-

SGS Approved Powder Sintered Stainless Steel 316L Micro Porous Industrial Filter Element

HENGKO stainless steel filter elements are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have bee...

View Detail -

60micronSintered Porous Stainless Steel Gas Filter Stock for sale B01B-00134 HENGKO

HENGKO stainless steel filter elements are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have bee...

View Detail -

30 micron Porous Sintered Stainless Steel Sensor Housing and Gas Filter Stock for sale ...

HENGKO stainless steel filter elements are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have bee...

View Detail -

50-60micron Porous Sintered Stainless Steel Gas Filter Stock for sale D30mm HENGKO

HENGKO stainless steel filter elements are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have bee...

View Detail -

50micron Custom Design Porous Sintered Stainless Steel Gas Filter Stock for sale D33.6...

HENGKO stainless steel filter elements are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have bee...

View Detail -

Single-Layer Sintered Mesh Flexible Tube Durable Corrosion-Resistant Ideal for Filtrati...

HENGKO stainless steel filter elements are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have bee...

View Detail -

0.5 Micron Sintered Stainless Steel 316L Porous Metal Cup Air Filters for Fluidized Bed...

HENGKO stainless steel filter elements are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have bee...

View Detail -

Industrial Single-Layer Sintered Wire Mesh Tube Lightweight Corrosion-Resistant Designe...

HENGKO stainless steel filter elements are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have bee...

View Detail -

0.5 5 20 60 micron sintered porous stainless steel 316L metal cups air filters for gas ...

HENGKO stainless steel filter elements are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have bee...

View Detail -

High-Precision 0.5 Micron Porous 316L Stainless Steel Metal Cup Filters for Industrial ...

HENGKO stainless steel filter elements are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have bee...

View Detail -

High Precision Stainless Steel HPLC Column Endcap Frit Filter for Analytical Separation...

HENGKO stainless steel filter elements are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have bee...

View Detail -

Sintered Stainless Steel 316L Air Filter Cups (0.5 Micron) for Efficient Gas Dispersion...

HENGKO stainless steel filter elements are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have bee...

View Detail -

Custom 30 Micro Porous Stainless Steel Sensor Housing OEM Manufacturer

HENGKO' New stainless steel filter elements are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They hav...

View Detail -

Industrial 316L Stainless Steel 0.5 Micron Porous Metal Air Filter Cups for Precise Gas...

HENGKO stainless steel filter elements are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have bee...

View Detail -

Industrial Grade Porous Stainless Steel Sensor Housing 30 Micron OEM Solutions

HENGKO' New stainless steel filter elements are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They hav...

View Detail -

30micron 60micron Stainless Steel 316L Sintered Porous Cups | High-Efficiency Air Filtr...

HENGKO stainless steel filter elements are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have bee...

View Detail -

30micron Porous Metal Gas Filter Stock for sale B01B-00107 HENGKO

HENGKO stainless steel filter elements are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have bee...

View Detail -

Custom 0.5 2 5 10 micron porous stainless steel 316L powder sintered metal filter for f...

HENGKO 5-micron sintered filters are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures to force a faster fi...

View Detail -

316 sintered stainless metal porous internal canister filters for high operating pressures

Product Describe HENGKO stainless steel filter elements are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatur...

View Detail

Main Features

Sintered stainless steel elements are designed to provide superior filtration efficiency and durability.

Some key features of these cartridges include:

1. High Filtration Efficiency:

The sintered stainless steel element is designed to efficiently capture pollutants, dirt and debris.

2. Durability:

These cartridges are designed to withstand high temperature, pressure and harsh operating conditions.

3. Corrosion Resistant:

The stainless steel material used in these cartridges is resistant to corrosion from chemicals, harsh liquids and gases.

4. Easy to clean:

The sintered stainless steel design of these filters makes them easy to clean and reuse many times.

5. Versatility:

Sintered stainless steel filter elements can be used in a wide range of applications such as water and wastewater treatment,

oil and gas processing, pharmaceuticals, food and beverage processing.

6. Long service life:

These ink cartridges are long-lasting and require less frequent replacement, saving money over time.

7. Wide Temperature Range:

These filter cartridges can withstand a wide range of temperatures, from very low to very high temperatures,

making them suitable for use in a variety of applications.

