-

Zosefera Zamafuta Zapamwamba za Sintered Bronze

Tsatanetsatane Wazogulitsa Kuyambitsa Sefa yathu yamafuta apamwamba kwambiri yokhala ndi Sintered Bronze Fuel Element - yankho labwino kwambiri kwa aliyense amene akufunika ...

Onani Tsatanetsatane -

Sintered Copper Bronze Grounding Plate

Deters Electrolysis ndi Galvanic Corrosion Imachepetsa Kusokoneza kwa RF Ndi Kupititsa patsogolo Ntchito Zamagetsi Kulandiridwa bwino kwa zida zanu za GPS, nyengo ...

Onani Tsatanetsatane -

Porous Metal Sintered Mini Cylinder

Zitsulo za porous ndi chimodzi mwazinthu zambiri zoyenera kupanga zitsulo. Ubwino wa Sintered Mini Cylinder Powdered zitsulo zili ndi nambala yayikulu ...

Onani Tsatanetsatane -

Zosefera za Acid ndi Alkali Zolimba Kwambiri 316L Zosefera Zachitsulo Zosapanga dzimbiri...

Fotokozerani Zogulitsa HENGKO biomedical fyuluta imapangidwa ndi 316L chitsulo ufa wothira kutentha kwambiri, wokhala ndi porosity yofanana ya 0.2-0.5 um, corrosion resista...

Onani Tsatanetsatane -

CEMS Online Smoke Analyzer Gas Sampling Probe 44.5mm * 121mm ndi Unique Probe Design

Fotokozani Zogulitsa * Kupatukana kwafumbi munjira * Pazambiri zafumbi pamwamba pa 3g/m3 * Malo akulu ogwira ntchito * Moyo wautali * Kupanikizana kotsika ...

Onani Tsatanetsatane -

Porous zitsulo zosefera chubu cha kasamalidwe ka matenthedwe kuyenga ndi mankhwala apadera | HENGKO

HENGKO machubu osapanga dzimbiri osapanga dzimbiri amapangidwa ndi sintering 316L ufa wa zinthu kapena multilayer zitsulo zosapanga dzimbiri ma mesh pa kutentha kwambiri. Iwo ali ndi ...

Onani Tsatanetsatane -

316L SS zosapanga dzimbiri zitsulo zosefera sintered, Makonda microporous faifi tambala monel Inco ...

Zipangizo zachitsulo za HENGKO zimapangidwa kudzera pakutentha kwamphamvu kwa waya wa waya wosapanga dzimbiri kapena 316L ufa pa kutentha kwambiri. Ku...

Onani Tsatanetsatane -

Makandulo amtundu wa Sintered 316L chitsulo chosapanga dzimbiri mesh katiriji reusable

HENGKO imapereka mndandanda wambiri wamakatiriji azitsulo zosapanga dzimbiri omwe amapangidwira kuti azigwiritsidwa ntchito m'mafakitale osiyanasiyana, kuphatikiza mafuta a petrochemicals ...

Onani Tsatanetsatane -

Anti-corrosion Microns Powder Porous Sintered Metal Filter Cartridge For Sefa System

HENGKO imapanga machubu osefera a porous omwe amapereka kusinthasintha pamapangidwe chifukwa amatha kukhala opanda pake kapena akhungu okhala ndi makulidwe ochepa a khoma la 1mm. Zogulitsa izi ndi c...

Onani Tsatanetsatane -

sintered porous zitsulo zosefera zakuthupi media, porosity 0.2 μm ~ 100 micron titaniyamu mon ...

Ku HENGKO, njira yopangira zida zawo zachitsulo zokhala ndi porous imaphatikizapo kutentha kwa 316L ufa kapena mauna achitsulo osapanga dzimbiri ambiri ...

Onani Tsatanetsatane -

porous zitsulo zosapanga dzimbiri katiriji fyuluta kwa mkulu kuthamanga mpweya kuyeretsa olimba ...

HENGKO imapanga zida zake zachitsulo potenthetsa 316L ufa kapena mauna achitsulo chosapanga dzimbiri pa kutentha kokwera. wawo...

Onani Tsatanetsatane -

Luso 0.2 mpaka 120 microns yaying'ono porosity mkuwa inconel monel 316 316L chitsulo chosapanga dzimbiri ...

Chitsulo cha porous chimapangidwa ndi kukanikiza chitsulo cha ufa kukhala mawonekedwe osiyanasiyana, omwe amamangiriridwa ndi sinter kuti apange cholimba komanso chopanda mphamvu. Izi zosiyanasiyana ...

Onani Tsatanetsatane -

Zosefera za Sintered Bronze zokhala ndi mawonekedwe enieni a OEM a Sefa

HENGKO ikhoza kupatsa makasitomala mwayi wopanga zosefera ndi zida zamkuwa zokhala ndi mawonekedwe apadera. Iliyonse mwa mapulogalamu apaderawa ...

Onani Tsatanetsatane -

5 10 20 90 120 ma microns sintered porous zitsulo zamkuwa zosapanga dzimbiri 316L Mipikisano cholinga ...

HENGKO imapanga zinthu zosefera muzinthu zambiri, makulidwe, ndi zokokera kuti zitha kufotokozedwa mosavuta ndi mawonekedwe ndi kasinthidwe...

Onani Tsatanetsatane -

yunifolomu mphamvu sintered porous zitsulo micron fyuluta fluidizers bronze mkuwa mkuwa fizi...

Zosefera zakuya zimagwiritsidwa ntchito kuchotsa tinthu tamadzimadzi. Izi zikutanthauza kuti zakumwa zimatha kukhala zomveka bwino, zabwino kapena zosefedwa. Zosefera ndizoyenera ...

Onani Tsatanetsatane -

sintered air filter medium spheric bronze filter element

HENGKO SINTERED BRONZE OIL FILTER imayikidwa mu sparging, chitetezo cha sensor, gasi, kusefera kwamadzi, kunyowetsa, kunyamula kochuluka ndi zina zomwe solu ...

Onani Tsatanetsatane -

Kuyenda kulamulira ndi kugawa madzimadzi sintered fyuluta mbale / pepala, ufa sintered porous ...

Zosefera zakuya zimagwiritsidwa ntchito kuchotsa tinthu tamadzimadzi. Izi zikutanthauza kuti zakumwa zimatha kukhala zomveka bwino, zabwino kapena zosefedwa. Zosefera ndizoyenera ...

Onani Tsatanetsatane -

Porous zitsulo sintered mkuwa zosefera uniaxial masilindala ndi chimodzi chatsekedwa mapeto ndi hex.

Kufotokozera Zazidziwitso HENGKO imapanga zosefera mumitundu yambiri, makulidwe, ndi zokokera kuti zitha kufotokozedwa mosavuta ndi charac...

Onani Tsatanetsatane -

Porous zitsulo sintered porous mkuwa zosefera mbale/shiti kwa kuyenda ndi kulamulira phokoso

Zosefera zakuya zimagwiritsidwa ntchito kuchotsa tinthu tamadzimadzi. Izi zikutanthauza kuti zakumwa zimatha kukhala zomveka bwino, zabwino kapena zosefedwa. Zosefera ndizoyenera ...

Onani Tsatanetsatane -

Medical mankhwala mankhwala amadzimadzi mafuta ndi mpweya 3um-90 microns ufa porous zonse zitsulo nthunzi sint...

HENGKO machubu a porous fyuluta amatha kukhala opanda kanthu kapena akhungu ndipo makulidwe a khoma osachepera 1 mm. Amapangidwa ndi isostatic compaction ya ufa mu flexible mo ...

Onani Tsatanetsatane

Kodi Sefa ya Sintered Powder Metal ndi Zofunikira Zazikulu

Zosefera zachitsulo za sintered ndi mtundu wa fyuluta wopangidwa ndi sintering, kapena kutentha, kusakaniza kwa ufa wachitsulo

mpaka atalumikizana kuti apange cholimba cholimba. Izi zimapanga porous zakuthupi zomwe zimatha kugwira

zoipitsa ndi zonyansa zina, kuzipanga kukhala zosefera zogwira ntchito zosiyanasiyana.

1.Hndi Porosity

Chimodzi mwazabwino zazikulu za zosefera zachitsulo za sintered ufa ndi zawomkulu porosity. Pores mu fyuluta

ndi ang'onoang'ono, omwe amayambira kukula kwa ma microns 0,2 mpaka 10, omwe amawalola kuchotsa bwino.

mitundu yambiri ya zonyansa zochokera ku zakumwa ndi mpweya. Zimawapangitsa kukhala abwino kugwiritsidwa ntchito pamagalimoto,

mlengalenga, ndi mafakitale azachipatala, komwe ukhondo ndi ukhondo ndizofunikira.

2.Kukhalitsa

Ubwino wina wa sintered ufa zitsulo Zosefera ndi awokukhazikika. Njira yopangira sintering imapanga a

olimba, olimba kapangidwe kugonjetsedwa ndi kuvala ndi kung'ambika, kulola fyuluta kupirira kupsyinjika mkulu ndi

kutentha popanda kupunduka kapena kusweka. Zimawapangitsa kukhala oyenera kugwiritsidwa ntchito m'malo ovuta,

monga mumainjini kapena makina ena ochita bwino kwambiri.

3. Easy Clean

Mmodzi wa mavuto ntchito sintered ufa zitsulo Zosefera kuti akhoza kukhalazovuta kuyeretsa ndikugwiritsanso ntchito.

Chifukwa ma pores ndi ang'onoang'ono, kuchotsa zonyansa zomwe zatsekeredwa mu fyuluta kungakhale kovuta, kuzipanga

zofunika kusintha fyuluta m'malo moyeretsa. Zitha kukhala zokwera mtengo, makamaka pazogwiritsa ntchito pomwe

fyuluta imagwiritsidwa ntchito pafupipafupi. zedi mulinso ndi njira yotsuka.

Ngakhale izi ndizochepa, zosefera zachitsulo za sintered zimagwiritsidwa ntchito kwambiri chifukwa champhamvu komanso kulimba kwake.

Ndiwo gawo lofunikira munjira zambiri zamafakitale ndi kupanga, zomwe zimathandiza kuonetsetsa kuti ntchitoyo ikuchitika

chiyero ndi ubwino wa zakumwa ndi mpweya. Ndi kuthekera kwawo kutchera mitundu yosiyanasiyana ya zoipitsa ndikupirira

zotengera chilengedwe, sintered ufa zitsulo Zosefera ndi chida chofunika kwambiri kuti ntchito

ndi kudalirika kwa makina ndi zida.

Chifukwa chiyani HENGKO Sintered Powder Metal Zosefera

Perekani Mayankho Opambana Osefera

Mitundu yathu ya ma sintered powder zitsulo zosefera ndizopambana pamagwiritsidwe osiyanasiyana ofunikira;

porous sinterwapadera katundu zitsulo ntchito zosiyanasiyana mkulu-anzanu sparging zida zabwino ndi

kugawa mofanana kwa mpweya kukhala zamadzimadzi.

Porous sintered ufa zitsulo Zosefera, nthawi zambiri okhala ndi zolumikizira zazikulu zoyenda bwino, amagwiritsidwa ntchito kupatukana

zolimba kuchokera ku mitsinje ya gasi mkatinjira zosiyanasiyana. Zomwe zili zofunika kwambiri ndi izi:

1. Kutentha kwapamwamba, Kukhazikika kwa kutentha mpaka 950 ° C

2. Oyenera kuthamanga kwakukulu kosiyana

3. High dzimbiri kukana

4. Wapadera sinter bonded cholumikizira

5. Mapangidwe odzithandizira okha ndi mphamvu zamakina apamwamba

6. Kuchita bwino kwambiri kumbuyo kugunda

7. Palibe kuwotcherera kwa porous media

8. Kusinthasintha kwapangidwe, Mawonekedwe Osiyanasiyana omwe alipo, ndikusintha mwamakonda anu

9. Pa 10,000 zosiyanasiyana za muyezo ndi makonda kukula / mawonekedwe zilipo

10. Yaikulu Yogawa gasi / madzi amadzimadzi

11. Adopt Food-class 316L ndi 304L chitsulo chosapanga dzimbiri kapena bronze

12. Zosavuta Zoyeretsedwa ndi Zogwiritsidwanso Ntchito

ZOTHANDIZA ZATHU

Monga wopanga wapamwamba kwambiri wazosefera zazitsulo za porous, HENGKO imapereka mayankho aukadaulo apamwamba.

kwa malo otentha kwambiri komanso owononga.

Nthawi zambiri zinthu zosefera zitsulo za sintered zimapangidwa ndi chitsulo chosapanga dzimbiri, bronze, ma aloyi opangidwa ndi faifi tambala, ndi titaniyamu ndipo amatha.

kukhala wowotcherera mosasunthika ndi ma aloyi apadera kuti musinthe mawonekedwe osiyanasiyana ndi cholumikizira cha ulusi kapena nozzle ya mpweya.

Kusefedwa kumatanthauzidwa ndi kukula kwake kwa pore.

Zida Zosankha

HENGKO ikupezeka mumitundu yosiyanasiyana.

The powder metal solution imapangitsa kupanga mapangidwe ndi zofunikiramunthu ndondomeko zofunika zosavuta.

Zida zomwe zilipo:

1. Chitsulo chosapanga dzimbiri (muyezo 316L),

2. Mofulumira,

3. Ikoneleni,

4. Moneli,

5. Bronze,

6. Titaniyamu

7. Special Alloys pa pempho.

Mapulogalamu

1. Kusefera kwa Gasi

Timapereka zinthu zingapo ndi njira zosefera mpweya wotentha m'mafakitale, komanso kutentha kwa ntchito

kawirikawiri amapitirira 750 ° C kwa nthawi yaitali. Zosefera izi nthawi zambiri zimagwira ntchito m'makina omwe ali ndi kudziyeretsa okha

kuthekera, ndi zinthu zosefera ziyenera kukhala zokhoza kusinthikanso pamtundu uliwonse. chonchozosefera zachitsulo za sintered powder

ndizo zabwino kwambiri, ndipo mawonekedwe onse amatha kukumana; mwanjira imeneyo, zosefera zathu za porous zosungunuka zimagwiritsidwa ntchito mochulukira mu mpweya wambiri

mafakitale osefa.

2. Kuchepetsa

Zida zothamanga kwambiri zimafunikira zosefera, monga kulumikizana ndi mpweya wamadzimadzi komwe kumafunikira kuti muchitepo kanthu: kuvula, kusakaniza,

kapena kufalikira. M'mapulogalamu ena ambiri, timakuthandizani kuti muwonjezere magwiridwe antchito polimbikitsa ndikupanga zabwino kwambiri

yankho loyenera kutengera mitundu yayikulu yamagulu a sparger omwe alipo.

3. Sefa yamadzimadzi

Timaperekanso zosefera zopangidwa mwamakonda komanso zodzithandizira zokha kuti zisungunuke mpaka kusefa bwino kwa 0.1µm mumadzimadzi. The

Zosefera zazitsulo za sintered ufa zitha kupangidwa ndi masangweji apawiri, ndi magiredi awiri olumikizidwa ndi ufa

Kutulutsa kokhazikika komanso kofanana ndikuwongolera kuyenda poyerekeza ndi zosefera zopangidwa mwachizolowezi. The sintered

porous chimbale ndiye fyuluta wangwiro njira zokhudza chothandizira. Zosefera zathu za sintered powder metal zili ndi a

moyo wonse womwe umaposa mayankho opikisana ambiri chifukwa chopanda kuwotcherera ndi kulumikizana "kolimba-olimba".

4. Fluidizing

Tikupereka makonda zida fluidizing kwa kachitidwe mafakitale atsopano ndi alipo tediously kulamulira osiyana

mapangidwe opanga zosefera kuti awonetsetse kuti gasi ali ndi gawo labwino kwambiri lomwe limapangitsa kuyenda bwino kapena kusakanikirana kwa ambiri

media zosiyanasiyana, kuphatikizapo mkuwa, zitsulo zosapanga dzimbiri, ndi polyethylene. Komanso, chifukwa fluidizing cones zopangidwa

khola sintered zitsulo zipangizo zambiri kudzidalira, tikhoza kupereka zosefera ndi flanges kulumikiza

monga pakufunika.

Mnzathu

Mpaka Pano HENGKO ali ndi ntchito zikwizikwi zamakampani ochokera kumakampani ambiri kuphatikiza chemistry ndi mafuta, chakudya, zamankhwala ndi zina

Komanso ma laboratories ambiri amakampani ndi mayunivesite omwe amapereka kwa nthawi yayitali. Ndikukhulupirira kuti mudzakhala m'modzi wa iwo,

funsani ife lero ngati mukufuna.

Momwe Mungasinthire Zosefera za Sintered Powder Metal Kuchokera ku HENGKO

Pamene muli nazoZosefera Zapadera Zopangira Sintered Meltzamapulojekiti anu ndipo simungapeze Zosefera zofanana kapena zofanana

mankhwala, Welcomekulumikizana ndi HENGKO kuti tigwire ntchito limodzi kuti tipeze yankho labwino kwambiri, ndipo nayi njira ya

Zosefera za OEM Porous SungunulaniChonde Onani ndiLumikizanani nafelankhulani zambiri.

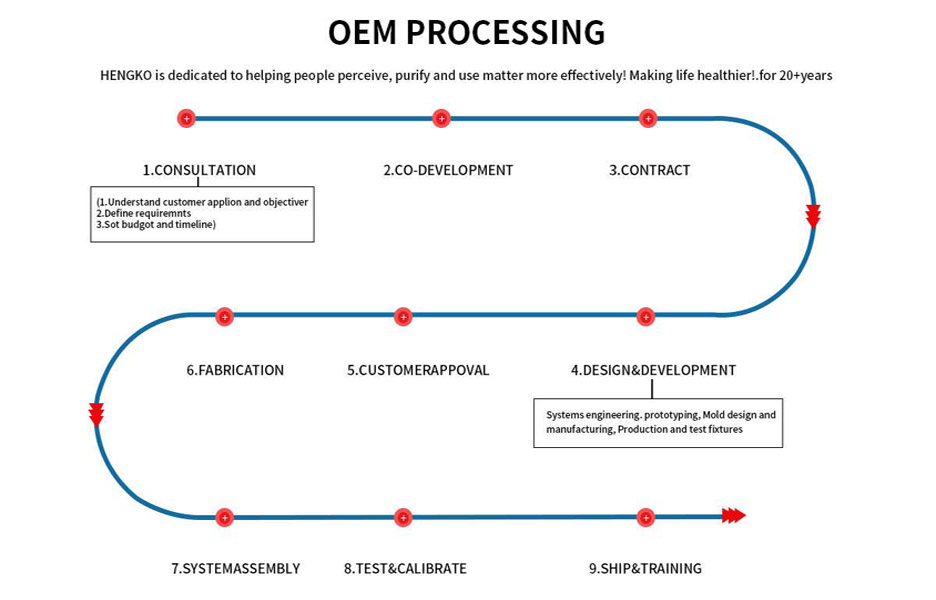

HENGKO Adadzipereka Kuthandiza Anthu Kuzindikira, Kuyeretsa ndi Kugwiritsa Ntchito Zinthu Mwachangu! Kupangitsa Moyo Kukhala Wathanzi Pazaka 20.

1.Kufunsira ndi Lumikizanani ndi HENGKO

2.Co-Development

3.Pangani Mgwirizano

4.Design & Development

5.Makasitomala avomerezedwa

6. Fabrication / Mass Production

7. Msonkhano wa System

8. Yesani & Sanjani

9. Manyamulidwe

Ndiye bizinesi yanu ndi yotani? ndipo muli ndi mafunso okhudza zosefera zitsulo ndipo mukufuna kuti tithane nazo kapena kusintha mwamakonda

Zosefera zapadera zazitsulo za porouspa chipangizo ndi makina anu? Chonde ingomasukani kutitumizira mafunso, Gulu lathu la R&D litero

athe kukupatsirani mayankho achangu komanso okhutiritsa.

FAQ

1. Kodi sintering mu powder metallurgy ndi chiyani?

Sintering imagwiritsidwa ntchito muzitsulo za ufa kutembenuza ufa wachitsulo kukhala chinthu cholimba, chopotoka. Njira imeneyi imaphatikizapo

kutenthetsa zitsulo zazitsulo ku kutentha pansi pa malo ake osungunuka, zomwe zimapangitsa kuti tinthu tigwirizane

pamodzi ndi kupanga dongosolo lolimba.

Njira yopangira sintering imagwiritsidwa ntchito kwambiri popanga zitsulo ndi zigawo zake, monga mayendedwe, magiya,

ndi zosefera. Imapereka maubwino angapo kuposa njira zina zopangira, monga kuponyera kapena kufota, kuphatikiza

mtengo wotsika, kusinthasintha kwakukulu kwapangidwe, komanso kuthekera kopanga mawonekedwe ovuta ndi mapangidwe.

Panthawi ya sintering, zitsulo zazitsulo zimayikidwa mu nkhungu kapena kufa, zomwe zimatsimikizira mawonekedwe a

gawo lomaliza. Kenako nkhunguyo amaiika m’ng’anjo, mmene imatenthedwa mpaka kutentha kumene kumangotsala pang’ono kusungunuka

pmafuta achitsulo. Pamene zitsulo zazitsulo zimatenthedwa, zimayamba kugwirizana ndi kupanga cholimba.

Monga zitsulo ufa sinter, pores pakati particles kukhala ang'onoang'ono ndi ang'onoang'ono. Zimapanga porous

zakuthupi zomwe zimakhala zamphamvu komanso zolimba komanso zimakhala ndi malo okwera kwambiri, zomwe zimapangitsa kuti zikhale zabwino kwa ntchito zoterezi

monga kusefera ndi chothandizira thandizo. Ikhoza kulamulira kukula ndi kugawa kwa pores mwa kusintha sintering

kutentha ndi nthawi komanso mapangidwe azitsulo zazitsulo.

Njira ya sintering ikatha, zinthu zolimba, zaporous zimachotsedwa mu nkhungu ndikuloledwa

zabwino. Gawo lomalizidwalo litha kupangidwa ndi makina kapena kukonzedwa kuti lipange mawonekedwe ndi kukula komwe mukufuna.

Sintering ndi njira yosunthika yomwe imatha kupanga zitsulo zambiri ndi zida. Imakhala ndi maubwino ambiri,

kuphatikizapo mtengo wotsika, kusinthasintha kwa mapangidwe, ndi luso lopanga maonekedwe ovuta ndi mapangidwe. Zotsatira zake,

sintering imagwiritsidwa ntchito kwambiri popanga zitsulo ndi zida zamagalimoto, zakuthambo, ndi

mafakitale azachipatala.

2. Chifukwa chiyani sintering ndi yofunika mu zitsulo ufa?

Sintering ndi njira yofunika mu zitsulo ufa chifukwa zomangira particles mu zitsulo ufa

kupanga chinthu cholimba, chogwirizana. Amachitidwa potenthetsa ufawo mpaka kutentha pansi pa malo ake osungunuka,

zomwe zimapangitsa kuti ma particles agwirizane ndi kufalikira.

Sintering ndikofunikira pazifukwa zingapo:

1. Zimalola kupanga magawo okhala ndi mawonekedwe ovuta omwe angakhale ovuta kapena osatheka kupanga

pogwiritsa ntchito njira zina zopangira.

2. Itha kugwiritsa ntchito kupanga magawo omwe ali ndi zida zamakina bwino, monga mphamvu yayikulu

ndi kuuma.

3. Sintering imatha kupanga zida za porous ndi porosity yoyendetsedwa, yomwe ndi yothandiza pakugwiritsa ntchito

monga zosefera ndi zothandizira.

Njira yopangira sintering imaphatikizapo kutenthetsa ufa mpaka kutentha kwa pafupifupi 80-90%

za malo ake osungunuka pansi pa zikhalidwe za kupanikizika kwakukulu ndi mlengalenga wolamulidwa. Zimayambitsa

particles kufalikira wina ndi mzake, kupanga olimba misa. The sintering ndondomeko akhoza kulamulidwa

kupanga ma microstructures osiyanasiyana ndi makina amakina, malingana ndi ntchito yeniyeni.

Mmodzi wa ubwino waukulu wa ufa zitsulo ndi kuti amalola kulenga mbali ndi akalumikidzidwa zovuta

ndi kulolerana kwenikweni. Ndi chifukwa chakuti ufa wachitsulo ukhoza kupangidwa mu mawonekedwe aliwonse pogwiritsa ntchito njira zosiyanasiyana,

monga kukanikiza ndi sintering. Kusinthasintha kumeneku kumapangitsa opanga kupanga magawo okhala ndi ma geometry ovuta

ndi miyeso yolondola, yomwe sizingatheke ndi njira zina zopangira.

Pomaliza, sintering ndi njira yofunika kwambiri muzitsulo za ufa chifukwa imalola kupanga magawo

ndi mawonekedwe ovuta, makina opangidwa bwino, komanso porosity yoyendetsedwa. Ndi sitepe yofunika kwambiri mu ufa

zitsulo ndondomeko ndi zimathandiza opanga kupanga mbali apamwamba ntchito zosiyanasiyana.

Chifukwa chake ngati mukadali ndi Mafunso aliwonse komanso Okonda Zosefera za Sintered Powder Metal, ndinu olandiridwa ku

titumizireni imeloka@hengko.com komanso mutha kutumiza zofunsira potsatira fomu yofunsira, tidzatumiza

kubwerera mkati mwa 24-Maola.