-

Biopharmaceutical purification and filtration porous filter plate 10um 20um 50um

A porous filter plate is a new type of high-efficiency porous filter material made of metal stainless steel powder through powder sieving, moulding, sinterin...

View Detail -

Sintered Copper Bronze Grounding Plate

Deters Electrolysis and Galvanic CorrosionReduces RF Interference and Improves Electronics Performance Better reception for your GPS devices, weather ...

View Detail -

sintered metal round depth filter sheets for cannabis oil production

Filtration In the production of stable cannabinoid products filtration is an essential step. To remove the waxes, fats and oil from the winterization a multi...

View Detail -

Stainless Steel Porous Metal Sheets SS316 Filter for Hydrogen Gas Diffusion

Stainless Steel Porous Metal Sheets SS316 Filter for Hydrogen Gas Diffusion Unlock the Versatility of Sintered Metal Elements with HENGKO! Our sintered meta...

View Detail -

Gas Diffusion Layers Sheet for MEAs, stainless steel porous metal sintered / wire mesh ...

HENGKO stainless steel filter plates are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been ...

View Detail -

Multi-layer sintered stainless steel mesh plate fluidized bed equipment Distributor bot...

Stainless steel mesh plate for fluid bed Control of gas distribution, powdered material transmission, and fluidization operation has been widely used in indu...

View Detail -

316 304 stainless steel plate – Sintered porous metal filter alien media

HENGKO stainless steel plate filters are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been ...

View Detail -

Corrosion resistant microns 316L stainless steel porous sintered filter metal sheets / ...

Product Describe HENGKO porous metal gas diffusion layers are the leading choice for high performance electrolyzer and fuel cell applications. The uniform po...

View Detail -

Easy Clean Micron Porous SUS Sintered 316L Stainless Steel Inline Metal Sheet Plate Rou...

The sintered porous metal sheets having high porosity were obtained from metallic powders by free spreading methods followed by sintering. The sintered struc...

View Detail -

0.2 5 10 40 Micron porous sintered powder stainless steel 316L metal plate filter for c...

The porous materials sintered plates obtained in layers by free spreading, compaction, and sintering metallic powders are used as a semi-product to obtain fi...

View Detail -

Customized 2 10 20 60 Micron Porous Sintered Stainless Steel 316L Metal Plate Filter

Depth filter sheets are used to remove particles from liquids. This means that liquids can be clear-, fine- or sterile-filtered. Filter sheets are ideal for ...

View Detail -

5 10 30 60 90 microns powder micro porous sintered metal sheet filter

Sintered metal filter sheets are widely used for removing foreign particles from many different kinds of flow media. Major application fields: General gases,...

View Detail -

HENGKO sintered stainless steel 316 porous metal gas diffusion layers filter sheet for ...

HENGKO stainless steel sintered wire mesh filter plate is made from multiple layers of woven wire mesh panel together using a sintering process. This process...

View Detail -

Medical grade micron stainless steel 316 316L wire mesh multi-layer plate / disc filter...

HENGKO sintered wire mesh filters have 5 sintered wire mesh layers with self-supporting construction for high mechanical strength and high-temperature resist...

View Detail -

Uniform strength sintered porous metal micron filter fluidizers bronze brass copper fil...

Depth filter sheets are used to remove particles from liquids. This means that liquids can be clear-, fine- or sterile-filtered. Filter sheets are ideal for ...

View Detail -

Flow control and fluid distribution sintered filter plate/sheet, powder sintered porous...

Depth filter sheets are used to remove particles from liquids. This means that liquids can be clear-, fine- or sterile-filtered. Filter sheets are ideal for ...

View Detail -

Porous metal sintered porous bronze filter plates/sheet for flow and sound control

Depth filter sheets are used to remove particles from liquids. This means that liquids can be clear-, fine- or sterile-filtered. Filter sheets are ideal for ...

View Detail -

porous metal filter disc square strainer micron sintered bronze filter sheet

HENGKO manufactures filter elements in a broad range of materials, sizes, and fittings so they can be easily specified with the characteristics and configura...

View Detail -

hepa sintered bronze stainless steel porous metal filter sheet for air/oil filter machine

HENGKO manufactures filter elements in a broad range of materials, sizes, and fittings so they can be easily specified with the characteristics and configura...

View Detail -

Custom sintered powder metal fitler sheet microns porosity bronze filter sheets for wat...

HENGKO manufactures filter elements in a broad range of materials, sizes, and fittings so they can be easily specified with the characteristics and configura...

View Detail

Main Features of Porous Metal Plate:

The main features of porous metal sheets include:

1.High Durability:

Porous metal sheets are made from robust materials like stainless steel, titanium, or nickel alloys,

providing excellent mechanical strength and resistance to corrosion, wear, and high temperatures.

| Material | Mechanical Strength | Corrosion Resistance | Wear Resistance | Temperature Resistance | Applications |

|---|---|---|---|---|---|

| Stainless Steel | High | High | High | Excellent (up to 800°C) | Filtration, chemical processing, oil & gas, pharmaceuticals |

| Titanium | Medium | Very High | Medium | Excellent (up to 600°C) | Aerospace, marine environments, medical applications |

| Nickel Alloys | Very High | Excellent | High | Superior (up to 1000°C) | High-temperature filtration, chemical processing, power generation |

2.Precise Filtration Control:

The controlled pore size and uniform distribution allow for precise filtration, offering consistent

performance across a wide range of applications.

3.Customizable Porosity:

Porous metal sheets can be customized in terms of pore size, shape,

and distribution, providing flexibility to meet specific filtration or flow requirements.

4.High Permeability:

Despite their strength, porous metal sheets allow for high permeability, ensuring

efficient flow rates for gases and liquids while maintaining filtration efficiency.

5.Chemical Compatibility:

These sheets are compatible with a wide range of chemicals, making them

ideal for use in harsh environments, including chemical processing and pharmaceutical industries.

6.Heat and Pressure Resistance:

The materials used in porous metal sheets can withstand extreme

temperatures and pressures, ensuring stability and reliability in demanding applications.

7.Low Maintenance and Long Lifespan:

Porous metal sheets are highly durable and resistant to clogging,

reducing the need for frequent maintenance and replacement, thus extending their service life.

8.Thermal and Electrical Conductivity:

In addition to filtration, porous metal sheets can also serve as thermal

and electrical conductors, broadening their application range.

These features make porous metal sheets ideal for applications in filtration, flow control, catalyst supports,

and separation processes in a variety of industries, such as aerospace, chemical processing, pharmaceuticals,

and environmental engineering.

Based on those Features,

How Can Porous Metal Sheets / Porous Sintered Stainless Steel Sheets Optimize Your Industrial Process?

If your industrial process involves filtration, fluid control, thermal management, or mechanical support, then porous metal sheets, especially porous sintered stainless steel sheets, are the perfect solution for you. Here’s how they can enhance your production efficiency and equipment stability:

1. High-Efficiency Filtration & Separation

*Gas & Liquid Filtration: Remove impurities and improve product purity in industries such as chemical processing, pharmaceuticals, and food production.

*Dust & Fume Collection: Effectively used in air purification and industrial exhaust systems.

*Oil & Water Separation: Enhance wastewater treatment and petroleum refining while improving environmental compliance.

2. Fluid Control & Pressure Regulation

*Gas Diffusion & Distribution: Ensure uniform airflow in applications like fuel cells, gas sparging, and aeration systems, improving efficiency.

*Pressure Equalization: Prevent equipment failure caused by pressure fluctuations in precision manufacturing and aerospace.

3. High-Temperature Resistance & Thermal Management

*Heat Exchange Systems: Improve cooling and heat dissipation in power plants, industrial furnaces, and high-temperature processing.

*Catalyst Support: Provide a stable structure for high-temperature catalytic reactions in petrochemical industries.

4. Noise & Vibration Reduction

*Noise Control: Reduce noise in automotive and industrial equipment, enhancing workplace comfort.

*Shock Absorption: Minimize mechanical vibration, extending equipment lifespan.

5. Structural Support & Mechanical Protection

*High Strength & Corrosion Resistance: Withstand acidic, alkaline, and high-pressure environments, ensuring long-term operational stability.

*Sensor & Electronics Protection: Serve as enclosures or protective layers for sensitive instruments, improving durability.

6. Customization to Meet Your Specific Needs

*Available in various pore sizes, thicknesses, and material compositions, allowing precise adaptation to your application requirements.

If you're looking for the best porous metal sheet solution for your industrial process, contact us today for expert recommendations!

Types of Porous Metal Sheet ?

Actually there are two main types of porous metal sheets you can find

in the porous metal sheet market :

1. Sintered metal sheets:

These are made by compacting and sintering metal powders. The pores in these sheets are typically

interconnected and can vary in size and shape. Sintered metal sheets are often used in applications

where high strength and good filtration are required, such as in filters, heat exchangers, and sound dampeners.

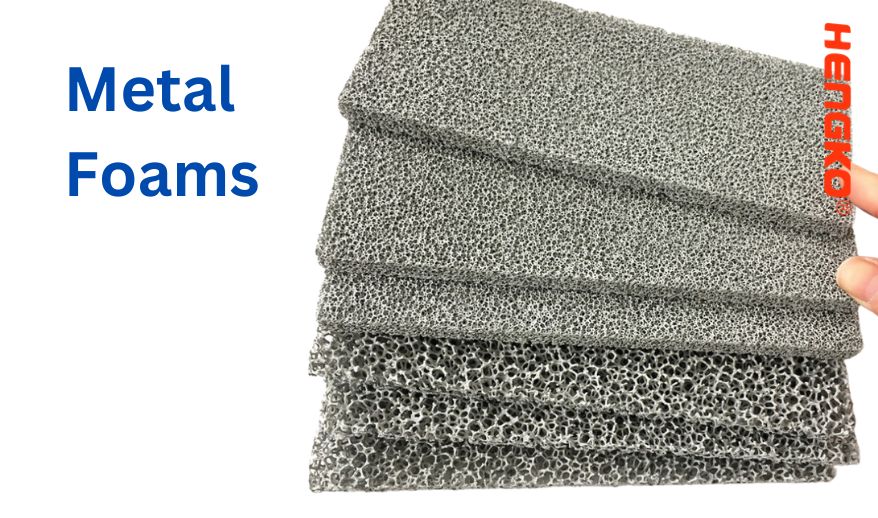

2. Metal Foams:

Metal foams are made by introducing gas bubbles into a molten metal and allowing it to solidify.

The pores in these sheets are typically closed-cell, meaning they are not interconnected. Metal foams are

often used in applications where lightweight and high strength are required, such as in aerospace and

automotive applications.

Here are some other types of porous metal sheets:

1. Woven wire mesh:

This type of mesh is made by weaving together thin wires. The pore size in woven wire mesh

can be controlled by the size of the wires and the weaving pattern. Woven wire mesh is often

used in applications where filtration and good flow properties are required, such as in screens and filters.

2. Expanded metal:

This type of sheet is made by slitting a solid sheet of metal in a specific pattern and then stretching it.

The pores in expanded metal are typically elongated and diamond-shaped. Expanded metal is often

used in applications where light weight and good strength are required, such as in safety guards and walkways.

Application of Sintered Porous Metal Sheet

Sintered porous metal sheets are a versatile filtration media due to their unique properties.

Here are some of the applications you may used to :

* High-Temperature Environments:

* Harsh Chemical Environments:

* High-Pressure Applications:

* Need for Precise Particle Control:

* Reusability and Regenerability:

Also Here are some industries that would particularly benefit from using sintered porous metal sheets in their filtration systems, you

can check if will be good for your system or device ?

* Chemical Processing - For filtering corrosive liquids and gases, and catalysts from process streams.

* Power Generation - High-temperature filtration of gases in power plants.

* Pharmaceutical Industry - Ensuring sterility and purity of products by removing bacteria and particulates.

* Food & Beverage Industry - Filtration for clarifying liquids, and removing unwanted particles.

* Water Treatment - Contribuing to purification processes by removing impurities from water.

Overall, sintered porous metal sheets are a valuable tool for industrial filtration applications requiring durability, high-temperature resistance, precise filtration, and reusability.

FAQ

1. What is a porous metal sheet, and how is it made?

A porous metal sheet is a type of material characterized by its permeable structure, made up of

interconnected pores or voids throughout its mass. These sheets are primarily produced through

a process known as sintering. Sintering involves compacting metal powder in a mold and then heating

it below its melting point. This heat treatment causes the metal particles to bond together without liquefying,

creating a solid structure with precisely controlled porosity.

The process allows for the manufacturing of sheets with varying pore sizes, shapes, and distribution,

tailored to specific applications. Sintered stainless steel sheets, for example, are widely used due to

their excellent mechanical properties, resistance to corrosion, and thermal stability.

2. What are the main applications of sintered stainless steel sheets?

Sintered stainless steel sheets are utilized in a wide range of applications due to their versatility and durability.

Some of the key applications include:

* Filtration:

Used in both gas and liquid filtration systems, they effectively remove particulate matter

due to their precise pore size.

* Sparging and Diffusion:

Ideal for gas-liquid reactions, aeration, and in brewing processes, where controlled

bubble size is crucial.

* Fluidization:

Employed in fluidized beds for various chemical processes, aiding in the even distribution

of gases through liquids or powders.

* Sensor Protection:

Shields sensitive components in harsh environments, preventing contamination

while allowing necessary environmental interactions.

* Catalyst Recovery and Support:

Provides an excellent platform for catalyst materials, facilitating

chemical reactions while allowing for easy recovery of precious catalysts.

3. How do you determine the appropriate pore size for a specific application?

Determining the appropriate pore size for a specific application involves considering

several factors, including the nature of the fluids or gases being processed, the types of

particles or contaminants to be removed, and the desired flow rate. For filtration applications,

the pore size is typically chosen to be slightly smaller than the smallest particle that needs

to be filtered out. In applications involving gas diffusion or sparging, the pore size affects the

size of the bubbles produced, which can significantly impact the efficiency of the process.

Consulting with porous metal sheet manufacturers like HENGKO can provide insights based on

extensive experience and technical expertise, ensuring the selection of an optimal pore size

for any given application.

4. What advantages do sintered stainless steel sheets offer over other materials?

Sintered stainless steel sheets offer several advantages over other materials, making them a

preferred choice for many industrial applications:

* Durability:

Their high strength and resistance to wear and tear ensure long service life under challenging conditions.

* Corrosion Resistance:

Stainless steel's inherent corrosion resistance is ideal for use in harsh chemical environments or

where exposure to corrosive elements is common.

* High-Temperature Stability:

They can withstand high temperatures without degrading, making them suitable for use in heat exchangers,

high-temperature filters, and other applications requiring thermal stability.

* Chemical Compatibility:

Stainless steel is compatible with a wide range of chemicals, reducing the risk of material degradation

and contamination.

* Cleanability and Sterilizability:

Their smooth, non-porous surfaces can be easily cleaned and sterilized, crucial in pharmaceutical

and food and beverage applications.

5. Can sintered stainless steel sheets be customized for unique applications?

Yes, sintered stainless steel sheets can be extensively customized to meet unique application requirements.

Customization can include variations in pore size, thickness, sheet size, and shape, as well as the inclusion

of specific alloying elements to enhance particular properties such as conductivity or heat resistance.

Manufacturers like HENGKO specialize in working closely with clients to design and produce bespoke porous metal

solutions that precisely meet the specifications and performance criteria required for their applications.

This level of customization ensures that the final product can perform optimally in its intended environment,

whether it involves unique filtration needs, specialized chemical processing, or any other industry-specific application.

Contact HENGKO

Ready to elevate your industrial application with bespoke porous metal solutions?

Reach out to us at ka@hengko.com and let's turn your challenges into successes.