Steam Filter Stainless Steel Filter Housings For Sterile Air, Steam, and Liquid Filtration

In production environments, HENGKO sintered metal filters and clean air solutions are essential to protect advanced or sensitive production processes, or to combat molecular or microbial contamination in the air.

Stainless Steel Filter Housings For Sanitary Applications

The Stainless Steel Filter housings are designed for filtering steam in the pharmaceutical, biotechnology, chemical, electronic, food, and beverage industries.

Stainless Steel Filter Housings are equipped with sanitary NPT thread or flange connections and have an electropolished surface finish. The top vent needs to be sealed with a medicinal plug (not factory equipped), while the bottom condensate drain is equipped with a medicinal valve. Stainless Steel Filter housings are designed to yield low differential pressures at high flow rates.

Available in 12 different sizes with a capacity range for steam from 100 to 17,100 lbs/hr at 50 psi. It is also possible to choose how the fittings are connected (e.g., threaded, etc.) to make the filter fit your specific requirements.

Features & Benefits

• Multiple sizes can be customized to meet all your purification requirements for steam filtration applications.

• High quality 316L sintered stainless steel filter media construction with 304 SS welded end caps ensure excellent material resistance to steam.

• The heavy-duty design can withstand pressure differentials up to 72 psi and an operating temperature range of -60° C to 600° C.

• The Sintered ASF 5 micron element exceeds 3-A guidelines for producing Culinary Steam (95%@ 2 microns) under Accepted Practice T609-04.

• The 50+% porosity level ensures high dirt holding capacity at low differential pressure and high flow rate.

• Multiple regeneration methods can be used, including backwashing, ultrasonic cleaning, and cleaning with hydrogen peroxide and other chemicals, resulting in longer filter life and lower operating costs.

• Compliant with FDA standards. Cartridges are manufactured in accordance with ISO 9001 standards.

Applications

There are several terms used for steam. Process steam is used in process applications as an energy source for process heating, pressure control, and mechanical drives. Cooking steam needs to meet the dairy industry's 3A cooking standards. While steam used for food processing generally does not come into contact with the final product, steam used for cooking can, and often does, come into direct contact with the final product.

Sterile Air, Steam, and Liquid Filtration

• Aseptic packaging

• Breweries

• Chemicals

• Dairies

• Electronics

• Food and beverage

• Pharmaceuticals

• Plastics

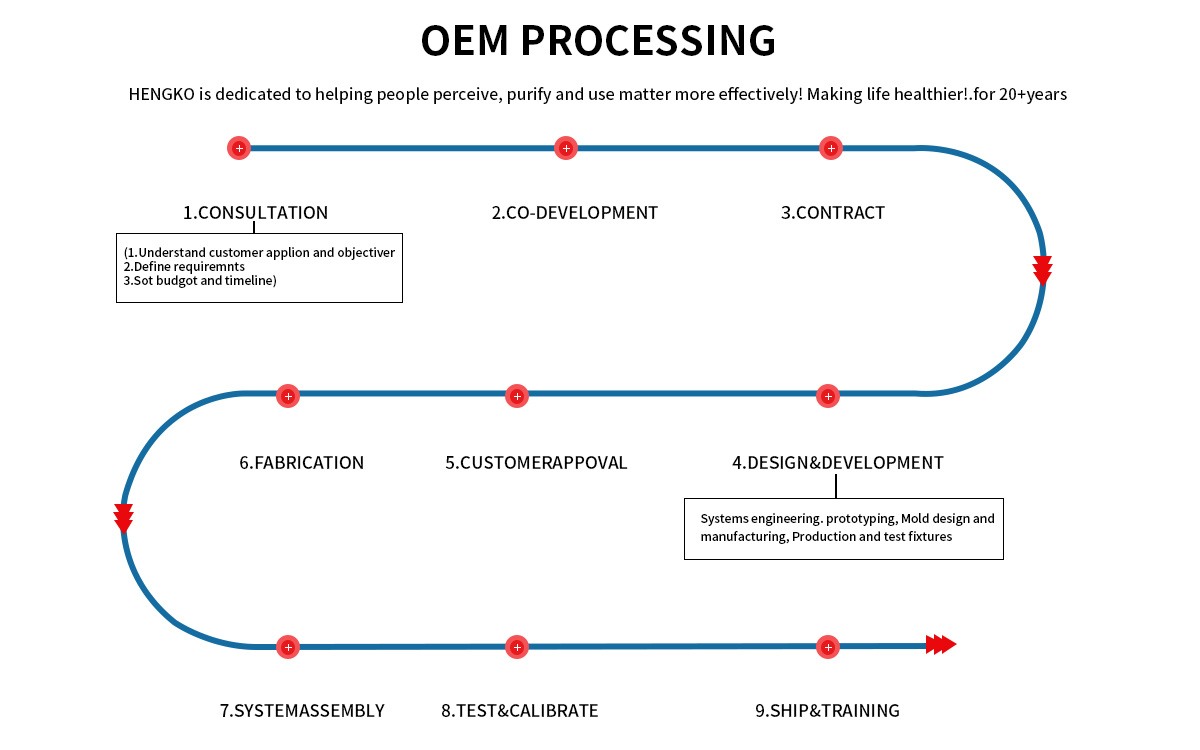

Can't find a product that meets your needs? Contact our sales staff for OEM/ODM customization services!