Manufacturer of China Porous stainless steel Sintered Filter Tube, Porous metal filters disc

Our advancement depends on the superior gear ,superb talents and consistently strengthened technology forces for Manufacturer of China Porous stainless steel Sintered Filter Tube, Porous metal filters disc, Welcoming fascinated organizations to cooperate with us, we glance ahead to possessing the opportunity of working with companies round the earth for joint development and mutual results.

Our advancement depends on the superior gear ,superb talents and consistently strengthened technology forces for China Filter Disc, Porous metal filters disc, We win many reliable customers by rich experience, advanced equipments, skilled teams, strict quality control and best service. We can guarantee all our goods. Customers' benefit and satisfaction are always our biggest goal. You should contact us. Give us a chance, provide you with a surprise.

2 10 20 microns stainless steel 304/316L bronze sintered porous metal filters disc for industry or filtration system

Porous Sintered Metal Filters consist of highly uniform, interconnected networks of pores with tortuous paths that trap solid particles in a gas or liquid flow streams. Excellent depth filters with superior mechanical strength. Stainless Steel Type 316L withstands temperatures up to 750°F (399°C) in oxidizing and 900°F (482°C) in reducing environments. These steam autoclavable filters can be cleaned by other methods, such as ultrasonic baths or reverse flow flushing. If your application requires even greater resistance to corrosion, temperature, wear, and vibration, other nickel-based alloys are available.

The material used to produce these filters is 316L stainless steel. They are made by uniaxial compaction of powder in a rigid tool with the negative shape of the part and then sintered. The pore size is adjusted by changing the compaction pressure and/or the particle size of the powder.

Powder metallurgy technology is able to create other shapes, such as blind cylinders and other special geometries. In these cases, it is necessary to build a specific tool according to the required design.

Want more information or would like to receive a quote?

Click the Online Service at the top right to contact our salespeople.

E-mail:

ka@hengko.com sales@hengko.com f@hengko.com h@hengko.com

1. Accurate pore size, uniform and even-distributed apertures. Pore size range: 0.1um to 120 microns;

2. Good breathability, fast gas & liquid flow rate and uniform divergence. it is far superior to other peer products with the optimization of special processes in HENGKO.

3. Good filtration dustproof and interception effect, high filtration efficiency. The pore size, speed of the flow and other performances can be customized as requested;

4. High supporting load capacity, no need to use other auxiliary supports, can be directly used as structural elements;

5. Stable structure, particles are tightly bound without migration, almost inseparable under harsh environment;

6. High fatigue strength and impact stress, high pressure resistant, suitable for applications with high pressure difference and flow rate. Sintered porous stainless steel filter elements for long-term usage under high pressure fluid (40mpa) conditions are available;

7. Resistance to high temperature and heat shock. HENGKO stainless steel filter elements can operate at 600 degrees celsius, can withstand high temperature even in oxidized atmospheres;

8. Excellent functions of separation and noise reduction as a result of special multidimensional honeycomb nested capillary structure;

9. Different from other peers, HENGKO stainless steel filter elements haven't been corroded in a variety of environments. The performances of anti-corrosion and rust-proof are close to dense stainless steel products;

10. More than 10K product sizes and types to choose from, customizable as needed for stainless steel filtering products with multiple complex structures;

11. Tiny diameter( 5-20 mm), the length for long filter tube can be up to 800 mm;

12. The processable dimension for plate filter can be up to L 800 * W 450 mm;

13. The maximum diameter for disc filter can be up to 450 mm;

14. Exquisite product appearance will upgrade your product level and image greatly as apparent parts;

15. A variety of cleaning methods are available, strong regeneration ability after reverse cleaning, long service life.

Q1. Why porous metal?

-- Filtration systems using sintered metal media for gaseous, solid and liquid separation have proven to be an effective and

efficient alternative to other separation methods that can be vulnerable to pressure peaks, high temperatures and/or corrosive environments. Sintered metal is highly efficient in removing particulates, delivers reliable performance, is easy to clean and has a long life in comparison with leaf filters, filter bags, plate and frame filters.

Q2. What kind of structures can you make?

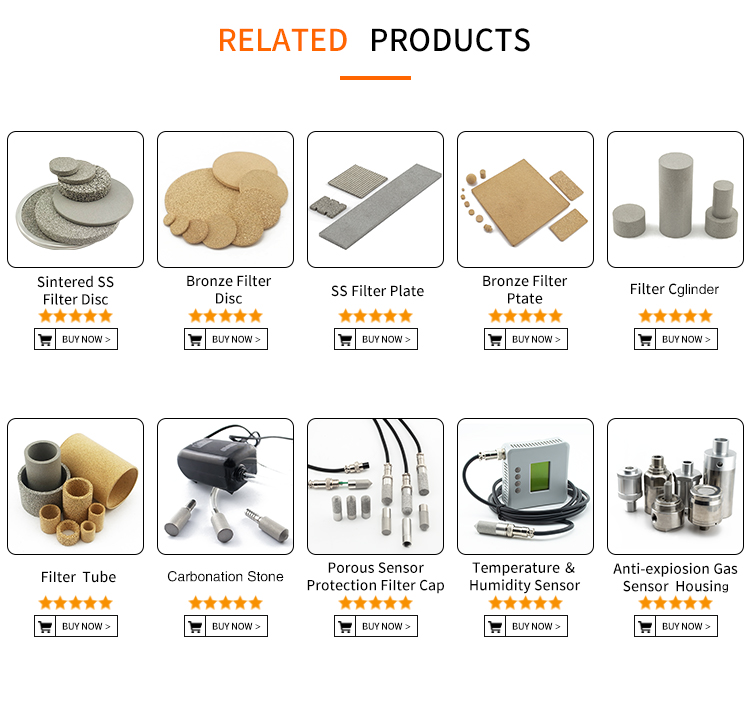

-- We make various types like disc, tube, cup, cartridge, plate, etc.

Q3. Do you provide customized services?

-- Yes, of course.

Q4. If samples available?

-- Sure, no problem.