filters are used in heating, ventilation, and air conditioning (HVAC) systems to filter out dust, pollen, and other airborne contaminants. They can withstand high temperatures and are easy to clean and maintain.

How to choose right Stainless Steel Filter for your filtration project ?

Choosing the right stainless steel filter for your filtration project depends on a variety of factors. Here are some key considerations:

1. Material Compatibility:

The filter material must be compatible with the substance you're filtering. Stainless steel is generally resistant to many chemicals, but certain substances may require a specific type of stainless steel.

2. Filtration Size:

The size of the particles you need to filter out will determine the filter pore size you need. Filters are rated based on their ability to remove a certain size of particle, so choose a filter with a pore size suitable for your application.

3. Flow Rate:

The flow rate is the amount of fluid that passes through the filter in a given amount of time. Higher flow rates may require larger or multiple filters.

4. Operating Conditions:

The operating temperature and pressure of the process can influence the type of filter you need. Ensure the filter you choose can withstand your process's conditions.

5. Cleaning and Maintenance:

Consider how easy the filter will be to clean and maintain. Some filters can be reused and cleaned, while others are disposable.

6. Budget:

The cost of the filter is always a factor. While higher quality filters may cost more upfront, they may save money in the long run due to longer lifespans and lower maintenance costs.

7. Certifications:

If you're working in a regulated industry like food and beverage or pharmaceuticals, you may need a filter that meets certain standards or certifications.

Here's a basic process you could follow:

1. Identify the properties of the material you are filtering:

This includes its viscosity, chemical properties, and the size and type of particles it contains.

2. Define your filtration goals:

Determine what you want to achieve with your filtration process, like removing all particles above a certain size, or achieving a certain level of purity.

3. Consider your operating conditions:

This includes factors like temperature, pressure, and flow rate.

4. Look at different types of stainless steel filters:

Each type has its advantages and disadvantages, so compare them to find the one that best suits your needs.

5. Consult with a filtration expert or manufacturer:

They can provide valuable advice and help you make an informed decision.

6. Test the filter:

If possible, try out the filter before you commit to purchasing it. This can help you verify that it will work for your application.

Engineered Solutions Support

For over 20 years, HENGKO has successfully provided solutions for more than 20,000 intricate filtration and

flow control issues across a variety of industries worldwide. We are confident in our ability to customize solutions

to meet your complex engineering needs and provide the optimal stainless filters for your requirements.

We invite you to share your project details with us so that we can offer professional advice and the best possible

solution for your metal filter needs. Please contact us today to get started!

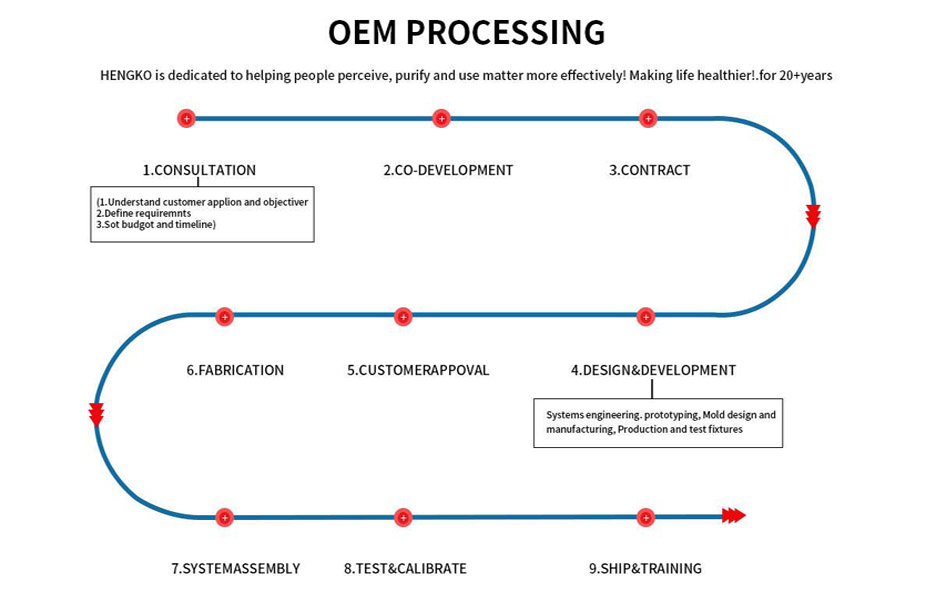

How to Customize Sintered Stainless Steel Filter

If you require a Special Design for your project and are unable to find the appropriate filter products,

please do not hesitate to contact HENGKO.

We will work closely with you in order to find the best solution as soon as possible. Please refer to the following

process for our OEM Sintered Stainless Metal Filters.

Please check out the details and feel free to contact us to discuss further.

HENGKO is dedicated to helping people perceive, purify, and utilize matter more effectively. With over two decades

of experience, we strive to make life healthier for all.

