I. Introduction

The Critical Role of Porous Metal Filters in Modern Industries

You play a crucial role in ensuring that your operations maintain high product quality, operational efficiency, and regulatory compliance. In your industry—whether it’s pharmaceuticals, food processing, chemical manufacturing, or water treatment—filtration is essential to keep environments clean and free of contaminants.

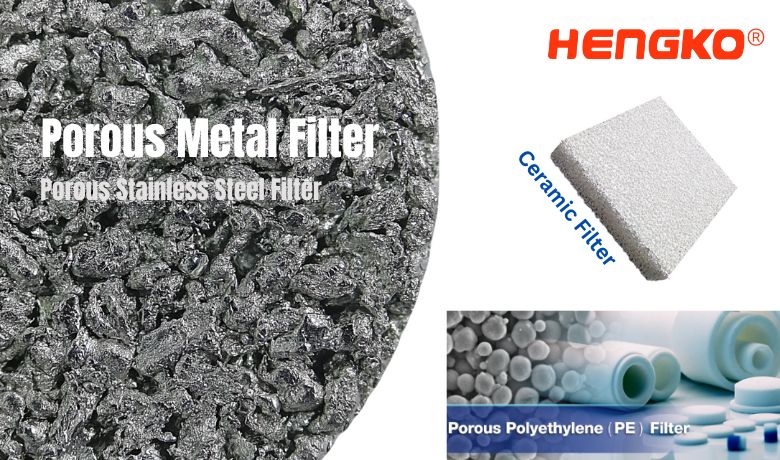

While you might have relied on traditional filter materials like paper, fabric, or ceramics, you now have the opportunity to explore an advanced alternative. Porous metal media technology has captured attention due to its superior durability, efficiency, and reusability.

Why Compare Porous Metal Filters to Traditional Materials?

When you choose a filtration system, cost-effectiveness, reliability, and long-term performance are critical factors. In this article, you will find an in-depth comparison between porous metal filters and traditional filtration materials. You’ll break down their pros and cons across key factors:

- Filtration Performance: How effectively do they remove contaminants?

- Durability & Longevity: How long do they last, and how well do they withstand harsh environments?

- Maintenance & Reusability: Are they easy for you to clean and maintain?

- Environmental Impact: Which option is more sustainable for your operation?

- Cost Considerations: Which filter type offers you the best long-term value?

Sintered metal filters are known for their durability and reusability in various filtration applications, making them a reliable choice for many industries.

By exploring these aspects, you’ll understand why many industries are increasingly turning to porous metal filters—and when traditional options might still serve your needs best.

II. Understanding Porous Metal Filters

Definition and Composition

A sintered porous metal filter is a filtration device you can rely on, crafted from metal components engineered with a network of interconnected pores. Typically, these filters are made through processes like sintering, where powdered metal is heated until its particles bond together, or diffusion bonding, which joins metal sheets or fibers under high temperature and pressure. This precise manufacturing creates consistent, well-defined pore sizes that are key to achieving reliable and precise filtration performance for your applications.

Key Features and Benefits

- Durability: You will appreciate that porous metal filters are renowned for their high strength and their ability to withstand extreme temperatures, pressures, and corrosive environments. Porous metals, characterized by their high surface area and lightweight, offer unique properties that enhance their performance in various applications. This robustness makes them an excellent choice in demanding industrial settings.

- Reusability: Thanks to their robust design, these filters are easy for you to clean and maintain. This reusability translates into long-term savings by reducing the need for frequent replacements and minimizing downtime in your operations.

- Precision Filtration: The controlled pore size achieved during manufacturing ensures that you get consistent filtration. This precision is essential if you require reliable separation of particles, providing both high efficiency and accuracy in contaminant removal.

Common Applications

The versatility and durability of porous metal filters make them ideal for a wide range of industries. You can use them in:

- Chemical Processing:

For applications that demand resistance to high temperatures and aggressive chemicals. - Aerospace:

Where you need reliable performance under extreme conditions. - Pharmaceuticals:

To ensure precise filtration and maintain the purity of your products. - Other Industries:

Such as food processing, water treatment, and oil & gas—where filtration efficiency and durability are paramount.

