Threads, the intricate spirals found on bolts, screws, and within nuts, are far more complex than they appear. They vary in design, size, and function, shaping the way components fit together in everything from simple machinery to advanced engineering systems. In this guide, we delve into the basics of thread design, exploring the fundamental aspects that differentiate one thread from another. From the gender of threads to their handedness, and from their pitch to their diameter, we uncover the critical elements that make threads an essential yet often overlooked marvel of engineering.

Check details as following as we unravel the intricate world of threads, providing you with a foundational understanding essential for both the curious novice and the seasoned professional.

Some important terms of Thread

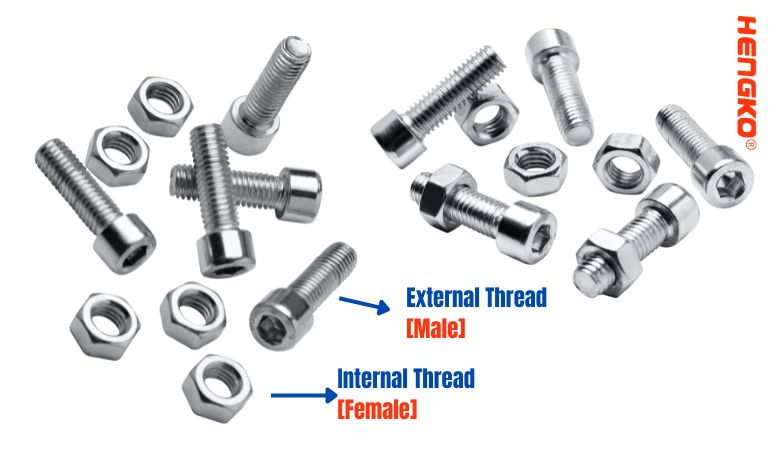

Using gendered terms can perpetuate harmful stereotypes and contribute to a culture of exclusion. By using more neutral terms like "external" and "internal" threads, we can be more inclusive and avoid unintended bias.

* Accuracy: The analogy breaks down further when considering non-binary thread forms and applications.

It's important to be accurate and inclusive in technical language as well.

* Alternatives: There are already clear and well-established technical terms for thread characteristics:

* External threads: Threads on the outside of a component.

* Internal threads: Threads on the inside of a component.

* Major diameter: The largest diameter of the thread.

* Minor diameter: The smallest diameter of the thread.

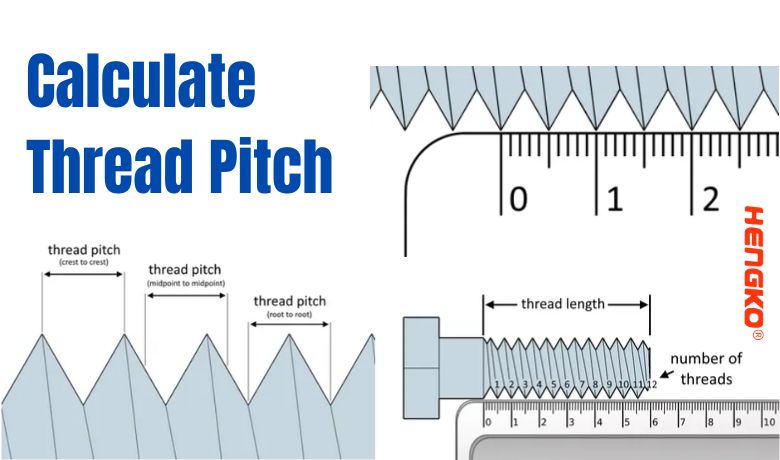

* Pitch: The distance between two corresponding points on adjacent threads.

Using these terms provides accurate and unambiguous information without relying on potentially harmful analogies.

Threads are used in filter assemblies

Sintered filters are widely used in various industries for filtration purposes. They are made by bonding metal powders

together through a heat treatment process called sintering. This creates a strong, porous structure that can effectively

filter out particles from fluids or gases.

Threads are commonly used in filter assemblies to connect different components together.

The thread length is crucial in ensuring a secure connection and proper function of the filter assembly. Here are some

specific examples of how threads are used in sintered filter assemblies:

* Filter cartridge end caps:

Many sintered filter cartridges have threaded end caps that allow them to be screwed into filter housings.

This creates a secure seal and prevents leaks.

* Filter housing connections:

Filter housings often have threaded ports that allow them to be connected to piping or other equipment.

This allows for easy installation and removal of the filter assembly.

* Pre-filters:

Some filter assemblies use pre-filters to remove larger particles before they reach the sintered filter.

These pre-filters may be screwed into place using threads.

* Drainage ports:

Some filter housings have threaded drainage ports that allow for the removal of collected fluids or gases.

The specific type of thread used in a filter assembly will depend on the application and the size of the filter.

Common thread types include NPT, BSP, and Metric.

In addition to the examples above, threads may also be used for other purposes in sintered filter assemblies, such as:

* Attaching sensors or gauges

* Mounting brackets

* Securing internal components

Overall, threads play an important role in ensuring the proper function and performance of sintered filter assemblies.

Ultimately, the choice of terminology is up to you.

However, I encourage you to consider the potential impact of using gendered language and the benefits of

using more neutral and inclusive alternatives.

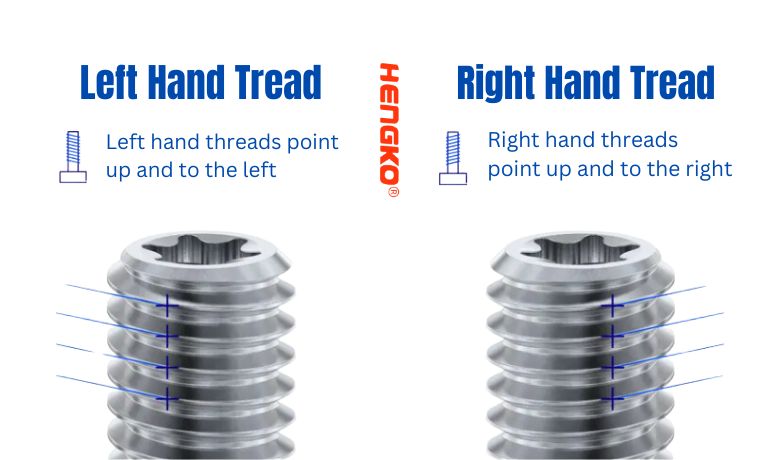

Handedness of Threads

Why are right-handed threads more common?

* There's no definitive historical reason, but some theories suggest it could be due to the natural bias of most

people being right-handed, making it easier to tighten and loosen right-handed threads with their dominant hand.

* Right-handed threads also tend to be self-tightening when subjected to rotational forces in the same direction

as tightening (e.g., a bolt on a spinning wheel).

Applications of left-handed threads:

As you mentioned, left-handed threads are often used in situations where loosening due to vibration or rotational forces is a concern,

such as: They are also used in specific tools and equipment where a different direction of rotation is needed for functionality.

* Gas bottles: To prevent accidental opening due to external pressure.

* Pedal bicycles: On the left side to prevent them from loosening due to the forward rotation of the wheel.

* Interference fits: To create a tighter, more secure fit that resists disassembly.

Identifying thread handedness:

* Sometimes the thread direction is marked directly on the fastener (e.g., "LH" for left-handed).

* Observing the angle of the threads from the side can also reveal the direction:

1.Right-handed threads slope upwards to the right (like a screw going uphill).

2. Left-handed threads slope upwards to the left.

Importance of handedness in sintered filters and common usages.

Handedness, referring to the direction of thread rotation (clockwise or counter-clockwise), is indeed crucial in sintered filter

applications for several reasons:

Sealing and Leak Prevention:

* Tightening and Loosening: Proper handedness ensures components tighten securely when turned in the intended direction

and loosen easily when needed. Mismatched threads can lead to over-tightening, damaging the filter or housing, or incomplete

tightening, causing leaks.

* Galling and Seizing: Incorrect thread direction can create friction and galling, making components difficult or impossible to separate.

This can be especially problematic during maintenance or filter replacement.

Standardization and Compatibility:

- Interchangeability: Standardized thread handedness allows for easy replacement of filter elements or housing with compatible parts, regardless of manufacturer. This simplifies maintenance and reduces costs.

- Industry Regulations: Many industries have specific regulations regarding thread handedness in fluid handling systems for safety and performance reasons. Using non-compliant threads can violate regulations and lead to safety hazards.

Common Usages and Handedness:

- Filter Cartridge End Caps: Typically use right-handed threads (clockwise to tighten) for secure attachment to filter housings.

- Filter Housing Connections: Generally follow industry standards, which often specify right-handed threads for pipe connections.

- Pre-filters: May use either right or left-handed threads depending on the specific design and intended direction of fluid flow.

- Drainage Ports: Usually have right-handed threads for easy opening and closing to drain fluids.

Hope this information can help you to understanding details of thread handedness!

