-

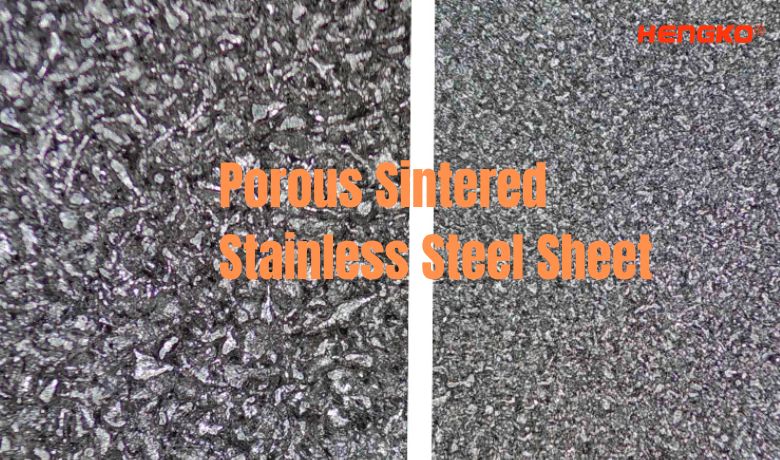

Stainless Steel Porous Metal Sheets SS316 Filter for Hydrogen Gas Diffusion

Stainless Steel Porous Metal Sheets SS316 Filter for Hydrogen Gas Diffusion Unlock the Versatility of Sintered Metal Elements with HENGKO! Our sintered meta...

View Detail -

Gas Diffusion Layers Sheet for MEAs, stainless steel porous metal sintered / wire mesh ...

HENGKO stainless steel filter plates are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been ...

View Detail -

Corrosion resistant microns 316L stainless steel porous sintered filter metal sheets / ...

Product Describe HENGKO porous metal gas diffusion layers are the leading choice for high performance electrolyzer and fuel cell applications. The uniform po...

View Detail -

Easy Clean Micron Porous SUS Sintered 316L Stainless Steel Inline Metal Sheet Plate Rou...

The sintered porous metal sheets having high porosity were obtained from metallic powders by free spreading methods followed by sintering. The sintered struc...

View Detail -

5 10 30 60 90 microns powder micro porous sintered metal sheet filter

Sintered metal filter sheets are widely used for removing foreign particles from many different kinds of flow media. Major application fields: General gases,...

View Detail -

HENGKO sintered stainless steel 316 porous metal gas diffusion layers filter sheet for ...

HENGKO stainless steel sintered wire mesh filter plate is made from multiple layers of woven wire mesh panel together using a sintering process. This process...

View Detail -

Flow control and fluid distribution sintered filter plate/sheet, powder sintered porous...

Depth filter sheets are used to remove particles from liquids. This means that liquids can be clear-, fine- or sterile-filtered. Filter sheets are ideal for ...

View Detail -

Porous metal sintered porous bronze filter plates/sheet for flow and sound control

Depth filter sheets are used to remove particles from liquids. This means that liquids can be clear-, fine- or sterile-filtered. Filter sheets are ideal for ...

View Detail -

porous metal filter disc square strainer micron sintered bronze filter sheet

HENGKO manufactures filter elements in a broad range of materials, sizes, and fittings so they can be easily specified with the characteristics and configura...

View Detail -

hepa sintered bronze stainless steel porous metal filter sheet for air/oil filter machine

HENGKO manufactures filter elements in a broad range of materials, sizes, and fittings so they can be easily specified with the characteristics and configura...

View Detail -

Custom sintered powder metal fitler sheet microns porosity bronze filter sheets for wat...

HENGKO manufactures filter elements in a broad range of materials, sizes, and fittings so they can be easily specified with the characteristics and configura...

View Detail

Main Features of sintered stainless steel sheet

There are many features of SS sheet, here we list some important features and hope

you can understand more details of their features:

The main features of sintered stainless steel sheets include:

1. High Porosity:

Sintered stainless steel sheets offer a high degree of porosity, providing efficient filtration

while maintaining structural integrity.

2. Durability and Strength:

These sheets are highly durable and resistant to wear, making them ideal for use in

harsh environments, including high pressure and temperature conditions.

3.Corrosion Resistance:

Made from stainless steel, these sheets resist corrosion, making them suitable for use

with aggressive chemicals, gases, and liquids.

4.Precision Filtration:

They allow for precise control of pore size, offering filtration for particles ranging from

microns to sub-microns.

