-

sintered sparger brewing carbonation wort aeration wands (Pure Oxygen) system for homeb...

HENGKO SS air stone is commonly used to aerate the wort before fermentation, which helps ensure a healthy start to the fermentation process. The HENGKO 2.0 m...

View Detail -

Sintered Metal Sparger of Stainless Steel Porous Sparger Types for Home Brewing Device

HENGKO sintered spargers introduce gases into liquids through thousands of tiny pores, creating bubbles far smaller and more numerous than with drilled pipe ...

View Detail -

Stainless Steel Sparger 2 Micron Stainless Steel Carbonation Diffusion Stone for Bacter...

Introducing HENGKO's innovative sintered spargers - the ultimate solution for efficient gas-liquid contact in a variety of industries. Our spargers use thou...

View Detail -

Installed Directly Porous Metal In-Line Sparger Tube Generate Small Bubbles

HENGKO sintered spargers introduce gases into liquids through thousands of tiny pores, creating bubbles far smaller and more numerous than with drilled pipe ...

View Detail -

Sintered porous micron stainless steel spargers homebrew wine wort beer tools bar acces...

HENGKO sintered spargers introduce gases into liquids through thousands of tiny pores, creating bubbles far smaller and more numerous than with drilled pipe ...

View Detail -

Micro Spargers Increase Gas Transfer and Improve Upstream Reactor Yields for Bioreactors

Introducing HENGKO sintered spargers - the ultimate solution to introduce gases into liquids with ease! Our innovative spargers feature thousands of tiny po...

View Detail -

Metal In-Tank Porous Spargers to Increase Gas Absorption

HENGKO sintered spargers introduce gases into liquids through thousands of tiny pores, creating bubbles far smaller and more numerous than with drilled pipe ...

View Detail -

Micro spargers bubble air aeration stone for bioreactor assembly

Micro spargers from HENGKO reduce bubble size and increase gas transfer to reduce gas consumption and improve upstream reactor yields. HENGKO spargers can in...

View Detail -

Sintered stainless steel 316L micro air sparger and brewing diffuser carbonation ozone ...

Product Name Specification SFB01 D1/2''*H1-7/8'' 0.5um with 1/4'' Barb SFB02 D1/2''*H1-7/8'' 2um with 1/4'' Barb SFB03 D1/2''*H1-7/8'' 0.5u...

View Detail -

316L stainless steel porous sparger tube sintered tip for fermentation vessel accessories

Attaches to the tip of the sparger tube, this 316L stainless steel sintered tip is available in a variety of pore sizes. The 5 10 15 50 100 pore frit is the ...

View Detail -

SFB02 2 microns sintered stainless steel micro porous air diffusers spargers used in me...

Product Name Specification SFB02 D1/2''*H1-7/8'' 2um with 1/4'' Barb HENGKO carbonation stone is made of the food grad...

View Detail -

Nitrogenous wine Tool Diffusion Professional Effective Aeration Stone Beer Brewage 316L...

Product Name Specification SFB01 D1/2''*H1-7/8'' 0.5um with 1/4'' Barb SFB02 D1/2''*H1-7/8'' 2um with 1/4'' Barb SFB03 D1/2''*H1-7/8'' 0.5um...

View Detail -

SFC02 2 micron MFL Carbonation Sparger Inline Diffusion Stone for bubbling water/Bubble...

Hydrogen water is clean, powerful, and with hydron. It helps to purify the blood and gets the blood moving. It can prevent many kinds of diseases and improve...

View Detail -

Inline 2µm Carbonation Diffusion Stone MFL Sparger for Bubbled Water & Beverage Ae...

Hydrogen water is clean, powerful, and with hydron. It helps to purify the blood and gets the blood moving. It can prevent many kinds of diseases and improve...

View Detail -

316L Stainless Steel 2µm Sparger Pipe for Fine Gas Diffusion in Tanks & Reactors

HENGKO stainless steel sparger pipe is designed for efficient gas diffusion—especially in hydrogen water systems where clean and stable microbubble generati...

