-

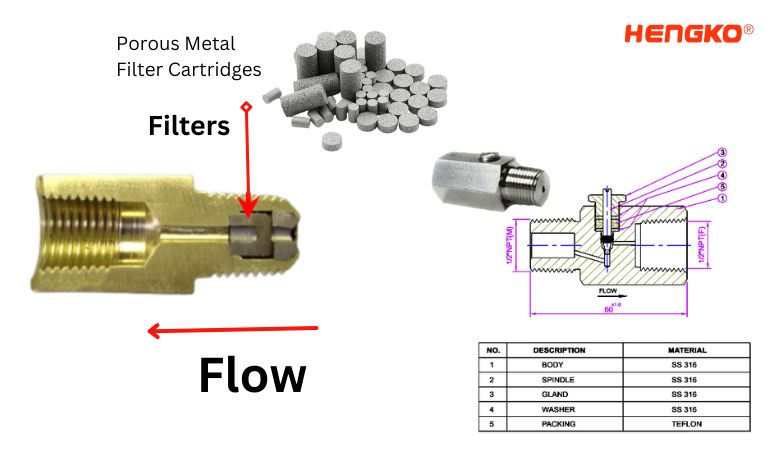

Porous metal snubbers eliminating variations in line pressure caused by hydraulic or pn...

HENGKO manufactures filter elements in a broad range of materials, sizes, and fittings so they can be easily specified with the characteristics and configura...

View Detail -

Corrosion-resistant soundproof intake air snubbers & breather vents, sintered bras...

Pneumatic Sintered Mufflers Filters utilize porous sintered bronze filter elements secured to standard pipe fittings. These compact and inexpensive mufflers ...

View Detail

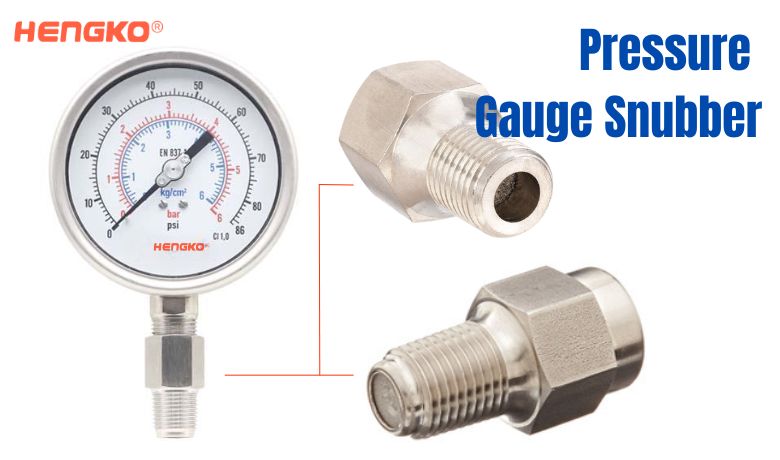

What is Pressure Gauge Snubber ?

In Short, A pressure gauge snubber is a small device that is installed in line between a pressure gauge and the process piping system .

It is used to dampen the effects of rapid pressure fluctuations, pulsations, and vibrations that can be present in a process stream.

These fluctuations can cause the pressure gauge needle to vibrate or bounce, making it difficult to read the pressure accurately.

In severe cases, they can also damage the pressure gauge mechanism.

Pressure gauge snubbers work by restricting the flow of pressure to the gauge. This restriction slows down the rate at which pressure changes can reach the gauge, thereby damping out the fluctuations. There are two main types of pressure gauge snubbers: restrictor and orifice type, and porous media type.

*Restrictor and orifice type snubbers use a small orifice or a narrow passage to restrict the flow of pressure.

The size of the orifice is typically sized based on the pressure gauge and the process conditions.

*Porous media type snubbers use a porous element, such as a sintered metal disc, to restrict the flow of pressure.

The porosity of the element determines the amount of restriction.

Pressure gauge snubbers are typically used in applications where there are rapid pressure fluctuations, such as:

*Reciprocating pumps and compressors

*Hydraulic systems

*Pipelines with pulsating flow

*Systems with pressure surges

Types of Pressure Gauge Snubber and How to Choose ?

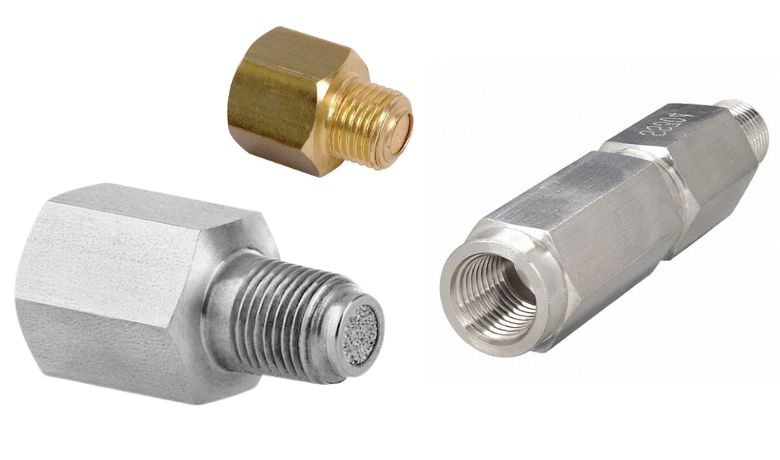

The best type of pressure gauge snubber for your application will depend on a few factors, including the fluid being used, the pressure range, and the amount of pulsation. Here's a breakdown of the three types you mentioned:

Porous Disc Type Snubber:

*This is the simplest and most economical type of snubber.

*It consists of a housing with a fine mesh disc that restricts the flow of fluid to the pressure gauge.

Porous disc type snubber

*Pros:

- Low cost

- Easy to install and maintain

- Wide range of applications

*Cons:

- Can clog with debris over time

- Not as effective for high pressure applications or applications with large amounts of pulsation

2. Piston-type snubber:

This type of snubber uses a free-floating piston to restrict the flow of fluid to the pressure gauge.

As pressure increases, the piston moves to block the flow path, dampening pressure spikes.

Piston type snubber

*Pros:

- More effective for high pressure applications and applications with large amounts of pulsation

- Self-cleaning - debris is flushed through the snubber as the piston cycles

*Cons:

- More expensive than porous disc type snubbber

- May not be suitable for all fluids (e.g., viscous fluids)

3. Adjustable pressure gauge snubber:

*This type of snubber allows you to adjust the amount of restriction on the flow of fluid to the pressure gauge.

*This can be useful for applications where the amount of pulsation varies.

Adjustable pressure gauge snubber

*Pros:

-Most versatile type of snubber

-Can be adjusted to meet the specific needs of the application

*Cons:

-Most expensive type of snubber

-More complex to install and maintain

Here We Make a table summarizing the key differences between the three types of snubbers:

| Feature | Porous Disc | Piston-Type | Adjustable |

|---|---|---|---|

| Type of restriction | Mesh disc | Free-floating piston | Needle valve |

| Cost | Low | Medium | High |

| Ease of use | Easy | Easy | More complex |

| Suitability for high pressure | Limited | Good | Good |

| Suitability for pulsating flow | Limited | Good | Good |

In general, a porous disc type snubber is a good choice for most applications.

However, if you are working with high pressure or pulsating flow, a piston-type snubber

may be a better option. An adjustable pressure gauge snubber is the most versatile option,

but it is also the most expensive.

For more information or to discuss your specific OEM Pressure Gauge Snubber requirements,

please contact us at ka@hengko.com.

We look forward to providing you with tailored solutions for your pressure gauge system.