-

SFT11 SFT12 1/4”MFL wine tool micron diffusion professional oxygenation carbonati...

1. Better Than Shaking a Keg! 2. Are you tired of carbonating your beer the unpredictable way? You crank up the PSI in the keg, shake, and wait with ...

View Detail -

0.5 2 10 microns stainless steel home brewing wort beer pure oxygenation kit aeration w...

HENGKO carbonation stone is made of the food grade best stainless steel material 316L, healthier, practical, durable, high temperature resistant, and anti-c...

View Detail -

0.5 micron 2.0 stainless steel barb homebrew wort beer oxygen keg kit inline carbonatio...

HENGKO carbonation stone is made of the food grade best stainless steel material 316L, healthier, practical, durable, high temperature resistant, and anti-c...

View Detail -

SFW21 sintered stainless steel oxygenation kit 3/16” aeration wand diffusion stone

Product Name Specification SFW21 D1/2''*H26'' .5um with 3/16'' wand HENGKO carbonation stone is made of the food...

View Detail -

Inline 2µm Carbonation Diffusion Stone MFL Sparger for Bubbled Water & Beverage Ae...

Hydrogen water is clean, powerful, and with hydron. It helps to purify the blood and gets the blood moving. It can prevent many kinds of diseases and improve...

View Detail -

316L Stainless Steel 2µm Sparger Pipe for Fine Gas Diffusion in Tanks & Reactors

HENGKO stainless steel sparger pipe is designed for efficient gas diffusion—especially in hydrogen water systems where clean and stable microbubble generati...

View Detail -

SFC02 2 micron MFL Carbonation Sparger Inline Diffusion Stone for bubbling water/Bubble...

Hydrogen water is clean, powerful, and with hydron. It helps to purify the blood and gets the blood moving. It can prevent many kinds of diseases and improve...

View Detail -

0.5 2.0 micron SS stainless steel beer oxygen air aeration carbonation stone with 3/16&...

0.5 2.0 micron SS stainless steel beer air aeration carbonation oxygen stone with 3/16" 1/4" 3/8" wand barb 1/2" NPT Thread for home brewing HENGKO oxyge...

View Detail -

0.5 2 micron stainless steel home brewing wort beer aeration oxygen carbonation stone w...

HENGKO carbonation stone is made of the food grade best stainless steel material 316L, healthier, practical, durable, high temperature resistant, and anti-c...

View Detail -

SFT12 2 micron 1/4” MFL 316L stainless steel micron diffusion aeration oxygen stone

Product Name Specification SFT12 D5/8''*H3'' 2um with 1/4'' MFL Sintered air stone diffusers are often used for gas di...

View Detail -

1.5” Tri Clamp Oxygenation Stone Brewing Carbonation Aeration Diffusion Stone wit...

Sintered air stone diffusers are often used for gas distribution and air aeration. They have a wide range of pore sizes from 0.2 microns to 120 microns allow...

View Detail -

SFC01 MFL 0.5 sintered porous micro bubble carbonation oxygen generator diffusion stone

Product Name Specification SFC01 D7/17''*H3-7/8'' .5um with 1/4'' MFL An extremely fine diffusion stone is des...

View Detail -

Sintered stainless steel micro hydrogen ozone oxygen generator diffuser air stone for w...

HENGKO stainless steel ozone diffuser made of 316L stainless steel material has the advantage of durable, high-temperature resistance, anti-pressure and unif...

View Detail -

SFW In-Line wort Inline carbonation stone aeration wands (pure oxygen) for Beer Brewing

Sintered air stone diffusers are often used for porous gas injecting. They have different pore sizes(0.5um to 100um) allowing small bubbles to flow through t...

View Detail -

SFT01 SFT02 1/2″NPT X 1/4”bard inline 0.5um, 2um carbonation oxygenation flare diffusi...

Sintered air stone diffusers are often used for porous gas injecting. They have different pore sizes(0.5um to 100um) allowing small bubbles to flow through ...

View Detail -

SFH02 2 Micron sintered stainless steel inline oxygenation diffusion aeration stone 1/2...

