-

Sintered Porous Metal Stainless Steel Bacteria HEPA Filter for Medical Oxygen Concentrator

HENGKO Sintered porous metal Stainless steel bacteria HEPA filter for Medical Oxygen Concentrator adopts medical grade stainless steel material, have the ad...

View Detail -

Pharmaceutical Industry Medical Grade Sintered Metal Stainless Steel Filter

Sintered metal filters with dryers and mills within the pharmaceutical industry. When these elements are used with dryers and mills, they are contained withi...

View Detail -

HENGKO Sterilizing Grade Media Bacteria Filtration 0.2 5um Filter Media Sintered Porous...

Introducing HENGKO's Sterilizing Grade Porous Metal Filter for Medical and Life Science Applications! HENGKO's newly developed porous metal filter is...

View Detail -

Acid and Alkali Resistant More Durable 316L Porous Stainless Steel Filter Sintered Filt...

Product Describe HENGKO biomedical filter is made of 316L metal powder sintered at high temperature, with a uniform porosity of 0.2-0.5 um, corrosion resista...

View Detail -

Wall Type Single Flowmeter Medical Oxygen Humidifier Medical Equipment at Hospital,sint...

This range of oxygen flowmeter with humidifier is for the metered delivery of gas, giving flow rates of between 1 and 15 L/min(other flow ranges available) i...

View Detail -

RS485 RHT35 IP65 temperature and humidity transmitter sensor probe for Climate monitori...

HENGKO temperature and humidity module adopt high precision RHT series sensor equipped with a sintered metal filter shell for large air permeability, fast ga...

View Detail -

Wireless HK96MCNL thread M10*1.0 relative humidity probe housing for medical refrigerator

HENGKO wireless temperature and humidity sensor adopt high precision RHT series sensor equipped with a sintered metal filter shell for large air permeability...

View Detail -

High flow non-invasive ventilator Inspiratory Bacteria Filter air inlet medical grade ...

HENGKO's filter element of the ventilator is stainless steel 316, stainless steel 316L, which has the characteristics of filtering and dustproof. Its materia...

View Detail -

HENGKO Inspiratory Bacteria non invasive assisted mini personal lung Ventilation medic...

HENGKO's filter element of the ventilator is stainless steel 316, stainless steel 316L, which has the characteristics of filtering and dustproof. Its materia...

View Detail -

Tidal Volume Delivery From Medical ICU Respiratory Mechanical Ventilation Filter , 316...

HENGKO's filter element of the ventilator is stainless steel 316, stainless steel 316L, which has the characteristics of filtering and dustproof. Its materia...

View Detail -

Medical Bacterial/Viral tidal volume delivered filter with heat and moisture exchange ...

HENGKO's filter element of the ventilator is stainless steel 316, stainless steel 316L, which has the characteristics of filtering and dustproof. Its materia...

View Detail -

HENGKO medical Respiratory Mechanical tidal volume delivered filter for ventilator brea...

HENGKO's filter element of the ventilator is stainless steel 316, stainless steel 316L, which has the characteristics of filtering and dustproof. Its materia...

View Detail -

High flow non-invasive ventilator circuit bacteria air inlet medical grade 316L stainl...

HENGKO's filter element of the ventilator is stainless steel 316, stainless steel 316L, which has the characteristics of filtering and dustproof. Its materia...

View Detail -

3D Printed porous metal filter OEM filtration & flow control designs for medical d...

HENGKO manufactures filter elements in a broad range of materials, sizes, and fittings so they can be easily specified with the characteristics and configura...

View Detail -

Medical expiratory filters ventailtor input inspiratory bacteria filter stainless steel...

The ventilator filter element filters dust from the air. HENGKO's filter element of the ventilator is stainless steel 316, stainless steel 316L, which has th...

View Detail -

Medical breathing non-invasive ventilator oxygen gas choke inspiratory pressure flow f...

The ventilator filter element filters dust from the air. HENGKO's filter element of the ventilator is stainless steel 316, stainless steel 316L, which has th...

View Detail -

Medical non-invasive anaesthesia portable ventilator oxygen gas choke system inspirator...

The ventilator filter element by HENGKO aims to efficiently filter and eliminate dust from the air, using safe and non-toxic stainless steel 316 and 316L. Th...

View Detail -

Replaceable medical non-invasive ventilator oxygen gas choke breathing circuit bacteria...

HENGKO's ventilator filter element is designed to effectively filter and remove dust from the air. It is made of safe, non-toxic stainless steel 316 and 316L...

View Detail -

HENGKO respirator ventilator oxygen gas choke breathing machine artificial mechanical v...

HENGKO respirator ventilator oxygen gas choke breathing machine artificial mechanical ventilation filter for medical mechanical ventilator Product Descripti...

View Detail -

ICU mechanical air ventilator breathing respiratory machine Medical stainless steel Hig...

The ventilator filter element filters dust from the air.HENGKO's filter element of the ventilator is stainless steel 316, stainless steel 316L, which has the...

View Detail

Types of Medical Grade Metal Filters

Medical-grade metal filters come in various types, each designed to meet the unique requirements

of different medical applications. Here are some common types of medical-grade metal filters:

1. Sintered Stainless Steel Filters

*Description:

Made from stainless steel powder that is compressed and sintered at high temperatures, these filters offer

excellent durability, high resistance to corrosion, and can handle high-pressure environments.

*Applications:

Used in gas filtration, fluid filtration, and sterilization systems in medical devices and equipment.

2. Porous Stainless Steel Filters

*Description:

These filters feature a highly porous structure, providing exceptional flow rates while maintaining high particle retention.

*Applications:

Ideal for air and gas filtration in applications like respiratory devices, medical breathing circuits, and ventilation systems.

3. Medical Gas Filters

*Description:

Specially designed for filtering medical gases, these filters ensure that gases such as oxygen, nitrous oxide, or air remain

free from contaminants like dust, bacteria, and particulates.

*Applications:

Commonly used in oxygen delivery systems, anesthesia machines, and respirators.

4. Sterilizing Grade Filters

*Description:

These filters are designed to remove bacteria, viruses, and other microorganisms from liquids and gases,

ensuring the safety of medical fluids.

*Applications:

Used in IV solutions, dialysis systems, and pharmaceutical production.

5. Mesh Filters

*Description:

Made from woven or sintered metal mesh, these filters are highly durable and capable of handling larger particles.

*Applications:

Often used in fluid filtration for medical devices, such as blood filtration systems or pharmaceutical

manufacturing processes.

6. Micron Filters

*Description:

These filters are designed to capture particles of specific micron sizes, ensuring the filtration of contaminants

that can impact medical procedures or equipment.

*Applications:

Used in blood filtration, IV fluid filtration, and injectable drug formulations.

7. High-Temperature Filters

*Description:

Constructed from materials that can withstand extreme temperatures, these filters are used in

applications where heat resistance is crucial.

*Applications:

Found in sterilization chambers, autoclaves, and high-temperature medical equipment.

8. Endotoxin-Free Filters

*Description:

These filters are specifically designed to be endotoxin-free to prevent any harmful bacterial byproducts from

contaminating medical fluids or devices.

*Applications:

Used in parenteral drugs, medical fluid lines, and surgical instruments.

9. Liquid Filters

*Description:

These filters are specifically designed for liquid filtration in the medical field, ensuring contaminants are

removed while allowing the passage of the required fluids.

*Applications:

Commonly used in pharmaceutical production, IV systems, and dialysis units.

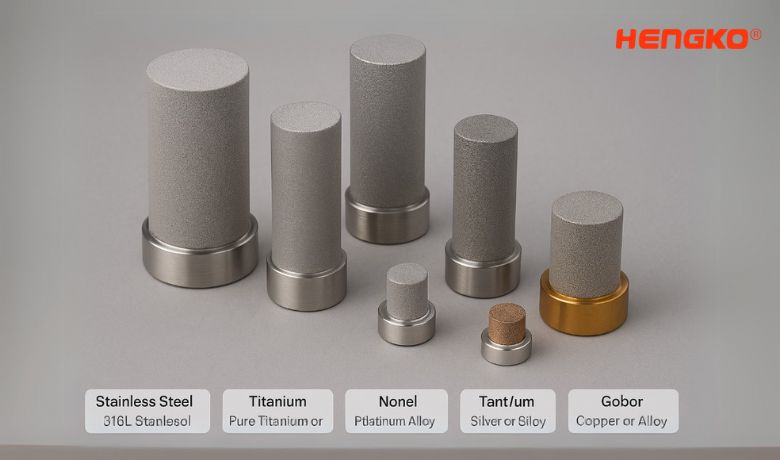

Main Materials of Medical Grade Filter

Some Main Metal Materials for Medical Grade Filters, please check details

Here’s a table summarizing the Medical Grade Metal Filters in English:

| Metal Filter Type | Material | Applications | Key Properties |

|---|---|---|---|

| Stainless Steel | 316L Stainless Steel | Pharmaceuticals, biotechnology, food and beverage | High temperature resistance, corrosion resistance, easy to clean and sterilize |

