SFC06 2 micron Fermenation Carb Stone Assembly, Stainless Steel for Home Brew

| Product Name | Specification |

| SFC06 1.5'' Tri Clamp Fitting Diffusion Stone | D3/4''*H10'' 2um, 1/4'' NPT Female thread |

HENGKO carbonation stone is made of the food grade best stainless steel material 316L, healthier, practical, durable, high temperature resistant, and anti-corrosion. It's easy to clean and won't crumble in beer or wort after use. The 2-micron stone is typically used for oxygenation applications, and the 0.5-micron carb stone is for carbonation applications. The carb stone's stem is long enough to reach the main fermentor body, so the bubbles don't just quickly combine and lose effectiveness. This stone can also be used for oxygenating the wort before fermentation!

2-micron oxygen stone used with an oxygen source or aeration pump to provide your yeast with oxygen pre-fermentation.

SFC06 2 micron Fermentation Carb Stone Assembly, Stainless Steel for Home Brew

• Carbonating stones increase the surface area contact with the beer by producing tiny bubbles of CO2, which dissolve more readily in beer than more giant bubbles.

• Carbonating stones are generally made of porous stainless steel. It works well for producing curtains of tiny bubbles readily absorbed into the cold beer.

How to use the diffusion stone

1. The “stone” sits inside the keg near the bottom.

2. A hose barb attaches it to a length of tubing (generally about 2 feet of 1/4” ID thick wall vinyl hose) which is affixed to the short downtube under the “in” or “gas side” post.

3. When the CO2 is connected, it sends a tremendous number of gas bubbles out through the beer. The minuscule bubbles create a huge amount of surface area to help absorb CO2 rapidly into the beer. This is actually a miniature version of a device used by commercial breweries everywhere.

4. Carbonation should be virtually instantaneous, though the manufacturer recommends carbonating your beer at least a few hours before serving.

It is desirable at the beginning of the carbonating process to use a relatively low differential pressure between the stone and the head space in the tank while bleeding gas from the top of the tank.

- This can scrub unwanted dissolved air from the beer picked up during transfer, filtration, or brewing.

- Be especially careful not to overdo this: too much CO2 scrubbed through the beer can cause foaming in the tank and strip away the desirable nose from the beer.

In an ideal world, all of the CO2 from the stone would be absorbed into the beer, but things are rarely ideal, so just because you have 10 psi in the headspace doesn’t necessarily mean you have 2.58 volumes in the beer.

• Each tank should be tested during carbonation to ensure proper carbonation levels with high-quality calibrated gauges on your tester

• Beer carbonation using a stone can take a few hours to several days

• Best results were achieved using a relatively slow-step carbonation process which tends to yield smaller bubbles and better head retention than rapid carbonation by agitation. Step carbonation refers to adding gas slowly and ensuring the carbonation stone always makes a curtain of tiny bubbles.

Product Show ↓

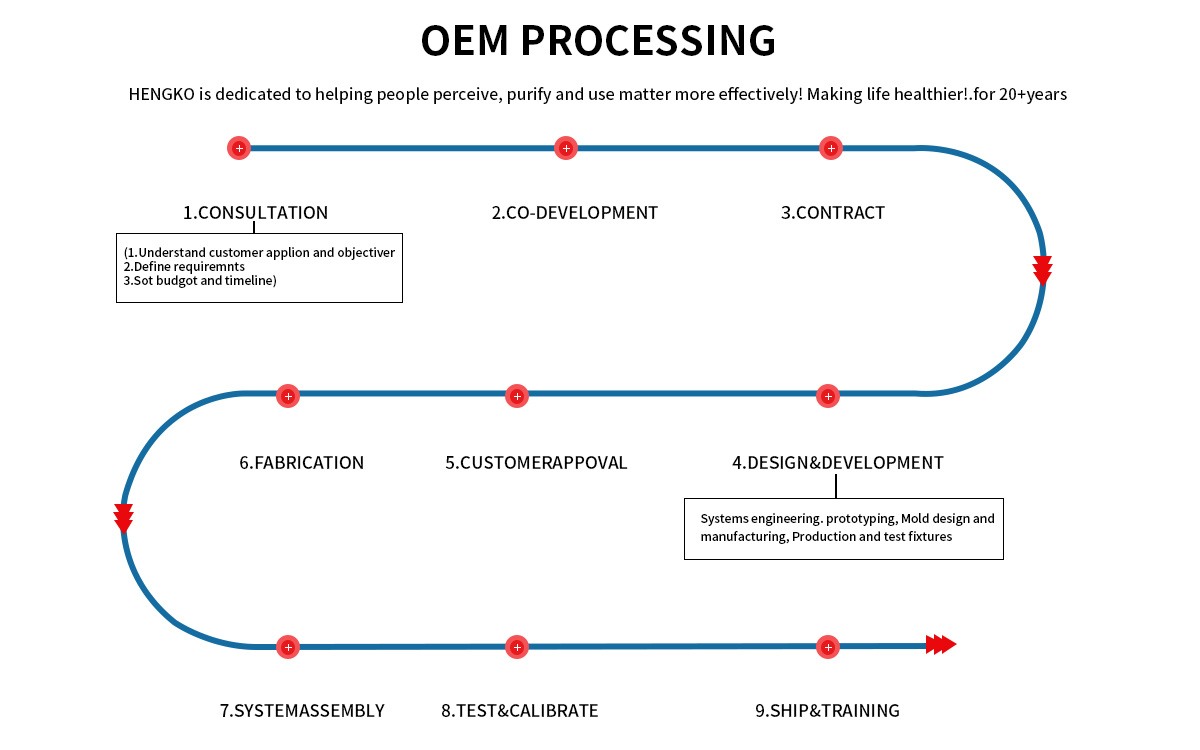

Can't find a product that meets your needs? Contact our sales staff for OEM/ODM customization services!