-

High performance porous sintered metal stainless steel isostatic filters tubes support ...

Stainless steel sintered tubes are made of stainless steel powder, processed by sintering technology. This product can purify the contaminated media and achi...

View Detail -

Explosion Proof Sintered Filter Gas Sensor Housing for Process and Analytical Gas Appli...

Gas sensor housing are safety devices that allow flow of combustible gases while preventing ignition. The (sintered metal filter media) gas sensor housing pr...

View Detail -

Metallic Sintered Filter for Filtration PM2.5

Metallic Sintered Particulate Filter Replacement metal airstone water dust It prevents dirt and debris from entering and clogging the pump The metallic ...

View Detail -

Stainless Steel Metal Mesh Filter last Chance Filters for the Printing Industry

HENGKO manufactures metal mesh filter elements in a broad range of materials, sizes, and fittings so they can be easily specified with the characteristics an...

View Detail -

Highly Engineered Custom Sintered Porous Metal Flame Arrestor Assemblies

Flame arrestors are safety devices that allow the flow of combustible gases while preventing ignition. HENGKO designs components to meet specific flow condit...

View Detail -

316L Stainless Steel Porous Metal Media 1/4″ and 1/2″ Face Seal Gasket Filter for Extre...

HENGKO manufactures porous metal media in a broad range of materials, sizes, and fittings so they can be easily specified with the characteristics and config...

View Detail -

Industrial Anti-clog Precision Porous Metal Flow Restrictors for Healthcare and Life Sc...

HENGKO manufactures filter elements in a broad range of materials, sizes, and fittings so they can be easily specified with the characteristics and configura...

View Detail -

Low Flow Drug Delivery Flow Elements by Sintered Metal Elements to Deliver the Drug Mol...

Pharmaceutical or medical device companies seek new ways to deliver their drug molecules to patients (Porous metal flow filter). For drugs that require freq...

View Detail -

Sintered Metal Stainless Steel Porous Mesh Filters for in High Pressures Environments

Hengko’s food-grade textile filters are primarily manufactured in the form of cups, threaded cups, discs, and extended area packs. These filters are primaril...

View Detail -

SS 316L Process Sample Gas Analyzer Filters Gas Sample Probe for Air and Gas Filtration

High-pressure housings are constructed entirely from 316L stainless steel, either with Viton or PTFE seals. Suitable for both liquids and gases, these housin...

View Detail -

stainless steel 316 sintered metal filter 30-90 microns filter element – space al...

Product Describe HENGKO stainless steel filter elements are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatur...

View Detail -

High-purity sintered porous 316L stainless steel steam filters effective retention of p...

SINTERED METAL FILTERS FOR THE REMOVAL OF PARTICLES High-purity filters and spargers are specially designed to meet strict requirements for the removal of pa...

View Detail -

Porous filters liquid-solid process filters for high temperature & corrosive envir...

HENGKO offers liquid-solid process sintered metal filters for high-temperature & corrosive environments. HENGKO manufactures filter elements in a ...

View Detail -

Custom sintered stainless steel round disc filter for flameproof and fire resistance

Sintered metal materials are a popular choice because these highly engineered materials consist of a uniform, interconnected porosity that can be fabricated ...

View Detail -

OEM sintered stainless steel porous metal fluidizers fluid for material transfer or tra...

HENGKO’s porous metal fluidizers provide an optimum solution for material transfer or transport applications that require strength, elevated temperature tole...

View Detail -

Sintered Metal Fame Arrestors Manufacturer for the Storage and Transportation of Inflam...

Flame Arrestors are safety devices that allow the flow of combustible gases while preventing ignition. The Flame Arrestorprevents the flame from transferring...

View Detail -

3D Printed porous metal filter OEM filtration & flow control designs for medical d...

HENGKO manufactures filter elements in a broad range of materials, sizes, and fittings so they can be easily specified with the characteristics and configura...

View Detail -

Good grade sintered porous metal stainless steel textile filters for polymer filtration

Good-grade sintered metal stainless steel textile filters for polymer filtration Hengko’s food-grade textile filters are primarily manufactured in the form ...

View Detail -

Microns porous stainless steel sintered filters inline reusable washable fuel filter

Captures dirt and grit as small as 40 microns before they can cause damage to the intake system. CNC polished alloy body with the sintered metal internal ele...

View Detail -

Pre-filtration of smoke sampling – sintered stainless steel 304 316 316L filter e...

Product Describe Boost Your Gas Analysis with HENGKO's Gas Sampling Probes! When it comes to accurate and reliable gas analysis, HENGKO has you covered. Our...

View Detail

Why use Porous Metal Filter for your filtration project ?

Porous metal filters offer several advantages that make them an excellent choice for a variety of filtration projects,

so we list some main features, please check as following :

1.High Durability and Strength:

Porous metal filters are typically made from robust materials such as stainless steel, which provides excellent

resistance to high pressures, thermal stress, and corrosive environments.

This makes them suitable for demanding industrial applications where durability is critical.

2.Efficient Filtration:

These filters are designed with a controlled pore structure that enables efficient separation of particles,

even at very small sizes. The precise control over pore size distributions ensures consistent performance

in capturing contaminants.

3.High Temperature Capability:

Metal filters can operate effectively at much higher temperatures than polymer-based filters, making them

ideal for processes involving high heat, such as in the chemical and petrochemical industries.

4.Chemical Resistance: Metal filters are resistant to a wide range of chemicals, allowing them to be used in

applications involving harsh solvents, acids, and bases without degrading.

5.Cleanability and Reusability:

Porous metal filters can be cleaned and reused, which is not only cost-effective but also reduces waste.

Techniques such as backflushing, ultrasonic cleaning, and chemical cleaning can restore filter capacity.

6.Customizability:

They can be engineered to meet specific filtration requirements, including various shapes, sizes, and materials.

This customizability allows for tailored solutions that fit specific operational needs.

7.Sintered Metal Strength:

Sintering, the process used to create many porous metal filters, bonds metal particles together without melting

them, resulting in a highly porous but strong structure that withstands both mechanical and thermal stresses better

than non-sintered counterparts.

These characteristics make porous metal filters a reliable choice for sectors like pharmaceuticals, food and beverage,

aerospace, and industrial manufacturing, where high performance and reliability are essential.

Why Choose HENGKO for Wholesale Sintered Porous Metal Filters?

HENGKO provides a range of options to meet your specific project needs. Our filters have a proven track record in various industrial

applications such as filtration, dampening, sparging, sensor protection, pressure regulation, and more.

As a top-quality manufacturer of porous metal sintered filters in China, we offer the following:

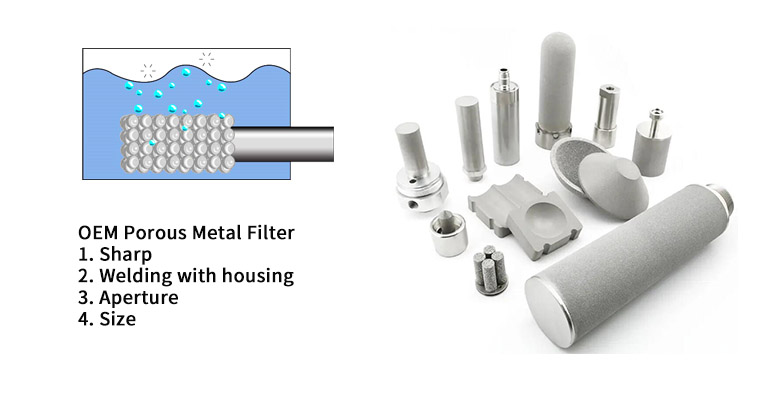

* Unique OEM designs in size, pore size, materials, layers, and shapes

* A professional R&D team for fast and efficient supply solutions

* Products that meet CE standards for quality and stability

* Comprehensive service from engineering to after-sale support

* Rich experience and Expertise in the chemical, food, and beverage industry's application projects.

