Sintered Sparger Stainless Steel Material Quick Change for Bioreactor Systems

In bioreactor systems, optimal mass transfer of gases like oxygen or carbon dioxide is difficult to accomplish. Oxygen, in particular, is poorly soluble in water - and even less in cell culture and fermentation broths. Oxygen transfer is aided by agitation used to mix nutrients and to keep the cell culture or fermentation homogeneous. There are limits to agitation speed due to high power consumption as well as damage to organisms resulting from excessive tip speed.

In bioreactor systems, optimal mass transfer of gases like oxygen or carbon dioxide is difficult to accomplish. Oxygen, in particular, is poorly soluble in water - and even less in cell culture and fermentation broths. Oxygen transfer is aided by agitation used to mix nutrients and to keep the cell culture or fermentation homogeneous. There are limits to agitation speed due to high power consumption as well as damage to organisms resulting from excessive tip speed.

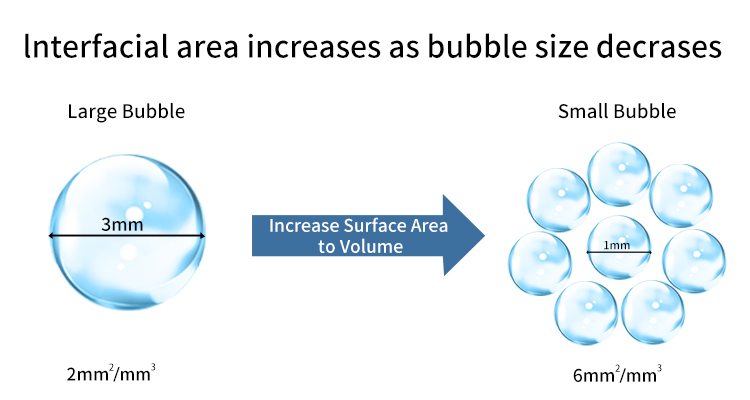

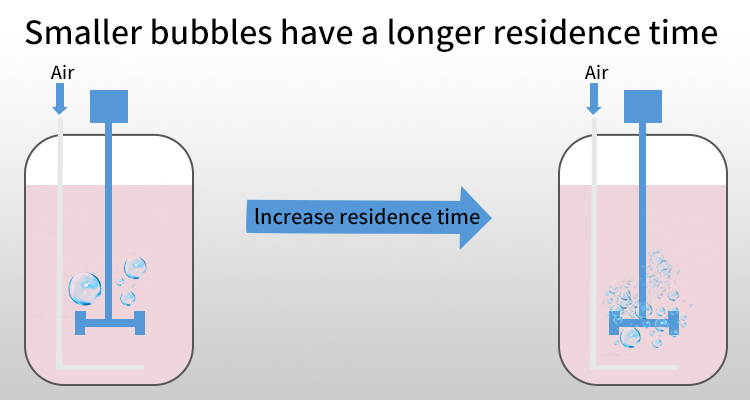

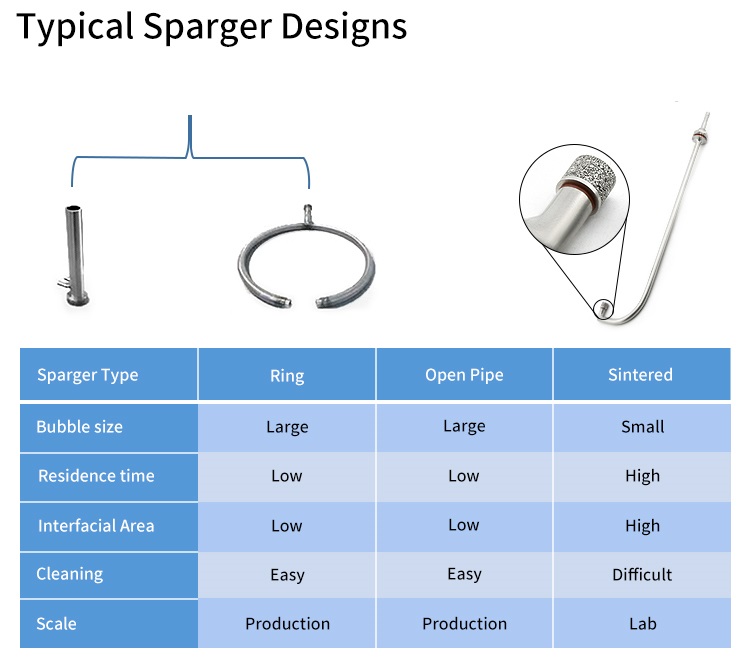

Agitation alone does not provide the adequate mass transfer. Using a HENGKO porous metal sparger greatly increases mass transfer rates in this equipment. The introduction of gases into stirred or unstirred reactor vessels via millions of tiny bubbles increases the gas-to-liquid contact areas allowing for optimal mass transfer rates.

