0.5 5 10 micron filter sintered filter cartridge for lead-free reflow oven

A nitrogen shield in the soldering area of the jet soldering machine, with a first nitrogen dispersion tube provided in front of the first nozzle of the jet soldering machine and a second nitrogen dispersion tube provided at the rear of the second nozzle of said jet soldering machine.

A nitrogen shield in the soldering area of the jet soldering machine, with a first nitrogen dispersion tube provided in front of the first nozzle of the jet soldering machine and a second nitrogen dispersion tube provided at the rear of the second nozzle of said jet soldering machine.

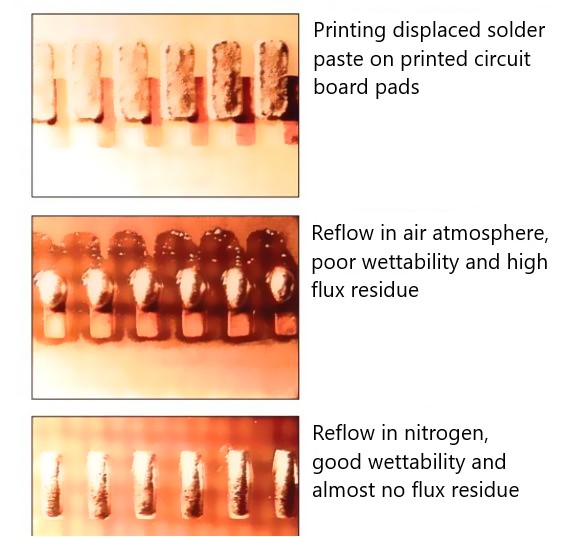

The first nitrogen-sintered filter cartridge, the second nitrogen-sintered filter cartridge, and the third nitrogen-sintered filter cartridge have several gas holes for emitting nitrogen. The sintered filter cartridge with the constant song is used; when working, the nitrogen gas heated to a preset temperature is made to be injected from the air holes of each of the three nitrogen diffusion tubes to diffuse throughout the soldering area, providing nitrogen protection, thereby reducing the oxygen content in the soldering area and achieving the purpose of reducing the generation of trash due to the oxidation of the tin material.

TYPICAL APPLICATIONS

- Water Treatment (PH Control)

- Biofuel/Fermentation (Oxygenation)

- Wine Production (O2 Stripping)

- Beer Production (Carbonation)

- Chemical Production (Volatile Stripping/Reactions)

- Mining (Agitation)

Sintered 0.5 7 10 15 30 60 microns porous metal stainless steel filter capillary tube for lead-free reflow oven

Currently, the existing jet soldering equipment is not installed as a nitrogen protection device in the welding process, which quickly leads to the oxidation of electronic components' solder foot. The welding process stomata produce spot residues, and tin surface oxidation intensified, tin dross and tin insoluble matter increased, seriously limiting the welding quality and manufacturing costs.