-

High Quality Sintered Bronze Fuel Sefa

Details Chigadzirwa Kuunza yedu yepamusoro-ye-iyo-mutsara Fuel Sefa neSintered Bronze Fuel Element - mhinduro yakakwana kune chero munhu ari kuda yemhando yepamusoro...

View Detail -

Sintered Copper Bronze Grounding Plate

Deters Electrolysis uye Galvanic Corrosion Inoderedza Kupindira kweRF uye Inovandudza Magetsi Ekuita Kugamuchirwa kuri nani kwemidziyo yako yeGPS, mamiriro ekunze ...

View Detail -

Porous Metal Sintered Mini Cylinder

Porous simbi ndeimwe yezvinhu zvakawanda zvakakodzera kugadzira mabheji. Benefits dzeSintered Mini Cylinder Powdered metals dzine nhamba huru...

View Detail -

Asidhi uye Alkali Inodzivirirwa Yakanyanya Kusimba 316L Iine Porous Stainless Simbi Sefa Sintered Sefa...

Chigadzirwa Rondedzera HENGKO biomedical sefa yakagadzirwa ne316L simbi poda yakanyungudutswa pakupisa kwakanyanya, ine yunifomu porosity ye0.2-0.5 um, corrosion resista...

View Detail -

CEMS Online Smoke Analyzer Gasi Sampling Probe 44.5mm*121mm iyo Yakasarudzika Probe Dhizaini

Chigadzirwa Rondedzera * Kupatsanurwa kweguruva mukuita * Kune guruva rakawanda pamusoro pe3g/m3 * Yakakura inoshama nzvimbo * Hupenyu hurefu * Yakaderera musiyano pressur...

View Detail -

Porous simbi sefa chubhu yekupisa manejimendi kunatsa uye yakakosha kemikari | HENGKO

HENGKO Stainless simbi sefa machubhu anogadzirwa ne sintering 316L poda zvinhu kana multilayer Stainless simbi waya mesh pakupisa kwakanyanya. Ivo vanga vari ...

View Detail -

316L SS Stainless simbi simbi sintered mafirita, Customized microporous nickel monel inco ...

HENGKO's porous metal zvinhu zvinogadzirwa kuburikidza nekuomarara kupisa kurapwa kwemultilayer simbi isina waya mesh kana 316L hupfu pakupisa kwakanyanya. Kus...

View Detail -

Kenduru mhando Sintered 316L Stainless simbi mesh sefa reusable cartridge

HENGKO inopa muunganidzwa wakakura wesimbi isina tsvina mafirita cartridges akagadzirirwa kushandiswa muhuwandu hwakawanda hwemaindasitiri, kusanganisira petrochemicals ...

View Detail -

Anti-corrosion Microns Powder Porous Sintered Metal Sefa Cartridge Yekusefa System

HENGKO inogadzira porous sefa machubhu anopa kuita zvakasiyana-siyana mukugadzira sezvo achigona kuve mhango kana mapofu ane hushoma hwemadziro ukobvu hwe1mm. Zvigadzirwa izvi c...

View Detail -

sintered porous simbi sefa zvinhu midhiya, porosity 0.2 μm ~ 100 micron titanium mon ...

PaHENGKO, maitiro ekugadzira yavo porous simbi zvinhu anosanganisira kupisa kurapa 316L hupfu zvinhu kana multilayer Stainless simbi waya mesh pakakwirira t...

View Detail -

porous simbi Stainless simbi katuriji sefa yekumanikidza yakakwira kucheneswa kwemhepo yakasimba ...

HENGKO inogadzira zvinhu zvayo zvesimbi zvine porous nekupisa inobata 316L poda zvinhu kana multilayer simbi isina waya mesh pane yakakwirira tembiricha. Zvavo...

View Detail -

Unyanzvi 0.2 kusvika 120 microns micro porosity ndarira inconel monel 316 316L Stainless simbi ...

Porous simbi inogadzirwa nekudzvanya simbi yehupfu kuita akasiyana maumbirwo, ayo anobva asungirirwa sinter kugadzira yakasimba uye inert chimiro. Izvi zvakasiyana-siyana ...

