The sintered metal elements produced by HENGKO have been widely used in the coal chemical industry for over 20+ years.

Coal-rich countries are always looking for ways to optimize and utilize their coal resources more.

The coal energy and chemical industries will play an important role in the sustainable use of energy.

Nowadays, In the continuous exploration and research of the new coal chemical industry, technologies

such as pressurized powder coal gasification, coal-to-oil, coal-to-olefins, and coal-to-methanol

have been widely produced and applied in domestic enterprises, which is of great significance to

reduce the environment caused by coal combustion pollution and reduce dependence on imported

oil. And However, in the course of this technical reform of coal resources, HENGKO's sintered metal

elements also have been widely used in the coal chemical industry.

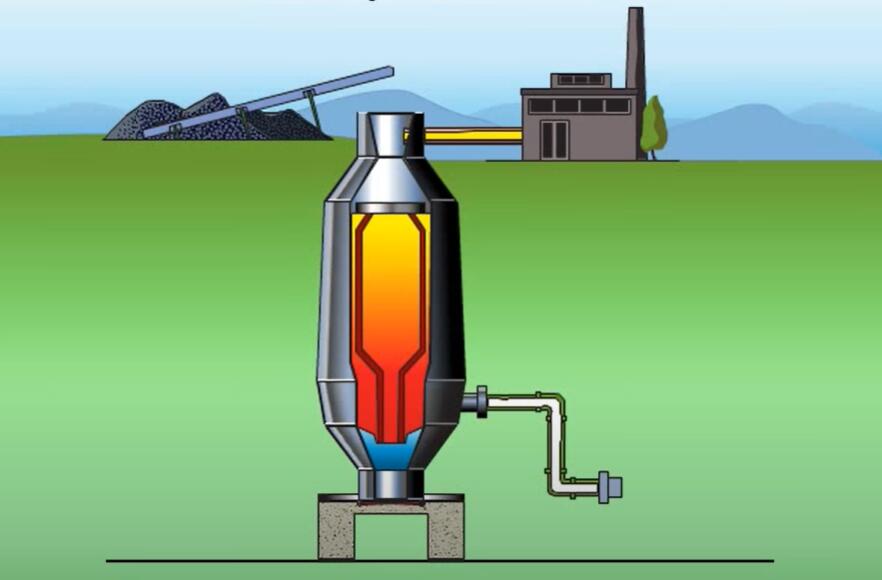

There is a pulverized coal conveying system in the pulverized coal gasification unit, such as HT-L,

SHELL, or GSP. The gas-conveying medium is nitrogen or carbon dioxide. This technology's pressurized

feeding system of pulverized coal is an important component. When nitrogen is used for pressurized

conveying of pulverized coal, since the particle size of the pulverized coal is very small, the adhesion

phenomenon is likely to occur during the flow of the particles, resulting in bridging problems. After the

ventilation cone device is added, the nitrogen gas can enter the tank through the ventilation cone at

the bottom of the powder coal discharge tank, and the powder in the storage tank is pressurized to

homogenize the powder, thereby reducing the force between the powders, making the particles flow smoothly.

Pipeline purging also plays an important role in the pressurized conveying of pulverized coal. When

the pulverized coal enters the pipeline, the pulverized coal is easily piled up under high pressure,

and the pipeline is clogged, so it cannot move the coal smoothly, and the addition of the pipeline

purging device in the conveying pipeline effectively solves this phenomenon. The principle is that the

gas passes through the micropores in the pipe cleaner. A uniform thin gas film is formed on the inner

wall of the cleaner so that the split body is in a suspended fluidized state and smoothly flows into the

lower-end conveying pipe, thereby avoiding powder accumulation and making the conveying effect

more efficient.

Under the premise of fully understanding the production process and working environment,

HENGKO will meet your filtration and separation requirements as much as possible through

a customized professional service by our O.E.M R&D Team. At the same time, we provide

excellent technical support to solve any problems you encounter during use.

Sintered metals, including sintered bronze, can be used in various processes in the coal chemical industry.

Some examples include:

1. Filtration: Sintered metals can be used as filter elements to remove contaminants from coal-derived liquids,

such as coal tar, coal water slurry, and coal-derived fuels.

2. Heat exchangers: Sintered metals can be used as the heat transfer surface in heat exchangers, which are

used to transfer heat between two fluids in the coal chemical industry.

3. Gas diffusers: Sintered metals can be used as gas diffusers in coal gasification processes, which involve

converting coal into a gas that can be used as a fuel.

4. Valves: Sintered metals can be used as valve components in coal chemical processes, such as control valves,

pinch valves, and butterfly valves.

5. Sensors: Sintered metals cup can be used as the sensing element in sensors used in the coal chemical industry,

such as temperature sensors and pressure sensors, humidity sensor probe etc

6. Bearings: Sintered metals can be used as bearing components in coal chemical equipment, such as

conveyor belts and pumps.

In summary, sintered metals can be used in various processes in the coal chemical industry, including filtration,

heat exchange, gas diffusion, valve components, sensor components, and bearings.

Applications

●

Sintered filters can be used in various coal chemical applications to filter contaminants from fluids.

Some examples include:

● Filtration of coal tar: Sintered filters can remove contaminants from coal tar, a thick, black liquid that

is a byproduct of the coal gasification process.

● Filtration of coal water slurry: Sintered filters can remove contaminants from coal water slurry, a

mixture of coal and water used as fuel in certain power plants.

● Filtration of coal-derived fuels: Sintered filters can remove contaminants from coal-derived fuels,

such as synthetic natural gas (SNG) and coal-to-liquids (CTL), produced by converting coal into

coal, a gas or liquid form.

● Filtration of coal gas: Sintered filters can remove contaminants from coal gas produced by coal

gasification and be used as fuel.

In summary, sintered filters can be used in various coal chemical applications to filter contaminants

from fluids, including coal tar, coal water slurry, coal-derived fuels, and coal gas.

Any questions and insterested for the OEM to custom your sintersted metal filter for your

coal filtration project, you are welcome to contact us by email ka@hengko.com for details

and price list, we will send back within 24-Hours.

Main Applications

What is Your Industry ?

Contact us know details and get best solution for your application