-

Stainless Steel 316 Micro Spargers and Filter in Bioreactors and Fermentors

Product Describe The function of the bioreactor is to provide a suitable environment in which an organism can efficiently produce a target product. * Cell b...

View Detail -

In-tank porous metal spargers or multiple sparger assembly for a large tank, increase g...

Attaches to the tip of the sparger tube, this 316L stainless steel sintered tip is available in a variety of pore sizes. The 5 10 15 50 100 pore frit is the ...

View Detail -

multi – bioreactor sparger for the fermenter sartorius

The Stainless Steel Fermenter|Bioreactor for Your Laboratory A bioreactor is a type of fermentation vessel that is used for the production of various chemica...

View Detail -

HENGKO OEM Sintered Steel Filter and Sparger

OEM Sintered stainless steel diffuser / sparger, for aerating in liquid. HENGKO’s sintered sparger are unsurpassed in strength, precision and uniformity. The...

View Detail -

Sintered Stainless Steel Sparger Porous Metal Diffuser for Gas Applications

OEM Sintered stainless steel diffuser / sparger, for aerating in liquid. HENGKO’s sintered sparger are unsurpassed in strength, precision and uniformity. Th...

View Detail -

Sintered Microsparger in Bioreactor System for Green chemistry industry

The importance of aeration and gas dispersion to achieve good oxygen mass transfer cannot be understated. This is at the heart of the ability of mic...

View Detail -

Replacement Micro-Bubble Porous Sparger Tips for Fermentation / Bioreactor Air Aeration...

Advantages of HENGKO Porous Metal Micro Spargers Due to the low solubility of oxygen in many cell culture mediums, optimizing this critical nutrient can be ...

View Detail -

Sintered Micro Porous Sparger in Benchtop for Bioreactors and Laboratory Fermenter

Every bioreactor sparging system is designed for the introduction of oxygen to feed cell cultures. Meanwhile, the system must remove carbon dioxide to preven...

View Detail -

Quick Change Sparger System for Bioreactors and Fermentors Air Sparger Accessories- Mic...

Stainless steel sparger is to supply enough oxygen to the microbes in submerge culture technique for proper metabolism. Each fermentation process requires a ...

View Detail -

316 L Powder Stainless Steel Metal Frit Spargers Building A Stainless Steel Filtering S...

Product Description This device is particularly good for fermentations that require a large population of yeast. Pilsners (or other beers fermented at low te...

View Detail -

HENGKO sintered porous carbonation stone air sparger bubble diffuser nano oxygen genera...

In bioreactor systems, optimal mass transfer of gases like oxygen or carbon dioxide is difficult to accomplish. Oxygen, in particular, is poorly soluble in w...

View Detail -

Sintered Sparger Tube with Porous Metal Stainless Steel Tank and In-line Spargers Used ...

Introducing the exceptional HENGKO sintered spargers, the ultimate solution to introducing gases into liquids. This innovative product utilizes thousands of...

View Detail -

HENGKO micron small bubble air sparger oxygenation carbanation stone used in acrylic wa...

Product Describe HENGKO air sparger bubble stone is stainless steel 316/316L, food grade, with a beautiful appearance, suitable for hotels, fine dining and o...

View Detail -

Sintered Sparger Stainless Steel Material Quick Change for Bioreactor Systems

In bioreactor systems, optimal mass transfer of gases like oxygen or carbon dioxide is difficult to accomplish. Oxygen, in particular, is poorly soluble in w...

View Detail -

Aeration Stone 20um Sintered Stainless Steel 316L Micro sparger Diffusion Stone Supplier

Hydrogen water is clean, powerful, and with hydron. It helps to purify the blood and gets blood moving. It can prevent many kinds of diseases and improve peo...

View Detail -

Sintered 316l stainless steel bubble hydrogen-rich water generator air sparger

Product Description Hydrogen water is clean, powerful, and with hydron. It helps to purify the blood and gets blood moving. It can prevent many kinds of di...

View Detail -

Stainless Steel Ozone Diffuser Stone Fine Air Sparger for Hydrogen Generator

Hydrogen water is clean, powerful, and with hydron. It helps to purify the blood and gets blood moving. It can prevent many kinds of diseases and improve peo...

View Detail -

Stainless Steel Aeration/Oxygen CO2 Diffusion Stone Micro Sparger for Microalgae Cultiv...

Micro-diffuser for Microalgae Cultivation, Photobioreactors & sintered sparger for microalgae cultivation is used in laboratories for growing algae. HEN...

View Detail -

Biotech Removable Porous Frit Micro Sparger for Mini Bioreactor System and Fermentors

Stainless steel sparger used as a cell retention device. The device consists of a metal tube and a sintered metal filter with a pore size of 0.5 – 40 µm. The...

View Detail -

sintered sparger brewing carbonation wort aeration wands (Pure Oxygen) system for homeb...

HENGKO SS air stone is commonly used to aerate the wort before fermentation, which helps ensure a healthy start to the fermentation process. The HENGKO 2.0 m...

