Humidity Transmitter over 95%RH Measurement for High Moisture Environment 4-20mA, RS485, 0-5V, 0-10V Output HG808-H

HG808-H High Wet Temperature Humidity Transmitter

The HG808-H by HENGKO is a high-performance industrial humidity and temperature transmitter engineered for extremely humid environments up to 98% RH. Built with durable materials and advanced sensor technology, it delivers accurate and stable measurements even in wet, steamy, or corrosive industrial settings — where typical sensors often fail.

Designed for long-term reliability, the HG808-H is the ideal solution for critical monitoring in high-moisture applications, such as:

✅ Food and beverage processing

✅ Drying chambers and industrial ovens

✅ Pharmaceutical cleanrooms

✅ Chemical and fermentation facilities

Highlights:

*Exceptional Stability Long Term Working in High Moisture / Humidity Condition

Long-term operation and lifespan in near-saturation humidity without degradation or drift.

*Precision Sensor Technology

High accuracy ±2% RH, ±0.2°C ensures reliable data for critical control systems.

*Robust Construction

Withstands harsh process environments, reducing downtime and maintenance.

*Safety & Compatibility

Built-in ESD protection, reverse polarity protection, and standard Modbus protocol ensure safe, seamless deployment.

Key Features :

New-generation design resists damage from long-term exposure to moisture-saturated environments.

Maintains accurate readings even under rapid temperature and humidity fluctuations.

✅ Wide Measurement Range

Temperature: -40°C to 190°C

Built-in algorithm to monitor and manage condensation risks.

