Introduction

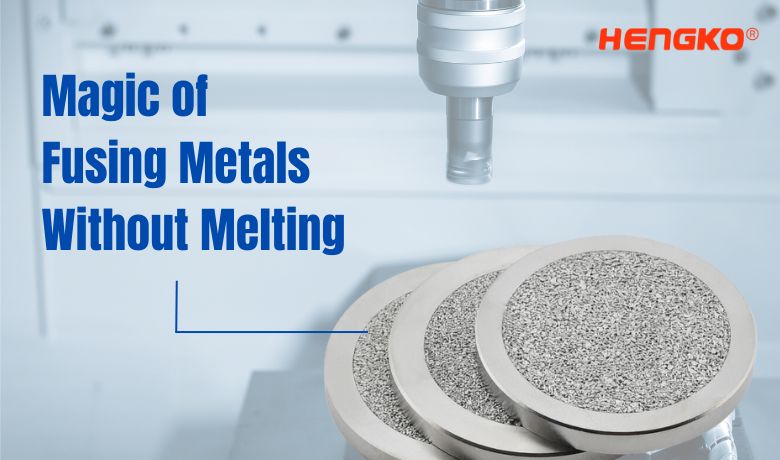

Sintering is a transformative process that plays a important role in manufacturing high-performance metal components,

including porous metal filters, sintered stainless steel cover, sintered suction filter, humidity housing, ISO KF filter, Sparger etc.

This technique involves compacting metal powders and heating them below their melting point, allowing particles to bond

and form a solid structure. This method is essential for creating components with precise specifications and enhanced

mechanical properties.

After check those information, maybe you also have more questions.

A key question arises:

How can metal particles fuse into one solid part without melting ?

The answer lies in the principles of solid-state sintering, where diffusion and particle rearrangement occur

at elevated temperatures, enabling the formation of strong inter-particle bonds.

So let us share more details and talk everything about Solid-State Sintering bellow.

What Is Solid-State Sintering?

Solid-state sintering is a manufacturing process used to create solid objects from metal powders

by applying heat and pressure without allowing the materials to melt.

This method distinguishes itself from other manufacturing techniques, particularly those that involve liquefied metals,

such as casting or welding, where the materials transition into a liquid state before solidification.

In solid-state sintering, metal particles are compacted together and subjected to high temperatures, typically

below the melting point of the base metal.

This heat facilitates atomic diffusion—the movement of atoms across the boundaries of adjacent particles

—allowing them to bond and form a cohesive solid mass.

As the temperature increases, the particles rearrange and grow together, enhancing the strength and integrity of the final product.

The key principle behind solid-state sintering is that the fusion of metal particles occurs at elevated temperatures without the

need for them to become liquid.

This unique approach enables manufacturers to achieve desired properties in the final components while maintaining dimensional

accuracy and preventing issues like shrinkage or distortion that can arise from melting. As a result, solid-state sintering is widely

used in applications where high-performance and precision are essential, such as in the production of porous metal filters.

The Role of Temperature and Pressure in Solid-State Sintering

Solid-state sintering is a process that enhances the density and strength of metal materials by heating metal particles

below their melting point and applying pressure.

The heat increases atomic mobility, while pressure facilitates atomic diffusion, allowing particles to bond and form

a cohesive structure without melting.

Key Points:

1. Temperature:

*Heats metal particles below their melting point, softening them.

*Enhances atomic mobility, enabling atoms to move more freely.

2. Pressure:

*Brings particles closer together, aiding in atomic diffusion.

*Helps fill gaps between particles, increasing material density.

3. Atomic Diffusion:

*Atoms migrate to fill voids between particles, creating a more cohesive structure.

*Results in a denser and stronger material.

4. Material State:

*The material remains solid throughout the process.

*No melting occurs; particles only soften to enable bonding.

This combination of heat and pressure ensures the formation of a dense, durable, and high-integrity material.

Atomic Diffusion: The Secret Behind Particle Fusion

Atomic diffusion is a key mechanism in solid-state sintering, enabling the fusion of metal particles without melting.

This process involves the movement of atoms, especially at contact points between particles, to form strong,

cohesive bonds.

What is Atomic Diffusion?

*The movement of atoms between particles, primarily at their contact boundaries.

*Enables particles to fuse by filling voids and creating a unified structure.

How it Works:

*Heating increases atomic energy and mobility.

*Atoms migrate at surfaces and edges, blending materials at contact points.

*This diffusion happens at temperatures below the melting point.

Results and Benefits:

*Forms strong bonds between particles, enhancing material strength.

*Maintains the integrity of the metal structure, avoiding distortion or phase changes caused by melting.

Atomic diffusion is the driving force behind the densification and cohesion in solid-state sintering,

ensuring high-performance materials.

Do Boundaries Between Metal Particles Really Disappear?

The boundaries between metal particles during sintering do not completely vanish, though they may become less distinct.

The extent to which they disappear depends on the sintering process and the application's requirements.

Particle Bonding

*Sintering promotes atomic diffusion, causing particles to bond and reducing visible boundaries.

*Complete disappearance of boundaries is rare, as some structures benefit from retained boundaries.

Porous Applications:

*In porous filters, retaining some boundaries preserves the porosity needed for flow and filtration.

*These boundaries contribute to defining the porous structure while maintaining material strength.

Influence of Sintering Conditions:

*Factors like temperature, pressure, and sintering duration affect how much the boundaries fuse.

*Adjusting these parameters allows for balancing particle bonding and structural functionality.

While sintering strengthens the material and reduces boundaries, preserving some degree of structure is

often crucial, especially in applications like porous filters or materials requiring controlled porosity.

Why Solid-State Sintering is Ideal for Porous Metal Filters

Solid-state sintering is particularly beneficial for creating porous metal structures, making it an ideal

choice for filtration applications.

The unique characteristics of this process allow for precise control over key properties, including porosity,

strength, and durability, which are essential for the effective performance of sintered metal filters.

1. Control Over Porosity:

One of the primary advantages of solid-state sintering is the ability to tailor the porosity of the final product.

By adjusting factors such as particle size, compaction pressure, and sintering temperature, manufacturers

can create filters with specific pore sizes and distributions.

This customization is crucial for achieving optimal filtration performance, ensuring that the filter effectively

captures contaminants while allowing the desired flow rate.

2. Enhanced Strength and Durability:

Sintering not only promotes bonding between particles but also enhances the overall mechanical strength

of the material. The process creates a robust structure that can withstand the pressures and stresses

encountered in industrial filtration applications.

As a result, sintered metal filters demonstrate exceptional durability, reducing the risk of breakage or

deformation over time, even in demanding environments.

3. Chemical Resistance:

The materials used in solid-state sintering, such as stainless steel and other alloys, often exhibit excellent

chemical resistance. This property is particularly important in filtration processes where exposure to

aggressive chemicals or corrosive substances is common. Sintered metal filters maintain their integrity

and performance under harsh conditions, ensuring long-lasting functionality.

4. Consistent Quality and Performance:

Solid-state sintering provides consistent and repeatable manufacturing results. The ability to control

processing parameters leads to high-quality products with uniform properties, minimizing variability in

performance. This consistency is vital in industrial settings where reliability and efficiency are paramount.

In summary, solid-state sintering is ideal for producing porous metal filters due to its ability to precisely

control porosity, enhance strength and durability, ensure chemical resistance, and maintain consistent quality.

These benefits make sintered metal filters a preferred choice for a wide range of industrial filtration

applications, delivering superior performance and reliability.

Common Misconceptions About Sintering: It’s Not About Melting

Sintering is often misunderstood, particularly the misconception that metal particles must melt in order to fuse

together. In reality, sintering is fundamentally a solid-state process that relies on bonding at the atomic level,

and this distinction has significant implications for various industries.

1. Misconception: Metal Particles Must Melt to Fuse

Many people believe that for metal particles to bond together, they need to reach their melting point.

However, solid-state sintering occurs at temperatures well below melting, where metal particles

become "soft" and allow atomic diffusion without transitioning into a liquid state.

This process promotes strong inter-particle bonds while preserving the material's solid integrity,

which is crucial for applications requiring precise dimensions and properties.

2. Advantage of Solid-State Bonding

The solid-state nature of sintering offers several advantages over melting-based processes.

Since there is no liquid phase involved, issues like shrinkage, distortion, and phase changes

are minimized. This ensures that the final product maintains its intended shape and mechanical

properties, which is especially important in industries such as aerospace, automotive, and filtration.

3. Enhanced Mechanical Properties

Sintered materials often exhibit superior mechanical properties compared to those made through

melting processes. The strong bonds formed during sintering lead to enhanced strength, wear resistance,

and durability. This makes sintered components ideal for demanding applications where performance

and reliability are critical.

4. Versatility Across Industries

Sintering's unique characteristics make it a preferred method in various industries, from producing

porous metal filters for efficient filtration to creating precision components for electronics and medical devices.

The ability to control porosity and other properties during sintering allows manufacturers to tailor products to

meet specific requirements.

In conclusion, it’s essential to recognize that sintering is not about melting but about creating strong, durable

bonds in a solid state. This understanding highlights the advantages of sintering in producing high-quality

components across a wide range of industries, making it a key technology in modern manufacturing.

Conclusion

In summary, solid-state sintering is a remarkable process that enables metal particles to fuse together without

melting, relying on atomic diffusion to create strong bonds.

This method is particularly effective for producing porous metal filters, offering precise control over porosity,

strength, and durability. The advantages of sintered metal components make them ideal for a variety of

applications across multiple industries.

If you're considering the benefits of sintered metal elements for your projects, we invite you to reach

out to HENGKO for expert advice.

Contact us at ka@hengko.com to discuss your OEM needs for sintered metal solutions.

Send your message to us:

Post time: Nov-02-2024