Here as follow is the List You need to know about the O.E.M Process Details:

1. Consultation O.E.M details with salesman and R&D Team

2. Co-Development, confirm O.E.M fee

3. Make a Formal Contract

4. Design & Development, Make Samples

5. Customer appoval for the sample details

6. Fabrication /Mass Production

7. Systemassembly

8. Test & Calibrate

9. Shipping Out

FAQ Guide of Sintered Stainless Metal Filters :

1. Why Use Stainless Steel to Be Filter ?

There are lot of advantage of stainless steel filters. main features as follow;

1. Strong Frame

2. Durable and cost-effective

3. Better filtering than normal filters

4. Can load high pressure, high temperature

5. Can be used in many harsh environments, resistant to alkali, acid and corrosion

Do You want to know the sintered filter working principle, if the advantage of the sintered

stainless steel can really help your filtration projects, please check the link to know details.

2. What is the Advantage and Disadvantage of of sintered stainless steel filters ?

For the Advantage is as the five points as above refered.

Then for the Disadvantage main is the cost will be higher than normal filters. but it is worth it.

Welcome to contact us for get price list.

3. What are the Available Types for Stainless Steel Filter?

For now , we have many design of stainless steel filter option

We divide them into five categories by shape:

1. Disc

2. Tube

3. Cup

4. Wire Mesh

5. Shaped, custom as your requires

So if you have any of those 316L or 316 stainless steel filters for your projects,

please feel free to contact us for know more details, you will get factory price directly.

4. How much Pressure Can a Stainless Steel Filter Can Bear ?

Normally for the sintered pressure of 316L stainless steel, we design can

accept up to 6000 psi input, but based on the design shape, thickness etc

5. What Temperature Extremes Can a Stainless Steel Filter Can use to ?

For 316 Stainless steel can withstand high temperature in the range of 1200-1300 degrees,

which can be used in relatively harsh conditions

6. When Should I Replace and Clean Stainless Steel Filter ?

Normally, we advice to replace or clean the sintered stainless steel filters when the The filtered

flow or the filtering speed is obviously lower than the data originally used, for example, it has

dropped by 60%. At this time, you can choose to reverse the cleaning first. If the filtering or

experimental effect still cannot be achieved after cleaning, then we recommend

that you try a new one

7. How to Clean Stainless Steel Filter ?

Yes, normal we advice to use ultrasonic cleaning

8. Can I Order Stainless Steel Filter Disc with Customized Dimension?

Yes, sure , you can welcome to customize the size and diameter as your design.

Please send your design idea to us by email asap, so we can supply best solution as your requires.

9. What is the Sample Policy for HENGKO ?

About the samples, we can accept one time free sample for each month, but for the free sample

details policy, please contact our salesman asap. because the free samples not always there.

10 What is the Delivery Time for Stainless Steel Filter from HENGKO ?

Normally, our manufacturing time for Stainless Steel Filter is about 15-30 days for O.E.M

stainless steel filters.

11. How to get a Quick Quote of Stainless Steel Filter from HENGKO ?

Yes, you are welcome to send email ka@hengko.com directly or send form inquiry as follow form.

12. how to clean stainless steel coffee filter ?

Cleaning a stainless steel coffee filter is a relatively straightforward process. Here are the steps you should follow:

-

Rinse Immediately After Use: Once you've finished brewing your coffee, rinse the filter immediately under warm water. This can help to prevent oils and coffee grounds from drying and sticking to the filter.

-

Soak in Warm Water and Soap: If the filter is particularly dirty, you can soak it in warm water with a little mild dish soap. Allow it to soak for about 10-15 minutes to loosen any stuck-on grime.

-

Scrub Gently: After soaking, use a soft bristle brush or a non-abrasive sponge to scrub the filter gently. Be careful not to scrub too hard, as this could damage the filter. Make sure you clean both the inside and outside of the filter.

-

Use a Vinegar Solution for Deep Cleaning: If the filter still seems dirty after scrubbing, you can do a deeper clean using a vinegar solution. Mix equal parts of white vinegar and water, then soak the filter in this solution for about 20 minutes. After soaking, scrub it again with the brush or sponge.

-

Rinse Thoroughly: After you've finished scrubbing, rinse the filter thoroughly under warm water. Make sure all soap or vinegar solution is completely rinsed off.

-

Dry Completely: Finally, make sure to dry your stainless steel coffee filter completely before storing it. You can let it air dry or pat it dry with a clean towel. Storing it while it's still wet could potentially lead to the growth of mold or mildew.

Remember to always check the manufacturer's instructions for cleaning your specific coffee filter, as some may have specific care instructions or warnings.

Regular cleaning can help ensure the longevity of your stainless steel coffee filter and keep your coffee tasting great.

Still have questions for the Stainless Steel Filter for your projects ?

you are welcome to send email directly by ka@hengko.com or Send form inquiry as follow form.