Thread Design

Both parallel and tapered threads play crucial roles in various applications, each with their own distinct advantages and uses.

To add some more depth to your explanation, here are some points you might consider:

1. Sealing Mechanisms:

* Parallel Threads:

They generally rely on external seals like gaskets or O-rings for leak-proof connections.

This allows for repeated assembly and disassembly without damaging the threads.

* Tapered Threads:

They create a tight, self-sealing connection due to the wedging action as they are screwed in.

This makes them ideal for high-pressure applications like pipes and fittings.

However, over-tightening can damage the threads or make them difficult to remove.

2. Common Standards:

* Parallel Threads:

These include standards like Unified Thread Standard (UTS) and Metric ISO threads.

They are common in general-purpose applications like bolts, screws, and nuts.

* Tapered Threads:

National Pipe Thread (NPT) and British Standard Pipe Thread (BSPT)

are widely used in plumbing and fluid power systems.

Applications:

* Parallel Threads: Used in furniture assembly, electronics, machinery, and various other applications where frequent disassembly and clean seals are required.

* Tapered Threads: Ideal for plumbing, hydraulics, pneumatic systems, and any application requiring a leak-proof connection under pressure or vibration.

Additional notes:

* Some thread standards like BSPP (British Standard Pipe Parallel) combine the parallel form with a sealing ring for leak-proof connections.

* Thread pitch (distance between threads) and thread depth also play important roles in thread strength and functionality.

Relevance of each thread design type in sintered metal filters.

While thread design itself isn't inherent to the filter type, it plays a crucial role in the functionality and performance

of sintered metal filter assemblies. Here's how different thread designs impact sintered metal filters:

Common Thread Designs:

* NPT (National Pipe Thread): Widely used in North America for general piping applications. Offers good sealing and is readily available.

* BSP (British Standard Pipe): Common in Europe and Asia, similar to NPT but with slight dimensional differences. Crucial to match standards for proper fit.

* Metric Threads: Standardized globally, offering wider thread pitch options for specific needs.

* Other Specialized Threads: Depending on the application, special thread designs like SAE (Society of Automotive Engineers) or JIS (Japanese Industrial Standards) might be used.

Relevance of Thread Design:

* Sealing and Leak Prevention: Proper thread design ensures tight connections, preventing leaks and maintaining filter integrity. Mismatched threads can cause leaks, compromising performance and potentially leading to safety hazards.

* Assembly and Disassembly: Different thread designs offer varying ease of assembly and disassembly. Factors like thread pitch and lubrication requirements need to be considered for efficient maintenance.

* Standardization and Compatibility: Standardized threads like NPT or Metric ensure compatibility with standard filter housings and piping systems. Using non-standard threads can create compatibility issues and complicate replacements.

* Strength and Pressure Handling: Thread design influences the strength and ability to handle pressure in the filter assembly. High-pressure applications might require specific thread types with deeper engagement for better load distribution.

Choosing the Right Thread Design:

* Application Requirements: Consider factors like operating pressure, temperature, fluid compatibility, and desired assembly/disassembly frequency.

* Industry Standards: Adhere to relevant industry standards and regulations for your specific region or application.

* Compatibility: Ensure seamless compatibility with filter housings, piping systems, and potential replacement parts.

* Ease of Use: Balance the need for a secure seal with ease of maintenance and potential future replacements.

Remember, while thread design isn't directly linked to the type of sintered metal filter, it's a critical factor for the overall performance and integrity of the filter assembly. Choose the right thread design based on your specific application needs and consider consulting with a filtration expert for guidance.

Pitch and TPI

* Pitch: Measured in millimeters, it's the distance from one thread crest to the next.

* TPI (Threads Per Inch): Used for inch-sized threads, indicating the number of threads per inch of length.

Relationship between Pitch and TPI:

* They essentially measure the same thing (thread density) but in different units and measurement systems.

1. TPI is the reciprocal of pitch: TPI = 1 / Pitch (mm)

2. Converting between them is straight forward: To convert TPI to pitch: Pitch (mm) = 1 / TPI

To convert pitch to TPI: TPI = 1 / Pitch (mm)

Key Differences:

* Measurement Unit: Pitch uses millimeters (metric system), while TPI uses threads per inch (imperial system).

* Application: Pitch is used for metric fasteners, while TPI is used for inch-based fasteners.

Understanding Thread Density:

* Both pitch and TPI tell you how tightly packed the threads are on a fastener.

* A lower pitch or higher TPI means more threads per unit length, resulting in a finer thread.

* Finer threads generally offer:

1. Stronger resistance to loosening due to vibration or torque.

2. Improved sealing ability when used with appropriate fittings.

3. Less damage to mating threads during assembly and disassembly

However, finer threads may also:

* Be more susceptible to cross-threading or stripping if not aligned properly.

* Require more force to tighten and loosen.

Choosing the Right Thread Density:

* The specific application and its requirements determine the optimal pitch or TPI.

* Factors like strength, vibration resistance, sealing needs, and ease of assembly/disassembly should be considered.

* Consulting appropriate standards and engineering guidelines is crucial for selecting the right thread density for your specific needs.

Diameter

Threads have three key diameters:

* Major Diameter: The largest diameter of the thread, measured at the crests.

* Minor Diameter: The smallest diameter, measured at the roots.

* Pitch Diameter: A theoretical diameter between the major and minor diameters.

Understanding Each Diameter:

* Major Diameter: This is the critical dimension for ensuring compatibility between mating threads (e.g., a bolt and a nut).

Bolts and nuts with the same major diameter will fit together, regardless of pitch or thread form (parallel or tapered).

* Minor Diameter: This affects the strength of the thread engagement.

A larger minor diameter indicates more material and potentially higher strength.

* Pitch Diameter: This is an imaginary diameter where the thread profile has equal amounts of material above and below.

It plays a crucial role in calculating thread strength and other engineering properties.

Relationships between Diameters:

* The diameters are related by the thread profile and pitch. Different thread standards (e.g., metric ISO, Unified National Coarse)

have specific relationships between these diameters.

* Pitch diameter can be calculated using formulas based on major and minor diameters, or found in reference tables for specific thread standards.

Importance of Understanding Diameters:

* Knowing the major diameter is essential for selecting compatible fasteners.

* Minor diameter impacts strength and might be relevant for specific applications with high loads.

* Pitch diameter is crucial for engineering calculations and understanding thread properties.

Additional Notes:

* Some thread standards define additional diameters like "root diameter" for specific purposes.

* Thread tolerance specifications determine permissible variations in each diameter for proper functionality.

I hope this information further clarifies the roles and importance of different thread diameters! Feel free to ask if you have any further questions.

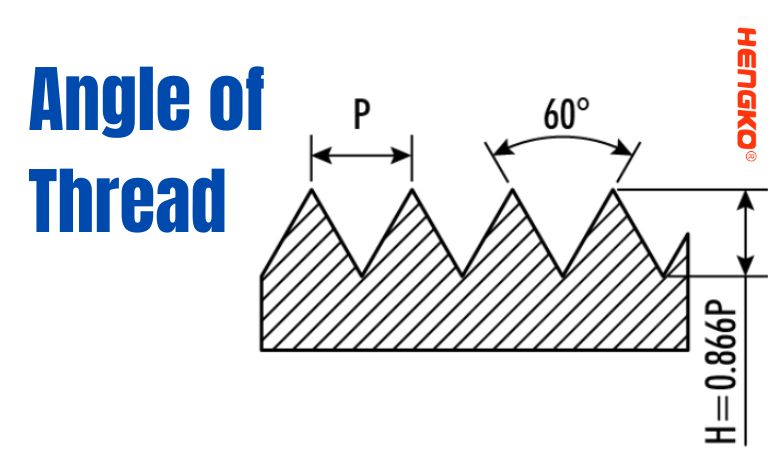

Angle

* Flank Angle: The angle between the thread flank and the perpendicular line to the axis.

* Taper Angle: Specific to tapered threads, it's the angle between the taper and the center axis.

Flank Angle:

* Typically, flank angles are symmetrical (meaning both flanks have the same angle) and constant throughout the thread profile.

* The most common flank angle is 60°, used in standards like Unified Thread Standard (UTS) and Metric ISO threads.

* Other standard flank angles include 55° (Whitworth threads) and 47.5° (British Association threads).

* Flank angle affects:**1. Strength: Larger angles generally offer better torque resistance but are less tolerant of misalignment.

2. Friction: Smaller angles create less friction but might compromise self-locking ability.

3. Chip formation: Flank angle influences how easily cutting tools can create threads.

Taper Angle:

* This angle defines the rate of diameter change along the tapered thread.

* Common taper angles include 1:16 (National Pipe Thread - NPT) and 1:19 (British Standard Pipe Thread - BSPT).

* Taper angle ensures a tight, self-sealing connection as the threads compress against each other upon tightening.

