Sintered stainless steel aluminum gas sensor probe housing for natural gas detector

An apparatus and method for packaging and operating a gas sensor for use in high-temperature gas environments.

An apparatus and method for packaging and operating a gas sensor for use in high-temperature gas environments.

A gas sensor can be configured, which includes a sensor element and a housing in which the sensor element is located.

A parallel gas path can be configured, wherein said parallel gas path is based on the natural differential, pressure with respect to the velocity of said gas.

The parallel gas path is preferably vertical to provide sufficient, friction to soot particles compared to the gas, such that when a partial quantity of said gas reaches said sensor element, said soot particles are avoided by the said sensor element.

Explosion-proof sensor assemblies are made of 316 stainless steel for maximum corrosion protection. A sinter-bonded flame arrestor provides the gas diffusion path to the sensing elements while maintaining the flame-proof integrity of the assembly. Sensing elements are specially designed for maximum poison resistance and long life in harsh industrial environments, with sensor life typically 2 years or more.

Advantage:

High sensitivity to combustible gas in a wide range

Fast response

Wide detection range

Stable performance, long life, low cost

Stainless steel housing for extremely harsh working conditions

Want more information or would like to receive a quote?

Click the Online Service button at the top right to contact our salespeople.

Customized Isolation sparks catalytic bead combustible sintered stainless steel gas sensor housing for the protection sensing element

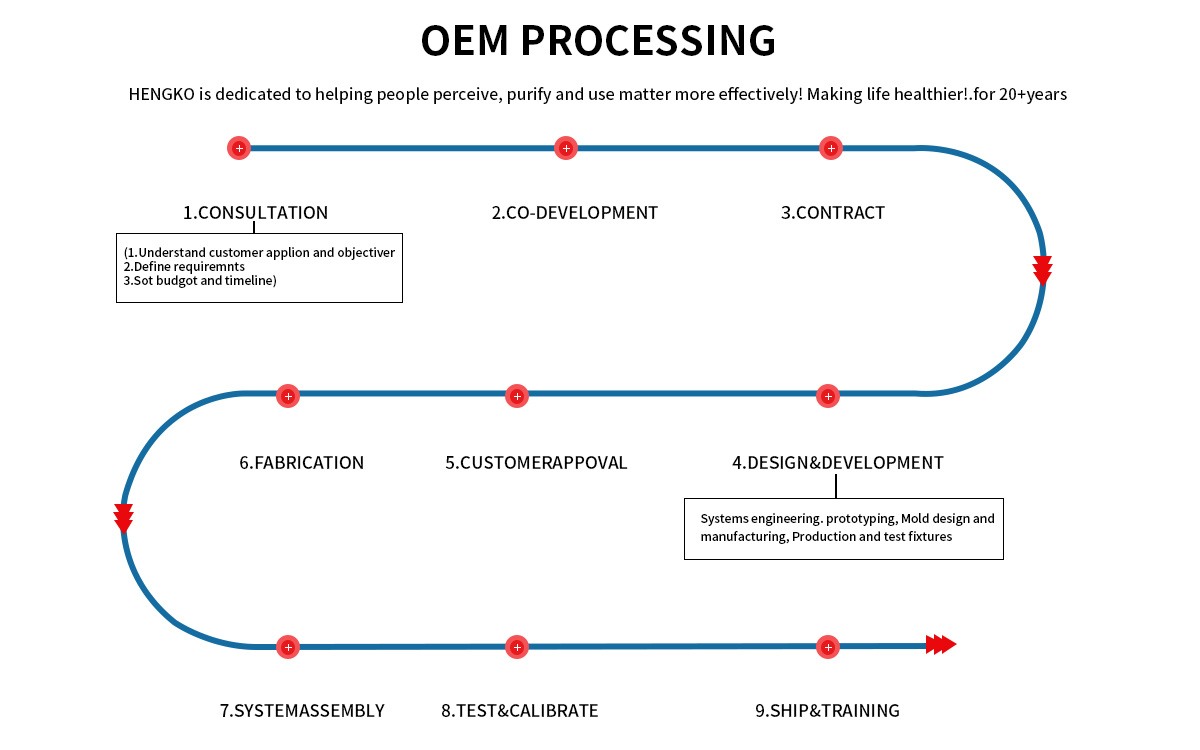

Can't find a product that meets your needs? Contact our sales staff for OEM/ODM customization services!

Can't find a product that meets your needs? Contact our sales staff for OEM/ODM customization services!