View Detail -

Sintered stainless steel 316L micro air sparger and brewing carbonation ozone bubble st...

Sintered air stone diffusers are often used for porous gas injecting. They have different pore sizes(0.5um to 100um) allowing small bubbles to flow through t...

View Detail -

Sintered stainless steel 316L aeration carbonation stone air stone ozone air sparger 0....

HENGKO carbonation stone is made of the food grade best stainless steel material 316L, healthier, practical, durable, high temperature resistant, and anti-co...

View Detail -

home brew beer kit carbonation stone air sparger aeration stone diffusion used for hydr...

Sintered air stone diffusers are often used for gas distribution and air aeration. They have a wide range of pore sizes from 0.2 microns to 120 microns allow...

View Detail -

Air sparger bubble diffuser carbonation stones provide the quickest method for infusing...

HENGKO Diffusion Stones, or 'Carbonations Stones', are commonly used to aerate the wort before fermentation, which helps ensure a healthy start to the fermen...

View Detail -

Stainless steel 316L SFC04 home brew 1.5″ Tri Clamp fitting 2 micron diffusion stone ai...

HENGKO sintered spargers introduce gases into liquids through thousands of tiny pores, creating bubbles far smaller and more numerous than with drilled pipe ...

View Detail

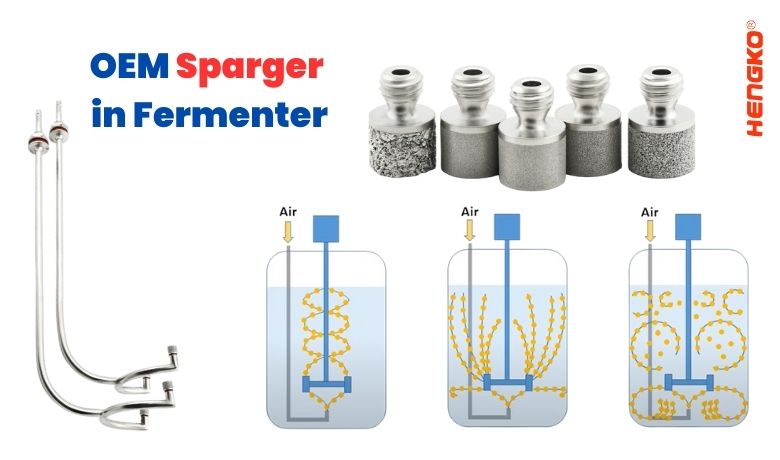

How Many Types of Sparger in Fermenter ?

The sparger used in a fermenter is crucial for distributing gas throughout the culture medium, a necessary process for the microbial cultures in the fermenter to thrive.

There are several types of spargers that can be used in fermentation processes, each with its unique characteristics:

1. Porous or Sintered Spargers: These spargers have a porous structure that allows the gas to be broken down into very fine bubbles, increasing the surface area for oxygen transfer. The small bubbles also ensure more even distribution of gas throughout the fermenter.

2. Pipe or Tube Spargers: This is a simple sparger design where gas is introduced into the fermenter through holes in a pipe or tube. The size and distribution of the holes can be adjusted to control the size and distribution of the gas bubbles.

3. Nozzle Spargers: In this design, gas is forced through a nozzle to create bubbles. The pressure and flow rate of the gas can be adjusted to control the bubble size and distribution.

4. Disk or Sieve Spargers: These are flat spargers with numerous small holes that create fine bubbles when gas is forced through them.

5. Jet Spargers: These spargers use the kinetic energy of the incoming gas to break the gas into fine bubbles. Jet spargers usually require higher pressures than other types of spargers.

The choice of sparger depends on a variety of factors, including the type of microorganism being cultured, the required gas flow rate, the desired bubble size, and the design of the fermenter.

Main Features of Sparger in Fermenter

A sparger is an important component of a fermenter used in biotechnology for microbial fermentation processes. It is used to introduce air or other gases into the fermentation mixture in order to provide oxygen for the growth and metabolism of microorganisms. Some of the main features of a sparger in a fermenter include:

1. Material: Spargers are typically made of stainless steel or other materials that are resistant to corrosion and can withstand the harsh conditions of the fermentation process.