5.Reusability:

Sintered stainless steel sheets can be cleaned and reused multiple times, making them

cost-effective and environmentally friendly over the long term.

6.Thermal Resistance:

They can withstand extreme temperatures without degrading,

which makes them ideal for high-temperature applications.

7.Mechanical Stability:

These sheets maintain their structure under various mechanical stresses,

including high flow rates and pressure differentials.

8.Chemical Compatibility:

Sintered stainless steel sheets are compatible with a wide range of chemicals, ensuring reliable

performance in various industrial processes.

These features make sintered stainless steel sheets suitable for applications like filtration, gas

and liquid distribution, fluidization, and more.

Types of sintered stainless steel sheet

There are several types of sintered stainless steel sheets, each designed for specific applications

and varying operational requirements.

The main types include:

1. Single-layer Sintered Stainless Steel Sheet

* Description: A basic sheet made from a single layer of stainless steel particles sintered together.

* Applications: Used for general-purpose filtration, ventilation, and diffusion applications where low-cost and basic filtration are sufficient.

2. Multi-layer Sintered Stainless Steel Sheet

* Description: Composed of multiple layers of sintered stainless steel meshes or fibers, arranged in a specific structure to enhance

mechanical strength and filtration efficiency.

* Applications: Ideal for high-pressure and high-temperature filtration, providing a gradient in pore sizes for effective multi-stage filtration.

Used in industries like petrochemical, pharmaceutical, and food processing.

3. Sintered Wire Mesh Sheet

* Description: Made from layers of stainless steel wire mesh sintered together, offering a balance of strength and filtration.

* Applications: Often used in fluidization, solid particle filtration, and backwashing systems. Suitable for gas and liquid filtration

in industries like chemical processing and wastewater treatment.

4. Sintered Fiber Felt Sheet

* Description: Created by sintering stainless steel fibers into a porous sheet. It offers a high surface area and porosity.

* Applications: Used in fine filtration of gases and liquids, especially in environments requiring high dirt-holding capacity and low pressure drop.

Common in the aerospace and automotive industries.

5. Perforated Sintered Stainless Steel Sheet

* Description: Stainless steel sheets that are perforated and then sintered to improve rigidity and filtration capabilities.

* Applications: Useful in industries requiring both filtration and structural support, such as catalyst recovery, fluid distribution,

and as support for finer filtration media.

6. Laminated Sintered Stainless Steel Sheet

* Description: A combination of multiple sintered sheets laminated together, usually with different pore sizes to create a filtering gradient.

* Applications: These sheets are employed in applications needing high filtration precision and mechanical strength, such as hydraulic filtration,

polymer filtration, and as filter cartridges for high-viscosity liquids.

7. Sintered Metal Powder Sheet

* Description: Made by sintering stainless steel powder into a sheet form. Offers uniform porosity and precise filtration.

* Applications: Ideal for applications involving gas diffusion, fluid filtration, and protection of sensitive equipment from particulate contamination.

Often used in medical, aerospace, and fuel systems.

8. Custom-made Sintered Stainless Steel Sheet

* Description: These sheets are custom-manufactured to specific sizes, shapes, and filtration characteristics based on user requirements.

* Applications: Designed for unique industrial applications where off-the-shelf solutions don't meet the required specifications, such as specialized

filtration systems in chemical plants or custom fluid distribution systems.

Each type offers distinct advantages and is chosen based on the specific operational conditions, such as pressure, temperature, filtration level,

and chemical compatibility.

Application SS Sheet :

Sintered stainless steel (SS) sheets are highly versatile and find applications across various industries due to their durability, corrosion resistance, and precise filtration capabilities. Below are key application areas:

1. Filtration Systems

*Gas Filtration: Used in the filtration of gases in industries such as petrochemical, pharmaceutical, and chemical processing, where they can filter out fine particulate matter and contaminants.

*Liquid Filtration: Employed in the filtration of liquids in industries like water treatment, food and beverage processing, and oil and gas. Their precision filtration helps remove contaminants from water, oils, and other liquids.

2. Aerospace and Defense

*Fuel and Hydraulic Filtration: Sintered SS sheets are used to filter contaminants in fuel lines and hydraulic systems in aircraft and military equipment, ensuring safe and reliable operation under extreme conditions.

*Heat Shields: The high thermal resistance of sintered SS sheets makes them suitable for use as heat shields or protective layers in aerospace applications.

