Ever brewed a cup of coffee or watched sand trickle

through an hourglass?

You've witnessed the magic of filtration in action! This fundamental process separates components of a mixture

using a barrier that allows some things to pass through while capturing others.

Understanding different filtration methods unlocks a toolbox for countless applications, from purifying water

to crafting exquisite perfumes.

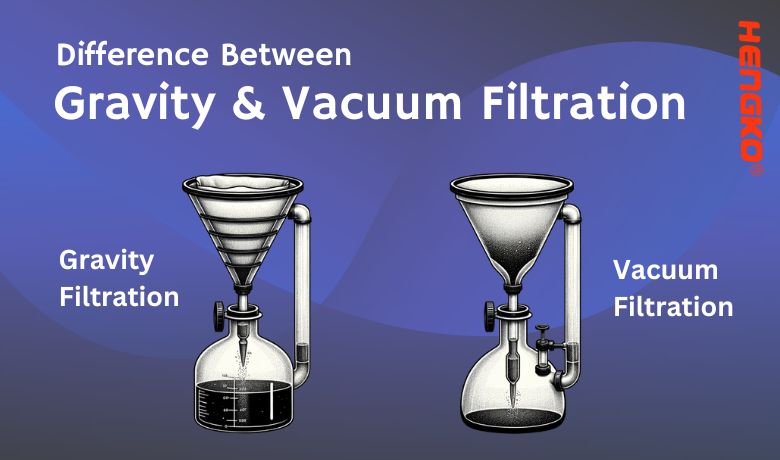

Today, we delve into the essence of two popular techniques: gravity filtration and vacuum filtration, revealing

their contrasting strengths and quirks. Buckle up, as we embark on a journey through the fascinating

world of separation!

Power of Gravity Filtration

Gravity filtration is a simple yet effective technique that utilizes the Earth's gravitational pull to separate mixtures.

It's like a microscopic gatekeeper sifting through your drink, allowing only the desired components to pass while

leaving the unwanted ones behind.

Here's how it works:

1. Setting the stage:

A porous filter paper, acting as the gatekeeper, is placed inside a funnel positioned over a collecting container.

This could be a flask, beaker, or even a simple cup.

2. Gravity takes the reins:

The mixture is gently poured onto the filter. Gravity pulls the liquid, called the filtrate, through the tiny pores of the paper,

leaving behind the solid particles, known as the residue, on top.

3. Separation achieved:

The filtered liquid drips into the collecting container, neatly separated from the unwanted solids.

Gravity filtration shines in various applications:

* Clarifying liquids:

Removing suspended particles, like sediment from wine or tea, to achieve a clear liquid.

* Collecting precipitates:

Isolating solid products from chemical reactions, such as filtering calcium carbonate crystals

from a vinegar and baking soda mixture.

* Purifying water:

Separating impurities like sand and clay from water using sand and charcoal filters for safe drinking.

This gentle technique is typically used for:

* Coarse particles:

Gravity excels at filtering larger particles as they get easily trapped on the filter paper.

* Small volumes:

Filtering large quantities with gravity can be slow and impractical.

* Heat-sensitive materials:

The lack of pressure makes it ideal for substances that might degrade under vacuum.

Types of materials commonly filtered using gravity filtration include:

* Chemical precipitates

* Coffee grounds

* Tea leaves

* Sediment from liquids

* Biological samples

While gravity filtration excels in simplicity and its gentle touch, it can be slow and unsuitable for certain tasks.

In the next section, we'll explore its powerful counterpart: vacuum filtration!

Unveiling the Speed Demon: Vacuum Filtration

Gravity filtration has served us well, but if you crave speed and finesse, prepare to meet its turbocharged cousin:

vacuum filtration. Imagine the same separation principle, but this time, a powerful vacuum pump creates a pressure

difference, pulling the liquid through the filter with the force of a miniature tornado.

