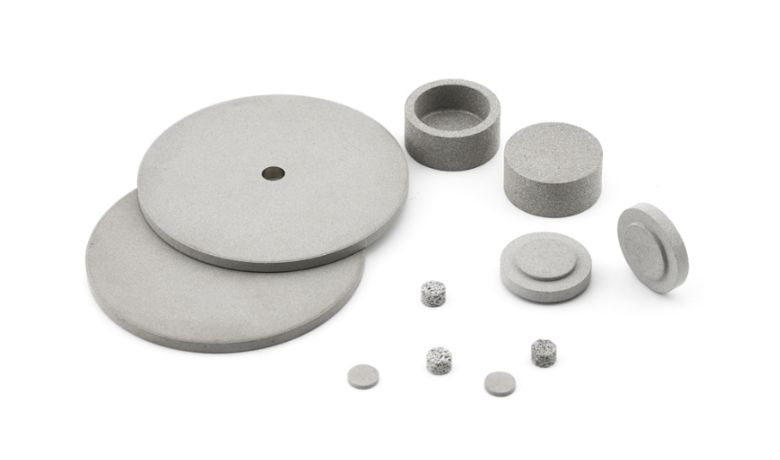

Today, sintered filters are used more and more, but do you know why these metal filters are slowly replacing the previous generation of filter elements?

Yes, it must be that the sintered filter element has many irreplaceable features, and the price and the cost be cheaper.So If you are interested to know more details, please continue to read following.

What Is a Filter ?

Filter is an indispensable device for conveying media pipelines, usually installed in pressure relief valve, water level valve, square filter and other equipment at the inlet end of the equipment. The filter is composed of cylinder body, stainless steel filter mesh, sewage part, transmission device and electrical control part. After the water to be treated passes through the filter cartridge of the filter mesh, its impurities are blocked. When cleaning is required, as long as the detachable filter cartridge is taken out and reloaded after treatment, it is therefore extremely convenient to use and maintain.

What Is the Working Principle of Sintered Metal Filter ?

Sintered metal filters are efficient, two-dimensional, filter type, and particles are collected on the surface of the medium. The correct choice of media grade must balance the needs of filtration applications for particle retention, pressure drop, and backwash capability. There are basically three process factors to consider: the velocity of the fluid through the filter medium, the viscosity of the fluid, and the particle properties. Important particle properties are particle shape, size, and density. Hard, regular-shaped particles that form incompressible cakes, such as FCC catalysts, are well suited for surface filtration.

The filtration operation is based on a constant flow rate, increasing the pressure drop until the terminal pressure drop is reached. The final condition will be reached when the catalyst cake thickness is increased to the point where the fluid flow pressure drop is maximal for a given flow and viscosity condition. The filter is then backwashed by pressurizing the filter with gas, followed by a quick opening of the backwash discharge valve. This backwashing procedure produces an instantaneous high reverse differential pressure, which can effectively remove solids from the medium surface. The reverse flow of clean liquid (filtrate) through the medium helps remove solids and flush them out of the filter.

History of Filters

Thousands of years ago, the ancient Egyptians used the first ceramic filters made of porous clay pots. Experiments in seawater desalination in the 17th century led to the creation of multi-layer sand filters. Nobel-prize laureate Richard Zsigmondy invented the first membrane filter and ultra-fine membrane filter in 1922. In 2010, the nanotechnology filter was introduced. Until today, sintered metal filters are widely used in all walks of life, and play an irreplaceable role in production and life.

Applications

With the development of economy and the needs of production and life, filter has been used in various fields for its advantages. In this part, we list some for you.

① Beverage Industry

The method of making carbonated water by injecting carbon dioxide into water was first discovered by an Englishman, Joseph Priestley, in the late 18th century, while hanging a bowl of distilled water over a keg of beer in a brewery. The oil of sulfuric acid is dropped onto chalk to produce carbon dioxide gas, which is dissolved into the water in a mixing bowl. Later, Swedish chemist Torbern Bergman invented a power generator that used sulfuric acid to extract carbonated water from chalk. Carbonated water is actually made using a soda siphon or a home carbonation system or by dropping dry ice into the water. Food-grade carbon dioxide used to carbonate beverages typically comes from ammonia plants.

At present, the sintered stainless steel filter, such as porous sparger, is widely used to sparge gas into water. The porous sparger ensures the distribution of the gas in the liquid through thousands of tiny pores. The sparger produces smaller but more bubbles than the drilled tube and other sparging methods. The surface of the porous sparger has thousands of holes, causing a large amount of gas to pass through a specific location in the liquid. So carbon dioxide can be dissolved into water evenly.

Advantages:

A: Compared with the previous use of chemical methods to produce carbon dioxide, stainless steel porous sparger uses physical methods to evenly dissolve carbon dioxide in water through micropores, which is more efficient, stable in nature, and will not produce harmful substances.

B: Stainless steel filter especially HENGKO sintered stainless steel filter made of stainless steel 316L, which has passed FDA food grade certification, can be safely used in beverage industry, reducing the risks of health.

② Water Process Industry

In the 1700s wool, sponges, charcoal and sand were the most popular ways to filter particles out of water. In 1804, John Gibb created the first filter that used sand to filter water. Commissioned by Queen Victoria in 1835, an Englishman Henry Dalton invented the ceramic candle filter to treat water. His filter uses the small aperture of ceramic to filter out contaminants such as dirt, debris and bacteria. In 1854, British scientist John Snow discovered that chlorination of contaminated water could purify the source and make it safe to drink.

Nowadays, with the development of science and technology, the filtration equipment has been greatly improved and sintered stainless steel filter has been mainly applied to the water process industry.

Advantages:

A: Compared with ceramic filter, the stability of stainless steel filter is very strong. The materials used in stainless steel filter are alloy materials. The stability and various resistance and tolerance of this material are better than those of traditional filter materials. And the maintenance frequency will not be very high, the service life is relatively long.

B: Stainless steel filter itself has high material strength. Through reasonable design, it can carry more filtration functions. It needs a stainless steel filter that can meet the needs to complete a variety of filtration work in the production process.

C: HENGKO sintered 316L stainless steel filter has passed FDA food grade certificate, which can guarantee the safety of water.

③ Pharmaceutical Industry

With the development of the times and technology, the pharmaceutical industry has increasingly strict requirements for filtration, especially in the field of high performance liquid chromatography. As the pipeline and column packing of liquid chromatography instruments are generally micron, the tiny solid particles in the mobile phase are very likely to cause blockage of the whole instrument system, affect the experimental process and even damage the instrument, so the purity requirements of mobile phase are very high. Chromatographic pure reagents are usually required. When the experimental requirements are high, in order to further avoid the influence of small particles in the mobile phase on the instrument and the experiment, it is necessary to install an online stainless steel filtration device in front of the column. The online filter can filter the mobile phase well.

Advantages:

A: UHPLCS high-pressure in-line filters adopts a cup structure and has the advantage of Less dead volume, no leakage, and low back pressure.

B: UHPLCS sintered 316L stainless steel filter is certificated by FDA, which is healthy and harmless.

Recommendation

After reading this passage, maybe you can’t wait to pick a good filter for your business. Here we list some for you.

①HENGKO Biotech Removable Porous Frit Micro Sparger for Mini Bioreactor System and Fermentors

Stainless-steel sparger used as cell retention device. The device consists of a metal tube and a sintered metal filter with a pore size of 0.5 – 40 µm. The sparger is inserted into the vessel headplate using a compression fitting.

Sparging has significant effect on oxygen transfer and carbon dioxide stripping which affects cell growth and productivity.

HENGKO sintered filter products are widely used in bio-fermentation tanks as a gas distributor and have higher gas distribution efficiency compared with similar products.

Application:

l Aquaculture

l Cosmetics

l Human nutrition

l Pharmaceuticals

l Food supplements

l Natural pigments

② uHPLCs High Efficiency Solvent Inlet Filters, Tube Stem, 1/16”

Solvent Inlet Filters offer the HIGHEST EFFICIENCY and DURABILITY with a WIDE RANGE OF MATERIALS at the LOWEST PRICES

Tube Stem Fitting Adapted for push on flexible tubing or PEEK compression fittings for ease of use.

Fitting Size: 1/8” / 1/6'' / 1/16'' Tube Stem

Pore Size: 2um, 5um, 10um, and 20um

Material of Construction: Passivated 316(L) SS

Solvent Inlet Filters offer a wide variety of options and benefits to meet your desired HPLC/UHPLC system protection.

To sum up, filter is an indispensable device for conveying media pipelines, usually installed in pressure relief valve, water level valve, square filter and other equipment at the inlet end of the equipment. It has developed for a long history. Currently, sintered stainless steel filter has been widely used in various industries such as food and beverage, water process, pharmaceuticals etc. for its advances like safety and harmlessness. When picking a stainless steel filter, you should carefully consider your application.

If you also have projects need to use a Sintered Metal Filter, you are welcome to contact us for details, or you can send email by ka@hengko.com, we will send back within 24-hours.

Post time: Nov-21-2022