-

Craft beer brewing kit sintered 316 stainless steel 2 micron micro bubble air oxygenati...

HENGKO POROUS SPARGER is ROSH and FDA certificate of safety and environmental protection and can be used in food applications of sintered stainless steel air...

View Detail -

HENGKO micron small bubble air sparger oxygenation carbanation stone used in acrylic wa...

Product Describe HENGKO air sparger bubble stone is stainless steel 316/316L, food grade, with a beautiful appearance, suitable for hotels, fine dining and o...

View Detail -

Stainless Steel 316 Carb Stone Brewing for Homebrew Carbonation – Yeast Oxygenation Kit

Sintered air stone diffusers are often used for porous gas injecting. They have different pore sizes(0.5um to 100um) allowing small bubbles to flow through i...

View Detail -

Oxygenation / Tri-Clamp Carbonation Stone Assembly

Carbonation stone is used in containers to inject and diffuser gases (such as carbon dioxide) into beer. It can be made of finely sintered stainless steel. U...

View Detail -

SFH01 inline oxygenation diffusion stone

This is a great option for putting oxygen into your wort as you transfer from the kettle or plate chiller into your fermentor. It comes with a 1/2" NPT and a...

View Detail -

SFT01 SFT02 1/2″NPT X 1/4”bard inline 0.5um 2um carbonation oxygenation Diffusio...

Product Name Specification SFT01 D5/8''*H3'' 0.5um with Flare thread, M14*1.0 thread SFT02 D5/8''*H3'' 1um with Flare thread, M14*1...

View Detail -

0.5, 2 Micron SFT01 SFT02 Homebrew Oxygenation Diffusion Stone Beer Carbonation Aeratio...

Product Name Specification SFT01 D5/8''*H3'' 0.5um with Flare thread, M14*1.0 thread SFT02 D5/8''*H3'' 1um with Flare thread, M14*1....

View Detail -

0.5, 2 Micron Oxygenation Stone Brewing Carbonation Aeration Diffusion Stone For DIY Ho...

HENGKO aeration stone is made of the food-grade best stainless steel material 316L, healthier, practical, durable, high temperature resistant, and anti-corr...

View Detail -

SFT11 SFT12 1/4”MFL wine tool micron diffusion professional oxygenation carbonati...

1. Better Than Shaking a Keg! 2. Are you tired of carbonating your beer the unpredictable way? You crank up the PSI in the keg, shake, and wait with ...

View Detail -

0.5 2 10 microns stainless steel home brewing wort beer pure oxygenation kit aeration w...

HENGKO carbonation stone is made of the food grade best stainless steel material 316L, healthier, practical, durable, high temperature resistant, and anti-c...

View Detail -

SFW21 sintered stainless steel oxygenation kit 3/16” aeration wand diffusion stone

Product Name Specification SFW21 D1/2''*H26'' .5um with 3/16'' wand HENGKO carbonation stone is made of the food...

View Detail -

1.5” Tri Clamp Oxygenation Stone Brewing Carbonation Aeration Diffusion Stone wit...

Sintered air stone diffusers are often used for gas distribution and air aeration. They have a wide range of pore sizes from 0.2 microns to 120 microns allow...

View Detail -

SFT01 SFT02 1/2″NPT X 1/4”bard inline 0.5um, 2um carbonation oxygenation flare diffusi...

Sintered air stone diffusers are often used for porous gas injecting. They have different pore sizes(0.5um to 100um) allowing small bubbles to flow through ...

View Detail -

SFH02 2 Micron sintered stainless steel inline oxygenation diffusion aeration stone 1/2...

Sintered air stone diffusers are often used for porous gas injecting. They have different pore sizes(0.5um to 100um) allowing small bubbles to flow through t...

View Detail -

0.5 Micron 2 Micron Homebrew Oxygenation Diffusion Stone Carbonation Aeration For Beer ...

Sintered air stone diffusers are often used for porous gas injecting. They have different pore sizes(0.5um to 100um) allowing small bubbles to flow through ...

