-

High Quality Sintered Bronze Fuel Filter

Product Details Introducing our top-of-the-line Fuel Filter with Sintered Bronze Fuel Element - the perfect solution for anyone who is in need of a high-qual...

View Detail -

Sintered Copper Bronze Grounding Plate

Deters Electrolysis and Galvanic CorrosionReduces RF Interference and Improves Electronics Performance Better reception for your GPS devices, weather ...

View Detail -

Sintered Bronze Filters with OEM Specific Shape for Filtration

HENGKO could offer customers the possibility of manufacturing filters and porous bronze components with specific shapes. Each of these special applications r...

View Detail -

5 10 20 90 120 microns sintered porous metal bronze stainless steel 316L multi-purpose ...

HENGKO manufactures filter elements in a broad range of materials, sizes, and fittings so they can be easily specified with the characteristics and configura...

View Detail -

Uniform strength sintered porous metal micron filter fluidizers bronze brass copper fil...

Depth filter sheets are used to remove particles from liquids. This means that liquids can be clear-, fine- or sterile-filtered. Filter sheets are ideal for ...

View Detail -

sintered air filter medium spheric bronze filter element

HENGKO SINTERED BRONZE OIL FILTER is applied in sparging, sensor protection, gas, and liquid filtration, dampening, bulk handling and etc. which for the solu...

View Detail -

Flow control and fluid distribution sintered filter plate/sheet, powder sintered porous...

Depth filter sheets are used to remove particles from liquids. This means that liquids can be clear-, fine- or sterile-filtered. Filter sheets are ideal for ...

View Detail -

Porous metal sintered bronze brass filter uniaxial cylinders with one closed end with hex.

Product Description HENGKO manufactures filter elements in a broad range of materials, sizes, and fittings so they can be easily specified with the charac...

View Detail -

Porous metal sintered porous bronze filter plates/sheet for flow and sound control

Depth filter sheets are used to remove particles from liquids. This means that liquids can be clear-, fine- or sterile-filtered. Filter sheets are ideal for ...

View Detail -

Medical chemical liquid oil and gases 3um-90 microns powder porous all-metal steam sint...

HENGKO porous filter tubes can be hollow or blind and have a minimum wall thickness of 1 mm. They are made by isostatic compaction of powder in a flexible mo...

View Detail -

OEM sintered porous metal bronze filter media membrane filters

HENGKO manufactures filter elements in a broad range of materials, sizes, and fittings so they can be easily specified with the characteristics and configura...

View Detail -

3-90 micron bronze sintered double-open ends replacement filter tube for refining and s...

HENGKO porous filter tubes can be hollow or blind and have a minimum wall thickness of 1 mm. They are made by isostatic compaction of powder in a flexible mo...

View Detail -

3 to 90 microns porous metal sintered bronze filter pipe fitting for oil filter filtrat...

HENGKO porous filter tubes can be hollow or blind and have a minimum wall thickness of 1 mm. They are made by isostatic compaction of powder in a flexible mo...

View Detail -

Custom 35 50 microns fuel filter sintered bronze filter disc disk for heavy duty and in...

HENGKO manufactures filter elements in a broad range of materials, sizes, and fittings so they can be easily specified with the characteristics and configura...

View Detail -

High temperature resistance pressure reusable microns porous metal bronze brass filter ...

HENGKO porous filter tubes can be hollow or blind and have a minimum wall thickness of 1 mm. They are made by isostatic compaction of powder in a flexible mo...

View Detail -

Metal powder sintered porous porosity bronze 316 stainless steel micro filters discs

The bronze porous sintered filter element is made of copper alloy powder sintered at high temperature. It has high filtration precision, good air permeabili...

View Detail -

Personal customization 15 45 90 micron powder sintered brass bronze porous metal oil fi...

HENGKO manufactures filter elements in a broad range of materials, sizes, and fittings so they can be easily specified with the characteristics and configura...

View Detail -

porous metal filter disc square strainer micron sintered bronze filter sheet

HENGKO manufactures filter elements in a broad range of materials, sizes, and fittings so they can be easily specified with the characteristics and configura...

View Detail -

filter tubes of porous metal bronze powder sintered filter cylinder for ptocess air and...

HENGKO porous filter tubes can be hollow or blind and have a minimum wall thickness of 1 mm. They are made by isostatic compaction of powder in a flexible mo...

View Detail -

sintered metal filter disc for wastewater treatment, 5 20 micron 304 316L stainless ste...