3. Chemical and Petrochemical Industry

*Catalyst Support: Sintered stainless steel sheets are used as catalyst support structures in chemical reactors where they provide high surface area for chemical reactions while offering high-temperature and corrosion resistance.

*Corrosive Fluid Filtration: The corrosion-resistant properties of sintered SS sheets make them ideal for filtering corrosive chemicals, acids, and solvents in refineries and chemical plants.

4. Food and Beverage Industry

*Sterile Filtration: Used in the filtration of food products, beverages, and pharmaceutical liquids where sterilization and precise filtration are required. For example, sintered SS sheets are used in breweries for sterile air and CO₂ filtration during the fermentation process.

*Liquid Processing: These sheets are applied in processing dairy, juice, and other liquid foods to remove particulates while ensuring product purity and safety.

5. Water and Wastewater Treatment

*Water Purification: Sintered stainless steel sheets are used in water filtration systems to remove suspended solids and impurities from drinking water or industrial wastewater.

*Membrane Pre-filtration: Often employed as pre-filters in membrane filtration systems to extend the life of more expensive filtration membranes by removing larger particulates first.

6. Oil and Gas Industry

*Downhole Sand Control: Used in sand control screens in oil and gas extraction, sintered SS sheets prevent sand from entering the extraction pipelines while allowing the flow of oil and gas.

*Fluid Distribution Systems: They are used to filter and distribute fluids in critical oil and gas processes, where high pressure and corrosive fluids are present.

7. Medical and Pharmaceutical Industry

*Sterilization Filters: Sintered stainless steel sheets are widely used in medical device manufacturing for sterilization purposes and in pharmaceutical production to maintain sterile environments.

*Implantable Devices: The biocompatibility of stainless steel makes sintered SS sheets suitable for use in medical implants and surgical tools that require filtration and durability.

8. Energy and Power Generation

*Fuel Cells: Sintered SS sheets are used as porous support structures and gas diffusion layers in fuel cells to enhance the efficiency and reliability of energy conversion processes.

*Nuclear Applications: In nuclear power plants, these sheets are used for filtering and controlling radioactive fluids and gases, as they can withstand extreme radiation and temperature

conditions.

9. Automotive Industry

*Exhaust Filtration: Sintered stainless steel sheets are used in automotive exhaust systems for particulate filtration, helping to reduce emissions and comply with environmental regulations.

*Fuel Filtration: These sheets are used in fuel filtration systems to ensure clean fuel delivery to the engine, improving performance and efficiency.

10. HVAC Systems and Air Filtration

*Air Filtration: Sintered stainless steel sheets are used in air filtration systems for industrial ventilation, clean rooms, and HVAC systems, providing high-efficiency particulate air (HEPA) filtration and maintaining air quality.

*Humidity and Temperature Control: Employed in protective covers for humidity and temperature sensors, ensuring accurate readings and extending sensor life.

11. Fluidization Systems

*Gas Sparging: Sintered SS sheets are used for gas sparging applications in chemical and pharmaceutical processes, where they help evenly distribute gas into a liquid or powder for reactions, fermentations, or mixing processes.

*Powder Fluidization: In systems where powders need to be fluidized with gas for processing, sintered SS sheets offer uniform and efficient gas distribution.

12. Electronics and Semiconductor Manufacturing

*Precision Cleaning: Used in ultra-fine filtration in the semiconductor industry, where contaminant-free environments are crucial. Sintered SS sheets help in filtering chemicals and process gases used in chip manufacturing.

*EMI/RFI Shielding: Sintered stainless steel sheets are sometimes employed for electromagnetic interference (EMI) or radio-frequency interference (RFI) shielding, protecting sensitive electronics from interference.

These diverse applications highlight the adaptability and functionality of sintered stainless steel sheets across a broad spectrum of industries, making them essential in critical filtration, structural, and fluid distribution applications.

FAQ on Sintered Stainless Steel Sheets

1. What is the manufacturing process of sintered stainless steel sheets?

Sintered stainless steel sheets are produced through a multi-step process:

▪ Powder Preparation: Stainless steel powder is carefully selected and sized.

▪ Compaction: The powder is compacted into a mold under high pressure, forming a green body.

▪ Sintering: The compacted mold is heated in a furnace to a temperature below the melting point, allowing the particles to fuse.

▪ Cooling: The sheet is cooled gradually to enhance its properties.

2. What are the benefits of sintered stainless steel sheets?

▪ Corrosion Resistance: Excellent performance in harsh environments.

▪ Strength: High mechanical strength compared to other porous materials.