8. Multi-micron ratings:

Sintered stainless steel elements are available in a variety of micron ratings, ensuring

there is an option for every filtration need.

How to Chose Right Stainless Steel Cartridge Filter ?

Choosing the right stainless steel cartridge filter elements for your specific application is essential to

ensure the longevity and efficiency of your filtration system. Here's a guide to help you make an informed decision:

1. Application and Fluid Type:

Determine the type of fluid you will be filtering. Different fluids have varying chemical properties, which can affect the choice of housing material and construction.

Consider whether the fluid is corrosive, requires a sanitary-grade housing, or has any other special requirements.

2. Flow Rate:

Identify the desired flow rate of your system. This is often expressed in gallons per minute (GPM) or liters per minute (LPM).

Ensure the housing can handle your system’s flow rate without causing excessive pressure drop.

3. Operating Pressure and Temperature:

Check the maximum operating pressure and temperature of the housing. Ensure it exceeds the system's operating conditions to provide a safety margin.

4. Housing Size and Cartridge Compatibility:

Determine the number and size of the cartridges you will be using.

Ensure the housing is compatible with the length and diameter of your cartridges. Common lengths include 10", 20", 30", and 40".

5. Inlet/Outlet Size and Orientation:

Choose a housing with the appropriate inlet and outlet sizes to match your system's pipework.

Consider the orientation (e.g., in-line or side-entry) to ensure ease of installation and maintenance.

6. Material of Construction:

Ensure the housing is made of high-quality stainless steel (often 304 or 316L) to resist corrosion and provide durability.

If your application is in a highly corrosive environment or requires high purity, you might need a housing made from 316L stainless steel or other superior grades.

7. Seal Materials:

Choose a housing with seals (O-rings or gaskets) compatible with the fluid being filtered. Common materials include Buna-N, Viton, EPDM, and PTFE.

8. Certifications and Standards:

If required, ensure the housing meets relevant certifications or standards such as ASME code, 3-A sanitary standards, or others applicable to your industry.

9. Ease of Maintenance:

Opt for a design that allows for easy cartridge replacement and cleaning.

Swing bolt closures or quick-open designs can provide easier access compared to threaded closures.

10. Vent and Drain Ports:

These are essential for safe operation and maintenance. Ensure the housing has appropriately sized and positioned vent and drain ports.

11. Features and Accessories:

Determine if you need additional features like differential pressure gauges, sample ports, or mounting legs.

Some housings come with built-in bypass valves, which can be useful during cartridge change-outs.

12. Cost and Warranty:

Always balance between quality and cost. A cheaper housing might not be durable and could end up costing more in the long run due to frequent replacements or failures.

Check the warranty terms and ensure the manufacturer stands behind their product.

Lastly, it's always beneficial to work closely with suppliers or manufacturers. They can provide valuable insights and recommendations based on your specific requirements.

Production Process:

The Stainless Steel Filter Cartridges and porous metal filters Cups can be customized for various

applications and specifications.

The filter cartridge and cup can be designed with different inner and outer diameter, height and aperture.

It can also be welded together with aluminum or stainless steel housings, making it easy to customize diameter,

aperture, thickness, alloys, and media grades. These can be altered to meet various filtration, flow, and chemical

compatibility requirements for your product or project.

If you have high requirements for the Stainless Steel Filter Cartridges, HENGKO welcomes you even more!

Our professional engineer team will design professional solutions for you to meet your high requirements

testing and certification.

HENGKO has a professional technical team to provide technical support and can design customized products

on demand with drawings and samples. Due to the many specifications and sizes, specific prices cannot be

identified individually.

If you want to know price details above Sintered Cartridges and Cup Filters list, please don't hesitate to contact

our sales before placing an order.

Application :

Sintered Stainless Steel Filter Cartridges and Cups are utilized in various processes including distillation,

absorption, evaporation, filtration, and others in industries such as petroleum, refining, chemical, light industry,

pharmaceutical, metallurgy, machinery, ship, automobile tractor, and others. These filters are designed to

eliminate droplets and liquid foam entrained in steam or gas, provide flame arresting, facilitate various filtration

options, and control various flows. Stainless steel filter elements and porous metal cups have different applications

across different industries.

