Metal In-Tank Porous Spargers to Increase Gas Absorption

HENGKO sintered spargers introduce gases into liquids through thousands of tiny pores, creating bubbles far smaller and more numerous than with drilled pipe and other sparging methods. The result is a greater gas liquid contact area, which reduces the time and volume required to dissolve gas into a liquid. We calibrate our spargers to work with a variety of different gases, such as a nitrogen sparger, air sparger, or CO2 sparger. If you require unique specifications for your sparger, we'll work with you to create a custom sparger design solution.

HENGKO sintered spargers introduce gases into liquids through thousands of tiny pores, creating bubbles far smaller and more numerous than with drilled pipe and other sparging methods. The result is a greater gas liquid contact area, which reduces the time and volume required to dissolve gas into a liquid. We calibrate our spargers to work with a variety of different gases, such as a nitrogen sparger, air sparger, or CO2 sparger. If you require unique specifications for your sparger, we'll work with you to create a custom sparger design solution.

with excellent performance of fast flow rate, outstanding aeration effect, high temperature, and pressure resistance, they are widely used for foam kits, fermentation equipment, home brewing device, ozone/oxygen/CO2/N2 diffuser, bioreactor, aquaculture, etc.

Micro spargers from HENGKO reduce bubble size and increase gas transfer to reduce gas consumption and improve upstream reactor yields. Micro spargers can increase mass transfer rates in a standard drilled pipe or single-opening dip tubes.

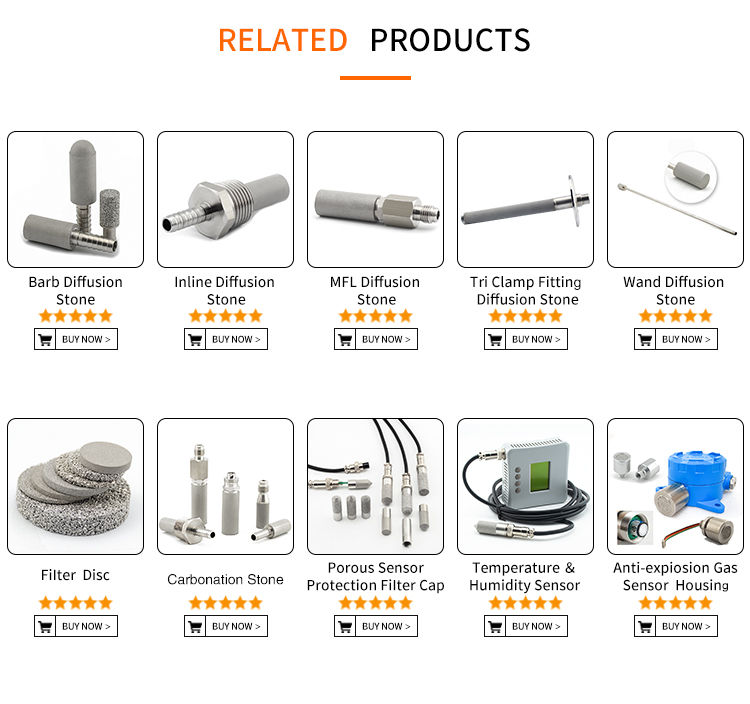

porous metal In-Tank spargers ( single sparger or multiple sparger assembly ) increase gas absorption