These features position the porous metal filter as a superior alternative in environments where you require consistent, high-performance filtration over extended periods.

III. Overview of Traditional Filter Materials

Types of Traditional Filters

- Ceramic Filters:

You might find ceramic filters offer high filtration precision because of their uniform and fine pore structure. They are highly effective in removing contaminants, though they can be brittle—making them less ideal for applications where mechanical shock or vibration is a concern. - Polymer and Fiberglass Filters:

These filters are often chosen because they’re cheaper and lighter. They can provide satisfactory filtration for many standard applications, but their lower heat resistance might limit your use in environments with elevated temperatures or corrosive conditions. - Paper or Disposable Filters:

If you need a low-cost solution, you might opt for paper filters. Their simple design is widely used, though they’re typically single-use, which means you’ll need to replace them regularly. This can lead to higher operational costs and more frequent maintenance for you.

Key Features and Benefits

Traditional filter materials have distinct advantages you should consider:

- Cost-Effectiveness:

The lower initial cost of many traditional filters, such as paper and polymer-based options, can be attractive when you’re working with budget constraints or in applications where high precision isn’t critical. - Simplicity in Design:

Their straightforward design often results in ease of installation and replacement, which can be a significant benefit in processes where you don’t require the high performance of advanced filtration systems.

Manufacturing Process of Metal Filters

The manufacturing process of metal filters is a meticulous and multi-step procedure that ensures the creation of high-quality, durable, and efficient filtration solutions. It begins with the careful selection of raw materials, typically metal powders such as stainless steel powder, chosen for their specific properties like temperature resistance and corrosion resistance.

The next step is powder production, where the selected metal is ground into fine particles. These metal powders are then subjected to the sintering process, a critical phase where the powders are heated to a temperature below their melting point. This causes the particles to bond together, forming a solid structure with interconnected pores. The sintering process is essential for achieving the desired porosity and structural integrity of the filter, allowing for precise control over pore size and distribution.

After sintering, the filters undergo various finishing processes to enhance their performance and durability. These may include additional heat treatments, surface polishing, and the application of protective coatings. The entire manufacturing process can be customized to produce filters with specific properties tailored to the needs of different applications, ensuring superior filtration performance, very high mechanical strength, and long-term reliability.

Components and Configurations of Porous Metal Components

Porous metal components are versatile and can be configured in numerous ways to meet the demands of various industrial applications. The primary components include filter elements, filter housings, and end caps, each playing a crucial role in the overall functionality of the filtration system.

Filter elements are the core of the system, typically made from materials like stainless steel powder. These elements are designed with specific pore sizes and shapes to achieve the desired filtration efficiency. The controlled pore structure ensures consistent performance, making them ideal for applications requiring precise flow control and contaminant removal.

Filter housings, which encase the filter elements, are often constructed from robust materials such as stainless steel or high-strength plastics. These housings are designed to withstand high pressures and temperatures, providing a secure and durable environment for the filter elements. The design of the housing can be customized to fit specific installation requirements and operational conditions.

End caps are used to seal the filter elements, preventing contamination and ensuring a secure fit within the housing. They are typically made from the same material as the filter elements to maintain compatibility and durability. The combination of these components results in a filtration system that offers superior performance, reliability, and longevity.

Common Limitations

Despite their advantages, you should be aware of several challenges with traditional filters:

- Limited Lifespan:

Many traditional filters, particularly disposable types, have a short operational life. This means you must frequently replace them, which can increase long-term costs. - Maintenance Challenges:

In certain industrial applications, filters made from polymers or fiberglass might struggle under extreme conditions, leading you to face increased maintenance and potential operational downtime. - Lower Performance Under Extreme Conditions:

Traditional filter materials may not perform consistently in environments with high temperatures, pressure fluctuations, or corrosive substances. This limitation can compromise filtration efficiency and the overall reliability of your processes.