Application of Sintered Porous Metal Filters Products

1. Filtration in gas and liquid processing industries:

Sintered porous metal filters are used to filtrate liquids and gases in various processing industries, including petrochemical, chemical, and pharmaceutical manufacturing.

2. Medical devices for filtration and separation:

Sintered porous metal filters are used in medical devices such as dialysis machines, ventilators, and blood filters. These filters are chosen for their high precision, consistent pore size and structure, and biocompatibility.

3. Automotive exhaust gas filtration:

Sintered porous metal filters are used in automotive applications to reduce emissions and improve engine performance. They can be used to filter particles and gases from the exhaust stream to reduce air pollution.

4. Food and beverage filtration:

Sintered porous metal filters are used in the food and beverage industry to filter and clarify liquids. They are particularly useful for applications involving high temperature, high pressure, or harsh chemicals.

5. Water treatment systems:

Sintered porous metal filters are used in water treatment systems to remove contaminants, purify water, and improve water quality. They can also be used in wastewater treatment systems to separate solids from liquids.

6. Aerospace fuel systems:

Sintered porous metal filters are used in aerospace fuel systems to ensure the fuel is free of contaminants and to protect fuel pumps and injectors. They provide high-efficiency filtration, consistent flow, and low-pressure drop.

7. Biopharmaceutical production processes:

Sintered porous metal filters are used in biopharmaceutical production processes to clarify and purify liquids. They are particularly useful in applications with high sterilization and filtration requirements.

8. Environmental remediation and pollution control:

Sintered porous metal filters are used in environmental remediation and pollution control to remove contaminants from the air, water, and soil. They can be used to treat contaminated groundwater, remove heavy metals from waste streams, and provide clean air in industrial settings.

Engineered Solutions

At HENGKO, we have a proven track record of providing customized and effective solutions for even the most

intricate filtration and flow control issues for customers globally. Our R&D team is committed to delivering the

best solution for your industry needs. Partner with us and let us offer you our expertise in metal filtration and

supply best solution for your projects.

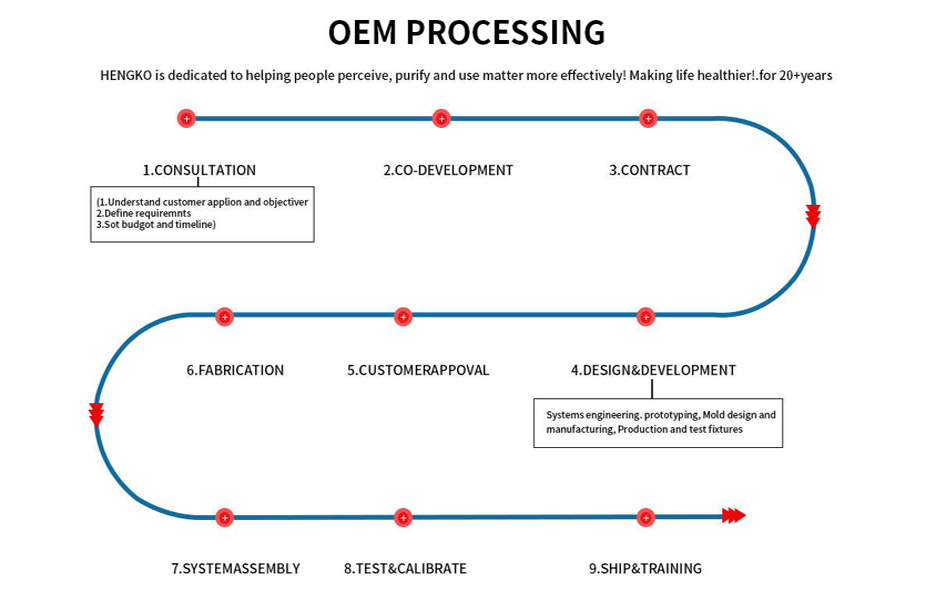

How to Customize Sintered Sintered Porous Metal Filters

Customizing Sintered Porous Metal Filters with HENGKO

If you have specific filtration needs and can't find a suitable product, reach out to HENGKO. Our team

will work with you to find the best solution. The process of customizing sintered porous metal filters includes:

1.Contacting HENGKO for consultation

2.Collaborative development

3.Signing a contract

4.Design and development

5.Customer approval

6.Fabrication and mass production

7.System assembly

8.Testing and calibration

9.Shipping and training

HENGKO has been dedicated to helping people manage, purify, and utilize matter more effectively for

over 20 years, making life healthier.

HENGKO is a renowned and experienced factory in sintered porous metal filters. Our professional technical

teams are focused on developing, designing, and manufacturing high-quality sintered porous metal elements

and porous materials, meeting the demands of various industries and applications. With extensive experience

and expertise, we have established strategic partnerships with many high-tech enterprises and key laboratories

in universities worldwide, further enhancing our ability to deliver innovative solutions for our clients.

Features of Sintered Porous Metal Filters

1. Simple to shape, process, join, and sanitize.

2. Offers filtration precision from 0.2 to 200 microns.

3. Possesses robustness for cleaning and repeated use.

4. Provides personalized support for a diversity of materials and measurements.

5. Typically utilized in environments with temperatures from 200°C to 650°C (high up 900°C) and

in conditions of acid or alkali corrosion.

FAQ Guide of Sintered Porous Metal Filters :

What is Sintered Porous Metal Filters ?

Sintered porous metal filters, also named saintered metal filters, for HENGKO main supply 316L stainless steel filers,

because there are many super small holes inside the metal , in order to let the gas and liquid to through and Separation of

unwanted impurities and solids, also because 316L stainless steel is can reach most of filtration requires but with reasonable

price for most of clients. so welcome you to contact us for know more details.

What Are Sintered Filters Used For?

A: For sintered filters same as most of normal filters, main to separate unwanted impurities and solids from our gas and

liquid materials, to make our gas purify as project requires.

Is Sintered Metal Porous?

A: Yes, sintered metal is porous inside, Irregular micron-sized pores, in order to filter impurities in gas or liquid, in order to

achieve the purpose of purification

Which Metal is Porous?

A: For Normal Metal sure not with small porous.

But people found some metal have special function as filtration, so more and more

metal to make with porous by sintered technology, to make to be kinds of design

sintered metal elements to used as filters, to filter impurities in gas or liquid, in

order to achieve the purpose of purification

How Do You Make Metal Porous?

A:For now, we most to use sintering process, sintering different metal powders

into shapes for various engineering applications to achieve the purpose of filtration

What is the Most Porous Material?

A: Till now popular metal porous material as filters is as follow;

- Stainless Steel Filter; 316L, 304L, 310, 347 and 430

- Bronze

- Inconel® 600, 625 and 690

- Nickel200 and Monel® 400 (70 Ni-30 Cu)

- Titanium

- Alloys

Is copper a porous metal?

Many application still use the copper porous metal, because it is lower cost.

but it is disadvantage is the service time will not longer than other quality materials, such as

stainless steel.

What is the difference between porous and non-porous?

A: The Big Different for porous and non-porous is , porous metal can let the gas or liquid to go through.

but non-porous can not.

If still like to know more about sintered filter working principle, please check our this blog check details.

Still Have Questions and Like to Know More Details For the Sintered Metal Filter, Please feel Free To Contact Us Now.

Also You Can Send Us Email Directly As Follow : ka@hengko.com

We Will Send Back With 24-Hours, Thanks for Your Patient !

Send your message to us: