Introduction

A pressure gauge snubber is a device designed to dampen the effects of pressure spikes and pulsations in mechanical systems.

By equalizing the rate at which a fluid or gas arrives at the measuring point, snubbers help maintain the readability and accuracy of pressure gauges and extend their service life.

They are particularly useful in applications where pressure transients can cause significant damage to sensors and other components

What is a Pressure Gauge Snubber and Why Do You Need One?

What is Pressure Gauge Snubber and

Why you need a Pressure Gauge Snubber ?

A pressure gauge snubber is a vital component in many mechanical systems.

It safeguards pressure gauges from damage by absorbing sudden pressure spikes and oscillations.

By damping these fluctuations, snubbers enhance gauge performance in several ways:

*Protection:

Acts as a barrier between the pressure source and the gauge, shielding it from harmful pressure surges.

*Improved Readability:

Creates steadier gauge readings, making them easier to interpret, especially in systems with pulsating pressures.

*Extended Gauge Life:

Reduces stress on gauge components, prolonging their lifespan and saving costs on replacements.

*Enhanced Accuracy:

Filters out rapid pressure changes, providing more precise and reliable pressure measurements.

*Versatility:

Compatible with a wide range of media, including water, steam, oil, gasoline, air, and various gases.

*Preservation of Calibration:

Maintains gauge accuracy for extended periods by preventing damage from pressure spikes.

In industries where accurate pressure readings and equipment reliability are paramount, pressure gauge snubbers are indispensable. They offer a cost-effective solution to safeguard equipment, improve measurement precision, and optimize system performance.

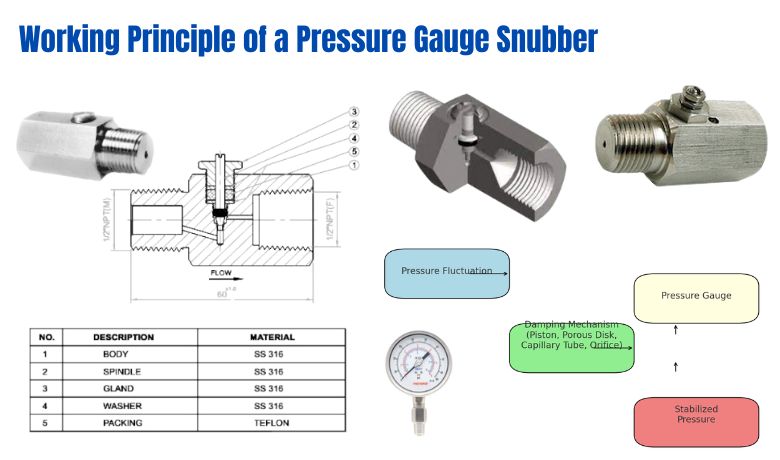

Working Principle of a Pressure Gauge Snubber

A pressure gauge snubber acts as a shield between the pressure source and the gauge, safeguarding it from harm. Its primary function is to dampen or reduce the impact of pressure surges and pulsations.

Damping Mechanism:

The core principle behind a snubber's operation revolves around restricting and controlling the flow of fluid or gas reaching the pressure gauge. This restriction creates a damping effect, smoothing out rapid pressure fluctuations.

There are two main approaches to achieving this damping:

1.Orifice or Restriction:

The snubber features a small opening (orifice) or another form of restriction that limits the flow rate of the fluid or gas.

When a pressure surge occurs, the fluid encounters resistance, preventing it from reaching the gauge instantaneously.

This delay allows the pressure wave to dissipate before it impacts the gauge.

2.Damping Element:

Some snubbers utilize a damping element, such as a piston or a porous material, to absorb the energy of the pressure surge.

This element moves or deforms in response to the pressure spike, reducing its intensity before it reaches the gauge.

Detailed Explanation (Piston-Type Snubber):

Let's use a piston-type snubber as an example to illustrate the damping mechanism:

1.Pressure Surge:

When a sudden pressure increase occurs in the system, the high-pressure fluid or gas pushes against the piston within the snubber.

2.Piston Movement:

The force of the pressure surge causes the piston to move, compressing the fluid or gas within the snubber.

3.Damping Effect:

As the piston moves, it creates resistance to the flow of fluid, effectively dampening the pressure spike.

The energy of the surge is absorbed by the piston's movement and the compression of the fluid.

4.Gradual Pressure Increase:

The dampened pressure is then gradually transmitted to the pressure gauge,

allowing the gauge to respond accurately without being damaged by the sudden pressure change.

By effectively damping pressure surges, snubbers protect pressure gauges from damage,

improve measurement accuracy, and extend the lifespan of the gauge.

The choice of snubber type depends on factors like the severity of pressure fluctuations, the type of fluid, and the required level of damping.

Function and Mechanism

Pressure gauge snubbers work by limiting the fluid's rate of pressure change, typically through a smaller fitting that restricts fluid flow.

This restriction delays the sudden rise in pressure downstream, effectively filtering out pressure spikes while allowing quasi-static pressure changes to pass through.

The result is a smoother and more stable pressure reading, which prevents damage to the pressure gauge and other sensitive components in the system

Types of Pressure Gauge Snubbers

Piston-Type Snubbers

Piston-type snubbers employ a movable piston within the device.

When subjected to rapid pressure surges, the piston shifts, obstructing the flow of fluid to the gauge.

This action effectively dampens the pressure spikes, protecting the gauge.

These snubbers are particularly effective in applications with severe pressure fluctuations

and are often used in hydraulic and pneumatic systems.

Porous Disk Snubbers

Porous disk snubbers utilize a fine-mesh disk to restrict fluid flow to the pressure gauge.

The disk's porosity determines the level of damping.

These snubbers are relatively simple and economical, making them suitable for various applications.

However, they are prone to clogging, especially when dealing with dirty or viscous fluids.

Capillary Tube Snubbers

Capillary tube snubbers use a long, narrow tube to restrict fluid flow.

The tube's length and diameter influence the damping capacity.

These snubbers offer precise control over pressure damping and are commonly

used in applications requiring high accuracy, such as instrumentation and calibration.

Orifice-Type Snubbers

Orifice-type snubbers feature a small opening (orifice) that restricts fluid flow.

The size of the orifice determines the damping level.

These snubbers are generally less expensive than other types but may have limitations in terms of flow capacity

and damping effectiveness compared to piston or capillary tube snubbers.

Note: The selection of a suitable pressure gauge snubber depends on various factors,

including the type of fluid, pressure range, pulsation frequency, and desired level of damping.

Why Stainless Steel Pressure Gauge Snubbers are Popular

Stainless steel pressure gauge snubbers are widely preferred due to their exceptional properties:

Durability and Corrosion Resistance

*Longevity:

Stainless steel is renowned for its resistance to wear and tear, ensuring the snubber maintains its integrity under harsh conditions.

*Corrosion Protection :

Its inherent resistance to corrosion makes it ideal for applications involving corrosive fluids or environments.

Mechanical Strength and Versatility

*High Strength:

Stainless steel offers excellent mechanical strength, capable of withstanding high pressures and vibrations without deformation.

*Diverse Applications:

Its versatility allows for use in a wide range of industries and applications, from chemical processing to food and beverage.

Applications in Various Industries

Stainless steel snubbers find utility across numerous sectors due to their reliability and compatibility:

*Chemical Processing:

Handles corrosive substances without compromising snubber integrity.

*Food and Beverage:

Meets hygienic standards and resists contamination.

*Pharmaceutical:

Ensures product purity in sterile environments.

*Oil and Gas:

Withstands high pressures and extreme temperatures.

*Marine:

Resists saltwater corrosion and provides durability in harsh conditions.

How to Choose the Right Pressure Gauge Snubber

Selecting the appropriate pressure gauge snubber is crucial for optimal system performance and gauge protection. Here are the key factors to consider for making the best choice:

Factors to Consider:

*Application:

Tips for Selecting the Best Snubber:

*Understand the System:

By carefully considering these factors and following these tips, you can select the ideal pressure gauge snubber to protect your equipment,

improve measurement accuracy, and enhance overall system reliability.

Installation of a Pressure Gauge Snubber

Installing a pressure gauge snubber is a relatively straightforward process, but it's essential to follow the correct steps to ensure optimal performance and safety.

Step-by-Step Installation Guide

1.Shut Down System:

Before starting any installation, ensure the system is completely depressurized and isolated.

Common Mistakes to Avoid

*Incorrect Snubber Selection:

Using a snubber that is not compatible with the system or gauge can lead to inaccurate readings or damage to the equipment.

*Improper Installation:

Loose connections or cross-threading can cause leaks or system failures.

*Neglecting System Shutdown:

Working on a pressurized system can be dangerous. Always ensure the system is completely isolated before starting any work.

*Ignoring Maintenance:

Regular inspection and maintenance of the snubber are essential for optimal performance.

Maintenance Tips for Pressure Gauge Snubbers

Proper maintenance of your pressure gauge snubber is crucial for ensuring its continued performance and protecting your pressure gauge.

Regular Inspection and Cleaning

*Visual Inspection:

Regularly check for signs of damage, such as cracks, leaks, or corrosion.

*Cleaning:

Depending on the type of snubber and the fluid it's exposed to, cleaning may be necessary.

Use appropriate cleaning solvents and follow manufacturer's guidelines.

*Clogging Prevention:

For porous disk snubbers, regular cleaning can prevent clogging, which can affect performance.

Troubleshooting Common Issues

*Inaccurate Readings:

Check for obstructions, damage, or incorrect installation. Ensure the snubber is compatible with the fluid and pressure conditions.

*Rapid Gauge Fluctuation:

This could indicate a damaged or worn-out snubber. Replace the snubber if necessary.

*Leaks:

Tighten connections, inspect for damage, and replace any worn or damaged components.

Ensuring Long-Term Accuracy and Performance

*Follow Manufacturer Guidelines:

Adhere to the manufacturer's recommendations for maintenance, replacement, and operating conditions.

*Calibration:

While snubbers don't typically require calibration, the pressure gauge itself should be calibrated regularly to ensure accurate readings.

*Environmental Factors:

Protect the snubber from extreme temperatures, vibrations, and corrosive environments.

By following these maintenance tips, you can extend the life of your pressure gauge snubber and maintain accurate pressure readings.

The Role of Pressure Gauge Snubbers in Hydraulic Systems

Hydraulic systems are prone to pressure surges and pulsations due to the nature of fluid power.

These rapid pressure fluctuations can significantly impact the accuracy and lifespan of pressure gauges.

This is where pressure gauge snubbers become indispensable.

Importance of Snubbers in Maintaining System Stability and Accuracy

*Protection of Pressure Gauges:

Snubbers act as a shield, absorbing the shock of pressure spikes, preventing damage to the gauge's internal components.

*Improved Gauge Readability:

By smoothing out pressure fluctuations, snubbers provide more stable and accurate gauge readings.

*System Stability:

Snubbers contribute to overall system stability by reducing pressure variations, which can affect other components.

Specific Benefits in Hydraulic Applications

*Extended Gauge Life:

In hydraulic systems, where pressure fluctuations are common, snubbers significantly extend the life of pressure gauges.

*Accurate Pressure Measurements:

Hydraulic systems often require precise pressure control. Snubbers enhance measurement accuracy by filtering out noise.

*Reduced Maintenance:

By protecting the gauge, snubbers help reduce maintenance costs and downtime.

Comparing Pressure Gauge Snubbers: Stainless Steel vs. Brass vs. Other Materials

When selecting a pressure gauge snubber, the material plays a crucial role in determining its suitability for specific applications. Different materials offer unique advantages and disadvantages, impacting durability, resistance to corrosion, and compatibility with various fluids. Here's a comparison of stainless steel, brass, and other common materials used in pressure gauge snubbers.

Pros and Cons of Different Materials

| Material | Pros | Cons | Best Applications |

|---|---|---|---|

| Stainless Steel | - Highly resistant to corrosion | - More expensive than brass and other materials | - Harsh environments |

| - Durable and strong | - Heavier than some alternatives | - Chemical processing | |

| - Suitable for a wide range of temperatures | - Oil and gas industries | ||

| - Non-reactive and easy to clean | - Food and pharmaceutical industries | ||

| - Marine environments | |||

| Brass | - Cost-effective | - Less corrosion-resistant than stainless steel | - General-purpose applications |

| - Good machinability | - Not suitable for highly corrosive environments | - Water systems | |

| - Lightweight | - HVAC systems | ||

| - Adequate for moderate temperatures | - Low to moderate pressure systems | ||

| Carbon Steel | - Strong and durable | - Prone to rust and corrosion if not protected | - High-pressure systems |

| - Cost-effective | - Requires protective coatings for corrosion resistance | - Industrial applications | |

| - Good for high-pressure applications | - Structural applications | ||

| Plastic | - Lightweight and corrosion-resistant | - Limited temperature and pressure range | - Low-pressure systems |

| - Inexpensive | - Less durable than metal alternatives | - Non-corrosive fluid systems | |

| - Suitable for non-corrosive fluids | - Chemical storage tanks | ||

| Monel | - Excellent corrosion resistance, especially to seawater | - Expensive | - Marine environments |

| - Strong and durable | - Limited availability | - Chemical processing | |

| - Good for high-pressure and high-temperature applications | - Oil and gas industries |

Choosing the Right Material for Specific Applications

1.Harsh Environments and Corrosive Fluids:

Stainless steel and Monel are excellent choices due to their superior corrosion resistance and durability. These materials are ideal for chemical processing, marine, and oil and gas industries.

2.General-Purpose Applications:

Brass offers a cost-effective solution for systems with moderate temperatures and pressures. It's suitable for water systems, HVAC, and low to moderate pressure systems.

3.High-Pressure Systems:

Carbon steel is strong and durable, making it a good choice for high-pressure applications in industrial settings. However, it requires protective coatings to prevent rust and corrosion.

4.Low-Pressure and Non-Corrosive Systems:

Plastic snubbers are lightweight, inexpensive, and corrosion-resistant, making them suitable for low-pressure applications with non-corrosive fluids, such as chemical storage tanks.

5.Marine Environments:

Monel is highly resistant to seawater corrosion, making it the best choice for marine applications. Its strength and durability also make it suitable for high-pressure and high-temperature environments.

By understanding the pros and cons of different materials, you can select the most appropriate pressure gauge snubber for your specific application, ensuring optimal performance and longevity.

Conclusion

Pressure gauge snubbers play a crucial role in protecting pressure gauges from surges and pulsations, ensuring accurate and stable readings.

Choosing the right material for your pressure gauge snubber is essential for optimal system performance and longevity.

Whether you need the durability of stainless steel, the cost-effectiveness of brass, or the specialized properties of Monel,

selecting the appropriate snubber material is key to maintaining the efficiency and reliability of your system.

For more information or personalized advice on selecting the best pressure gauge snubber for your needs,

feel free to contact HENGKO at ka@hengko.com.

We're here to help you find the perfect solution for your pressure measurement challenges.

Contact us today at ka@hengko.com to discuss your specific requirements!

Send your message to us:

Post time: Aug-05-2024