By understanding both the strengths and weaknesses of traditional filter materials, you can make more informed decisions about when to deploy these options versus investing in advanced solutions like porous metal filters.

IV. Comparative Analysis: Pros and Cons

When you select a filtration system, it’s crucial to weigh the strengths and limitations of each option. Here’s a detailed comparison of porous metal filters versus traditional filter materials across several critical factors.

Performance & Durability

- Porous Metal Filters:

These filters are engineered for extreme conditions. You can count on them to withstand high temperatures, pressures, and corrosive environments without compromising their structural integrity or filtration performance—making them ideal for high-demand industrial applications. - Traditional Filters:

While many traditional filters (such as ceramic, polymer, and paper types) perform well under standard operating conditions, you might find they degrade faster under high-stress scenarios. Their materials may not cope as effectively with harsh environments, leading to a shorter lifespan and potentially lower overall reliability.

Reusability & Maintenance

- Porous Metal Filters:

One of the standout advantages for you is the reusable design of porous metal filters. With proper cleaning protocols, you can restore these filters to near-original performance repeatedly. This reusability leads to significant long-term cost savings and longer maintenance intervals, ensuring smoother operational workflows. - Traditional Filters:

In contrast, traditional filters are frequently designed as disposable solutions. This single-use nature often requires frequent replacements, increasing maintenance frequency and leading to higher operational costs over time. Regular filter changes can also cause operational interruptions for you.

Maintenance and Cleaning of Metal Filters

To ensure the optimal performance and longevity of metal filters, regular maintenance and cleaning are essential. Various cleaning methods can be employed, each suited to different types of contaminants and operational conditions.

Backflushing is a common method where the flow of fluid is reversed through the filter, effectively dislodging and removing accumulated contaminants. This method is particularly useful for filters that handle large particulate matter and can be performed without removing the filter from its housing, minimizing downtime.

Ultrasonic cleaning uses high-frequency sound waves to create microscopic bubbles in a cleaning solution. These bubbles implode upon contact with the filter surface, dislodging fine particles and contaminants. This method is highly effective for removing stubborn deposits and is gentle enough to preserve the filter’s structural integrity.

Chemical treatments involve the use of specialized cleaning agents to dissolve and remove contaminants. These treatments can be tailored to the specific type of fouling present, ensuring thorough cleaning without damaging the filter material. Regular maintenance and cleaning not only restore the filter’s performance but also extend its operational lifespan, reducing the need for frequent replacements and minimizing operational disruptions.

Environmental Impact

- Porous Metal Filters:

Their ability to be cleaned and reused translates directly into a lower environmental footprint for your operations. By minimizing waste, you contribute to a more sustainable practice. - Traditional Filters:

The disposable nature of many traditional filters means they contribute to higher environmental waste. Frequent disposal not only impacts landfill usage but also necessitates additional resource consumption to manufacture new filters.

Cost Comparison

- Initial Investment vs. Long-Term Operational Costs:

Traditional filters typically offer a lower upfront cost, which might be attractive for projects with strict initial budget constraints. However, when you account for long-term operational costs—including frequent replacements and increased maintenance—traditional filters may become less cost-effective over time. - Scenario-Based Effectiveness:

In applications where operating conditions are mild and replacement costs aren’t prohibitive, traditional filters might be a practical option for you. Conversely, in high-demand industrial settings where durability and consistent performance are critical, the higher initial investment in porous metal filters can be offset by their extended lifespan and reduced maintenance requirements.

Filtration Accuracy & Efficiency

- Porous Metal Filters:

Thanks to precision manufacturing, porous metal filters offer consistent pore sizes that are essential if you require high filtration accuracy. This consistency ensures effective separation of particles, making them particularly beneficial in precision-critical applications such as pharmaceutical processing. - Traditional Filters:

Although traditional filters can provide satisfactory filtration performance under standard conditions, they may not offer the same level of precision and efficiency as porous metal filters. Variability in pore sizes and material properties might lead to inconsistencies in filtration quality, especially in precision-critical applications.

Limitations and Challenges of Porous Metal Filters

While porous metal filters offer numerous advantages, they also present certain limitations and challenges that must be addressed to ensure optimal performance.

One of the primary challenges is the potential for clogging. As contaminants accumulate within the filter’s pores, the flow rate can decrease, leading to reduced efficiency. Regular cleaning and maintenance are crucial to mitigate this issue and maintain consistent performance.

Corrosion is another potential challenge, particularly in environments with harsh chemicals or extreme conditions. Selecting materials with high corrosion resistance, such as stainless steel powder, can help address this issue. Additionally, protective coatings and treatments can be applied to enhance the filter’s resistance to corrosive elements.

Porous metal filters may also face limitations in applications with very high flow rates or pressures. In such cases, the filter’s structural integrity must be carefully evaluated to ensure it can withstand the operational demands. Customizing the filter design and material selection can help overcome these challenges, providing a solution that meets the specific requirements of the application.

Comparative Table

| Feature | Porous Metal Filters | Traditional Filters |

|---|---|---|

| Performance & Durability | Withstand extreme conditions, including high temperatures, pressures, and corrosive environments. | Perform well in mild conditions but can degrade faster under stress. |

| Reusability & Maintenance | Reusable with proper cleaning protocols, leading to long-term cost savings and fewer maintenance interruptions. | Typically disposable, requiring frequent replacements and resulting in higher maintenance costs over time. |

| Environmental Impact | Lower waste due to reusability, making them a more sustainable option. | Higher environmental waste due to the frequent need for disposal. |

| Cost Comparison | Higher initial investment; long-term savings from durability and reusability can make them more cost-effective in high-demand scenarios. | Lower upfront cost, but long-term operational expenses can add up due to repeated replacements and maintenance requirements. |

| Filtration Accuracy & Efficiency | Manufactured with consistent pore sizes for precise filtration, ideal for precision-critical applications like pharmaceutical processing. | Satisfactory for standard applications, but may lack the consistency and precision required in high-end or sensitive processes. |

This table gives you a clear, at-a-glance overview of the pros and cons of each filter type, helping you quickly understand the benefits and trade-offs between porous metal filters and traditional materials.

Summary

In summary, if you operate in high-demand industrial environments, you will find that porous metal filters excel with their robust performance, reusability, and precise filtration capabilities. Although they require a higher initial investment, they offer long-term cost savings and a reduced environmental footprint. On the other hand, traditional filters might be more suitable for less demanding applications because of their lower upfront costs and simpler design, but they come with limitations in durability, maintenance, and precision under extreme conditions.

This comparative analysis should help you determine which filtration option best meets your specific operational requirements, budget constraints, and environmental considerations.

V. Frequently Asked Questions (FAQs)

Q1: What are the main advantages of porous metal filters over traditional filter materials?

A: You will notice that porous metal filters offer superior durability, precision filtration, and reusability. Their ability to withstand extreme temperatures, pressures, and corrosive environments makes them ideal for demanding industrial applications. Over time, their long service life and consistent performance result in significant cost savings compared to disposable traditional filters.

Q2: How do porous metal filters maintain their performance over time?

A: You can count on their robust construction and precision manufacturing processes, such as sintering or diffusion bonding, to ensure consistent pore sizes and structural integrity. Regular cleaning and proper maintenance allow these filters to retain high performance even under continuous and harsh operating conditions.

Q3: Are porous metal filters more cost-effective in the long run?

A: Although you may face a higher initial investment, the durability and reusability of porous metal filters significantly reduce long-term operational costs. Fewer replacements and reduced maintenance downtime mean better cost-effectiveness for your high-demand industrial applications.

Q4: What maintenance steps are required for porous metal filters?

A: Typically, you will need to follow a regular cleaning schedule—often involving backflushing, ultrasonic cleaning, or chemical methods—to remove accumulated contaminants. Following these recommended cleaning protocols helps restore the filters’ efficiency and extends their operational lifespan.

Q5: In which industries do porous metal filters offer the most benefits?