View Detail -

Sintered Bronze Mafirita ane OEM Yakananga Shape yekusefa

HENGKO inogona kupa vatengi mukana wekugadzira mafirita uye porous bronze zvikamu zvine chaiwo maumbirwo. Imwe neimwe yeaya akakosha maapplication anoita ...

View Detail -

5 10 20 90 120 microns sintered porous simbi yebhuronzi Stainless simbi 316L yakawanda-chinangwa ...

HENGKO inogadzira mafirita zvinhu muhupamhi hwezvinhu, saizi, uye mafirita kuitira kuti zvigone kutsanangurwa zviri nyore nehunhu uye configura...

View Detail -

Uniform simba sintered porous simbi micron sefa fluidizers bronze ndarira mhangura fil...

Depth filter sheets inoshandiswa kubvisa zvimedu kubva kune zvinwiwa. Izvi zvinoreva kuti zvinwiwa zvinogona kujeka-, zvakanaka- kana sterile-sefa. Sefa mapepa akanakira ...

View Detail -

sintered air filter medium spheric bronze filter element

HENGKO SINTERED BRONZE OIL FILTER inoshandiswa mu sparging, kudzivirira sensor, gasi, uye kusefa kwemvura, kunyorovesa, kubata kwakawanda uye nezvimwe izvo kune solu ...

View Detail -

Kuyerera kunodzora uye kugovera kwemvura sintered sefa ndiro / pepa, upfu sintered porous ...

Depth filter sheets inoshandiswa kubvisa zvimedu kubva kune zvinwiwa. Izvi zvinoreva kuti zvinwiwa zvinogona kujeka-, zvakanaka- kana sterile-sefa. Sefa mapepa akanakira ...

View Detail -

Porous metal sintered bronze brass sefa uniaxial cylinders ine imwe yakavharwa magumo ane hex.

Chigadzirwa Tsanangudzo HENGKO inogadzira mafirita zvinhu muhupamhi hwezvinhu, saizi, uye mafitoti kuitira kuti zvigone kutsanangurwa zviri nyore necharac...

View Detail -

Porous metal sintered porous bronze filter plates/sheet rekuyerera uye kudzora inzwi

Depth filter sheets inoshandiswa kubvisa zvimedu kubva kune zvinwiwa. Izvi zvinoreva kuti zvinwiwa zvinogona kujeka-, zvakanaka- kana sterile-sefa. Sefa mapepa akanakira ...

View Detail -

Mushonga wemakemikari emvura mafuta uye magasi 3um-90 microns porous porous all-metal steam sint...

HENGKO porous sefa machubhu anogona kunge asina buri kana bofu uye aine hushoma hwemadziro ukobvu hwe1 mm. Iwo anogadzirwa ne isostatic compaction yehupfu mune inoshanduka mo ...

View Detail

Chii chinonzi Sintered Powder Metal Sefa uye Hunhu Huru

Sintered powder metal sefa imhando yesefa inogadzirwa nekupisa, kana kudziyisa, musanganiswa wesimbi hupfu

kusvikira dzabatana pamwechete kuti dziumbe chimiro chakasimba. Iyi nzira inogadzira porous zvinhu zvinogona kuteya

zvinosvibisa uye kumwe kusvibiswa, zvichiita kuti ive sefa inoshanda kune akasiyana maapplication.

1.High Porosity

Imwe yemabhenefiti akakosha e sintered poda simbi mafirita ndeye yavohigh porosity. Mapores ari musefa

madiki, anowanzo kubva pakukura kubva pa 0.2 kusvika ku10 microns, izvo zvinovatendera kuti vanyatso bvisa.

huwandu hwakawanda hwezvinosvibisa kubva kune zvinwiwa uye magasi. Zvinoita kuti dzive dzakanakira kushandiswa mumotokari,

zvemuchadenga, uye maindasitiri ezvokurapa, uko kuchena nekuchena kwakakosha.