View Detail

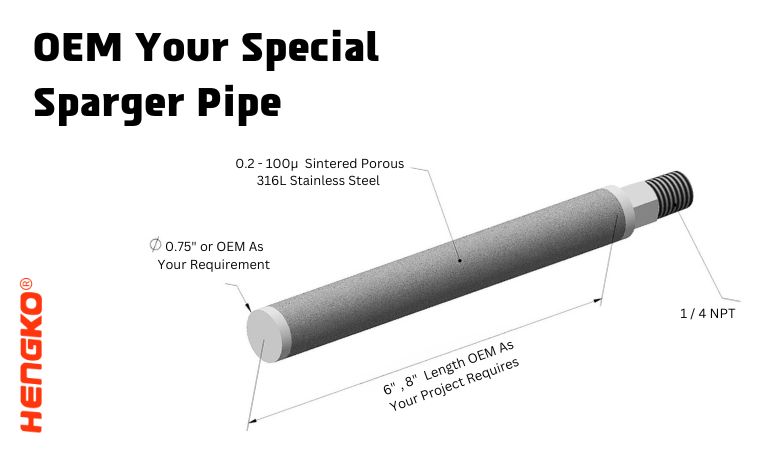

What Is a Sparger Pipe?

As Above information, actually, we can know a sparger pipe is a gas distribution device typically made from

stainless steel tubing with precision-drilled perforations.

When compressed air, nitrogen, oxygen, CO₂, or other gases enter the pipe, they exit through the holes and form

bubbles in the surrounding liquid.

These bubbles create mixing, agitation, aeration, or gas–liquid mass transfer depending on the application.

Sparger pipes are preferred in tanks and reactors that require:

*High gas flow rates

*Large bubble size

*Resistance to corrosion and pressure

*Simple structure and low maintenance

*Easy cleaning and sanitation

Because sparger pipes have larger bubble sizes than porous spargers, they are ideal for general aeration

and industrial agitation applications where fine dispersion is not required.

How Sparger Pipes Work(Working Principle)

A sparger pipe operates on the simple principle of perforated-tube aeration:

1. Gas enters the sparger tube through an inlet or manifold

2. Internal pressure forces the gas through precision-drilled holes

3. Bubbles are released into the liquid

4. Rising bubbles create agitation, circulation, and oxygen transfer

5. The pattern and size of the holes determine bubble size and distribution

Key Factors Influencing Performance

| Parameter | Effect on Performance |

|---|---|

| Hole Diameter | Larger holes → larger bubbles → lower dispersion efficiency but higher flow capacity |

| Hole Spacing | Affects gas distribution uniformity |

| Tube Diameter | Influences pressure drop and flow rate |

| Gas Flow Rate | Higher flow → stronger agitation but larger bubbles |

| Installation Position | Depth affects backpressure and bubble retention time |

HENGKO engineers can design the hole pattern to optimize the bubble pattern for your tank or bioreactor geometry.

Main Features of Sparger Pipe

A sparger pipe is a type of pipe used in a variety of industrial applications, particularly in the chemical and petrochemical industries.

It is main used for the injection of gas into a liquid, typically to facilitate a chemical reaction or for other process requirements.

As following are some of the features of a sparger tube, please check it.

1. Material:

Sparger pipes are typically made from stainless steel or other corrosion-resistant materials.

This is important because they are often used with aggressive chemicals and must withstand harsh operating conditions.

2. Design:

The design of a sparge pipe is critical to its effectiveness.

It typically includes a series of small holes or perforations along the length of the pipe to allow gas to escape and disperse into the liquid.

The spacing and size of the holes can be customized based on the specific process requirements.

3. Size:

The size of a sparger pipe can vary depending on the application, but they are generally smaller in diameter than other types of pipes used in the same process.

This is because the gas injected through the sparger tube must be finely dispersed into the liquid for optimal results.

4. Connection:

Sparger pipes can be connected to a variety of other equipment and piping systems.

They may be threaded, welded, or connected with flanges, depending on the requirements of the process.

5. Cleaning:

Because sparger pipes are used in processes involving chemicals and other materials, they must be regularly cleaned to prevent buildup and corrosion.

They can be cleaned with mechanical means, such as brushing or blasting, or with chemical solutions.

Overall, sparger tubes play a critical role in many industrial processes, and their design and construction must be

carefully tailored to each specific application to ensure optimal performance and efficiency.

Sparger Pipe Classify

Sintered metal sparger pipes can be classified based on various criteria.

Here are some possible classifications:

Based on the Type of Gas Introduced:

*Carbon dioxide

*Argon

*Other gas sparger pipes

Based on the Shape or Design:

*Straight design

*U-shaped pipe

*Coiled tube

*Other shaped pipes

Based on the Porosity:

*Low porosity sparger tube (less than 30%)

*Medium porosity pipe (30-50%)

*High porosity sparge pipe (more than 50%)

Based on the Application:

*Wastewater treatment sparger pipe

*Fermentation sparger tube

*Chemical processing sparge pipe

*Pharmaceutical production sparger pipe

*Other industrial sparger system

Based on the Materials:

*Stainless steel sparger pipe

*Hastelloy sparger tube

*Inconel sparge pipe

*Other alloy sparger pipes

Note that these classifications are not exhaustive and other criteria

can also be used to classify sintered metal sparger pipes.