Here's how it differs from gravity filtration:

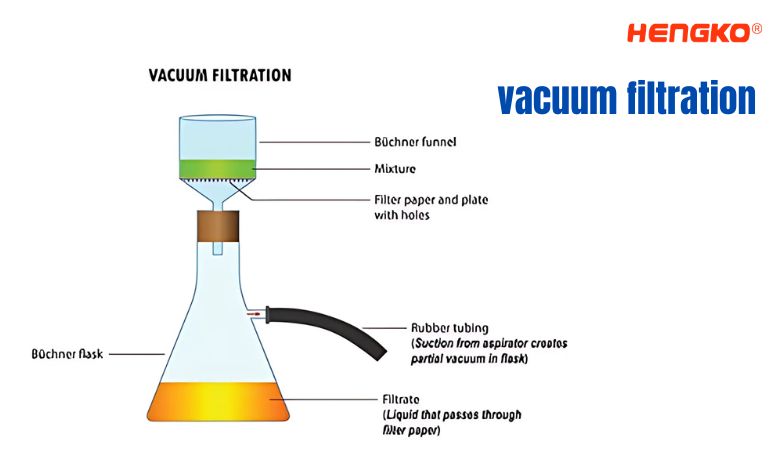

* Vacuum power:

A special funnel, often called a Büchner funnel, connects to a flask through a rubber adapter.

The flask is attached to a vacuum pump that removes air, creating a negative pressure below the filter.

* Liquid on demand:

Instead of passively dripping through, the liquid is actively sucked through the filter, significantly speeding up the process.

* Drier results:

The vacuum pulls the liquid through and also draws air through the residue bed, leading to a drier cake of solids compared to gravity filtration.

These perks make vacuum filtration ideal for:

* Fine particles:

Smaller particles easily pass through the filter under higher pressure, making it suitable for

purifying solutions with finer impurities.

* Large volumes:

Vacuum filtration tackles large quantities efficiently, perfect for industrial or research applications.

* Time-sensitive processes: When speed is crucial, vacuum filtration delivers immediate results.

* Efficient drying:

The drier residue cake saves time and minimizes solvent usage compared to gravity filtration.

Therefore, vacuum filtration thrives in these scenarios:

* Chemical synthesis:

Filtering precipitates after reactions, often involving fine particles.

* Environmental analysis:

Analyzing water samples for suspended solids.

* Pharmaceutical production:

Clarifying and purifying large volumes of solutions.

* Drying samples:

Preparing solid samples for further analysis by removing excess liquid.

However, remember:

*Vacuum power has its limits:

Choose filter papers appropriate for the pressure to avoid tearing or leaks.

*Not for heat-sensitive materials:

The pressure and potential heat generated by the pump might degrade delicate substances.

In conclusion, both gravity and vacuum filtration have their unique strengths. Gravity filtration offers simplicity and gentleness,

while vacuum filtration delivers speed and efficiency for larger volumes and finer particles.

Choosing the right tool depends on your specific needs and the nature of your mixture.

Now, you're equipped to navigate the world of filtration like a pro!

Unveiling the Duel: Gravity vs. Vacuum Filtration

Both gravity and vacuum filtration separate mixtures, but their methods and strengths diverge significantly.

Let's dissect their key differences to help you choose the champion for your specific needs.

Speed:

Winner: Vacuum filtration. By applying negative pressure, it pulls the liquid through the filter much faster than gravity's gentle tug.

This can mean seconds instead of minutes or even hours, especially for large volumes or fine particles.

Efficiency:

Winner: Vacuum filtration (again!).

The pressure forces more liquid through the filter, leaving a drier residue cake and potentially clearer filtrate.

However, efficiency also depends on filter paper choice and pre-filtration steps.

Equipment:

Gravity: Simpler and cheaper. Requires a funnel, filter paper, a stand to hold the funnel, and a receiving container.

Vacuum: More complex and expensive. Needs a Büchner funnel (specific type with a flat bottom), filter paper, a vacuum

flask, a rubber adapter, and a vacuum pump.

