-

Sintered micron stainless steel porous metal filter cylinder for gas filtration

Product Describe Sintered Metal Filter Cartridges: Porous metal filters have a wide variety of industrial filter uses. These reusable, high-quality filters a...

View Detail -

Pharmaceutical Industry Medical Grade Sintered Metal Stainless Steel Filter

Sintered metal filters with dryers and mills within the pharmaceutical industry. When these elements are used with dryers and mills, they are contained withi...

View Detail -

Resists High Temperature Stainless Steel Sintered Powder Filter Element filter cartridg...

Product Describe Sintered powder filter element also named metal porous sintered filter is made of titanium or stainless steel powder. It is a new style of m...

View Detail -

Porous Metal Powder Sintered Stainless Steel Catalyst Recovery Filters for Catalyst Rec...

A brief introduction to the working principle of catalyst filter (sintered filters) equipment: HENGKO Sintered Metal Catalyst Filter uses catalysts to recove...

View Detail -

HENGKO Superior Membrane Surface Porous Sintered Metal Filter

Product Description:Upgrade your filtration efficiency and prolong the lifespan of your filters! HENGKO's sintered porous stainless steel filter product util...

View Detail -

Biopharmaceutical purification and filtration porous filter plate 10um 20um 50um

A porous filter plate is a new type of high-efficiency porous filter material made of metal stainless steel powder through powder sieving, moulding, sinterin...

View Detail -

Enhance Filtration Efficiency with High-Quality Sintered Metal Filter Train Accessories

Are you looking for top-notch filtration solutions for your train? Look no further! Our high-quality sintered metal filter train accessories are here to revo...

View Detail -

HENGKO® Grab Sampler Filter

Introducing: Filtered Grab Sampler with Sintered Metal Filter, the perfect tool for accurate and reliable sampling in a wide range of industries. This innova...

View Detail -

Porous Metal 316L Filter for catalytic reactions Granular Bed Filtration

Introducing the Porous Metal 316L Filter - Your One-Stop Solution for Chemical Detection! Are you tired of dealing with inefficient and complex chemical dete...

View Detail -

wide mouth jar mason jar with stainless steel sintered filter disc for high temperature...

Small changes, big benefits! We store bentonite clay inside the jar and bake it in a vacuum oven to remove moisture. Even with the lid on the clay gets out o...

View Detail -

In-Line Gasket Filters for the filtration of gases

Gasket Filter for the filtration of gases For protecting regulators and MFCs, protects critical components from particle damage In-Line Design Easy Installat...

View Detail -

NW25 and KF25 Flange-Centering O-Ring with Fine Filter

ISO-KF and NW Sintered Metal Filter Centering Ring NW-16、NW-25、NW-40、NW-50 Supplier With fine filter (sintered porous metal filter or choose wire mesh f...

View Detail -

NW16 KF16 Flange-Centering O-Ring with Fine Filter

ISO-KF and NW Sintered Metal Filter Centering Ring NW-16、NW-25、NW-40、NW-50 Supplier With fine filter (sintered porous metal filter or choose wire mesh f...

View Detail -

NW50 KF50 Vacuum Flange Centering ring with Sintered Metal Filter, stainless steel, 50 ...

NW50 KF50 Centering ring with Sintered Metal Filter, stainless steel, 50 ISO-KF Product material: stainless steel 304,316 Installation method: use with clam...

View Detail -

NW16 KF16 KF Centering Ring to Sintered Metal Filter

NW16 / KF16 KF Centering Ring to Sintered Metal Filter • NW16 (KF16, QF16) Series• Viton (Fluorocarbon, FKM) O-Ring• Viton: 200°C Maximum• 0.2 µm Pore Size•...

View Detail -

KF25 and NW25 Centering Ring with Sintered Metal Filter

NW25 / KF25KF Centering Ring with Sintered Metal Filter • NW25 (KF25, QF25) Series• Viton (Fluorocarbon, FKM) O-Ring• Viton: 200°C Maximum• 0.2 µm Pore Siz...

View Detail -

Gas sampling probe Pre-Filter

Gas sampling probe Pre-Filter Dust separation in the process For dust concentrations up to 3g/m3 Large active surface Long lifetime Low differential pressu...

View Detail -

Filter Regulator for Diaphragm Pump Accessories

Filter Regulator for Diaphragm Pump Accessories Here to give you my two cen tech tip using a filter regulator with the pneumatic actuator values it's a smal...

View Detail -

One-Way Valves for Bronchoscopic Lung Volume Reduction

One-Way Valves for Bronchoscopic Lung Volume Reduction Bronchoscopic alternatives to lung volume reduction surgery (LVRS) have been recently proposed; the a...

View Detail -

Sintered Cartridge Filter for Polysilicon

Sintered cartridge filter for polysilicon production HENGKO sintered metal filters provide clean air, which in turn improves people's health, protects critic...

View Detail

Custom OEM Sintered Metal Filter Manufacturing

HENGKO offers fully customized OEM sintered metal filter solutions designed to meet

specific filtration system requirements, including high temperature, high pressure,

and corrosive operating environments.

Custom Materials Options

We manufacture sintered metal filters using a wide range of metals and alloys, including:

*Stainless Steel**: 316L, 316, 304L, 310, 347, 430

*Bronze / Brass**: Sintered bronze filter media

*Nickel Alloys**: Nickel 200, Monel® 400 (70Ni–30Cu)

*Inconel®**: 600, 625, 690

*Titanium**

*Other specialty alloys** available upon request

Filter Shapes & Structures

Custom sintered metal filters can be manufactured in various shapes, such as:

3. Sintered Metal Filter Cartridge

4. Sintered Stainless Steel Plate

5. Sintered Porous Metal Sheet

6. Sintered Cup

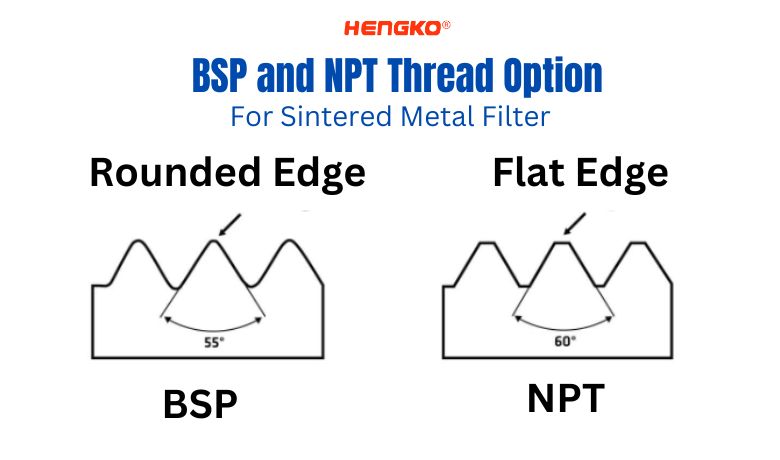

Thread & Connection Options

OEM thread and connection designs are available, including:

- NPT

- BSP

- G

- PF

- Other custom thread specifications

Key Parameters for Customization

To recommend the most suitable sintered metal filter solution,

the following parameters should be defined:

- Pore size / porosity

- Micron rating

- Required flow rate

- Filter media and operating conditions

Why Choose Sintered Metal Filters for Your Filtration Projects:

Sintered metal filters are made from metal powders that are pressed and sintered (fused) to form a porous,

solid structure. These filters are known for their high strength, durability, and ability to filter out very small particles.

8 Main Features of Sintered Metal Filters

HENGKO offers a range of metal sintered filter products, including sintered stainless steel, sintered bronze,

sintered mesh, and sintered titanium filters, metal powder filters, sintered metal filter discs, and sintered stainless

steel tubes. Our filters are designed for applications requiring high levels of anti-corrosion, high temperature,

and high precision performance.

1. High Strength:

Sintered metal filters are made from metal powders, which gives them high strength

and durability.

2. High-temperature Resistance:

Sintered metal filters can withstand high temperatures, making them

suitable for high-temperature environments.

3. Corrosion Resistance:

Sintered metal filters are resistant to corrosion and can be used in corrosive

environments.

4. Chemical Resistance:

Sintered metal filters resist most chemicals, making them suitable for chemical

processing applications.

5. High filtration Efficiency:

Sintered metal filters have a very fine pore structure, which allows them to

filter out very small particles effectively.

6. High dirt-holding Capacity:

Sintered metal filters have a high dirt-holding capacity, meaning they can

filter large volumes of fluids before they need to be replaced.

7. Easy to Clean:

Sintered metal filters can be easily cleaned and reused, making them cost-effective

in the long run.

8. Versatility:

Sintered metal filters can be made in various shapes and sizes to meet the specific needs

of different applications.

For porous metal filters, stainless steel is an ideal choice for filtration in chemical processing, petroleum refining,

power generation, pharmaceutical production, and other applications.

For HENGKO, all sintered filter elements undergo strict quality testing before shipping, including filtration efficiency

and visual inspection. Our sintered metal filters have higher particle removal efficiency, corrosion resistance, less

pressure drop, easier cleaning, and backwash advantages compared to other metal filter suppliers.

If our current offerings do not meet your filtering requirements, please contact us with your material, dimension,

and application needs.

Application of Sintered Filter Products

Sintered filters are used in a wide range of industries, including chemical processing,

petroleum refining, power generation, and pharmaceutical production.

They are ideal for use in applications where a high level of filtration efficiency is required,

and where the filter must be able to withstand high temperatures, pressures, and corrosive environments.

Some of the most common applications of sintered filter products include:

Liquid Filtration

Sintered metal filters are commonly used for liquid filtration in a variety of industries.

They are particularly useful in applications where the liquid being filtered is viscous or contains a high level of solids.

Sintered filters can remove particles as small as 1 micron, making them ideal for use in applications

where a high level of filtration efficiency is required.

Fluidizing

Sintered metal filters can also be used for fluidizing applications, where they help to evenly distribute

gas or liquid through a bed of solid particles. This is particularly useful in applications such as catalysis,

where it is important to ensure that all reactants are evenly distributed.

Sparging

Sintered metal filters can also be used for sparging applications, where they help to introduce gas into a liquid.

This is particularly useful in applications such as fermentation, where it is important to ensure that

the liquid being fermented is well-aerated.

Diffusion

Sintered metal filters can also be used for diffusion applications, where they help to evenly distribute

gas or liquid through a membrane.

This is particularly useful in applications such as fuel cells, where it is important to ensure that the reactants

are evenly distributed across the membrane.

Flame Arrestor

Sintered metal filters can also be used as flame arrestors, where they help to prevent the spread of

flames or explosions.

This is particularly useful in applications such as refineries or chemical plants, where flammable

materials are present.

Gas Filtration

Sintered metal filters are also used for gas filtration in a wide range of industrial applications.

They are particularly useful in applications where the gas being filtered contains a high level of

moisture or other contaminants. Sintered filters can remove particles as small as 0.1 micron,

making them ideal for use in applications where a high level of filtration efficiency is required.

Food and Beverage

Sintered metal filters are also used in a variety of food and beverage applications,

including the filtration of beer, wine, and other beverages.

They are particularly useful in applications where a high level of filtration efficiency is required,

and where the filter must be able to withstand high temperatures and corrosive environments.

If you require a sintered filter product that meets specific material, dimension, or application requirements,

please feel free to contact us to discuss your needs.

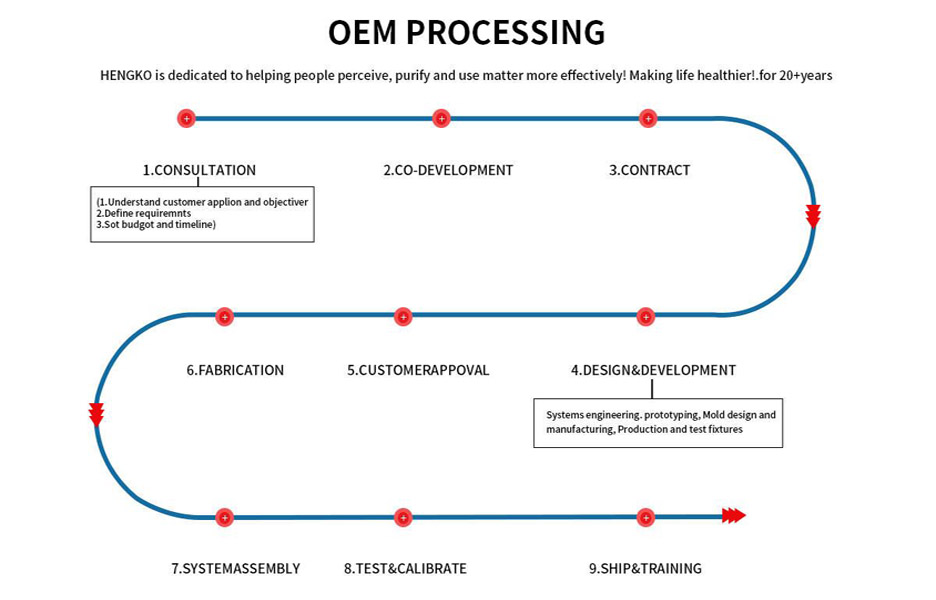

Customize Sintered Metal Filter Process

Welcomes to take your special design requirements filters to contact us, we will find the best filter solution for

your filtration requirements. and you can follow a comprehensive process to ensure that the final product meets

all necessary specifications. The process includes:

1. Consultation and Contact HENGKO

2. Co-Development

3. Make a Contract

4. Design & Development

5. Customer Approval

6. Fabrication /Mass Production

7. System assembly

8. Test & Calibrate

9. Shipping & Installation

If you require a sintered filter product that meets specific material, dimension, or application requirements,

please contact us to discuss your needs.

What Sets HENGKO Apart in the Sintered Metal Filter Industry?

Why Choose HENGKO's Sintered Metal Filters?

HENGKO’s sintered metal filters are highly regarded by our customers for their exceptional dirt holding capacity and long lifespan.

Manufactured through a meticulously controlled sintering process, these OEM Sintered Metal filters offer uniformly distributed pores

with micron ratings ranging from 0.1μ to 100μ, ensuring precise and reliable filtration.

Key Benefits of HENGKO’s Sintered Metal Filters:

1.Stable and Durable Design:

Our filters maintain a stable shape with excellent resistance to impact and alternating loads,

making them highly durable even under challenging conditions.

2.Superior Air Permeability:

With consistent filtration efficiency, our sintered metal filters provide excellent air permeability,

ensuring optimal performance in various applications.

3.High Strength and Corrosion Resistance:

Designed to withstand high pressure and highly corrosive environments, our filters offer exceptional unloading strength,

making them ideal for demanding industrial settings.

4.High-Temperature Performance:

Particularly suitable for high-temperature gas filtration,

our sintered metal filters perform reliably in extreme environments.

5.Customization Options:

We offer customized solutions with a wide range of materials, shapes, and connection sizes to meet specific application needs.

As a reputable manufacturer in China, HENGKO specializes in producing sophisticated sintered metal filters.

Our team of professional technicians is dedicated to the development and manufacturing of high-performance

sintered stainless steel and porous materials.

Proudly recognized as a high-tech enterprise, HENGKO collaborates with leading universities both domestically

and internationally to continuously innovate and improve our products.

4-Tips When Choose & OEM Sintered Metal Filter You Should Care

There are several ways to customize sintered metal filters to meet specific application requirements.

Some common methods include:

1. Selecting the appropriate metal:

Different metals have different properties that can affect the performance of the

sintered metal filter. For example, stainless steel is corrosion-resistant and has a high melting point, while

aluminum is lightweight and has good electrical conductivity.

2. Specifying the pore size and shape:

Sintered metal filters can be designed with pores of different sizes and

shapes to suit different filtration needs. For example, a filter with smaller pores will be more effective at removing

smaller particles, while a filter with larger pores may be more suitable for high flow rates.

3. Varying the filter media thickness:

The thickness of the filter media can also be adjusted to suit specific

application requirements. Thicker media can provide greater filtration efficiency but may also result in higher

pressure drop and reduced flow rates.

4. Adjusting the temperature and pressure conditions:

Sintered metal filters can be designed to withstand specific

temperature and pressure conditions, depending on the application. It is important to consider these factors when

selecting a filter to ensure that it can withstand the system's operating conditions.

To customize a sintered metal filter to meet your specific requirements, consulting with an experienced engineer

or a technical expert in the field may be helpful. They can guide the appropriate design and material selection based

on the specific application requirements.

FAQ for Sintered Metal Filters

1. What is a Sintered Metal Filter ?

A short definition of sintered metal filter: It is a metal filter that uses metal powder particles of the same particle size

to be shaped by a stamping, high-temperature sintering is the process of metallurgy using powder-sized

bodies of different metals and alloys after stamping.

Metallurgy occurs by diffusion at temperatures below the melting point of high-temperature furnaces. The metals and alloys

commonly used today include aluminum, copper, nickel, bronze, stainless steel, and titanium.

There are different processes you can use to form the powder. They include grinding, automation, and chemical decomposition.

More Details about What is Sintered Metal filter, please go and check our this article.

2. Why Use Stainless Steel Metal to Make Filter?

To Choose Stainless Steel Metal as the main materials, just because have many benefits for stainless steel

1. Not easy to rust

2. The sintering temperature does not need to be too high

3. Pores are easy to control during sintering

4. Sintered molding is more durable and not easy to deform

5. Easy to clean

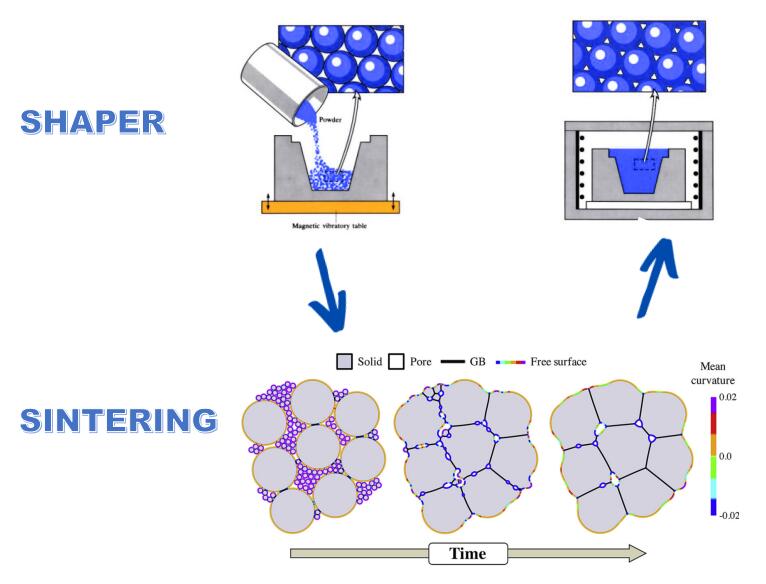

3. How is a Sintered Metal Filter Made ?

For the manufacturing process of Sintered metal filter, main have 3-steps as follow:

A: First step is to get the power metal.