Engineering Design Parameters(Technical Specifications)

Sparger pipes must be engineered based on your gas type, pressure, liquid properties, and tank geometry.

Typical Engineering Parameters

| Parameter | Range / Specification |

|---|---|

| Hole Diameter | 0.5–3.0 mm (depending on bubble size) |

| Hole Spacing | 5–20 mm |

| Tube OD | 6–60 mm |

| Working Pressure | 0.1–0.6 MPa |

| Working Temperature | −20°C to 300°C |

| Material Options | SS304, SS316L, 904L, Titanium, Hastelloy |

| Connection Types | Welded ends, NPT thread, Tri-Clamp, Flange |

Available Manufacturing Processes

*Laser drilling

*CNC machining

*TIG orbital welding

*Pickling & passivation

*Food-grade polishing

Provide your required specifications and our engineers will design an optimized sparger system.

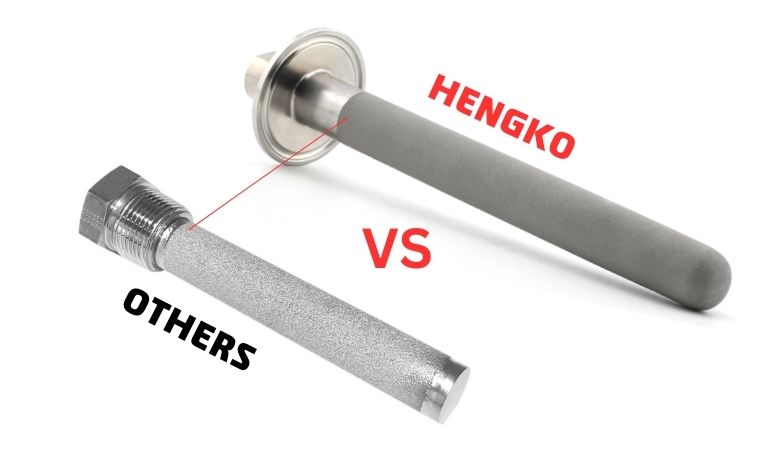

Sparger Pipe vs. Porous Sintered Sparger(Comparison)

Maybe till now, you heard sparger pipe and also porous sparger, then think you will one question, what is different ?

Choosing between a perforated sparger pipe and a sintered porous sparger depends on your aeration requirements.

Below is a clear engineering comparison:

| Feature | Sparger Pipe (Perforated Tube) | Porous Sintered Sparger |

|---|---|---|

| Bubble Size | 1–5 mm (large bubbles) | 20–200 µm (microbubbles) |

| Mass Transfer Efficiency | Medium | Very High |

| Gas Flow Capacity | High | Medium |

| Pressure Drop | Low | Medium |

| Cleanability | Very Easy | Requires backflush / CIP |

| Cost | Low | Medium / High |

| Applications | Water tanks, general aeration, mixing | Fermentation, bioreactors, precision aeration |

| Typical Materials | 304/316L stainless steel | 316L / Titanium / Nickel alloys |

When to Choose Sparger Pipe

*You need medium-to-large bubbles

*You require high flow capacity

*Your process doesn’t need micro-bubble oxygen transfer

*You need a lower-cost aeration solution

*You require easy cleaning (CIP-friendly)

When to Choose Porous Sparger

*You require high oxygen transfer efficiency

*You need microbubbles for fermentation / biotech

You need precise gas control

Applications of Sparger Pipes

Sparger pipes are used across a wide range of industrial and scientific processes.

1. Water & Wastewater Treatment

*Aeration

*Oxygenation

*Biological treatment tanks

2. Fermentation & Bioprocessing

*Mixing

*Agitation

*Degassing

3. Chemical Processing

*Reactor agitation

*Gas–liquid reactions

*Stripping & absorption

4. Food & Beverage Production

*Carbonation

*Oxygen removal

*Controlled aeration

5. Environmental Engineering

*Air stripping

*Odor control

*Aquaculture aeration

6. Pharma & Laboratory Use

*Small bioreactors

*Pilot reactors

*R&D mixing systems

FAQ – Sparger Pipe

Q1: What bubble size does a sparger pipe produce?

Typically 1–5 mm, depending on hole diameter and gas pressure.

Q2: How do I choose the right hole size?

Larger holes create larger bubbles suitable for general aeration.

Smaller holes give better dispersion but higher pressure drop.

Q3: Can sparger pipes be used for fermentation?

Yes, but for high oxygen transfer efficiency, porous sintered spargers are recommended.

Q4: What materials are best for corrosive chemicals?

316L, 904L, Titanium, or Hastelloy depending on the medium.

Q5: Do you support OEM manufacturing?

Yes, all dimensions and patterns can be customized based on your reactor/tank design.

Contact HENGKO for Sparger Pipe Solutions

Looking for a reliable sparger pipe manufacturer?

Contact HENGKO for engineering support, CAD design, and OEM manufacturing ka@hengko.com