2.Durability

Imwe mukana we sintered upfu simbi sefa ndezvavodurability. Iyo sintering process inogadzira a

yakasimba, yakasimba chimiro chinopesana nekupfeka uye kubvarura, ichibvumira sefa kuti imirisane nekumanikidza kwakanyanya uye

tembiricha pasina kuremara kana kutyoka. Inovaita kuti vakwanise kushandiswa munzvimbo dzinodiwa,

senge mumainjini kana mimwe michina inoshanda zvakanyanya.

3. Easy Clean

Imwe yematambudziko ekushandisa sintered poda simbi mafirita ndeyekuti ivo vanogona kuvezvakaoma kuchenesa uye kushandisa zvakare.

Nekuti ma pores madiki, kubvisa zvakavharirwa zvinosvibisa kubva kune sefa zvinogona kuoma, kuzviita

zvakakosha kutsiva sefa pane kuichenesa. Inogona kudhura, kunyanya kune zvikumbiro uko iyo

Sefa inoshandiswa kakawanda. chokwadi vane imwe nzira yekuchenesa.

Zvisinei nekupikiswa uku, sintered poda simbi mafirita anoshandiswa zvakanyanya nekuda kwekushanda kwawo uye kugara kwenguva refu.

Iwo chinhu chakakosha mune akawanda maindasitiri nekugadzira maitiro, ayo anobatsira kuve nechokwadi

kuchena uye kunaka kwezvinwiwa nemagasi. Nekugona kwavo kuteya huwandu hwakawanda hwezvinosvibisa uye kutsungirira

zvinoda nharaunda, sintered upfu simbi mafirita chinhu chakakosha chekuchengetedza kuita

uye kuvimbika kwemichina nemidziyo.

Nei HENGKO Sintered Powder Metal Filters

Supply Outstanding Filtration Solutions

Mhando dzedu dze sintered poda simbi sefa mhinduro dzakatanhamara mumhando dzakasiyana siyana dzinoda maapplication;

porous sintersimbi yakasarudzika zvivakwa zvinoshandiswa mumhando dzakasiyana-siyana dzekumanikidza sparging midziyo yefaindi uye

kuparadzirwa kwakafanana kwemagasi muzvinwiwa.

Porous sintered upfu simbi sefa, kazhinji nekuyerera-yakagadziridzwa yakakura nzvimbo yekubatanidza, inoshandiswa kuparadzanisa

maonda kubva gasi hova mukatinzira dzakasiyana-siyana. Iwo Main features ndeaya anotevera:

1. High-temperature kuramba, Thermal kugadzikana kusvika 950°C

2. Inokodzera kudzvinyirirwa kwepamusoro

3. High corrosion resistance

4. Unique sinter bonded connector

5. Chimiro chekuzvitsigira chine simba guru remagetsi

6. Excellent back pulse performance

7. Hapana welding ye porous media

8. Dhizaini kuchinjika, akasiyana maumbirwo aripo, uye gadzirisa

9. Pamusoro pe10,000 zvakasiyana-siyana zvemaitiro uye masikirwo emasikirwo / maumbirwo anowanikwa

10. Main Kune homogeneous gasi / kugovera kwemvura

11. Adopt Chikafu-kirasi 316L uye 304L simbi isina tsvina kana bhuronzi.

12. Easy Cleanable and Reusable Materials

YEDU Technical

Semugadziri wepamusoro-soro wezvigadzirwa zvitsva zvesimbi sefa, HENGKO inopa mamiriro-e-iyo-tekinoroji mhinduro.

kwepamusoro-tembiricha uye nzvimbo dzinoora.

Kazhinji sintered poda simbi sefa zvinhu zvinogadzirwa nesimbi isina tsvina, bhuronzi, nickel-based alloys, uye titanium uye inogona.

ve wakarukwa zvisina musono nemamwe alloys akakosha kugadzirisa kune imwe chimiro neshinda yakarukwa yekubatanidza kana mhepo yemhepo.

Defined filtration by chaiyo pore size distribution.

Materials Option

HENGKO inowanikwa mumhando dzakasiyana dzezvinhu.

Iyo hupfu simbi mhinduro inoita kusona dhizaini uye zvinodiwa kutimunhu muitiro zvinodiwa nyore.