Applications:

Gravity:

1. Ideal for clarifying liquids with coarse particles like coffee grounds or tea leaves.

2. Suitable for collecting precipitates from small-scale reactions, especially for heat-sensitive materials.

3. Used in purifying water at home or in small-scale settings.

Vacuum:

1. Best for filtering fine particles in large volumes, making it a go-to in chemistry, environmental analysis,

and pharmaceutical production.

2. Efficient for drying samples for further analysis.

3. Useful for rapidly filtering air-sensitive samples where exposure to air needs to be minimized.

Cost:

Gravity: Lower setup and operational costs due to simpler equipment.

Vacuum:

Higher initial investment for the pump and specialized equipment. Additional running costs due

to electricity usage.

The Final Verdict:

Both gravity and vacuum filtration have their place in the separation arena. If speed, efficiency, and handling fine

particles are priorities, vacuum filtration reigns supreme.

However, for simplicity, cost-effectiveness, and dealing with heat-sensitive materials, gravity filtration remains a

trusty champion. Ultimately, the "winner" depends on your specific needs and the nature of your mixture.

So, choose wisely and let the filtration wars commence!

Gravity Filtration vs. Vacuum Filtration: A Comparative Analysis

| Feature | Gravity Filtration | Vacuum Filtration |

|---|---|---|

| Speed | Slow | Fast |

| Efficiency | Moderate | High |

| Equipment | Simple: Funnel, filter paper, stand, receiving container | Complex: Büchner funnel, filter paper, vacuum flask, rubber adapter, vacuum pump |

| Applications | Clarifying liquids with coarse particles, collecting precipitates from small-scale reactions, purifying water at home | Filtering fine particles in large volumes, drying samples for analysis, rapidly filtering air-sensitive samples |

| Cost | Low | High |

| Image |

Vacuum Filtration setup: A Büchner funnel with a filter paper placed over a flask connected to a vacuum pump.

|

Additional Notes:

*Gravity filtration is gentler on heat-sensitive materials.

*Vacuum filtration can be more prone to leaks and requires careful filter paper selection for the pressure.

*The choice between the two methods depends on the specific needs of the application.

Pros and Cons of Gravity Vacuum Filtration

Choosing the right filtration method requires understanding the strengths and weaknesses of each approach.

Let's explore the pros and cons of both gravity and vacuum filtration:

Gravity Filtration:

Pros:

* Simple and inexpensive: Requires minimal equipment, making it readily accessible and low-cost.

* Gentle on materials: Suitable for heat-sensitive substances and samples prone to degradation.

* Easy to set up and use: Requires minimal technical expertise and can be readily performed in various settings.

* Safe for air-sensitive samples: No pressure applied, minimizing exposure to air for delicate materials.

Cons:

* Slow process: Can be time-consuming, especially for large volumes or viscous liquids.

* Less efficient: May not capture all fine particles or leave a slightly less clear filtrate compared to vacuum.

* Limited scale: Not ideal for processing large volumes of liquid due to slowness and potential overflow.

* Residue moisture: The residue cake remains saturated with liquid compared to vacuum filtration.

Vacuum Filtration:

Pros:

* Fast and efficient: Significantly faster than gravity, especially for large volumes and fine particles.

* Superior clarity: Creates a drier residue cake and potentially clearer filtrate thanks to the pressure.

* Handles large volumes: Efficiently filters large quantities of liquid, making it suitable for industrial or research applications.

* Faster drying: The pressure draws air through the residue, leading to quicker drying than gravity.

Cons:

* Complex and expensive: Requires specialized equipment like a vacuum pump, making it initially costly.

* Potential for leaks: Can be prone to leaks if the setup is not secure or the filter paper is unsuitable for the pressure.

* Not suitable for heat-sensitive materials: The pressure and pump heat generation might degrade delicate substances.

