-

Customized Size 316 Stainless Steel Filter for Medical Micro Capillary Tube of Fluid Be...

Product Describe The micron sintered filter cartridge is connected to the gas flow control board through the nitrogen input cartridge. The sintered filter ca...

View Detail -

Sintered filter cartridge quality guarantee cold drawn seamless stainless steel filter ...

Product Describe HENGKO stainless steel filter tubes are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures....

View Detail -

Stainless steel sintered porous micro air nano filter capillary tube for gas diffusion ...

Wave welding nitrogen sintered filter cartridge product content: can make the airflow uniform distribution, for wave welding nitrogen modification customers ...

View Detail -

Custom stainless steel 316L nitrogen gas filter tube for multipurpose filtration

HENGKO stainless steel filter tubes are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been w...

View Detail -

Professional Manufacturer Customized nano capillary nitrogen tube for lead-life reflow ...

HENGKO stainless steel filter tubes are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been w...

View Detail -

Customized size 316 stainless steel filter medical micro capillary tube for wave solder...

HENGKO stainless steel filter tubes are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been w...

View Detail -

Sintered 0.5 7 10 15 30 60 micron porous metal stainless steel filter capillary tube fo...

HENGKO stainless steel filter tubes are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been w...

View Detail -

OEM Industrial sintered metal porous filter tube, porosity 15 20 50 60 90 120 micron

HENGKO stainless steel filter tubes are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been w...

View Detail -

HENGKO stainless steel porous powder filter tube for throttle valve filter

HENGKO® stainless steel filter tubes are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been ...

View Detail -

sintered stainless steel powder metal filter tube -Anti-Corrosion & Long Service Life

HENGKO stainless steel filter tubes are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been w...

View Detail -

Long service life professional made 304 316 316L microporous powder sintered stainless ...

HENGKO stainless steel filter tubes are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been...

View Detail -

Big batches 10 25 micron Sintered porous metal medical stainless steel capillary tube

HENGKO stainless steel filter tubes are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been w...

View Detail -

40-50 um micron pore grade sintered porous metal SS stainless steel filter tube

HENGKO Sintered metal filter, components are manufactured with a controlled amount of porosity throughout the part to facilitate specific pressure flow contr...

View Detail -

5 25 microns sintered stainless steel 316L porous powder metal precise air filter tube

HENGKO stainless steel filter tubes are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been...

View Detail -

micron stainless steel sintered porous metal hydraulic filters tubes

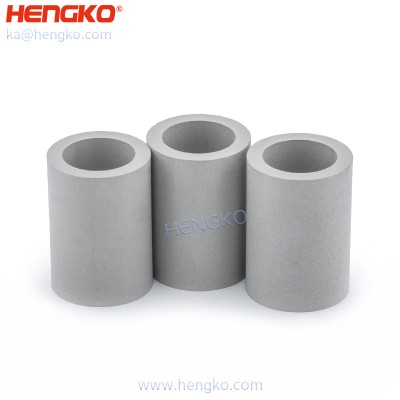

HENGKO porous filter tubes can be hollow or blind and have a minimum wall thickness of 1 mm. They are made by isostatic compaction of powder in a flexible mo...

View Detail -

Custom sintered porous metal 2 5 10 20 25 microns stainless steel 304/316L filter tube ...

Stainless Steel Sintered Filter Cartridge is specifically designed to optimize particulate capture through its asymmetrical pore structure. This structure p...

View Detail -

customized stainless steel 316 316L wire mesh tube / cartridge filter used for medical ...

HENGKO sintered wire mesh tube/cartridge filters are usually used for purification and filtration of liquid and gas, separation and recovery of solid particl...

View Detail -

Customized micron sintered porous metal stainless steel cylinder mesh filter tube for o...

Sinter wire mesh filters are usually used for purification and filtration of liquid and gas, separation and recovery of solid particles, transpiration coolin...

View Detail -

Sintered stainless steel wire mesh filter tube (filter cylinder) used in petroleum, che...

Sinter wire mesh filters are usually used for purification and filtration of liquid and gas, separation and recovery of solid particles, transpiration coolin...

View Detail -

Medical chemical liquid oil and gases 3um-90 microns powder porous all-metal steam sint...

HENGKO porous filter tubes can be hollow or blind and have a minimum wall thickness of 1 mm. They are made by isostatic compaction of powder in a flexible mo...

View Detail

Why Use Porous Metal Tube ?

There are several key reasons why sintered metal tube are used in various applications:

Filtration:

* Their primary function is filtration. The precisely controlled pore size allows them to remove impurities,

particles, and contaminants from fluids and gases. This can be crucial in industries like pharmaceutical,

chemical processing, and food and beverage, where purity is essential.

* Pore sizes can range from submicron to several millimeters, enabling them to filter out a wide range of particle sizes.

Controlled Flow:

* The porous structure allows for controlled flow of liquids and gases.

This can be used for aeration, gas distribution, fluidization, and other applications where precise control of flow is necessary.

* The uniform pore distribution ensures consistent flow throughout the tube, preventing channeling and uneven pressure distribution.

Durability and Strength:

* Made from metals like stainless steel, nickel, or bronze, porous metal tubes are highly durable and can withstand harsh operating

conditions, including high temperatures, pressures, and corrosive environments.

* This makes them suitable for long-term use in demanding industrial applications.

Other benefits:

* Porous metal tubes are also lightweight, easily cleaned, and recyclable. They can be readily machined and shaped into various forms,

further expanding their versatility.

Here are some specific examples of applications where porous metal tubes are used:

* Air diffusers: in wastewater treatment plants to introduce oxygen into the water for bacterial growth.

* Fuel filters: in automobiles and other vehicles to remove impurities from fuel.

* Medical implants: for bone ingrowth and drug delivery.

* Catalyst supports: in chemical reactors to hold and distribute catalysts.

* Silencers: in exhaust systems to reduce noise.

Ultimately, the specific reasons why someone would choose a porous metal tube depend on the specific application

and its requirements. However, their unique combination of filtration, controlled flow, durability, and other benefits

make them a valuable tool for a wide range of industries.

Main Function

The sintered metal tube is almost same function with other sintered metal filters or sintered metal sparger.

The main function of porous metal tubes is to provide efficient and reliable filtration, separation, and control

of fluid and gas flow.

These porous metal tubes are made from quality 316L SS metal particles that are fused together through a sintering

process, creating a structure with interconnected pores. The unique characteristics of porous metal tubes

enable them to serve several essential functions:

1. Filtration:

The primary purpose of porous metal tubes is to act as filters, removing impurities, particles, and contaminants from fluids and gases.

The precise control of pore size allows them to achieve fine filtration down to submicron levels, ensuring the purity of the medium being processed.

2. Gas and Liquid Dispersion:

Porous metal tubes are used to disperse gases or liquids evenly and uniformly. By controlling the pore size and distribution,

they can create a uniform flow pattern, preventing channeling and improving dispersion efficiency.

3. Fluidization:

In fluidized bed applications, these tubes are employed to fluidize solid particles, creating a suspended fluid-like state.

The uniform distribution of pores aids in achieving efficient and controlled fluidization.

4. Venting and Pressure Equalization:

Porous metal tubes are utilized for venting gases, equalizing pressure, or relieving vacuum conditions in various systems

and devices. They enable the passage of air or gas while preventing the entry of contaminants.

5. Noise Reduction:

In some applications, porous metal tubes are utilized as silencers or mufflers to reduce noise levels generated by the flow of gases or fluids.

6. Diffusion:

Porous metal tubes facilitate gas or liquid diffusion processes by allowing molecules to pass through their interconnected pores.

This property finds application in various fields, such as catalysis and mass transfer operations.

7. Support and Distribution:

In certain industries, porous metal tubes act as support structures for catalysts or other substances, providing a stable

framework and aiding in uniform distribution.

Due to their high porosity, durability, chemical resistance, and controllable pore structures, porous metal tubes find extensive

use in industries such as pharmaceuticals, petrochemicals, water treatment, automotive, aerospace, and many more,

where efficient filtration and controlled flow processes are crucial for optimal performance and safety.

Working Principle of Sintered Porous Metal Tubes

The working principle of sintered porous metal tubes is based on the unique properties of the sintered metal structure,

which allows for efficient filtration and controlled flow of fluids and gases. Here's an overview of the working principle:

1. Sintering Process:

Porous metal tubes are manufactured through a process called sintering. It involves compacting metal particles, typically

stainless steel or other metal alloys, into a specific shape, such as a tube. The metal particles are heated to a temperature

just below their melting point, causing them to fuse together, forming a solid and interconnected network of pores.

2. Pore Structure:

The sintered metal tubes have a defined pore structure due to the arrangement of metal particles during the sintering process.

The size, shape, and distribution of these pores can be precisely controlled during manufacturing to meet specific filtration requirements.

3. Filtration:

The primary function of sintered porous metal tubes is filtration. When a fluid or gas passes through the tube, contaminants,

particles, and impurities are captured within the pores. The pore size is designed to allow the desired fluid or gas to pass through

while blocking the unwanted substances.

4. Filtration Efficiency:

The filtration efficiency of sintered porous metal tubes depends on the pore size and the total surface area available for filtration.

Smaller pore sizes can capture finer particles, offering higher filtration efficiency.

5. Flow Control:

The interconnected pore structure of the sintered metal tubes enables precise control over fluid or gas flow. The size and

distribution of the pores influence the flow rate and pressure drop across the tube. This property is crucial in applications

where uniform flow distribution or controlled fluidization is required.

6. Durability and Resistance:

Sintered metal tubes are durable and resistant to mechanical stress, chemicals, and high temperatures. The sintering

process ensures that the metal particles are firmly bonded, providing structural integrity even under challenging operating conditions.

7. Reusability and Cleanability:

Sintered porous metal tubes can be easily cleaned and reused. They can withstand various cleaning methods,

such as backwashing, ultrasonic cleaning, or chemical cleaning, without compromising their filtration efficiency.

The working principle of sintered porous metal tubes makes them highly versatile and suitable for a wide range of

applications in industries such as petrochemicals, pharmaceuticals, water treatment, aerospace, and more. They are

chosen for their efficient filtration, durability, and ability to withstand harsh environments, providing reliable performance

in critical processes and systems.

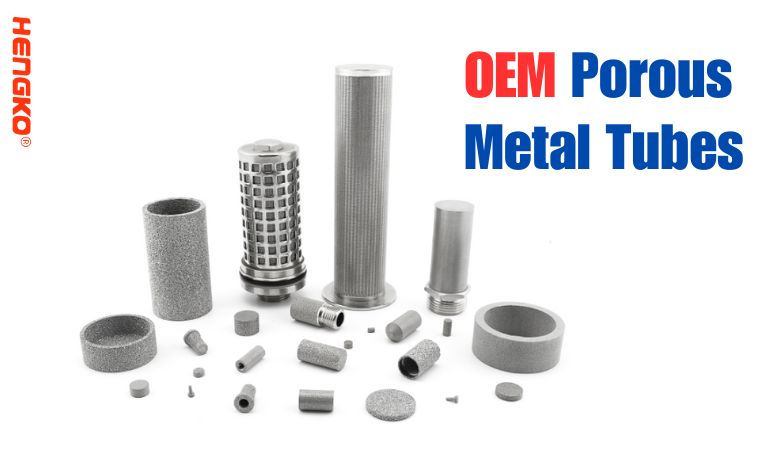

What You Should Care OEM Porous Metal Tubes ?

When considering OEM special porous metal tubes for your filtration system or projects, there are several

essential factors to take into account to ensure optimal performance and a successful implementation.

Here are some key considerations:

1. Filtration Requirements:

Clearly define the specific filtration requirements for your application. Determine the desired filtration efficiency,

pore size, and flow rate needed to achieve the desired results.

2. Fluid or Gas Characteristics:

Understand the properties of the fluid or gas to be filtered, including temperature, pressure, viscosity, and chemical

compatibility. Ensure that the selected porous metal material can withstand the intended operating conditions.

3. Pore Size and Structure:

Work with the OEM manufacturer to customize the pore size and structure of the porous metal tubes to match your

application's needs. Consider the particle size of contaminants to be removed and the desired flow characteristics.

4. Material Selection:

Choose the appropriate metal material based on its chemical resistance, mechanical properties, and compatibility with

the medium being filtered. Common materials include stainless steel, bronze, nickel, and titanium.

5. Design and Geometry:

Collaborate with the OEM manufacturer to design the tube's shape and dimensions to fit your system or project.

Consider factors such as length, diameter, and end connections for easy integration.

6. Filtration Efficiency and Pressure Drop:

Balance the filtration efficiency with the pressure drop across the porous metal tubes. Higher filtration efficiency may

lead to increased pressure drop, which could affect system performance.

7. Cleanability and Maintenance:

Discuss the cleanability and maintenance requirements of the porous metal tubes. Ensure they can be easily cleaned

and reused to optimize the lifespan and reduce downtime.

8. Customization and Expertise:

Work with an experienced OEM manufacturer with a proven track record in producing specialized porous metal tubes.

They should have the expertise to customize the tubes according to your unique needs.

By carefully considering these factors and collaborating closely with the OEM manufacturer, you can ensure that the

OEM special porous metal tubes are designed and tailored to meet your filtration system or project's unique needs,

ultimately leading to improved efficiency, reliability, and performance.

FAQ

1. What are the key features of porous sintered metal tubes?

Porous sintered metal tubes offer several key features that make them unique and highly advantageous for

various applications. These features include:

*High Filtration Efficiency:

The precise control of pore size allows for effective filtration down to submicron levels,

ensuring the removal of contaminants and impurities from fluids and gases.

*Durability and Strength:

Sintering process bonds metal particles, providing mechanical strength and resistance

to deformation, even under harsh conditions.

*Wide Temperature and Pressure Range:

The tubes can operate in extreme environments, maintaining structural integrity and filtration

efficiency across a broad range of temperatures and pressures.

*Chemical Compatibility:

They are chemically inert and resistant to corrosion, making them suitable for filtering aggressive

chemicals and corrosive media.

*Cleanability and Reusability:

Porous sintered metal tubes can be easily cleaned and reused multiple times, reducing maintenance

costs and extending the filter's lifespan.

2. How do porous sintered metal tubes function as filters?

The functioning of porous sintered metal tubes as filters is based on their interconnected pore structure.

When a fluid or gas flows through the tube, contaminants and particles are captured within the pores

while allowing the desired medium to pass through. The size, distribution, and arrangement of pores

determine the filtration efficiency and the type of particles that can be removed. The sintered metal's high

porosity and fine pores enable effective filtration, making these tubes ideal for critical applications where

precise and reliable filtration is required.

3. What are the considerations for installing porous sintered metal tubes in a system?

Proper installation is crucial to ensure the optimal performance of porous sintered metal tubes. Some considerations include:

*Proper Sealing:

Ensure secure and leak-free connections at both ends of the tube to prevent bypass and maintain filtration efficiency.

*Orientation:

Position the tube correctly to ensure the flow direction aligns with its designed function, whether it's for filtration, venting, or fluidization.

*Support and Protection:

Provide adequate support and protection to prevent damage to the tubes during installation and operation.

4. In which applications can porous sintered metal tubes be used?

Porous sintered metal tubes find applications across various industries, including:

Petrochemicals and Refining: For catalyst support, filtration of process fluids, and gas diffusion applications.

Pharmaceuticals: In sterile venting, gas filtration, and drug delivery systems.

Water Treatment: For wastewater treatment, aeration, and filtration of potable water.

Aerospace: In fuel and hydraulic systems for filtration and venting.

Automotive: In emission control, fuel filtration, and lubrication systems.

Food and Beverage: For beverage carbonation, aeration, and steam filtration.

5. How do porous sintered metal tubes contribute to system efficiency and performance?

Porous sintered metal tubes enhance system efficiency and performance by:

*Ensuring high filtration efficiency, leading to cleaner and more purified fluids or gases.

*Providing a uniform flow distribution, preventing channeling or uneven pressure distribution.

*Withstanding harsh conditions, reducing downtime and maintenance costs.

*Facilitating gas diffusion and fluidization processes, optimizing chemical reactions and mass transfer operations.

6. What quality control measures are employed during the manufacturing of porous sintered metal tubes?

HENGKO as a Top Sintered Metal Filter manufacturers implement stringent quality control measures throughout the manufacturing process. This includes:

*Material Quality: Using high-grade metal particles to ensure mechanical strength and chemical resistance.

*Pore Size Control: Precise control of sintering parameters to achieve the desired pore size and distribution.

*Dimensional Accuracy: Ensuring tight tolerances to meet customer specifications.

*Performance Testing: Conducting filtration efficiency tests, pressure drop assessments, and mechanical strength evaluations.

Don't hesitate to reach out to us for a consultation and let us help you optimize your filtration system or project.

Email us at ka@hengko.com now and take the first step towards enhanced efficiency and performance with

HENGKO's Quality Sintered metal tube.