Feature:

-Defined permeability and particle size retention

-Dispersing cooling material in a high temperature environment

-Filtration, washing, and drying in the pharmaceutical industry

-Save energy cost

-Reduce cycle time

-Produce a high gas quality product

Typical applications:

-Food and beverage

-Waste and water treatment

-Chemical process

-Pharmaceuticals.

Micro industrial sintered metal sparger stainless steel material quick change as agitation replacement of bioreactor systems

3~5μm micro sparger

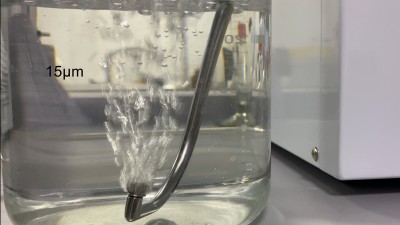

15μm micro sparger bioreactor

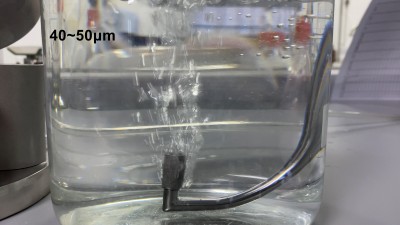

40~50μm sintered sparger

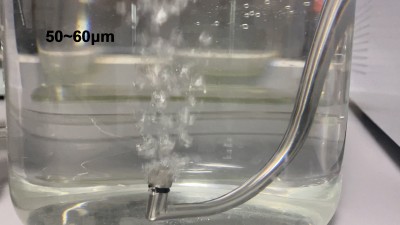

50~60μm stainless steel sparger

Which Micro Sparger is right for you?

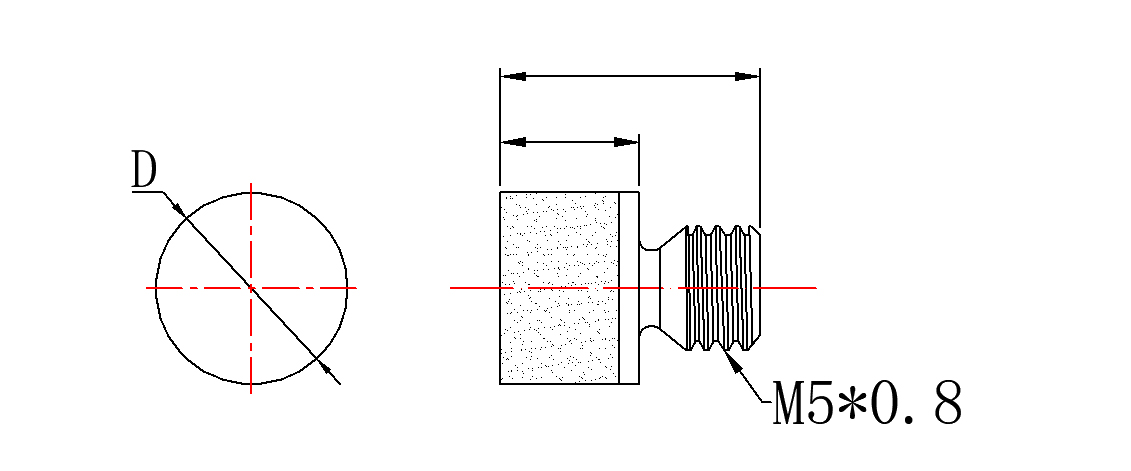

M5 Threaded Sparger Tips with O-Ring Grooves

| Media Grade | Overall Length(mm) | Active Porous Length(mm) | Diameter(mm) | Connection Thread |

| 2μm | 11.5 | 5.5 | 8.05 | M5*.8 |

| 5μm | 11.5 | 5.5 | 8.05 | M5*.8 |

| 10μm | 11.5 | 5.5 | 8.05 | M5*.8 |

| 15μm | 11.5 | 5.5 | 8.05 | M5*.8 |

| 50μm | 11.5 | 5.5 | 8.05 | M5*.8 |

| 100μm | 11.5 | 5.5 | 8.05 | M5*.8 |