▪ Filtration Efficiency: Ideal for filtering gases and liquids due to their uniform porosity.

▪ Customizability: Can be tailored for specific applications with varying pore sizes and thicknesses.

3. Are there any disadvantages to using sintered stainless steel sheets?

▪ Cost: Higher initial investment compared to non-porous materials.

▪ Porosity Limitations: May not be suitable for applications requiring absolute impermeability.

▪ Brittleness: Potential brittleness under extreme conditions if not properly designed.

4. Why use sintered stainless steel filters?

▪ High Filtration Efficiency: Effective at removing particles and contaminants.

▪ Durability: Can withstand extreme temperatures and pressures.

▪ Easy Maintenance: Can be cleaned and reused, reducing operational costs.

▪ Versatility: Suitable for various applications, including liquid and gas filtration.

5. What are the best metal grades for sintered stainless steel sheets?

▪ Type 304: Good corrosion resistance and weldability; suitable for many applications.

▪ Type 316L: Offers superior resistance to pitting and crevice corrosion, especially in chloride environments.

▪ Type 310: High-temperature applications due to excellent oxidation resistance.

6. Can you machine sintered stainless steel sheets?

▪ Yes, but: Requires specialized techniques and tools.

▪ Considerations: Use lower speeds and more cooling fluid to prevent overheating.

▪ Methods: Common machining methods include milling, drilling, and grinding.

7. How do you machine sintered stainless steel sheets?

▪ Preparation: Ensure the sheet is securely clamped to avoid movement.

▪ Tool Selection: Use carbide or high-speed steel tools.

▪ Cooling: Apply cutting fluids to maintain a lower temperature during machining.

▪ Techniques: Utilize precision techniques to achieve desired tolerances.

8. What products can be manufactured from sintered stainless steel sheets?

▪ Filters: Gas and liquid filters for various industrial applications.

▪ Spargers: For aeration in fermentation processes.

▪ Porous Components: Used in sensors and specialized mechanical parts.

▪ Custom Parts: Can be tailored for specific engineering needs.

9. Can you spot weld sintered stainless steel sheets?

▪ Yes, but: Requires careful technique to avoid damaging the porous structure.

▪ Preparation: Clean the surfaces to be welded for better adhesion.

▪ Welding Technique: Use low heat settings and rapid application to minimize thermal stress.

10. What are the popular sizes of sintered stainless steel sheets?

▪ Standard Sizes: Typically range from 100mm x 100mm to larger dimensions based on requirements.

▪ Custom Sizes: Can be fabricated to meet specific project needs, including thickness variations.

11. What is the maximum number of holes you can punch in a sintered stainless steel sheet?

▪ Depends on: The thickness and pore size of the sheet.

▪ General Guideline: Punching should be limited to maintain structural integrity; excessive holes can weaken the material.

12. How do you specify a porous sintered stainless steel plate?

▪ Key Specifications: Include pore size, thickness, material grade, and intended application.

▪ Consultation: Work with manufacturers to ensure requirements meet the desired performance standards.

13. What are the important design advantages of porous sintered stainless steel parts?

▪ Weight Savings: Lightweight compared to solid materials.

▪ Fluid Dynamics: Enhanced flow characteristics due to uniform porosity.

▪ Adaptability: Can be designed for various functions, such as filtration and structural support.

14. What is axial compaction in the manufacturing process of sintered stainless steel?

▪ Definition: A method of applying pressure along the axis of the powder to achieve uniform density.

▪ Benefits: Enhances the mechanical properties and overall strength of the final product.

15. How do you fabricate sintered stainless steel using gravity technology?

▪ Process: Gravity assists in filling molds with powder uniformly.

▪ Advantages: Ensures consistent density and reduces segregation of particles.

16. How do you manufacture sintered stainless steel sheets using the spray technique?

▪ Technique: Atomize stainless steel powder into fine droplets and deposit onto a substrate.

▪ Sintering: The deposited layer is then sintered to create a solid sheet.

▪ Applications: Ideal for creating coatings or layered structures.

17. What are the characteristics of Type 316L sintered stainless steel sheets?

▪ Corrosion Resistance: Exceptional resistance to chlorides and other corrosive environments.

▪ Low Carbon Content: Reduces the risk of carbide precipitation, enhancing weldability.

▪ Strength: Maintains strength at high temperatures, making it suitable for demanding applications.

If you're interested in learning more or need OEM special sintered stainless steel sheet filters,

reach out to us at ka@hengko.com for expert assistance and customized solutions!