The metal powder, You can obtain metal powders by grinding, automation, or chemical decomposition. You can combine one metal

powder with another metal to form an alloy during the fabrication process, or you can use only one powder. The advantage of sintering is that

it does not change the physical properties of the metal material. The process is so simple that the metal elements are not altered.

B: Stamping

The second step is to pour the metal powder into a pre-prepared mold in which you can shape the filter. The filter assembly is formed at room

temperature and under stamping. The amount of pressure applied depends on the metal you are using, as different metals have different elasticity.

After a high-pressure impact, the metal powder is compacted in the mold to form a solid filter. After the high-pressure impact procedure, you can

place the prepared metal filter in a high-temperature furnace.

C: High-temperature sintering

In the sintering process, the metal particles are fused to form a single unit without reaching the melting point. This monolith is as strong,

rigid, and porous a filter as the metal.

You can control the porosity of the filter by the process according to the flow level of the air or liquid to be filtered.

4. What is the Process of Sintering?

One important step is Sintering, so what is the process of sintering and to be metal filters ?

You can check as follow chart to understand clear.

5. What Are the Main Specifications of Sintered Metal Filter?

After the process of stamping and high temperature sintering, we can get the sintered metal filters, then in

order to know the quality of the sintered filters, normally, we will test some data of the filters, if the data reach

the requirements as the clients asked, then we can release to arrange to shipping out.

1. Porosity

2. Compression test

3. Flow test (gas and liquid)

4. Salt spray test (anti-rust test)

5. Dimensional appearance measurement

If still like to know more about sintered filter working principle, please check our this blog check details.

B: Application of Sintered Metal Filter

6. Where is the Application of Sintered Metal Filters?

As our clients refer some main application of the sintered filter as follow :

1.) Liquid Filtration 2. Fluidizing

3. Sparging 4. Diffusion

5. Flame Arrestor 6. Gas Filtration

7. Food and Beverage

7. Can l Use Sintered Metal Filters with Multiple Types of Oils?

Yes, but need to customize special pore size as the oil , also the flow control requirement, so

you can welcome to contact us to let us know your details.

8. Can a Sintered Metal Filter Continue to Work Even when the Conditions are Freezing?

Yes, for sintered metal filter, such as 316L sintered stainless steel filter can work under

-70 ℃~ +600℃ , so for most of sintered filter can work under freezing. but need to ensure

Liquid and gas can flow under the freezing condition.

9. What Kind of Chemicals Can filter by Sintered Metal Filters and Without Harming the Filter Body ?

We test most of chemicals that can be moved through this particular product without harming it,

such as phenol given that they are made using strong chemical-resistant materials.

1. ) Acid

Strong acids: include sulfuric acid (H2SO4), nitric acid (HNO3), and hydrochloric acid (HCl).

Weak acids in high concentrations, such as acetic acid

B Lewis acid solutions with special chemical properties, such as zinc chloride

2.) Strong Bases:

including sodium hydroxide (NaOH) and potassium hydroxide (KOH)

Alkali metals (such as sodium) in their metallic state Alkali and alkaline earth metal hydrides

High concentrations of weak bases such as ammonia

3.) Dehydrating agents,

including high-concentration sulfuric acid, phosphorus pentoxide, calcium oxide,

zinc chloride (non-solution), and alkali metal elements

4.) Strong oxidizing agents,

including hydrogen peroxide, nitric acid, and concentrated sulfuric acid.

5.)Electrophilic halogens

such as fluorine, chlorine, bromine, and iodine (the ions of halides are not corrosive),

and electrophilic salts such as sodium hypochlorite.

6.) Organic halides or halides of organic acids, such as acetyl chloride and benzyl chloroformate anhydride

7.) Alkylating agents such as dimethyl sulfate

8.) Some organic compounds

10. How to Clean Sintered Metal Filters ?

Proper cleaning is essential to maintain the performance and longevity of sintered metal filters.

