-

sintered filter stainless steel filter cylinder for water treatment aeration/dust extra...

HENGKO stainless steel filter tubes are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been w...

View Detail -

0.2um to 90 micron 5 – 100mm height powder or wire mesh porous sintered metal sta...

HENGKO stainless steel filter tubes are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been w...

View Detail -

Sintered metal powder porous 316l SS stainless steel filter tube, 2 μm 5 7 10 15 20 30 ...

HENGKO stainless steel filter tubes are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been w...

View Detail -

2 10 20 25 microns porous SS 304/316L metal sintered stainless steel filter tube for li...

HENGKO stainless steel filter tubes are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been w...

View Detail -

Sintered metal 316 stainless steel filter medical micro filter tube for liquid and gas ...

Product Describe Porous filter material has been widely used in metallurgical, chemical, pharmaceutical, aerospace, and aviation fields. Porous Metal media...

View Detail -

replacement sintered micron porous metal stainless steel filter cartridges for grease/o...

Stainless steel sintered filter is mainly composed of tubes, cylinders, cartridges, cups with flange, thread, and fasteners, etc... Installed in the pipeline...

View Detail -

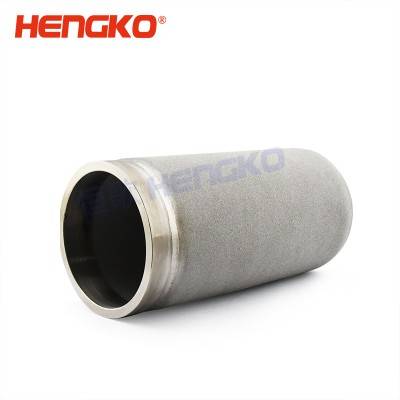

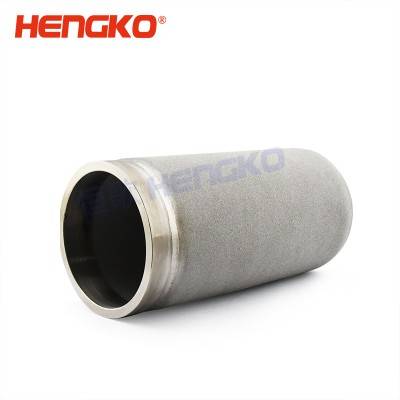

Sintered filter cartridge quality guarantee cold drawn seamless stainless steel filter ...

Product Describe HENGKO stainless steel filter tubes are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures....

View Detail -

Stainless steel sintered porous micro air nano filter capillary tube for gas diffusion ...

Wave welding nitrogen sintered filter cartridge product content: can make the airflow uniform distribution, for wave welding nitrogen modification customers ...

View Detail -

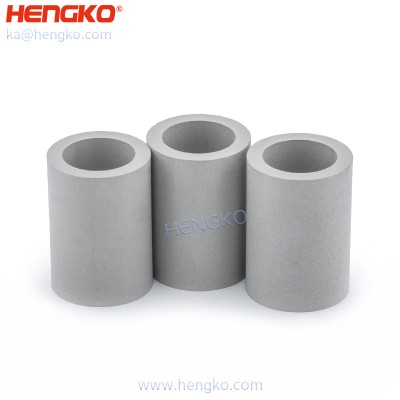

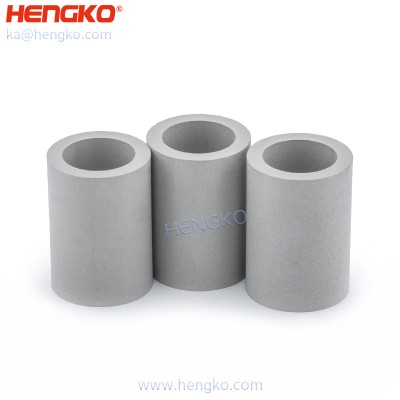

sintered metal stainless steel 316L porous air filtration foam filter candle

Stainless Steel Sintered Bushes are powder metallurgical parts, an essential sintered metal filter element manufactured by HENGKO. The high quality of this s...

View Detail -

Sintered 0.5 7 10 15 30 60 micron porous metal stainless steel filter capillary tube fo...

HENGKO stainless steel filter tubes are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been w...

View Detail -

Sintered metal powder stainless steel 316L industrial dust collector air filter cartridge

HENGKO stainless steel filter tubes are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been w...

View Detail -

Custom stainless steel 316L nitrogen sintered filter cartridge for Lead-free reflow ove...

HENGKO offers nitrogen gas soldering application solutions for reflow and wave soldering, solving the major problems faced by the electronics assembly and ...

View Detail -

Customized Sintered stainless steel filter element with uniform air permeability and st...

Product Describe HENGKO stainless steel filter elements are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatur...

View Detail -

Stainless steel 304 316l sintered metal porous cylinder filters

HENGKO nano micron pore-sized grade stainless steel filter tubes have excellent performances of smooth and flat internal and external tube walls, uniform por...

View Detail -

sintered stainless steel powder metal filter tube -Anti-Corrosion & Long Service Life

HENGKO stainless steel filter tubes are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been w...

View Detail -

Food grade microns 316L stainless steel powder sintered porous metal elements filter me...

Product Describe The Candle Filters are installed for clarification and recovery applications from liquids with low solids content ranging from 5% to PPM lev...

View Detail -

Long service life professional made 304 316 316L microporous powder sintered stainless ...

HENGKO stainless steel filter tubes are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been...

View Detail -

Customized high temperature resistance porous sintered stainless steel 316L cylinder fi...

HENGKO porous metal filters can be used in a wide array of applications across all industries. Capstan filters can be used to filter/separate, to throttle/da...

View Detail -

40-50 um micron pore grade sintered porous metal SS stainless steel filter tube

HENGKO Sintered metal filter, components are manufactured with a controlled amount of porosity throughout the part to facilitate specific pressure flow contr...

View Detail -

5 10 25 micorns porous 316L stainless steel powder/wire mesh sintered metal refillable ...

HENGKO stainless steel filter tubes are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been w...

View Detail

Why use Sintered Stainless Steel Filter ?

1. Superior Durability and Long Lifespan

*High-Temperature Resistance: Maintain structural integrity even in extreme heat.

*Corrosion Resistance: Withstand exposure to a wide range of corrosive chemicals for prolonged use.

*Mechanical Strength: Engineered to endure wear and tear, including high-pressure environments.

2. Advanced Filtration Precision

*Customizable Pore Size:

Tailored pore structures enable precise filtration for specific particles.

*High Efficiency:

Effectively eliminate contaminants, ensuring high product purity and process reliability.

3. Easy Maintenance and Reusability

*Effortless Cleaning: Designed for quick and efficient cleaning, reducing downtime and operational costs.

*Withstands High-Temperature Cleaning: Durable enough for rigorous cleaning procedures, ensuring thorough contaminant removal.

4. Exceptional Versatility

*Applicable Across Industries: Widely used in automotive, aerospace, pharmaceutical, food and beverage, and other sectors.

*Customizable Solutions: Can be tailored to fit unique application requirements, including size, shape, and pore structure.

5. Safety and Dependability

*Fire-Resistant:

Non-combustible material reduces fire risks in sensitive environments.

*Consistent Performance:

Delivers reliable results over extended periods, safeguarding product quality and safety.

Key Applications of Sintered Stainless Steel Filters

*Fluid Filtration:

Purifying liquids and gases by removing impurities.

*Air Filtration:

Eliminating dust, pollen, and airborne contaminants.

*Chemical Processing:

Ensuring efficient separation and purification of chemicals.

*Food and Beverage:

Filtering consumables to maintain purity and compliance.

*Automotive and Aerospace:

Enhancing performance by filtering lubricants and fuels.

Sintered Stainless Steel Filter vs Sintered Bronze Filter?

Sintered Stainless Steel Filter vs. Sintered Bronze Filter: Key Differences

When choosing between sintered stainless steel filters and sintered bronze filters, it’s important to understand their unique properties and suitability for various applications. Here's a detailed comparison:

1. Material Properties

Sintered stainless steel filters are made from stainless steel powders, commonly 316L or 304. They offer excellent resistance to acids, alkalis, and saline environments. With high mechanical strength, they are ideal for high-pressure and heavy-duty applications. Stainless steel filters perform well at extremely high temperatures and provide superior wear and tear resistance, making them durable for long-term use.

Sintered bronze filters are made from bronze or copper alloy powders. They offer moderate corrosion resistance, making them suitable for less aggressive environments. While less durable under high pressure, they perform adequately at moderate temperatures but may degrade at higher ranges. The softer material is more prone to wear in harsh conditions.

2. Filtration Performance

Sintered stainless steel filters offer highly uniform pore sizes, providing precise and consistent filtration. They are suitable for critical processes requiring high filtration efficiency.

Sintered bronze filters are adequate for less demanding filtration tasks. They are often used in applications where cost-effectiveness is more important than precision.

3. Cleanability and Maintenance

Sintered stainless steel filters can withstand ultrasonic cleaning, backflushing, and high-temperature sterilization. Their high reusability helps reduce long-term operational costs.

Sintered bronze filters have limited cleaning options due to their lower strength and temperature tolerance. They are generally less durable and may require more frequent replacements.

4. Cost

Sintered stainless steel filters have a higher initial cost due to their premium material and performance. However, their long lifespan and durability make them cost-effective over time.

Sintered bronze filters are more affordable initially, making them a good option for less demanding applications. However, frequent replacements may lead to higher long-term costs.

5. Applications

Sintered stainless steel filters are ideal for high-pressure systems, corrosive environments such as chemical processing or marine applications, high-temperature processes, and critical industrial sectors like pharmaceuticals and food and beverage.

Sintered bronze filters are suitable for low-pressure applications, moderate environments such as automotive or pneumatic systems, and budget-conscious filtration needs.

Summary: Choosing the Right Filter

Sintered stainless steel filters are best for applications requiring high durability, precision, resistance to extreme conditions, and long-term cost savings. Sintered bronze filters are ideal for cost-effective solutions in moderate operating conditions.

Here’s a detailed comparison of Sintered Stainless Steel Filters and Sintered Bronze Filters presented in a table format:

| Feature | Sintered Stainless Steel Filter | Sintered Bronze Filter |

|---|---|---|

| Material Composition | Stainless steel powders (e.g., 316L, 304) | Bronze or copper alloy powders |

| Corrosion Resistance | Excellent resistance to acids, alkalis, and saline environments | Moderate resistance, suitable for less aggressive environments |

| Mechanical Strength | High strength, suitable for high-pressure applications | Lower strength, less durable under high pressure |

| Temperature Resistance | Performs well at extremely high temperatures | Suitable for moderate temperatures; degrades at higher ranges |

| Durability | Superior wear and tear resistance; long lifespan | Softer material, more prone to wear |

| Filtration Precision | Highly uniform pore sizes; precise and consistent filtration | Adequate for general filtration tasks |

| Cleanability | Easy to clean; supports ultrasonic, backflushing, and high-temperature cleaning | Limited cleaning options; not ideal for rigorous processes |

| Reusability | High reusability; reduces long-term costs | Lower reusability; requires frequent replacements |

| Initial Cost | Higher due to premium material and performance | Lower; cost-effective for less demanding applications |

| Long-Term Cost | Cost-effective over time due to durability and reusability | Higher due to frequent replacements |

| Applications | High-pressure systems, corrosive environments, high-temperature processes, critical industrial sectors (pharmaceutical, food, etc.) | Low-pressure systems, moderate environments (automotive, pneumatic systems) |

| Common Industries | Chemical processing, marine, pharmaceuticals, food and beverage | Automotive, pneumatic systems, general filtration |

| Fire Resistance | Non-combustible; reduces fire hazards | Combustible under certain conditions |

What factors do i customize for your special Sintered Stainless Steel Filter ?

Factors to Customize for Your Special Sintered Stainless Steel Filter

Material Selection

You can choose from different stainless steel grades, such as 316L or 304, based on your requirements for corrosion resistance, temperature tolerance, and mechanical strength. Alternative alloys like Hastelloy can also be considered for specific chemical resistance needs.

Pore Size and Porosity

Pore size can be customized from microns to millimeters, depending on the particle size to be filtered. Porosity levels can be adjusted to achieve the desired balance between flow rate and filtration precision. Higher porosity offers better flow, while lower porosity enhances filtration accuracy.

Shape and Dimensions

Filters can be tailored to various shapes, including cylindrical, disc, cone, plate, or custom geometries, to fit your specific equipment or systems. Dimensions such as diameter, thickness, and length can also be adjusted to meet installation and operational needs.

Operating Environment Compatibility

Filters can be designed to withstand high-temperature environments and customized to handle different pressure levels, from low to high-pressure systems, ensuring compatibility with your operating conditions.

Connection and Mounting Design

Threaded connections or flanges can be added for easy installation, or filters can be designed for seamless integration through welding. Specialized connectors or housings can also be created for unique setups.

Filtration Efficiency

Single or multi-layer sintering options are available to enhance filtration precision and durability. Filters can also be designed for inside-out or outside-in filtration based on the application’s specific needs.

A smooth surface finish can be applied for applications requiring minimal adhesion, such as in food and beverage industries. Textured or coated surfaces can be used for added durability or enhanced chemical resistance.

Cleaning Compatibility

Filters can be designed to handle ultrasonic cleaning for reuse and resist chemical agents or sterilization processes to ensure long-term reliability and easy maintenance.

Application-Specific Features

For sparger applications, filters can be optimized with the right porosity for effective gas dispersion in liquids. Filters used for noise reduction can be designed with specific pore sizes and shapes to achieve efficient sound damping. Flow restrictors can be customized for precise flow control.

Certifications and Standards

Filters can be customized to meet industry-specific regulations, such as FDA, ISO, or ASME standards. Material certifications and batch traceability can also be provided for critical industries.

By providing detailed information about your application, operating conditions, and performance requirements, we can create a fully customized sintered stainless steel filter to suit your specific needs. Reach out to us for expert assistance!

Get Your Customized Sintered Stainless Steel Filter Today!

Ready to design the perfect sintered stainless steel filter for your application? Let us help you tailor every detail to meet

your exact needs, from material selection and pore size to shape, dimensions, and performance specifications.

Contact us today at ka@hengko.com to discuss your requirements and get started on your custom solution.

Our team of experts is here to provide the best OEM services to optimize your filtration, flow restriction, sparger,

and other industrial needs.

Email us now at ka@hengko.com and bring your unique filter solution to life!