| Titanium | Pure Titanium or Titanium Alloy | Highly corrosive environments (e.g., certain chemicals and biologics) | Excellent corrosion resistance, lightweight, biocompatible |

| Nickel | Nickel or Nickel Alloys (e.g., Hastelloy) | Extreme chemical environments | High temperature and corrosion resistance, suitable for strong acids and bases |

| Monel | Monel Alloy (Nickel-Copper) | Seawater and high-salinity environments | Excellent corrosion resistance, especially in chloride environments |

| Inconel | Inconel Alloy (Nickel-Chromium) | High-temperature and high-pressure environments | High temperature resistance, oxidation resistance, corrosion resistance |

| Platinum | Platinum or Platinum Alloy | High-purity chemicals and biologics | Extremely corrosion-resistant, chemically inert, expensive |

| Tantalum | Tantalum | Strong acid environments | Exceptional corrosion resistance, biocompatible |

| Silver | Silver or Silver Alloy | Antimicrobial filtration | Antimicrobial properties, corrosion resistance |

| Gold | Gold or Gold Alloy | High-purity chemicals | Chemically inert, corrosion-resistant, expensive |

| Copper | Copper or Copper Alloy | Antimicrobial filtration | Antimicrobial properties, good thermal conductivity |

Applications of Medical Grade Metal Filter for Medical Devices

main applications of sintered stainless steel metal filters in medical devices:

| Medical Device Category | Specific Devices | Applications of Sintered Stainless Steel Filters | Key Advantages |

|---|---|---|---|

| Respiratory Equipment | Ventilators, Anesthesia Machines, Oxygen Concentrators | Filtering airborne particles, bacteria, and viruses to ensure clean and sterile air for patients. | High-temperature resistance, sterilizable, ensures hygiene. |

| Hemodialysis Equipment | Hemodialysis Machines | Filtering impurities and microorganisms from dialysate to prevent contamination of patient’s blood. | High precision, corrosion-resistant, suitable for liquid filtration. |

| Infusion and Injection Devices | Infusion Pumps, Syringe Pumps | Filtering particles and microorganisms from medications to ensure drug purity. | Biocompatible, complies with medical standards (e.g., ISO 10993). |

| Surgical Instruments and Equipment | Endoscopes, Surgical Robots, Electrosurgical Devices | Filtering gases or liquids to ensure clean media during surgical procedures. | High-temperature and pressure resistance, reusable. |

| Laboratory Equipment | Bioreactors, Centrifuges, Chromatography Systems | Filtering culture media, reagents, or samples to ensure accurate experimental results. | Chemically resistant, suitable for various liquids and gases. |

| Medical Gas Equipment | Oxygen Generators, Nitrogen Generators, Compressed Air Systems | Filtering particles, oil mist, and moisture from medical gases to ensure gas purity. | High efficiency, pressure-resistant, long service life. |

| Sterilization and Disinfection Equipment | Autoclaves, Steam Sterilizers | Filtering steam or gases to ensure effective sterilization processes. | High-temperature and pressure resistance, withstands repeated sterilization. |

| Dental Equipment | Dental Chairs, Air Compressors | Filtering water and gases to ensure hygiene during dental procedures. | Corrosion-resistant, easy to clean. |

| In Vitro Diagnostic Equipment | Blood Analyzers, Urine Analyzers | Filtering particles from samples to ensure accurate diagnostic results. | High precision, biocompatible. |

| Pharmaceutical Production Equipment | Drug Production Lines, Filling Machines | Filtering drugs, solvents, or gases to ensure product quality. | Complies with GMP standards, chemically resistant. |

Key Advantages of Sintered Stainless Steel Filters

1.High Precision Filtration:

Customizable pore sizes (from microns to nanometers) for specific needs.

2.Corrosion Resistance:

Suitable for various chemical media, especially 316L stainless steel.

3.High-Temperature and Pressure Resistance:

Can withstand sterilization and high-pressure environments.

4.Easy to Clean and Sterilize:

Reusable, reducing long-term costs.

5.Biocompatibility:

Complies with medical standards (e.g., ISO 10993), ensuring safety.

Contact HENGKO today to OEM your custom Medical Grade Metal Filters!

Whether you need specialized filtration for medical gases, IV solutions, or high-precision devices,

our expert team is here to provide tailored solutions to meet your unique needs.

Reach out now at ka@hengko.com to discuss your requirements and receive high-quality, reliable

medical-grade filters designed for optimal performance and safety.