Sintered air stone diffusers are often used for porous gas injecting. They have different pore sizes(0.5um to 100um) allowing small bubbles to flow through t...

View Detail -

0.5 Micron 2 Micron Homebrew Oxygenation Diffusion Stone Carbonation Aeration For Beer ...

Sintered air stone diffusers are often used for porous gas injecting. They have different pore sizes(0.5um to 100um) allowing small bubbles to flow through ...

View Detail -

Flameproof Explosion-proof Housing for Combustible Oxygen Gas Leak Sensor Detector

HENGKO gas sensor detector is a kind of intelligent digitalgas sensor device, which provides comprehensive monitoring of combustible, toxic gas hazards in po...

View Detail

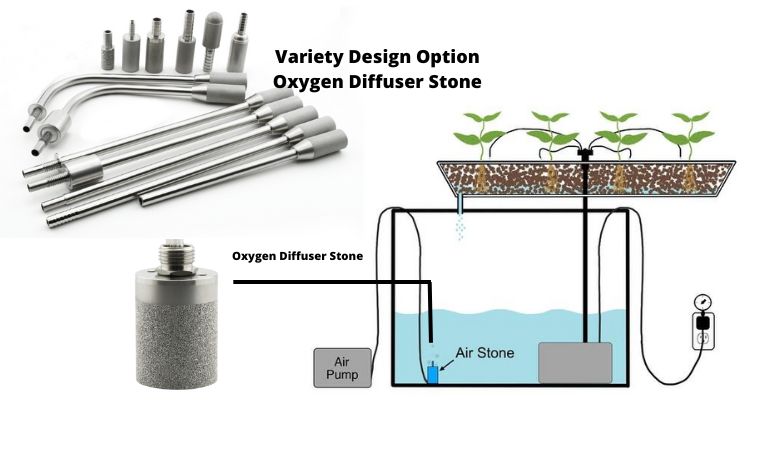

All Types of Oxygen Diffuser Stone

There are several types of oxygen diffuser stones available, each with its own advantages and disadvantages.

And also we can classify them according to different dimensions Here are some of the most common types:

By Material:

* 316L Stainless Steel : These are the most common type of diffuser stone. They are made from a porous material that allows air to pass through, creating bubbles. stainless steel stones are durable and relatively expensive, but they can become clogged over time and easy to clean.

* Rubber or EPDM: These stones are made from a flexible material that allows them to conform to the shape of the pond or tank. They are also resistant to clogging, but they are not as durable as ceramic stones.

* Silica: These stones are made from a very fine powder that creates tiny bubbles. They are very efficient at diffusing oxygen, but they are also the most expensive type of diffuser stone.

* Aluminum oxide: These stones are made from a very hard material that is resistant to wear and tear. They are also very efficient at diffusing oxygen, but they can be difficult to find.

By Shape:

* Round: These stones are the most common shape. They are easy to place in a pond or tank and they provide good all-around diffusion.

* Flat: These stones are designed to be placed on the bottom of a pond or tank. They provide excellent diffusion, but they can be difficult to clean.

* Bar: These stones are long and thin. They are ideal for large ponds or tanks, as they provide a wider area of diffusion.

* Disc: These stones are flat and round. They are ideal for small ponds or tanks, as they provide good diffusion without taking up too much space.

By Bubble size:

* Coarse: These stones create large bubbles. They are not as efficient at diffusing oxygen

as fine bubble stones, but they are less likely to clog.

* Fine: These porous metal stones create small bubbles. They are very efficient at diffusing oxygen,

but they can clog more easily.

Other factors to consider:

* Size: The size of the diffuser stone will depend on the size of your pond or tank.

* Weight: Some diffuser stones are heavier than others. This can be important if you are

using the stone in a pond with a lot of water movement.

* Price: Diffuser stones range in price from a few dollars to several hundred dollars.

Welcome to contact HENGKO to custom your special Oxygen Diffuser Stone.

![]()

Main Features of Oxygen Diffuser Stone

316L stainless steel is a type of stainless steel that is resistant to corrosion and has a lower carbon content than

other types of stainless steel. Some of the main features of 316L stainless steel include:

1. High Corrosion Resistance:

316L stainless steel has excellent corrosion resistance, making it suitable for use in a wide range of applications.