Here are some common applications for these products:

1. Water treatment:

Sintered stainless steel filter elements can be used in the water treatment industry to filter impurities, bacteria and other tiny particles in water. Porous metal cups are also commonly used in water treatment for reverse osmosis and desalination processes.

2. Food and beverage industry:

stainless steel filter elements and porous metal cups are used in the food and beverage industry to filter beer, wine, fruit juice, soda and other liquids.

3. Chemical industry:

These products are used in the chemical industry to filter and separate chemicals in different production processes.

4. Pharmaceutical industry:

In the pharmaceutical industry, stainless steel filter elements and porous metal cups are used in pharmaceutical manufacturing to filter out impurities in the final product.

5. Oil and gas industry:

These products are used in the oil and gas industry to filter out impurities and other solids in oil and gas that may cause damage to equipment and pipelines.

6. Automotive industry:

In the automotive industry, these products are used as filters for automotive fluids, including engine oil, transmission fluid, and hydraulic oil.

Overall, stainless steel filter elements and porous metal cups are versatile products that can be used in any industry that requires filtration and separation.

How to OEM / Customize Sintered Cartridges and Cup Filters

If you have specific design requirements for sintered cartridges and cup filters that cannot be met with existing

products, HENGKO can work with you to find the best solution. We offer OEM porous filter cartridges and cups,

and our customizable and innovative designs can be tailored to meet your unique needs.

Please contact us for further details and to discuss your project requirements.

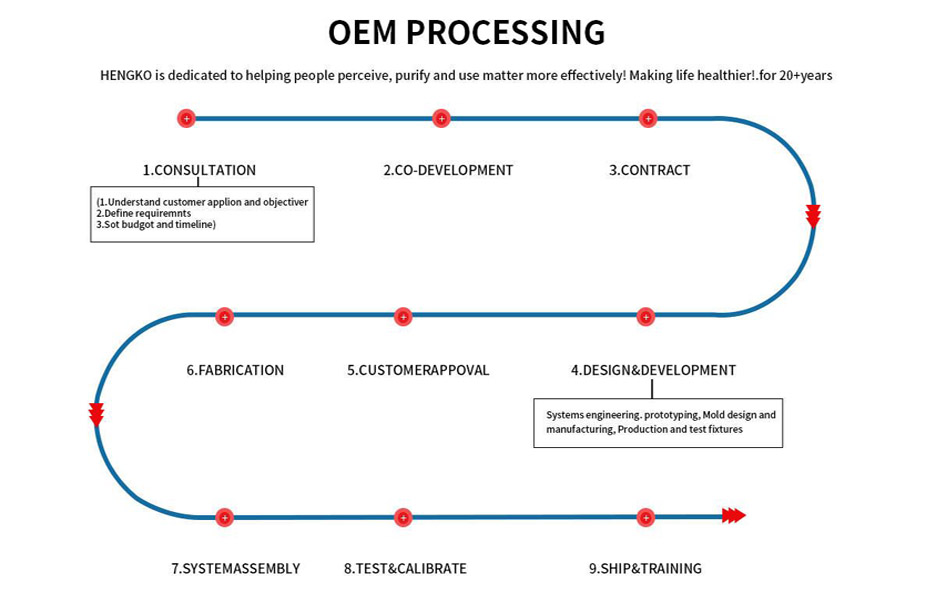

HENGKO's Mission

HENGKO is dedicated to helping people perceive, purify, and use matter more effectively.

For over 20 years, we have been making life healthier through innovative filtration solutions.

Our Process

1. Consultation and Contact HENGKO

2. Co-Development

3. Make a Contract

4. Design and Development

5. Customer Approval

6. Fabrication/Mass Production

7. System Assembly

8. Test and Calibrate

9. Shipping and Training

At HENGKO, we work closely with our clients to co-develop customized filtration solutions that

meet their unique needs. From consultation to shipping and training, we are committed to providing

high-quality products and exceptional customer service.

Why Work With HENGKO for Stainless Steel Filter Cartridges and Cups Filters

HENGKO offer sintered cartridges and cup filters that cater to the unique requirements of various applications.