Depending on the application—whether for gas or liquid filtration—different cleaning methods can be employed:

1.Blowback for Gas Applications:

*In gas filtration systems, blowback is a common method used to clean sintered metal filters.

This process involves reversing the flow of gas through the filter, dislodging trapped particles,

and clearing the filter media.

2.Backflush for Liquid Applications:

*For liquid filtration systems, backflushing is an effective cleaning method. This process reverses the flow of liquid through the filter to remove accumulated contaminants and restore the filter's performance.

3.Ultrasonic Cleaning:

*Ultrasonic cleaning is used to remove chemically inert materials from the filter. This method utilizes high-frequency sound waves to create microscopic bubbles in a cleaning solution, which effectively dislodge and remove contaminants from the filter surface.

4.Chemical Cleaning:

To remove stubborn contaminants, chemical cleaning methods can be employed. These may include:

*Solvent Cleaning:

Using appropriate solvents to dissolve and remove organic contaminants.

*Caustic Wash:

Utilizing alkaline solutions to break down and remove organic and inorganic materials.

*Acid Wash:

Acidic solutions are used to dissolve mineral deposits or oxides.

Water and Air Flush:

A combination of water and air flushing can be used to remove residues and ensure the filter is thoroughly cleaned.

These cleaning methods help to extend the life of sintered metal filters, ensuring they continue to provide efficient

and reliable filtration in various applications.

C: Order Information Sintered Metal Filter

10. Can l Customize sintered metal filter when Ordering from HENGKO?

Yes, Sure .

We Can O.E.M Sintered Metal Filters as your as follow specification requirements list :

1. Pore Size

2. Micron Rating

3. Flow Rate

4. Filter media you will use

5. Any size as your design

11. What is MOQ to Wholesale sintered metal filter from HENGKO ?

As A Professional Sintered Filter Manufacturer, we have some type for option such as Sintered Filters Disc,

Sintered Filters Tube, Sintered Filters Plate, Sintered Filters Cup, Sintered Filters Mesh, About the M.O.Q

will based on your design size and pore size etc , normal our M.O.Q is about 200 -1000pcs / item based on the design.

12. What makes HENGKO’s sintered metal filters unique?

1.) HENGKO’s sintered metal filters are distinguished by use of proprietary techniques

that guarantee consistent pore sizes and exceptional structural integrity.

2.) Moreover, HENGKO offers extensive customization options, allowing clients to tailor

the porosity, material, and design to perfectly match their specific application needs.

Case Study :

1. Case Study Spotlight: Industrial Gas Filtration

Improved Performance in Industrial Gas Filtration with Customized Sintered Metal Filters

Challenge:

An industrial gas processing plant faced issues with reduced efficiency in its filtration system,

leading to frequent maintenance and unexpected downtime.

The existing filters were unable to handle the high particle load, resulting in clogging and decreased flow rates.

Solution:

HENGKO’s experts recommended replacing the existing filters with custom-designed sintered metal filters tailored

for high particle load applications. These filters featured an optimized pore structure and enhanced durability,

specifically engineered to handle the demands of industrial gas filtration.

Result:

The new sintered metal filters were integrated seamlessly into the existing system, significantly reducing clogging

issues and maintenance frequency.

The improved filters provided a 30% increase in flow rate and enhanced overall system performance.

By adopting HENGKO’s custom sintered metal filters, the industrial gas processing plant experienced a marked

improvement in filtration efficiency, extended filter lifespan, and reduced operational downtime.

The solution not only improved productivity but also contributed to a more cost-effective operation by minimizing

maintenance expenses and ensuring uninterrupted system performance.

Still Have Questions and Like to Know More Details For the Sintered Metal Filter, Please feel Free To Contact Us Now.

Also You Can Send Us Email Directly As Follow : ka@hengko.com

We Will Send Back With 24-Hours, Thanks for Your Patient !