Zvinhu zviripo:

1. Stainless Simbi (yakajairwa 316L),

2. Hastelloy,

3. Inconel,

4. Monel,

5. Bronze,

6. Titanium

7. Special Alloys pakukumbira.

Applications

1. Gasi Sefa

Isu tinopa akawanda zvigadzirwa uye mhinduro dzekusefa magasi anopisa mumaindasitiri ekushandisa, uye tembiricha yekushandisa

kazhinji inodarika 750 ° C kwenguva yakareba. Masefa aya anowanzo shanda mumasisitimu ane otomatiki yekuzvichenesa

kugona, uye mafirita zvinhu zvinofanirwa kunge zvichikwanisa kudzoreredza zvizere pane yega kutenderera. sakaiyo sintered upfu simbi sefa

ndiyo yakanakisa sarudzo, uye ese maficha anogona kusangana; nenzira iyoyo, mafirita edu ane porous melt anoshandiswa zvakanyanya mugasi rakawanda

maindasitiri ekusefa.

2. Kuparadzana

Yakawanda yakakwirira-yekudzvanya michina inoda mafirita zvinhu, senge gasi-mvura yekubata inodiwa kuti uite: kubvisa, kusanganisa,

kana kupararira. Mune mamwe akawanda maapplication, isu tinokubatsira iwe kukwidziridza mashandiro ekuita nekurumbidza nekugadzira zvakanakisa

mhinduro yakakodzera yakavakirwa pane yakakura siyana inowanikwa sparger unit.

3. Kusefa kwemvura

Isu tinopawo yakasarudzika-yakagadzirwa uye yekuzvitsigira yekunyungudutsa mafirita zvinhu pasi kune kusefa kunyatsoita kwe0.1µm mumvura. The

sintered poda simbi mafirita anogona kugadzirwa ane mbiri sandwich, uye maviri sinter-akabatana hupfu magiredhi anopa

Zvinoenderana uye homogeneous kuburitswa uye kunatsiridza kuyerera zvichienzaniswa neyakagadzirwa mafirita. The sintered

porous disc ndiyo yakakwana sefa yemaitiro anosanganisira catalyst. Yedu sintered upfu simbi sefa zvinhu zvine a

Hupenyu hunodarika mhinduro dzakawanda dzekukwikwidza nekuda kweiyo isina welding dhizaini ine "yakasimba-yakasimba" yekubatanidza.

4. Fluidizing

Isu tinopa kugadzirisa fluidizing michina yezvitsva uye zviripo maindasitiri masisitimu nekudzora zvakasiyana

dhizaini yekugadzira mafirita kuti ive nechokwadi chekugovera gasi kwakaringana izvo zvinokonzeresa kuyerera kwakawanda kana kusanganiswa kwevazhinji

midhiya yakasiyana, kusanganisira bhuronzi, simbi isina tsvina, uye polyethylene. Mukuwedzera, nokuti fluidizing cones yakagadzirwa

yakatsiga sintered simbi zvinhu zvinowanzozvitsigira, isu tinogona kazhinji kupa mafirita ane anobatanidza flanges

sezvinodiwa.

MUMWE WEDU

Kusvika Iye zvino HENGKO vane zviuru zvemakambani emakambani kubva kumaindasitiri mazhinji aisanganisira chemestry nemafuta, chikafu, zvekurapa nezvimwe

Zvakare akawanda marabhoritari emakambani uye yunivhesiti kune yenguva refu yekudyidzana mutengesi. Ndinovimba iwe uchava mumwe wavo,

taura nesu nhasi kana uchida.