✔ PM Industry-Renowned Manufacturer of Stainless Steel Filter Cartridges over 20-years

✔ Unique Customized Designs as Different size, Melt, Layers and Shapes

✔ High Quality CE Standard, Stable shape, Meticulous Work

✔ Service from Engineering up to Aftermarket Support, Fast Solution

✔ Expertise in Various Applications in Chemical, Food, and Beverage Industries

FAQs for Sintered Stainless Steel Filter Cartridges

Stainless steel filter elements are an innovative solution for water filtration, food and beverage processing,

and many other applications that require the removal of contaminants from liquids.

Here are some frequently asked questions about stainless steel filters:

1. What is a stainless steel filter element?

The stainless steel filter element is a filter device made of high-quality stainless steel material.

They are designed to perform superior filtration while maintaining high durability and long-lasting performance.

2. What are the benefits of stainless steel filter elements?

Stainless steel elements offer several advantages, including:

- Durable: The stainless steel filter element is durable and resistant to corrosion, chemical damage and other forms of wear and tear.

- Efficient Filtration: These filter elements provide a high level of filtration performance to remove bacteria, metals and other contaminants from liquids.

- Easy to clean: The stainless steel filter element is easy to clean and can be reused many times, which is cost-effective.

3. What applications are stainless steel filter elements suitable for?

Stainless steel filter elements are suitable for a variety of applications including:

- Water Filtration: The stainless steel filter is suitable for removing harmful chemicals, particles and bacteria present in the water. They are used in drinking water filtration, marine and aquarium, and food and beverage process water.

- Oil and Gas Processing: Stainless steel filter elements effectively remove impurities, solids and contaminants present in oil and gas processing applications.

- Food processing: Stainless steel filter elements are used as part of the filtration process in the food and beverage industry, including breweries and distilleries.

4. Can the stainless steel filter element be customized?

Yes, stainless steel filter elements can be custom made to customer specifications. Customization options include mesh size, end fittings and lengths.

5. How do I clean my stainless steel filter?

The stainless steel filter element is easy to clean. Just soak them in cleaning solution and rinse with water. For heavy cleaning, ultrasonic cleaning equipment can be used.

To clean and maintain Sintered Stainless Steel Filter Cartridges, follow these steps:

1. Remove the filter cartridge from the filtration system.

2. Soak the filter cartridge in a cleaning solution for a few minutes.

3. Rinse the filter cartridge with clean water.

4. Allow the filter cartridge to air dry before re-installing it in the filtration system.

6. How long is the service life of the stainless steel filter element?

Stainless steel elements are durable and can last for years depending on application and maintenance.

7. What is the maintenance cycle of the stainless steel filter element?

In general, stainless steel elements require little maintenance and the frequency of cleaning depends on the application. In high-use applications or heavily polluted environments, it is recommended to clean them more frequently.

8. What is the difference between stainless steel filter elements and other types of filter elements?

Stainless steel elements are preferred over other types of elements because they are durable, provide better filtration performance, and are suitable for a variety of applications.

9. Where can I buy stainless steel filter elements?

Stainless steel filter elements are available from several suppliers worldwide.

It is very important to choose a supplier that is reliable and offers high quality products.

And you are right place on HENGKO, we focus on sintered stainless steel filter over

20 years. more details, please check our products for the Stainless Steel Filter Cartridges.

And you are welcome to contact us by email ka@hengko.com directly.

10. How much does the stainless steel filter element cost?

The cost of stainless steel elements varies by specification and customization.

However, they are cost-effective in the long run due to their durability and reusability.

11. How do I choose the right Sintered Stainless Steel Filter Cartridge for my application?

To choose the right Sintered Stainless Steel Filter Cartridge for your application, consider the following factors:

1. The type of application (e.g., liquid filtration, air filtration, etc.)

2. The level of filtration required

3. The temperature and pressure of the application

4. The chemical compatibility of the filter cartridge with the application

Still Have Questions and Like to Know More Details For the Sintered Stainless Steel Filter Cartridge ,

Please feel Free To Contact Us Now.

Also You Can Send Us Email Directly As Follow : ka@hengko.com

We Will Send Back With 24-Hours, Thanks for Your Patient !

Send your message to us: