In the pharmaceutical industry, maintaining the proper temperature range during the transportation and storage of temperature-sensitive drugs is critical to ensuring their efficacy and safety. Even minor deviations from the recommended temperature range can cause irreversible damage to the products, rendering them ineffective or even harmful to patients. To mitigate these risks, pharmaceutical companies are turning to real-time monitoring solutions that use IoT technology to provide continuous monitoring of the cold chain.

The Importance of Real-Time Monitoring for Cold Chain Drugs

Maintaining the proper temperature range during the transportation and storage of cold chain drugs is crucial to ensure their efficacy and safety. However, traditional temperature monitoring methods, such as manual checks and data loggers, are often unreliable and can result in delays in identifying temperature excursions. Real-time monitoring solutions that use IoT technology provide continuous monitoring of the temperature and other environmental conditions, alerting the relevant personnel immediately if there is a deviation from the recommended range. This allows pharmaceutical companies to take corrective action quickly, mitigating the risk of product loss and ensuring the safety and efficacy of the products.

How IoT Technology Can Help Monitor the Cold Chain

IoT technology can take temperature monitoring to the next level by providing real-time monitoring of the cold chain. By using IoT-enabled temperature sensors and data loggers, pharmaceutical companies can gain valuable insights into their cold chain environment, optimize their cold chain management practices, and ultimately improve their bottom line. The data can be accessed remotely through smartphones or computers, allowing personnel to monitor the cold chain environment from anywhere in the world.

In addition, IoT technology can help pharmaceutical companies identify patterns and trends in their cold chain data. This information can be used to optimize cold chain management practices and improve the efficiency of the supply chain.

Implementing a Real-Time Monitoring IoT Solution

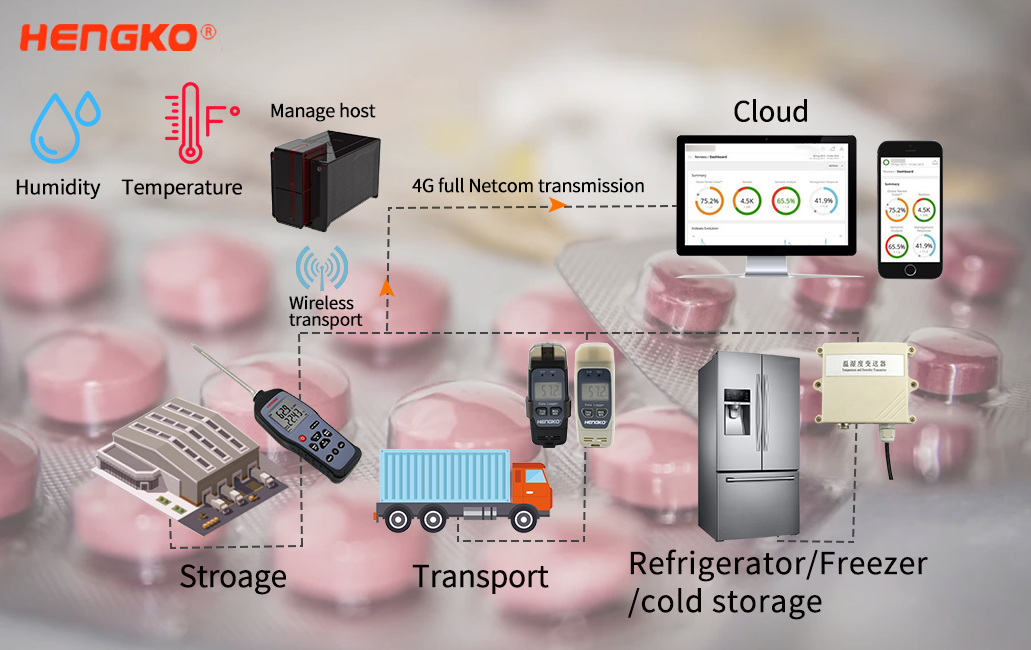

To implement a real-time monitoring IoT solution for cold chain drugs, pharmaceutical companies need to select the right sensors and IoT platform. Industrial temperature and humidity sensors are often preferred for pharmaceutical applications, as they are designed to withstand harsh environmental conditions and provide accurate and reliable measurements.

Once the sensors are installed, pharmaceutical companies need to connect them to an IoT platform using a wireless network. The IoT platform should provide a user-friendly interface for data visualization and analysis.

Drug is a special commodity that relates to human health. In China, medication safety and pharmaceutical quality are of utmost importance. The State Food and Drug Administration (SDA) has issued a notice requiring the implementation of information traceability for key varieties, such as anesthetic drugs, psychotropic drugs, and blood products, selected in the national centralized drug procurement by December 31, 2020.

What is drug traceability? According to GS1, a global organization that develops standards for identification and barcoding, traceability in healthcare is defined as a process that "enables you to see the movement of prescription drugs or medical devices across the supply chain." To achieve full-process information traceability, it is necessary to build and use the drug traceability system.

For special storage drug, the temperature and humidity monitor is essential. COVID-19 Vaccine vials to be stored at 2°C to 8°C (35°F to 46°F). HENGKO cold chain transport traceability system include sensor technology, IOT technology, wireless communication technique, electronic technology, network communication, etc. The hardware equipment safely and quickly collects and transmits real-time temperature and humidity data of the environment, interconnects with the cloud, strengthens the supervision of the cold chain transportation of vaccines and medicines, guarantees the quality and safety of medicines, and builds a protective wall for people's medication safety and inquiries.

HENGKO vaccine cold chain temperature and humidity monitor system can share and storage data via Cloud server and big data. Building all-around monitor traceability system to realize the full process vaccines cold chain warning, supervision and risk specification.

After the CFDA issued the notice, all provinces and cities have issued relevant documents to comprehensively promote the traceability system of key varieties of drugs, and some provincial and municipal governments have developed their own smart platform systems that require companies to access their drug traceability systems. Strict control of the drug not only ensure human’s health, but also effectively combat the influx of counterfeit and expired drugs into the market, causing losses.

Conclusion

Real-time monitoring IoT solutions are becoming increasingly popular in the pharmaceutical industry, as they provide continuous monitoring of the cold chain and ensure the efficacy and safety of temperature-sensitive drugs. By using IoT-enabled temperature sensors and data loggers, pharmaceutical companies can gain valuable insights into their cold chain environment, optimize their cold chain management practices, and ultimately improve their bottom line.

To learn more about how real-time monitoring IoT solutions can benefit your pharmaceutical company, contact us today.

Don't risk the safety and efficacy of your temperature-sensitive drugs. Contact us today to learn more about our real-time monitoring IoT solutions for the cold chain.

Post time: Aug-12-2021