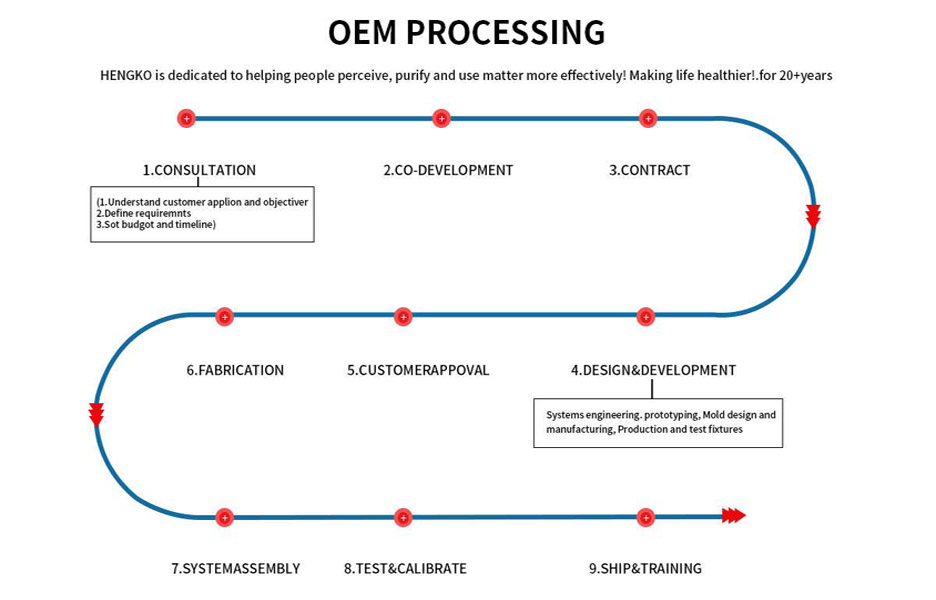

Maitiro ekugadzirisa Sintered Powder Metal Mafirita Kubva kuHENGKO

Kana Uine zvimweYakakosha Dhizaini Sintered Melt Sefayemapurojekiti ako uye haugone kuwana yakafanana kana yakafanana Sefa

zvigadzirwa, Welcomekubata HENGKO kushanda pamwe chete kuti uwane mhinduro yakanaka, uye heino maitiro e

OEM Porous Melt SefaPlease Check it uyeTaura nesutaura zvakawanda.

HENGKO Yakatsaurirwa Kubatsira Vanhu Kuona, Kuchenesa uye Kushandisa Matter Zvakawanda! Kuita Hupenyu Hutano Kupfuura Makore makumi maviri.

1.Kuonana uye Bata HENGKO

2.Co-Development

3.Ita Kondirakiti

4.Dhizaini & Budiriro

5.Mutengi akatenderwa

6. Kugadzirwa / Kugadzirwa Kwemisa

7. System Assembly

8. Edzai & Calibrate

9. Shipping

Saka indasitiri yako ndeipi? uye une mibvunzo nezve simbi mafirita uye unoda kuti tiite kana kugadzirisa

yakakosha porous metal filtersyemudziyo wako nemuchina? Ndapota ingonzwa wakasununguka kutitumira kubvunza, Yedu R&D timu ichaita

kukwanisa kukupa mhinduro dzinokurumidza uye dzinogutsa.

FAQ

1. Chii chinonzi sintering muupfu metallurgy?

Sintering inoshandiswa muupfu simbi kushandura hupfu hwesimbi kuita hwakasimba, hupfu. Iyi nzira inosanganisira

kudziyisa hupfu hwesimbi kusvika patembiricha iri pasi penzvimbo yadzo yekunyungudika, izvo zvinoita kuti zvimedu zvibatane

pamwe chete uye kugadzira chimiro chakasimba.

Iyo sintering process inowanzoshandiswa mukugadzira simbi zvikamu uye zvikamu, senge mabheya, magiya,

nemasefa. Inopa mabhenefiti akati wandei pane dzimwe nzira dzekugadzira, senge kukanda kana kuforoma, kusanganisira

mitengo yakaderera, dhizaini yakakura kuchinjika, uye kugona kugadzira zvimiro zvakaoma uye zvimiro.

Munguva yekupisa, simbi yehupfu inoiswa muforoma kana kufa, iyo inosarudza chimiro che

kupedza chikamu. Moudhi yacho inozoiswa muchoto, umo inodziiswa kusvika patembiricha iri pasi pekunyungudika

pchizoro chesimbi. Sezvo hupfu hwesimbi hunopisa, hunotanga kubatana pamwe chete uye kuumba chimiro chakasimba.