* Air exposure risk: If not properly monitored, the vacuum can pull air through the sample, potentially affecting air-sensitive materials.

| Feature | Gravity Filtration | Vacuum Filtration |

|---|---|---|

| Pros | Simple setup, easy to use, gentle on materials, safe for air-sensitive samples, inexpensive | Fast and efficient, superior clarity, handles large volumes, faster drying |

| Cons | Slow process, less efficient, limited scale, residue moisture | Complex and expensive, potential for leaks, not suitable for heat-sensitive materials, air exposure risk |

| Best for | Small volumes, heat-sensitive materials, coarse particles, minimal budget, readily available equipment | Large volumes, fine particles, high purity, fast separation, large-scale applications |

Balanced View:

Both methods have their place, and the ideal choice depends on your specific needs:

Use gravity filtration for:* Small volumes or heat-sensitive materials.

* Simple clarification with coarse particles.

* Low-cost setups or readily available equipment.

* Air-sensitive samples requiring minimal exposure.

Use vacuum filtration for:* Large volumes or fine particles needing fast separation.

* High efficiency and clear filtrate requirements.

* Large-scale industrial or research applications.

* Samples where quick drying is crucial.

Remember, there's no one-size-fits-all solution. Carefully consider your project's needs, budget,

and material properties before choosing the champion for your filtration quest!

Navigating the Filtration Maze: Choosing the Right Method

So, you're ready to filter, but staring at a sea of options can be daunting. Fear not, for with a little guidance,

you'll find the perfect filter for your needs! Here's how to navigate the filtration maze:

Step 1: Assess Your Needs:

* Volume: Are you dealing with a small vial or a vat? Choose gravity for small volumes and vacuum for larger ones.

* Material: Is your substance heat-sensitive or air-reactive? Opt for gravity for delicate materials and vacuum for robust ones.

* Desired Purity: Do you need sparkling clear filtrate or just want to remove large chunks? Vacuum often yields higher purity, but gravity can suffice for basic clarification.

* Speed and Efficiency: Are you on a tight deadline or want the cleanest possible separation? Vacuum excels in speed and efficiency, while gravity takes its time.

Step 2: Consider Your Resources:

* Budget: Can you afford a vacuum pump and specialized equipment? If not, gravity might be your budget-friendly hero.

* Accessibility: Do you have the necessary equipment readily available, or do you need to purchase additional items?

Choose the method with readily available materials for convenience.

* Technical Expertise: Are you comfortable setting up and operating a vacuum pump?

If not, gravity's simplicity might be more fitting.

Step 3: Consult the Experts:

If you're still unsure, don't hesitate to consult experts in your field. Chemists, lab technicians, or even experienced DIYers

can offer valuable insights based on their specific experience with different filtration methods.

Remember: The perfect filtration method is a match made in heaven for your specific needs. By carefully considering your

project's demands and resources, you'll be able to confidently choose the champion to separate your mixture with finesse

and efficiency. So, grab your funnel, pump, or both, and embark on your filtration adventure!

| Choosing Factor | Gravity Filtration | Vacuum Filtration |

|---|---|---|

| Scale | Small volumes | Large volumes |

| Material | Heat-sensitive, air-sensitive | Robust |

| Desired Purity | Basic clarification | High purity |

| Speed and Efficiency | Slow, less efficient | Fast, efficient |

| Budget | Low | High |

| Accessibility | Readily available equipment | Specialized equipment needed |

| Technical Expertise | Simple setup | Requires understanding of vacuum systems |

Throughout this blog, we've unveiled the fascinating world of filtration, exploring two of its star performers:

gravity and vacuum filtration. We've seen how they harness different forces – gravity's gentle pull and vacuum's

forceful tug – to separate mixtures, each excelling in distinct arenas.

Still unsure?

Don't hesitate to reach out! I'm always happy to answer your questions and help you navigate the filtration maze.

You can also consult trusted resources for further guidance. Remember, the perfect separation awaits with the right tool in hand.

Anyway, I hope this blog been informative and engaging. If you have any further questions or requests,

please don't hesitate to ask us . we are always happy to help in any way we can.

you can also send enquiry by email ka@hengko.com.

Post time: Dec-26-2023