Depth filter sheets are used to remove particles from liquids. This means that liquids can be clear-, fine- or sterile-filtered. Filter sheets are ideal for ...

View Detail

Sintered Bronze Filter Features:

1. High filtration accuracy, stable pores, and no change in pore size with pressure changes.

It can effectively remove suspended solids and particles, etc., with excellent filtration accuracy and good purification effect.

2. Good air permeability and small pressure loss. The filter element is completely composed of spherical powder,

with high porosity, uniform and smooth pore size, low initial resistance, easy back blowing, strong regeneration ability

and long service life.

3. High mechanical strength, good rigidity, good plasticity, oxidation resistance, corrosion resistance, no need for additional

skeleton support protection, simple installation and use, convenient maintenance, good assembly,

and can be welded, bonded and machined.

4. Uniform pores, especially suitable for occasions requiring high uniformity such as fluid distribution and

homogenization treatment.

5. Copper powder sintered products are formed at one time without cutting, the effective utilization rate of

raw materials is high, and the material is saved to the greatest extent.

It is especially suitable for components with large batches and complex structures.

6. Filtration accuracy: 3~90μm.

Sintered Bronze Filter Application:

Key applications of our porous bronze components include:

*Medium Purification: Enhances the quality of lubricating oil, fuel oil, and hydraulic systems.

*Flow Limitation: Regulates flow in hydraulic systems for optimal performance.

*Compressed Air Degreasing: Ensures clean and purified compressed air.

*Crude Oil Desanding Filtration: Effectively removes sand and impurities from crude oil.

*Nitrogen and Hydrogen Filtration: Provides sulfur-free filtration solutions.

*Pure Oxygen Filtration: Ensures high purity levels for oxygen applications.

*Bubble Generation: Facilitates efficient gas distribution.

Explore our solutions for reliable performance across various industrial applications!

Why HENGKO Sintered Bronze Filter

We can meet your strict as various applications requirements, sintered bronze filters with customizable and

innovative designs. We have applications for many filter projects, commonly used in superior industrial filtration,

dampening, sparging, sensor probe protection, pressure regulation and many more applications.

✔ Leading manufacturer of sintered bronze filter products

✔ Customized Designs products as different size, materials, layers and shapes, Aperture

✔ ISO9001 and CE standard Quality Control

✔ Before and After-sales Service from Engineer Directly

✔ Full Experience of Expertise in various Applications in Chemical, Food, and Beverage Industries

pneumatic silencer etc.

Application of Porous Bronze Filter Products

1. Fluid Separation: lubrication of fuels, Fluidization of fine powdery cement

2. Exhaust Silencers: Pneumatic Exhaust Mufflers, Breather Vents, Speed Control Mufflers

3. Chemical Application: Water Purifying, Chemical Products Manufacturing

4. Industrial Application: Pneumatic Cylinder Parts, Geared Motors & Gearboxes Parts

5. Transportation Industry: Spare Parts Used in Railway, Automotive, Boat and Marine Sectors

Engineered Solutions

In the Past Years, HENGKO has helped many super complex filtration and flow control problems and

find best solution for many kinds of Chemical and Lab Device and Projects all over the world, so you

can find our sintered metal products becoming more and more varieties. We have a professional team

solving complex engineering tailored to your application.

Welcome to Share Your Project and Work with HENGKO, We Will Supply Best Professional Sintered

Brass Filter Solution For Your Projects.