Sezvo simbi yehupfu sinter, pores pakati pezvikamu zvinova zviduku uye zviduku. Inogadzira porous

zvinhu zvakasimba uye zvakasimba asi zvakare zvine nzvimbo yakakwirira yepamusoro, izvo zvinoita kuti zvive zvakanaka kune zvikumbiro zvakadaro

sefiltration uye catalyst rutsigiro. Inogona kudzora ukuru uye kugoverwa kwe pores nekugadzirisa sintering

tembiricha uye nguva uye kuumbwa kwesimbi upfu.

Kana iyo sintering yapera, iyo yakasimba, ine porous zvinhu inobviswa kubva mukuumbwa uye inobvumirwa

kutonhora. Chikamu chakapedzwa chinogona kubva chagadzirwa kana kugadziridzwa kugadzira chimiro uye saizi inodiwa.

Sintering inzira yakasiyana-siyana inogona kugadzira simbi dzakawanda uye zvikamu. Inopa akawanda mabhenefiti,

kusanganisira mari yakaderera, dhizaini inoshanduka, uye kugona kugadzira maumbirwo akaomarara uye zvimiro. Semagumo,

sintering inoshandiswa zvakanyanya mukugadzira simbi zvikamu uye zvikamu mumotokari, aerospace, uye

maindasitiri ezvokurapa.

2. Sei sintering yakakosha muupfu metallurgy?

Sintering inzira yakakosha muupfu simbi nekuti inosungirira zvimedu muupfu hwesimbi kune

gadzira chinhu chakasimba, chakabatana. Inoitwa nekudziisa hupfu kune tembiricha iri pazasi pekunyungudika kwayo,

izvo zvinoita kuti zvimedu zvibatane kuburikidza nekupararira.

Sintering inokosha nokuda kwezvikonzero zvakawanda:

1. Inobvumira kugadzira zvikamu zvine zvimiro zvakaoma zvingave zvakaoma kana zvisingabviri kugadzira

kushandisa mamwe maitiro ekugadzira.

2. Inogona kushandisa kugadzira zvikamu zvine hunyanzvi hwekugadzirisa zvinhu, senge simba rakakura

uye kuoma.

3. Sintering inogona kugadzira porous zvinhu zvine controlled porosity, iyo inobatsira kune zvikumbiro

semasefa uye zvinokonzeresa.

Iyo sintering process inowanzo sanganisira kupisa hupfu kusvika kune tembiricha inosvika 80-90%

yekunyungudika kwayo pasi pemamiriro ekumanikidzwa kwakanyanya uye mhepo inodzorwa. Zvinokonzera

zvimedu kuti zvipararire mune mumwe nemumwe, zvichigadzira huremu hwakasimba. Iyo sintering process inogona kudzorwa

kugadzira huwandu hwakasiyana hwe microstructures uye mechanical properties, zvichienderana nekushanda chaiko.

Imwe yemabhenefiti akakosha ehupfu metallurgy ndeyekuti inobvumira kugadzirwa kwezvikamu zvine maumbirwo akaomarara

uye kushivirira chaiko. Imhaka yekuti iyo simbi poda inogona kuumbwa kuita chero chimiro uchishandisa akasiyana matekiniki,

zvakadai sokutsikirira uye sintering. Uku kuchinjika kunobvumira vagadziri kugadzira zvikamu zvine yakaoma geometry

uye zviyero zvakanyatsonaka, izvo zvisingabviri nemamwe maitiro ekugadzira.

Mukupedzisa, sintering inzira yakakosha muupfu metallurgy nekuti inobvumira kugadzirwa kwezvikamu

ine zvimiro zvakaoma, yakagadziridzwa michina, uye inodzorwa porosity. Idanho rinokosha muupfu

metallurgy process uye inoita kuti vagadziri vagadzire zvikamu zvemhando yepamusoro zvekushandisa kwakasiyana.

Saka kana uchine Chero Mibvunzo uye Unofarira iyo Sintered Powder Metal Filters, Unogamuchirwa

taura nesu neemailka@hengko.com uye zvakare unogona kutumira kubvunza nekutevera fomu rekubvunza, isu tichatumira

shure mukati 24-Hours.