Pharmaceutical Industry Medical Grade Sintered Metal Stainless Steel Filter

Sintered metal filters with dryers and mills within the pharmaceutical industry. When these elements are used with dryers and mills, they are contained within reverse air jet collectors containing several filter elements. These are used to collect product powders which can then be transferred back into the process.

Sintered metal filters with dryers and mills within the pharmaceutical industry. When these elements are used with dryers and mills, they are contained within reverse air jet collectors containing several filter elements. These are used to collect product powders which can then be transferred back into the process.

The main reason why sintered metal filters have been used is that they allow the whole system to be cleaned in place, which in turn overcomes the need to break the primary containment of the equipment.

Although the requirements of the reverse air jet system within the collector and clean-in-place (CIP) techniques can conflict, this problem has been overcome. Those systems that are now operational have indicated that systems using sintered metal filter elements can be validated and meet the requirements of current Good Manufacturing Practices as required in the pharmaceutical industry.

HENGKO medical grade 316l stainless steel filter has excellent permeation filtration separation function and can be filtered with high precision, filtration precision up to 0.2~120μm, industrial one-time molding, seamless integration, exquisite and unique process. Stable structure, strong toughness, and rigidity, good resistance to wear and tear, uniform pore distribution, high usage rate porosity up to 15~45%, long service life, can use direction cleaning, ultrasonic cleaning, can be used normally in 600 ℃ high temperature, chemical raw material corrosion environment. The product can be widely used in pharmaceutical plant separation filtration, chemical raw material separation filtration, vaccine production filtration, etc.

Sintered metal filters for dryers & mills in the pharmaceutical industry

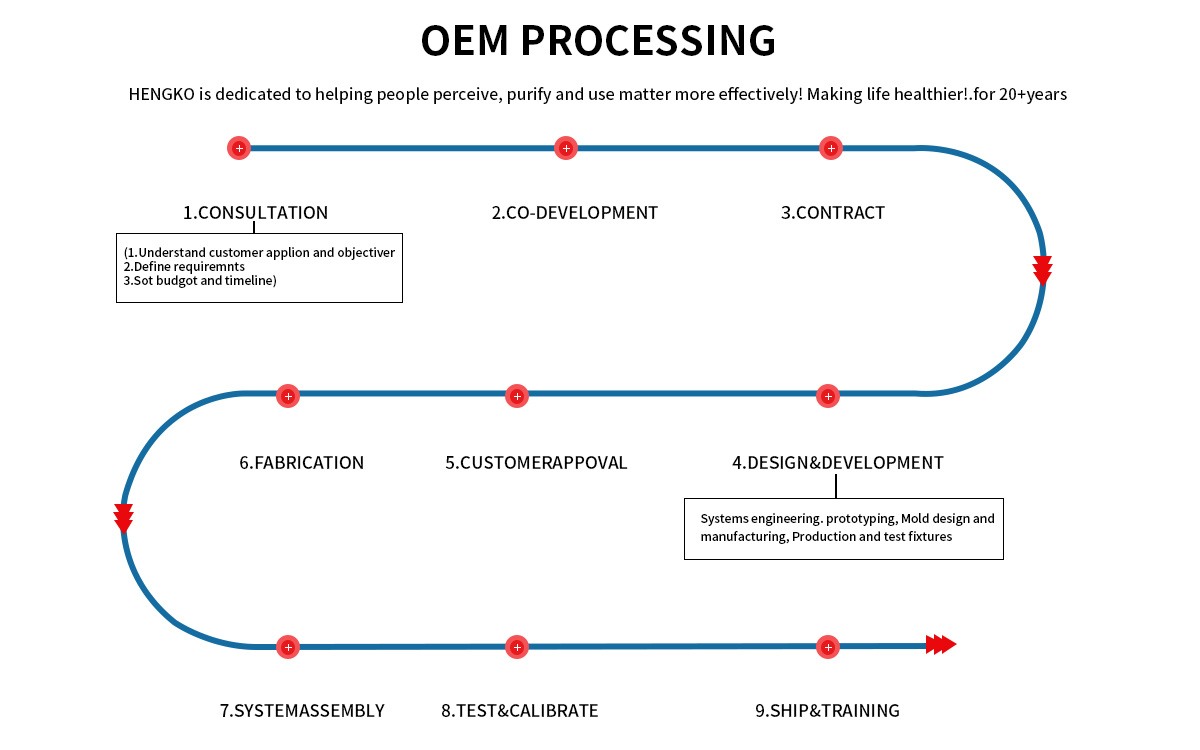

Can't find a product that meets your needs? Contact our sales staff for OEM/ODM customization services!

Can't find a product that meets your needs? Contact our sales staff for OEM/ODM customization services!