2. Design: The design of a sparger can vary depending on the specific requirements of the fermentation process. Some common designs include porous stones, bubble caps, and perforated plates.

3. Bubble size and distribution: The size and distribution of bubbles produced by the sparger can affect the efficiency of the fermentation process. The sparger should be designed to produce uniform bubbles of the appropriate size to maximize gas-liquid mass transfer.

4. Gas flow rate: The rate at which gas is introduced into the fermentation mixture can also affect the efficiency of the process. The sparger should be designed to provide a controlled and consistent gas flow rate.

5. Sterilization: Since the fermentation process is highly sensitive to contamination, the sparger should be designed for easy cleaning and sterilization.

6. Integration with other components: The sparger must be designed to integrate with other components of the fermenter, such as the agitator and temperature control system, in order to ensure optimal performance of the fermentation process.

7. Size: The size of the sparger will depend on the size of the fermenter and the volume of the fermentation mixture. The sparger should be designed to provide adequate gas transfer for the specific volume of the fermentation mixture being used.

8. Compatibility: The sparger should be compatible with the gas source being used (e.g. air, oxygen, nitrogen) and the type of microorganisms being used in the fermentation process.

What Function of sparger in fermenter ?

A sparger in a fermenter has several key functions, primarily related to the delivery and distribution of gas to support the fermentation process:

The role of the distributor in the fermenter

Porous spargers play a vital role in the fermentation process, providing a means of introducing oxygen or other gases into the liquid medium. The sparger is usually placed at the bottom of the vessel, where it releases gas into the liquid in the form of bubbles.

1. Gas Distribution:

The main function of a sparger is to distribute gas, usually air, oxygen, or carbon dioxide, throughout the liquid medium in the fermenter. This gas is necessary for the metabolism of the microorganisms used in the fermentation process.

2. Oxygen Transfer:

In aerobic fermentation, microorganisms require a constant supply of oxygen to carry out their metabolic activities. The sparger plays a critical role in ensuring efficient oxygen transfer from the gas phase to the liquid medium.

3. Enhancing Mass Transfer:

By creating small, fine bubbles, a sparger can increase the interfacial area between the gas and the liquid, enhancing the mass transfer of oxygen into the liquid medium. This is particularly important in high-density fermentation processes, which have high oxygen demands.

4. Maintaining Homogeneity:

The release of gas bubbles also helps to mix and maintain the homogeneity of the contents of the fermenter. This ensures that nutrients and oxygen are evenly distributed and that temperature and pH conditions remain consistent throughout the fermenter.

In summary, the sparger is a key component in a fermenter, providing and distributing the necessary gases for microbial metabolism, ensuring efficient mass transfer, and helping maintain optimal conditions within the fermenter.

At HENGKO, we specialize in providing customized spreader solutions for the fermentation industry. Our spreaders are constructed of high-quality sintered stainless steel material that is resistant to corrosion and wear, ensuring long-lasting performance and reliability.

We offer a wide range of spreader sizes and configurations to meet the specific needs of your fermentation process, and we can work with you to design and manufacture a spreader to your exact specifications.

Benefits of using HENGKO spreader in fermenter

- 1. Premium sintered stainless steel material resists corrosion and wear, ensuring long-lasting performance and reliability.

- 2. Customizable sizes and configurations to meet the specific needs of your fermentation process.

- 3. Efficient gas - Liquid mass transfer and mixing capabilities help maximize the yield and quality of fermented products

- 4. Expert support and guidance from our team of fermentation industry experts.

FAQ for Sparger in Fermenter

1. What is an injector in a fermenter?

A sparger is a device used to introduce air or other gas into the fermentation mixture in a bioreactor or fermenter. Used to provide oxygen for the growth and metabolism of microorganisms during the fermentation process.