A: Porous metal filters are particularly beneficial in industries where high durability and precision are critical. These include chemical processing, aerospace, pharmaceuticals, oil & gas, water treatment, and other sectors that require reliable performance under extreme conditions.

Q6: Can porous metal filters withstand extreme temperatures and pressures better than traditional filters?

A: Yes, you will find that porous metal filters are engineered to endure extreme conditions. Their high-strength metal construction allows them to maintain performance under elevated temperatures, pressures, and corrosive environments much more effectively than many traditional filter materials.

Q7: How do traditional filters compare in terms of environmental sustainability?

A: If you are concerned about environmental impact, note that traditional filters—especially disposable types like paper or certain polymers—contribute to higher waste due to their single-use nature. In contrast, porous metal filters are reusable and reduce waste over time, making them a more sustainable option for lowering your operation’s environmental footprint.

VI. Real-World Applications & Case Studies

Industry Examples

Aerospace:

In your aerospace applications, porous metal filters can be integrated into propulsion systems—such as propellant filters used in rocket engines. Their ability to maintain consistent performance under high-pressure conditions ensures that your critical systems operate safely and efficiently. Many aerospace companies adopt these filters to reduce downtime and improve the reliability of flight operations.

Chemical Processing:

If you work in chemical processing, you know that aggressive conditions—like high temperatures and exposure to corrosive chemicals—can quickly degrade conventional filters. Porous metal filters, with their robust construction, are successfully implemented to handle these challenges. Their superior durability minimizes process interruptions and supports continuous production in your challenging environments.

Pharmaceuticals:

In pharmaceutical manufacturing, where precision and cleanliness are non-negotiable, porous metal filters help you achieve fine particulate filtration and maintain the high purity of your end products. Their consistent pore sizes ensure that you meet stringent quality standards while providing a sustainable solution that you can clean and reuse—reducing contamination risks and lowering overall production costs.

Performance Metrics

Case studies from these industries show several key performance advantages that you can benefit from when using porous metal filters:

- Longevity:

You may observe that porous metal filters have a lifespan up to three times longer than conventional disposable filters. This extended service life translates into reduced replacement frequency and fewer operational disruptions. - Efficiency:

Comparative studies indicate that the precision pore structures of porous metal filters deliver superior filtration efficiency. In pharmaceutical applications, for example, they consistently achieve higher removal rates of sub-micron particles compared to ceramic or polymer filters. - Maintenance Costs:

While the upfront cost of porous metal filters can be higher, you can enjoy significant long-term cost savings. Many plants report maintenance cost reductions of up to 30% compared to operations relying on disposable filter media.

Testimonials or Expert Insights

“In our chemical processing facility, switching to porous metal filters was a game-changer. Not only did we see a marked improvement in filtration performance, but the durability of these filters has significantly lowered our maintenance costs. It’s a classic example of investing in quality for long-term gain.”

– Dr. Emily Carter, Process Engineering Manager

“The aerospace sector demands filters that can withstand extreme conditions without fail. Our tests with porous metal filters demonstrated exceptional reliability even under rapid pressure fluctuations and high temperatures. They’re now a critical component in our safety protocols.”

– James Rodriguez, Senior Aerospace Systems Engineer

These expert insights and real-world applications underscore how porous metal filters have transformed filtration processes in high-stakes environments. By leveraging their proven performance metrics, you can enhance your operational efficiency and reduce long-term costs.

Discover HENGKO's Porous Metal Filter Solutions

HENGKO, you can experience the exceptional performance of our porous sintered 316L stainless steel metal filters. Designed to deliver superior durability and precision, our filters are perfect for your gas filtration systems and liquid filter projects. We offer an exclusive OEM service that allows you to create a filter with your unique size, appearance, and specific pore size requirements.

Take advantage of this opportunity to customize your filtration solution exactly as you need it. For more details, simply contact HENGKO OEM by email at ka@hengko.com or visit our website at www.hengko.com. Let us help you achieve unparalleled filtration performance tailored to your project's demands.

Post time: Mar-13-2025