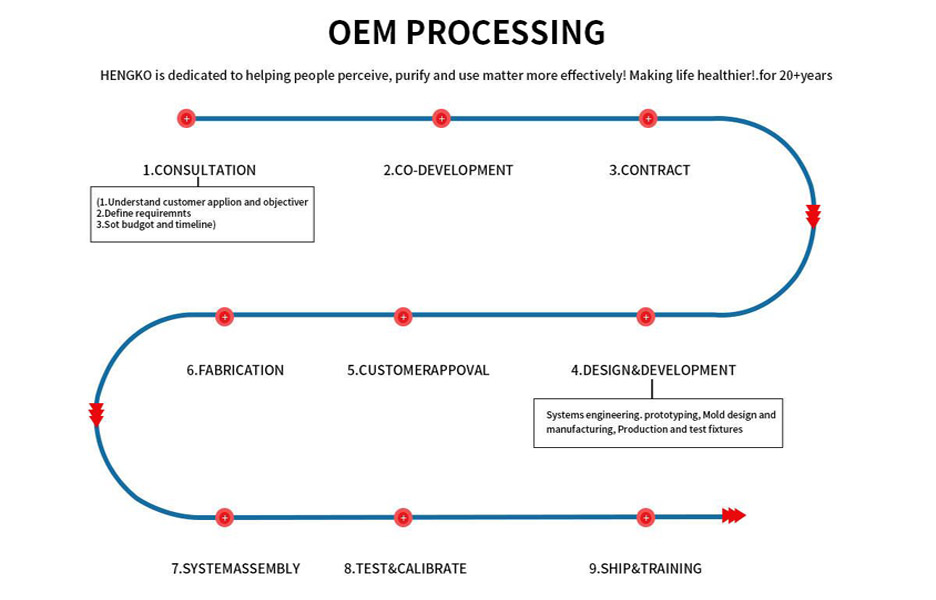

How to OEM / Customize Sintered Bronze Filter

When Your Project have some Special Requirements and Need to High-Class Sintered Bronze Filters can Reach,

But You can not find the same or similar Filter products, Welcome to contact HENGKO to work together to find the

best solution, and here is the process of OEM Sintered Bronze Filters,

Please Check it OEM Process List as below :

*Consultation: Reach out to HENGKO for initial discussions.

*Co-Development: Collaborate on project requirements and solutions.

*Contract Agreement: Finalize and sign the contract.

*Design & Development: Create and refine product designs.

*Customer Approval: Obtain client approval on designs and specifications.

*Fabrication / Mass Production: Begin production of the approved designs.

*System Assembly: Assemble components into the final system.

*Testing & Calibration: Conduct rigorous testing and calibration for quality assurance.

*Shipping & Training: Deliver the final product and provide necessary training.

HENGKO is Dedicated to Helping People Perceive, Purify and Use Matter More Effective ! Making Life Healthier !

We have work with many lab and university in China and all over the world, like Columbia university, KFUPM,

University of California, LINCOLN University of Lincoln

Main Features and Advantage of Sintered Bronze Filters

HENGKO focus on sintered porous melt filter over 20 years and we consists quality first, so we always supply high

quality sintered brass filter, main have sintered bronze discs, and sintered bronze tubes, sintered bronze plate filters

All have reliable performance for anti-corrosion, high temperature, and high precision application.

1. Uniform Porosity: Micron Rating of 1-120um with 99.9% Filtration Efficiency

2. High Strength: Minimum Thickness of 1 mm, to be 100mm max. : Higher mechanical Strength and Lower Pressure Drop

3. High Heat Tolerance : No Any Deforming or Degrading Even under 200℃

4. Chemical Resistance: Can Filter in Corrosive Fluids, a Variety of Gases, and Fuels

5. Easy Welding: Resistance Welding, Tin Welding, and Arch welding

6. Easy Machining: Easy Machining like Turning, Milling, Drilling

7. Long Life and Easy Clean : Sintered bronze filter structure is very stable, Easy to clean and can be used repeatedly

Please Send us inquiry about your detail requirements for the porous bronze filter, like Aperture, Size, Apperance Design ect.

Note: HENGKO packs sintered metal filters in each paper box to prevent damage or scratches.

Full FAQ Guide of Sintered Brass Filters and Application

What is Sintered Bronze Filter ?

Sintered bronze filter, also known as sintered brass filter, sintered copper filter, bronze sintered filter, is a filtration device

with high temperature resistance, pressure resistance and stable permeation characteristics. It is made of numerous

spherical bronze particles sintered by powder metallurgy.

The tightly controlled sintering process enables HENGKO sintered brass filters to produce uniform pore sizes and

distributions ranging from 0.1 to 100 microns. As a result, HENGKO sintered brass filters provide excellent air permeability

and high porosity.

How to Clean Sintered Bronze Filter ?

1. Conventional Cleaning:

Use high pressure water flush HENGKO bronze sintered filter from inside, then use high pressure air flush it in the same way.

Repeat this 3-4 times, then you can get the sintered bronze filter just like new buy.

2. Ultrasonic Cleaning:

This way is Simple and Effective, First put HENGKO sintered brass filter in an ultrasonic cleaner, then just waiting and take it out

after about half an hour.

3. Solution Cleaning:

Take the HENGKO sintered brass filter dip in the cleaning liquid, and the Liquid will react chemically with inside contaminants,

also just check and waiting about one hour, to check if the sintered bronze filter is clean, this way will help you efficiently

remove particles.

What is the Most Commonly Used Micron Copper Filter Element ?