It is particularly resistant to corrosion in chloride environments.

2. Good Mechanical Properties:

316L stainless steel has good mechanical properties, including high strength, good formability, and good weldability.

3. Non-Magnetic:

316L stainless steel is non-magnetic, making it suitable for use in applications where magnetism is a concern.

4. Low Carbon Content:

The low carbon content of 316L stainless steel makes it less susceptible to carbide precipitation and intergranular corrosion.

5. Good Dimensional Stability:

316L stainless steel has good dimensional stability, which means that it maintains its size and shape even when subjected to temperature changes and other stresses.

An oxygen diffuser stone is a device that is used to dissolve oxygen into a liquid, such as water.

It is typically made of a porous material, such as ceramic or stainless steel, and has a large surface

area to facilitate the transfer of oxygen from the air to the liquid. The oxygen diffuser stone is often

used in aquariums and other water systems to provide oxygen to the aquatic life.

Why Use Sintered Metal Filter for Oxygen Diffuser Stone, What is the Advantage ?

Sintered metal filters provide several key advantages for oxygen diffuser stones, particularly in the context of sparging and aeration processes in various industries:

1. Uniform Bubble Size:

Sintered metal filters can create fine, uniform bubbles that facilitate efficient gas-liquid interaction.

This can enhance the oxygenation process, ensuring more efficient and thorough oxygenation.

2. Durability and Longevity: Sintered metal is highly resistant to wear and tear, thermal stresses, and corrosion.

As a result, these filters typically have a long operational lifespan, reducing the need for frequent replacements.

3. High Temperature and Pressure Tolerance: Sintered metal can withstand high temperatures and pressures,

making it suitable for challenging industrial applications.

4. Easy Cleaning and Maintenance: Sintered metal filters are easy to clean, which is crucial for maintaining optimal

performance and for applications where hygiene is a critical factor, such as in brewing or biotech processes.

5. Backflush Capability: The structure of the sintered metal allows for backflushing, helping to clean

and maintain the filter without the need for disassembly.

6. Customizability: Sintered metal filters can be made with a variety of pore sizes and shapes, allowing for

customization to meet specific requirements of the oxygenation process.

7. Low Energy Consumption: Due to their efficiency in producing uniform bubbles and enhancing oxygen transfer,

sintered metal filters contribute to energy savings in oxygenation processes.

Given these advantages, sintered metal filters are an excellent choice for oxygen diffuser stones in a wide range of

industries and applications, from brewing and winemaking to water treatment and aquaculture.

Other Main Application of Oxygen Diffuser Stone

1. Water treatment:

Sintered metal oxygen diffuser stones are used to improve the efficiency of aeration systems in water treatment plants, which can help to reduce the concentration of contaminants and improve the overall quality of the water.

2. Aquaculture:

The stones are used to provide oxygen to fish and other aquatic organisms in aquaculture systems, which can help to improve the health and growth of these animals.

3. Industrial Gas Production:

The stones are used to disperse oxygen in the production of industrial gases, which can help to improve the efficiency and yield of the production process.

4. Waste Water Treatment:

The stones can be used in waste water treatment plants to improve the efficiency of the aeration process and reduce the concentration of contaminants in the water.

5. Aquariums:

In home and commercial aquariums, the stones can be used to provide oxygen to the aquatic animals and plants, which can help to improve their health and overall well-being.

6. Hydroponics:

In hydroponics systems, the stones can be used to provide oxygen to the roots of plants, which can help to improve their growth and health.

FAQ of Oxygen Diffuser Stone

1. What is a sintered metal oxygen diffuser stone?

A sintered metal oxygen diffuser stone is a device used to dissolve oxygen into a liquid, such as water. It is made of a porous metal, such as stainless steel, that has been sintered, or subjected to high heat and pressure, to create a highly porous surface.

2. How does a sintered metal oxygen diffuser stone work?

The sintered metal oxygen diffuser stone works by allowing air to pass through the porous surface and into the liquid, where the oxygen is dissolved. The large surface area of the diffuser stone facilitates the transfer of oxygen from the air to the liquid.

3. What are the benefits of using a sintered metal oxygen diffuser stone?

Sintered metal oxygen diffuser stones offer several advantages over other types of diffuser stones, making them a

popular choice for various applications. Here are some of the key benefits:

1.) Higher Efficiency:

* Sintered metal diffuser stones have a uniform and consistent pore size that optimizes bubble formation. This results in the generation of finer and denser bubbles, increasing the surface area for gas exchange and significantly improving oxygen diffusion efficiency compared to other stones like ceramic or rubber.

* The fine bubbles produced by sintered metal stones have a longer residence time in the water, allowing for more oxygen to be dissolved before they rise to the surface.

2.) Durability and Longer Lifespan:

* Sintered metal stones are made from high-grade stainless steel or other strong metals, making them resistant to wear, tear, and corrosion. This results in a significantly longer lifespan compared to other materials like ceramic or rubber, which can easily break or clog over time.

* The robust construction of sintered metal stones allows them to withstand harsh environments and frequent cleaning, making them ideal for long-term use in demanding applications.

3.) Reduced Clogging:

* Sintered metal stones have a unique porous structure that resists clogging from biofouling or other contaminants.

This is due to the smooth surface and uniform pore size, which makes it difficult for particles to adhere and block the pores.

* The ability to resist clogging reduces maintenance requirements and ensures consistent performance over a longer period.

4.) Compatibility:

* Sintered metal stones are compatible with a wide range of gases, including oxygen, ozone, and air. This makes them versatile and suitable for various applications requiring gas diffusion.

* Their compatibility with different gases allows them to be used in various industries, including aquaculture, wastewater treatment, and industrial processes.

5.) Other Advantages:

* Easy to clean: Sintered metal stones can be easily cleaned with a mild detergent or acid solution, restoring their original performance.

* Lightweight: Despite their strength, sintered metal stones are relatively lightweight, making them easier to handle and install.

* Environmentally friendly: Sintered metal stones are made from recyclable materials, making them an environmentally friendly option compared to some other types of diffuser stones.

4. Can sintered metal oxygen diffuser stones be used in aquariums?

Yes, sintered metal oxygen diffuser stones can be used in aquariums to provide oxygen to the aquatic life. They are often used in conjunction with an air pump or compressor to provide a continuous supply of oxygen.

5. How do I install a sintered metal oxygen diffuser stone?

To install a sintered metal oxygen diffuser stone, simply place it in the desired location within the water system and connect it to an air pump or compressor using an air hose.

6. How do I clean a sintered metal oxygen diffuser stone?

To clean a sintered metal oxygen diffuser stone, simply rinse it with clean water and let it air dry. It is important to clean the diffuser stone regularly to remove any build-up of dirt or debris that could clog the pores.

7. How long does a sintered metal oxygen diffuser stone last?

The lifespan of a sintered metal oxygen diffuser stone depends on how well it is maintained and how frequently it is used. With proper care, a sintered metal oxygen diffuser stone can last for many years.

8. Can sintered metal oxygen diffuser stones be used in saltwater systems?

Yes, sintered metal oxygen diffuser stones can be used in saltwater systems. They are resistant to corrosion and can handle the high levels of salt present in saltwater.

9. Are sintered metal oxygen diffuser stones noisy?

Sintered metal oxygen diffuser stones are generally not noisy, but the level of noise may depend on the type of air pump or compressor being used.

10. How much oxygen can a sintered metal oxygen diffuser stone dissolve?

The amount of oxygen that a sintered metal oxygen diffuser stone can dissolve depends on a variety of factors, including the size of the diffuser stone, the flow rate of the air, and the temperature and pH of the water. In general, a larger diffuser stone with a higher flow rate will be able to dissolve more oxygen.

Do you have more questions and interested for the Oxygen Diffuser Stone or have projects need the

Oxygen to diffusing, please feel free to contact us by email ka@hengko.com, our R&D team will get

your information together and supply you best solution within 48-hours.

![]()