Main Advantages of Dew Point Sensors and Transmitters

1.Highly accurate and reliable measurements:

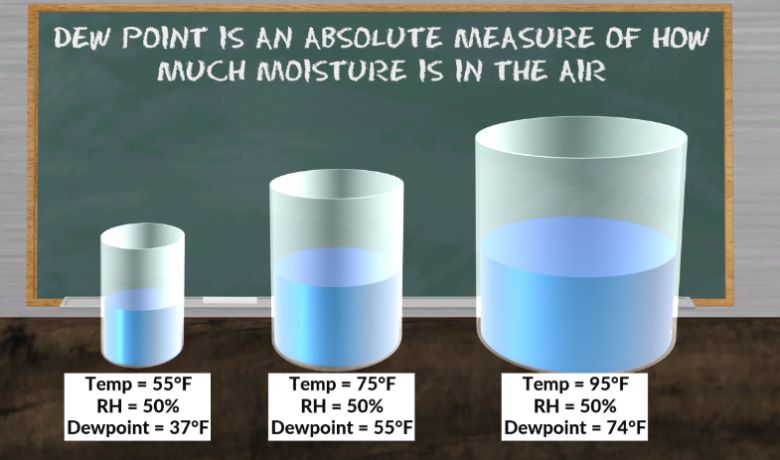

Dew point sensors and transmitters are designed to provide highly accurate and reliable measurements of the dew point temperature, the temperature at which air becomes saturated with water vapor. It is important for various applications, such as air conditioning, drying processes, and quality control in manufacturing.

2.Wide temperature range:

Many dew point sensors and transmitters are capable of measuring dew point temperatures over a wide range, often from -100°C to +20°C (-148°F to +68°F) or higher.

3.Compact size:

Dew point sensors and transmitters are typically small and lightweight, making them easy to install in various locations and applications.

4.Easy to install:

Many dew point sensors and transmitters are designed for easy installation, with simple wiring and mounting requirements.

5. Low maintenance:

Dew point sensors and transmitters generally require little maintenance, and many are designed with self-diagnostic capabilities to alert users if there are any issues.

6. Robust design:

Dew point sensors and transmitters are typically designed to withstand harsh environments and resist dust, moisture, and other contaminants.

7. Long lifespan:

Many dew point sensors and transmitters have a long lifespan and are designed to operate for many years with minimal maintenance.

8.Multiple output options:

Dew point sensors and transmitters are available with various output options, including analog and digital outputs, allowing users to integrate them easily into their systems.

9.Customizable:

Many dew point sensors and transmitters can be customized to meet the application's specific needs.

10. Versatile:

Dew point sensors and transmitters can be used in various applications and industries, including HVAC, pharmaceuticals, food and beverage, and many others.

11.Safety benefits:

Dew point sensors and transmitters can help ensure safe conditions in various applications, such as preventing the formation of condensation on pipes and equipment.

12.Energy efficiency:

By accurately measuring and controlling humidity levels, dew point sensors and transmitters can help improve energy efficiency in various applications.

What Kind of Dew Point Sensors and Transmitters Can Introduce for You ?

As a temperature and humidity monitoring instrument, the Dew point transmitter is popular in the industrial field. HENGKO 608 series dew point transmitter has the advantage of small size, accurate measurement, fast response, high-pressure resistance, and other advantages. It is an idea to select for Small industrial dryer. The Dew point transmitter is also widely used in the compressed air system.

After the system compresses the air, the dew point value will rise, causing moisture to easily precipitate and condense into condensation. Condensation is harmful to the machine. Therefore, dew point transmitters can be installed at fixed points inside and outside the system to monitor the air dew point for a long time to avoid condensation.

HENGKO HT-608 series dew point sensor is the best choice for industries such as compressors, electricity, medicine, batteries, natural gas pipelines, gas filling stations, compressed air systems, dryers, and dry air separation.

Feature:

Measurement range: (-30~60°C,0~100%RH)

Dew point: 0℃~60℃(-0-140°F)

Response time: 10S(1m/s wind speed)

Accuracy: Temperature(±0.1℃), Humidity(±1.5%RH)

Monitoring the dew point with a dew point transmitter is not only to prevent condensation from causing damage to the machine or pipeline, but it also has the purpose of saving energy and improving economic benefits. Many industrial fields need to use dryers. The principle of the machine is to regenerate by heating dry air. This process is very energy-intensive. By monitoring the dew point value of the dry air, the regeneration temperature of the dryer can be adjusted to avoid excessive use of the temperature and waste of energy.

HENGKO HT608 series dew point meter provides an ideal way for dew point measurement. The small volume can be measured deeply inside the cabinet, oven, and dryer, and it has a wide range of applications.

When using the dew point meter, it is necessary to pay attention to the influence of mirror pollution on the measurement. It is best to choose the dew point meter with the function of preventing pollution of the mirror surface. In addition, if you use a dew point transmitter in some industrial environments, the environment may contain some gas analysis pollutants, which will also cause mirror pollution to affect the accuracy of the measurement. If it is a gas with corrosive substances, it will further affect the service life of the transmitter.

Main Applications of Dew Point Sensors and Transmitters

1.Air conditioning and heating:

Dew point sensors and transmitters can measure and control humidity levels in air conditioning and heating systems, helping to ensure optimal comfort and energy efficiency.

2.Industrial drying processes:

Dew point sensors and transmitters can measure the moisture content of materials, allowing users to optimize drying times and improve efficiency.

3.Pharmaceutical manufacturing:

Dew point sensors and transmitters can monitor and control humidity levels in pharmaceutical manufacturing processes to ensure product quality and prevent contamination.

4.Food and beverage production:

Dew point sensors and transmitters can measure and control humidity levels in food and beverage production to help preserve product quality and prevent spoilage.

5.HVAC systems:

Dew point sensors and transmitters can monitor and control humidity levels in HVAC systems to ensure optimal comfort and energy efficiency.

6.Storage and transportation:

Dew point sensors and transmitters can monitor and control humidity levels in storage and transportation environments to prevent damage to sensitive goods.

7.Laboratories:

Dew point sensors and transmitters can monitor and control laboratory humidity levels to ensure optimal experiment conditions and prevent contamination.

8.Power generation:

Dew point sensors and transmitters can monitor and control humidity levels in power generation environments to prevent corrosion and improve efficiency.

9.Petrochemical refining:

Dew point sensors and transmitters can monitor and control humidity levels in petrochemical refining processes to prevent corrosion and improve safety.

10.Textile manufacturing:

Dew point sensors and transmitters can monitor and control humidity levels in textile manufacturing processes to improve quality and efficiency.

11.Metal processing:

Dew point sensors and transmitters can monitor and control humidity levels in metal processing environments to prevent corrosion and improve efficiency.

12.Paper and pulp production:

Dew point sensors and transmitters can monitor and control humidity levels in paper and pulp production processes to improve quality and efficiency.

What kind of application do you want to use the Dew Point Sensors and Transmitters to Monitor ?

Share with us for details and contact us by email ka@hengko.com, we will send back within 24-Hours.

Post time: Dec-01-2021