50 micron bronze filter is the popular pore size filter, clients main used to

separate oil particles from pcv/ccv air using 50 micron bronze filter. if you

also have project need to use the 50 micron filtration filters, you can

check the details for the link 50 micron.

How Do You Manufacture Sintered Bronze Filter ?

To Manufacture Sintered Bronze Filter Almost is the same as the sintered stainless steel filter,

you can check What Is Sintered Metal Filter

What are the Features of Sintered Bronze Filter ?

The Main Features of the Sintered Bronze Filter is almost the same as

the stainless steel filters, have many advantage ;

1. Strong structure , not easy to broke,

2.. Easy to clean and can repeated use.

3. Cost is better than stainless steel filters.

Then you also need to know some disadvantage :

1. Lifespan will be shorter than other metal filters.

2. Can not bear high pressure and high temperature, also Easy to react chemically

with other liquids and gases, so we advice to confirm if your liquid or gas is good

to work with bronze.

Is It Easy to Clean Sintered Bronze Filter ?

Yes, It is easy to clean, main to use backflush etc

How to Choose Sintered Bronze Filter Element for your project ?

1. Know what is your aim to filter for your liquid or gas, what is the pore size do you need

to use to filter.

2. if your test gas or liquid materials is work with the bronze.

3. what kind of design bronze filter element suit for your device

4. what is the size of your bronze filter element

5. How much pressure Do you apply high pressure to the filter during the filtration process?

you can confirm with us, or if need add higher pressure, then we will advice to use stainless steel

6. How do you plan to install the Sintered Bronze Filter for your filtration device.

What are the Advantages of Sintered Bronze Filter ?

Main advantages of the sintered bronze filters as follow :

1. Strong structure , not easy to broke

2.. Easy to clean and can repeated use.

3. Cost is better than stainless steel filters.

Other More Question for the sintered Bronze filters, please feel free to contact us.

1. What is the Filtration Efficiency of Sintered Bronze Filter?

Sintered bronze filters typically offer high filtration efficiency, effectively removing particulates ranging from microns to sub-microns, depending on the pore size of the filter.

2. What are the Applications of Sintered Bronze Filter?

Sintered bronze filters are used in various applications, including oil and gas processing, water treatment, chemical processing, and air filtration systems.

3. What are the sizes of Sintered Bronze Filter?

Sintered bronze filters come in various sizes, ranging from small discs and cartridges to larger cylindrical forms, customizable to fit specific application requirements.

4. Are there Limitations of the Sintered Bronze Filter?

While sintered bronze filters are robust, they may be prone to corrosion in highly acidic environments and can have limitations in extreme temperature applications.

5. What are the Design Considerations for Sintered Bronze Filter?

Key design considerations include pore size, filtration flow rate, material compatibility, and the specific operating conditions of the intended application.

6. Is There a Difference Between Sintered Bronze Filter and Bronzing Powder Filter?

Yes, sintered bronze filters are made from compacted bronze powders, while bronzing powder filters utilize a different filtration medium, typically focused on particulate capture rather than liquid filtration.

7. What are the Quality Standards for Sintered Bronze Filter?

Sintered bronze filters should comply with industry standards such as ISO 9001 for quality management and may also meet specific standards related to filtration efficiency and material safety.

8. What Makes Sintered Metal Filters Unique?

Sintered metal filters offer unique advantages such as high thermal and mechanical stability, reusability, and the ability to withstand harsh environments, making them suitable for demanding applications.

9. What is the difference Sintered Stainless Steel Filter Compare to Sintered Bronze Filter?

Sintered stainless steel filters generally offer superior corrosion resistance and higher strength compared to sintered bronze filters, making them more suitable for aggressive environments.

10. What are the Benefits of Sintered Bronze Cartridge Filters?

Sintered bronze cartridge filters provide excellent filtration efficiency, durability, and ease of maintenance, making them a cost-effective choice for various industrial applications.

When Should You Replace Sintered Bronze Filter ?

Normally, after use over 1-2 years, the bronze filter will change the color to be something black, Don't be

afraid, it's just an oxide formed from the oxidation of copper with air.

Then You Should think to change one when the filter need to add more pressure, or the Filtering is slower

than before.

Still Have Questions and Like to Know More Details For the Sintered Bronze Filter, Please feel Free To Contact Us Now.

Also You Can Send Us Email Directly As Follow : ka@hengko.com

We Will Send Back With 24-Hours, Thanks for Your Patient !