View Detail

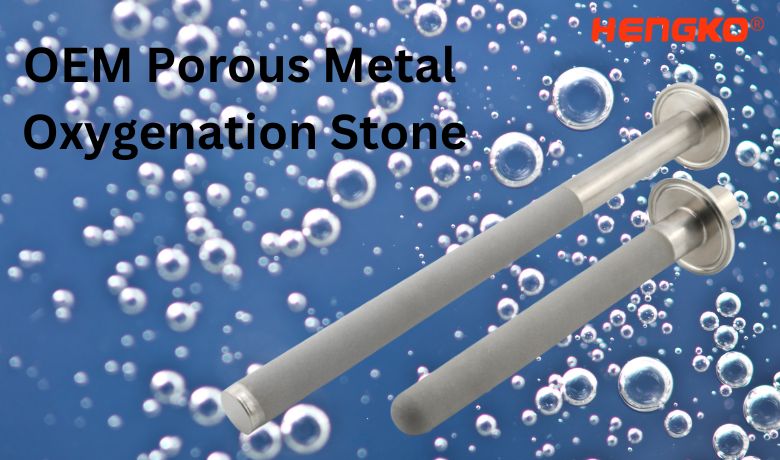

Main Feature of Porous Stainless Steel Diffuser Stone

The main feature of a porous metal oxygenation stone is its highly controlled and efficient gas diffusion.

This is achieved through two key properties:

1.Porous Structure:

The stone is made of sintered metal, which means tiny metal particles are fused together to create a network of

microscopic pores. These pores allow gas (like oxygen) to pass through while remaining small enough to

generate a large number of very fine bubbles.

These two features combine to create a stone that:

*Produces a fine, even stream of bubbles, maximizing oxygen-liquid contact.

Porous Metal Diffuser Stone vs Plastic Oxygenation Stone

Porous Metal Oxygenation Diffuse Stones:

1.Material:

Typically made from sintered stainless steel

2.Pros:

*Durability:

Very durable, can withstand high temperatures, pressures, and won't crack or break easily. Lasts a long time.

* Efficiency:

Millions of tiny pores create fine, even bubbles for efficient oxygen or CO2 diffusion.

* Cleaning:

Easy to clean and sanitize due to the non-porous metal exterior.

3.Cons:

*Cost: Generally more expensive than plastic stones.

*Weight: Heavier than plastic stones.

Plastic Oxygenation Stones:

1. Material:

Made from various plastics like nylon or ceramic

2. Pros:

*Cost: Affordable and readily available

*Weight: Lightweight

3. Cons:

*Durability: Less durable than metal stones. Prone to breakage and may become brittle over time, especially at high temperatures.

*Clogging: Pores can clog more easily, especially with oils or residue buildup.

*Efficiency: May not produce as fine or even bubbles as metal stones, potentially reducing diffusion efficiency.

In summary:

*If you prioritize durability, efficiency, and ease of cleaning, a porous metal stone is the better choice, despite the higher cost.

*If budget is a major concern, and you don't mind replacing the stone more often, a plastic stone might be sufficient.

Here are some additional factors to consider:

*Application: For purposes like home brewing where sanitation is crucial, metal stones might be preferred.

*Micron Rating: Look for the micron rating of the stone, which refers to the pore size. Lower microns generally create finer bubbles for better diffusion.

Also Here we make a comparison table between Porous Sintered Stainless Steel Diffuser Stone and Plastic Oxygenation Stone:

| Feature | Porous Sintered Stainless Steel Diffuser Stone | Plastic Oxygenation Stone |

|---|---|---|

| Material | 316L Stainless Steel | Plastic (usually PVC or similar materials) |

| Durability | Highly durable, resistant to corrosion and wear | Less durable, may degrade over time with exposure to chemicals or UV |

| Temperature Resistance | Can withstand high temperatures | Lower temperature tolerance, can deform or degrade at high temperatures |

| Pore Size | Precise control, 0.1 - 90μ | Typically larger pores (less control over size) |

| Pressure Resistance | High pressure resistance, ideal for industrial applications | Lower pressure tolerance, not ideal for high-pressure systems |

| Oxygenation Efficiency | High oxygen transfer rate due to fine porosity | Generally lower oxygen transfer efficiency |

| Chemical Resistance | Resistant to a wide range of chemicals and solvents | Limited chemical resistance, may degrade in harsh chemicals |

| Customization | Fully customizable in terms of size, shape, and pore size | Limited customization options |

| Cost | Higher initial cost due to material and manufacturing process | Lower initial cost |

| Applications | Used in industrial applications, brewing, aquariums, etc. | Primarily used in aquariums, less suitable for industrial use |

| Maintenance | Easy to clean and maintain, long lifespan | Requires more frequent replacement, can be difficult to clean |

| Environmental Impact | Recyclable and eco-friendly | Less environmentally friendly, harder to recycle |

If you're looking for stainless steel diffuser stones for your aeration system, feel free to contact HENGKO for

custom OEM solutions. We’d be happy to turn your design ideas into real products.

You can reach us via email or by filling out the form below.

We’ll respond within 24 hours with expert advice, design recommendations, and tailored manufacturing solutions.