* It's crucial for tapered threads to have the correct matching angle for a leak-proof seal.

Relationship between Angles:

* In non-tapered threads, the flank angle is the only relevant angle.

* For tapered threads, both flank and taper angles play a role:

1. The flank angle determines the basic thread profile and its associated properties.

2. The taper angle defines the rate of diameter change and influences sealing characteristics.

Crest and Root

* Crest: The outermost part of the thread.

* Root: The innermost part, forming the base of the thread space.

Above is just defined the crest and root of a thread.

While their locations within the thread seem simple, they play crucial roles in various aspects of thread function and design.

Here are some additional details you might find interesting:

Crest:

*This is the outermost edge of the thread, forming the contact point with its mating thread.

*The strength and integrity of the crest are critical for bearing the applied load and resisting wear.

*Thread damage, burrs, or imperfections on the crest can compromise the connection's strength and functionality.

Root:

*Located at the bottom of the thread, it forms the base of the space between adjacent threads.

*The depth and shape of the root are important for factors like:

1. Strength: A deeper root provides more material for load bearing and improved strength.

2. Clearance: Adequate root clearance is needed to accommodate debris, lubricants, or manufacturing variations.

3. Sealing: In some thread designs, the root profile contributes to seal integrity.

Relationship between Crest and Root:

*The distance between the crest and root defines the depth of thread, which directly impacts strength and other properties.

*The specific shape and dimensions of both crest and root depend on the thread standard (e.g., metric ISO, Unified Coarse) and its intended application.

Considerations and Applications:

*Thread standards and specifications often define tolerances for crest and root dimensions to ensure proper functionality and interchangeability.

*In applications with high loads or wear, thread profiles with reinforced crests and roots might be chosen for improved durability.

*Manufacturing processes and quality control are crucial for ensuring smooth, damage-free crests and roots on fasteners.

I hope this additional information adds depth to your understanding of the roles and importance of crest and root in threads.

Feel free to ask if you have any further questions or specific topics related to thread design that you'd like to explore!

Dimensions of Thread Types

Here's a breakdown of the dimensions of some common thread types you mentioned, along with images for better visualization:

M - ISO Thread (Metric):

*ISO 724 (DIN 13-1) (Coarse Thread):

1. Image:

2. Major diameter range: 3 mm to 300 mm

3. Pitch range: 0.5 mm to 6 mm

4. Thread angle: 60°

*ISO 724 (DIN 13-2 to 11) (Fine Thread):

1. Image:

2. Major diameter range: 1.6 mm to 300 mm

3. Pitch range: 0.25 mm to 3.5 mm

4. Thread angle: 60°

NPT - Pipe Thread:

*NPT ANSI B1.20.1:

1. Image:

2. Tapered thread for pipe connections

3. Major diameter range: 1/16 inch to 27 inches

4. Taper angle: 1:16

*NPTF ANSI B1.20.3:

2. Similar to NPT but with flattened crests and roots for better sealing

3. Same dimensions as NPT

G/R/RP - Whitworth Thread (BSPP/BSPT):

*G = BSPP ISO 228 (DIN 259):

1. Image:

2. Parallel pipe thread

3. Major diameter range: 1/8 inch to 4 inches

4. Thread angle: 55°

*R/Rp/Rc = BSPT ISO 7 (DIN 2999 replaced by EN10226):

1. Image:

2. Tapered pipe thread

3. Major diameter range: 1/8 inch to 4 inches

4. aper angle: 1:19

UNC/UNF - Unified National Thread:

*Unified National Coarse (UNC):

1. mage:

2. Similar to M Coarse Thread but with inch-based dimensions

3. Major diameter range: 1/4 inch to 4 inches

4. Threads per inch (TPI) range: 20 to 1

*Unified National Fine (UNF):

2. Similar to M Fine Thread but with inch-based dimensions

3. Major diameter range: 1/4 inch to 4 inches

4. TPI range: 24 to 80

Above information provides a general overview of the dimensions for each thread type. but specific dimensions may vary depending on the specific standard and application. You can find detailed tables and dimensions in relevant standards documents like ISO 724, ANSI B1.20.1, etc.

Feel free to ask if you have any further questions or need more information on specific thread types or dimensions!

Summary

This blog provides a comprehensive guide to thread design, focusing on its importance in machinery and sintered filters.

It covers thread gender (male and female), thread handedness (mainly right-handed), and the differences between parallel

and tapered threads. A must-read for understanding thread design and selecting the right thread for sintered filter applications.

Post time: Jan-30-2024