2. Why use a spreader in fermenter?

Spargers are used in fermenters to provide the necessary oxygen for the growth and metabolism of microorganisms during fermentation. Without a spreader, the fermentation process will not be efficient and may not produce the desired results.

3. What are the common materials used to make fermenter spreaders?

Fermenter spargers are usually made of stainless steel or other corrosion-resistant materials that can withstand the harsh conditions of the fermentation process.

4. How is a typical distributor for a fermenter designed?

The design of the fermenter distributor can vary according to the specific requirements of the fermentation process. Some common designs include porous stone, blister and perforated panels.

4. How does the size and distribution of the bubbles produced by the sparger affect the efficiency of the fermentation process?

The size and distribution of air bubbles produced by the sparger can affect the efficiency of the fermentation process. The sparger should be designed to produce uniform air bubbles of the appropriate size to maximize gas-liquid mass transfer.

5. What is the gas flow rate for a typical sparger in fermenter?

The gas flow rate of the sparger in the fermenter can be varied according to the specific requirements of the fermentation process. Spargers should be designed to provide a controlled and consistent gas flow rate.

6. How to clean and sanitize the sparger in the fermenter?

Since fermentation processes are highly sensitive to contamination, spargers should be designed for easy cleaning and disinfection. Typically, injectors can be cleaned by soaking them in a cleaning solution and then rinsing them with water. They can be sterilized by autoclaving or using other sterilization methods.

7. How does the spreader integrate with other components of the fermenter?

The sparger design must be integrated with other components of the fermenter, such as agitators and temperature control systems, to ensure optimum performance of the fermentation process. This integration can be achieved through careful design and engineering.

8. How to determine the size of the sparger for the fermenter?

The size of the sparger will depend on the size of the fermenter and the volume of the fermentation mixture. The sparger should be designed to provide adequate gas transfer for the specific volume of fermentation mixture used.

9. How compatible is the sparger with the gas source used in the fermenter?

The sparger should be compatible with the gas source used in the fermenter, such as air, oxygen or nitrogen. Compatibility can be determined through careful design and engineering.

10. How to install a distributor in fermenter?

The installation of a distributor in a fermenter will depend on the specific design of the fermenter and distributor. Typically, the sparger will be fitted through an opening in the fermenter and held in place.

11. How does the type of microorganism used in the fermentation process affect the design of the sparger?

The type of microorganisms used in the fermentation process can affect the design of the sparger. Some microorganisms require more oxygen than others, so spargers should be designed accordingly to ensure optimal growth and metabolism.

12 .Why use sparger in fermenter ?

One key feature of the sparger that makes it a crucial component of a fermenter is its ability to produce small, uniform gas bubbles. This property is especially pronounced in the case of a porous sparger in a fermenter.

Benefits of Porous Spargers

Optimal Oxygen Transfer: Porous spargers, often made of sintered metal, have a multitude of small pores that enable the production of fine bubbles when gas is forced through them. The fine bubbles increase the surface area for gas-liquid interaction, thus enhancing the mass transfer efficiency of oxygen from the gas phase to the liquid phase. Efficient oxygen transfer is critical for aerobic fermentation, as microorganisms require a steady supply of oxygen to carry out their metabolic activities.

Maintaining Homogeneity: Moreover, the release of fine bubbles into the medium helps maintain homogeneity in the fermenter. The rising bubbles induce a mixing effect that helps evenly distribute nutrients, maintain consistent temperature and pH conditions, and prevent the settling of cells.

Durability and Resistance: In addition, porous spargers made from sintered metal offer durability and resistance to corrosion, making them suitable for use in various fermentation media and ensuring longevity in operation.

In conclusion, the use of a sparger, and more specifically, a porous sparger in a fermenter, is crucial for efficient gas distribution, optimal oxygen transfer, maintaining homogeneity in the fermenter, and ensuring the overall success of the fermentation process.

Contact us today to learn more about how our spreaders can help you optimize your fermentation process and meet your production goals. Our team of experts can provide you with the support and guidance you need to succeed in the fermentation industry.