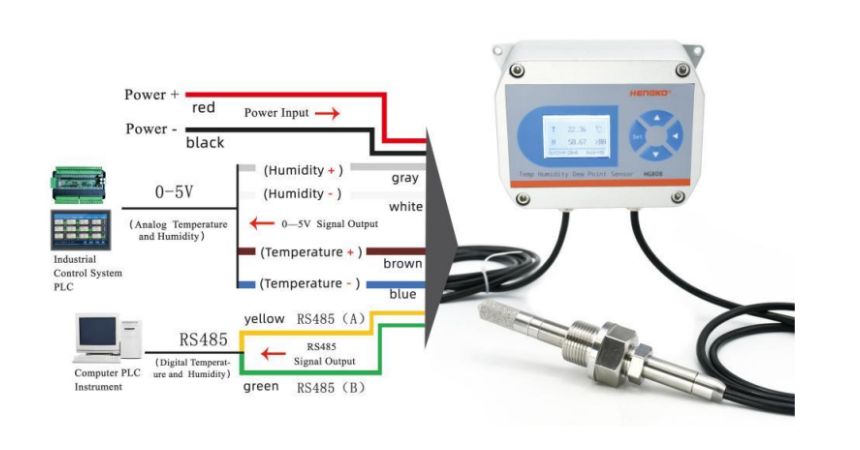

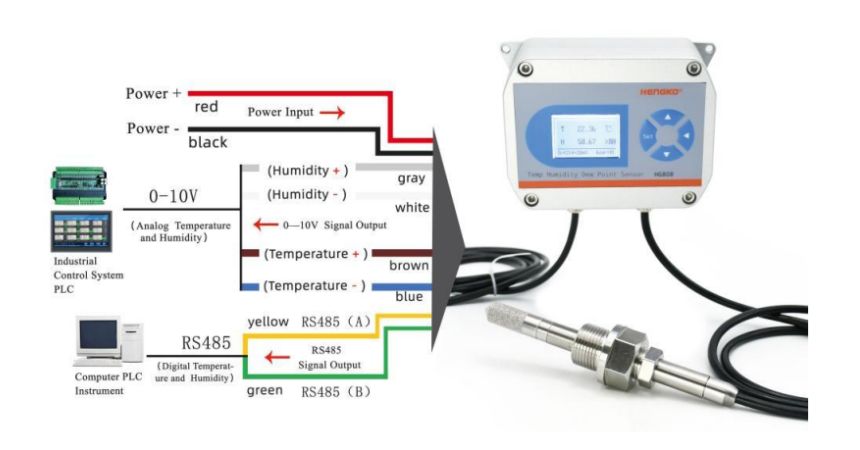

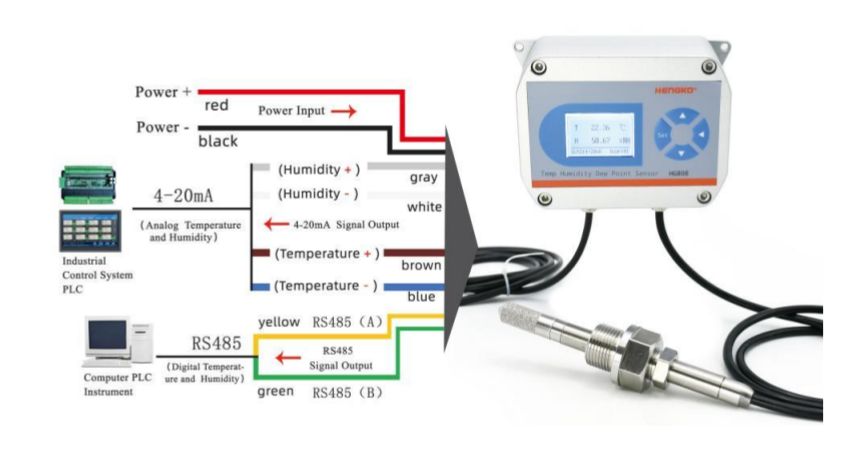

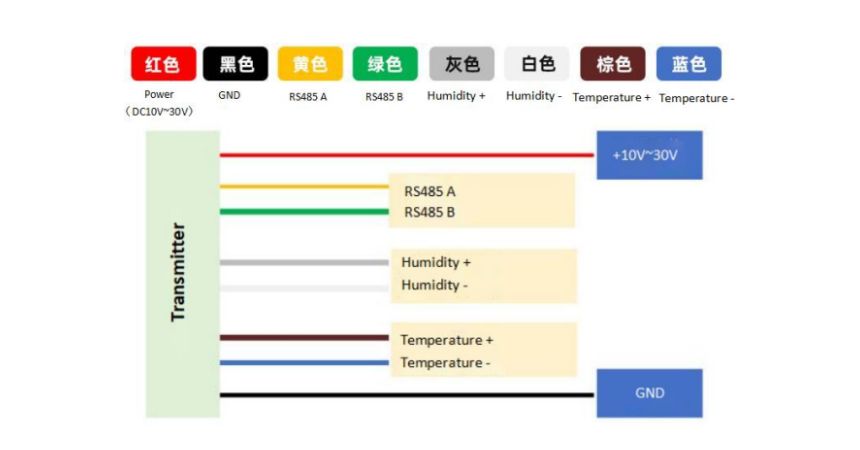

Supports RS485 Modbus RTU, 4–20mA, and optional 0–5V / 0–10V for easy integration.

Waterproof, anti-corrosion sensor housing with sintered metal filter for dust and vapor resistance.

On-screen T/RH/Dew Point readouts available for real-time monitoring.

Easy connection with PLCs, DCS, SCADA, and building control systems.

Built-in ESD and reverse polarity protection for reliable industrial use.

Data Sheet

Specification details for the HG808-H series Humidity Transmitter :

| Category | Specification |

|---|---|

| Temperature Range | -40 ~ +100°C (or -40°F to 212°F) |

| Humidity Range | 0 ~ 100% RH (Recommend < 95% RH) |

| Temperature Accuracy | ±0.1°C (@ 20°C) |

| Humidity Accuracy | ±2% RH (@ 20°C, 10 ~ 90% RH) |

| Power Supply | DC 10V ~ 28V |

| Power Consumption | < 0.5W |

| Analog Outputs | Humidity + Temperature: 4~20mA / 0-5V / 0-10V (one out of three) |

| RS485 Digital Output | Temperature, humidity, dew point, PPM (read simultaneously) |

| Resolution Ratio | 0.01°C / 0.1°C (optional) 0.01% RH / 0.1% RH (optional) |

| Baud Rate | 1200, 2400, 4800, 9600, 19200, 115200 (default: 9600 bps) |

| Acquisition Frequency | Fastest response: 1 second; other settings per PLC |

| Byte Format | 8 data bits, 1 stop bit, no check |

| Pressurization | 16 bar |

| Working Temperature | -20°C ~ +60°C, 0% RH ~ 95% RH (Non-condensation) |

| Probe Type |

Split type: Probe 5 - Pipeline :5A# / 5B# |

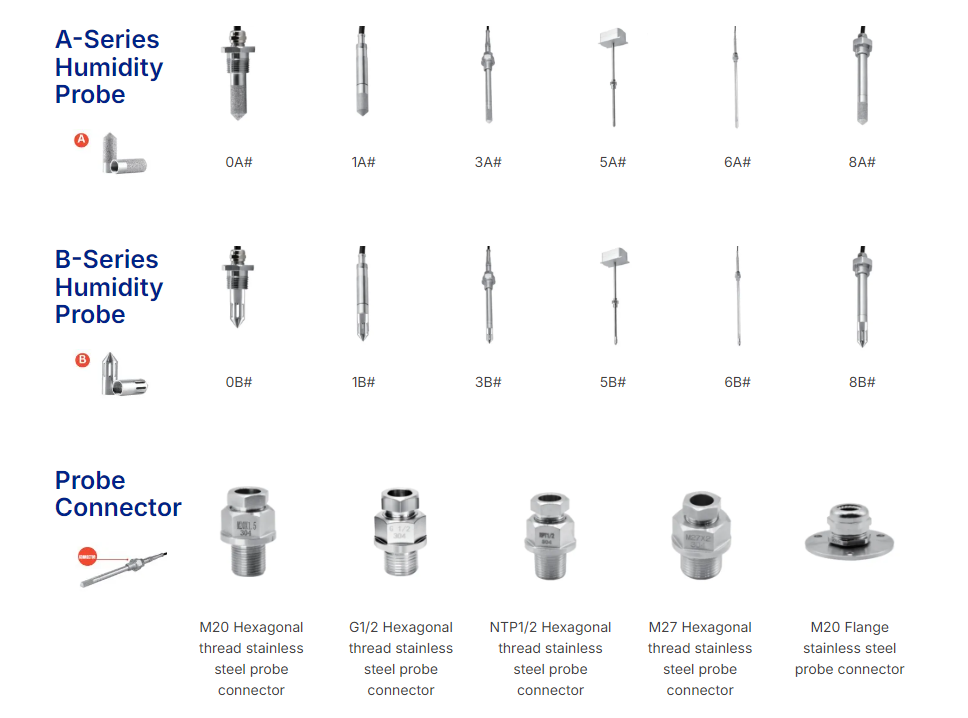

We offer 6 types of probes for the HG808 Humidity Transmitter, with each type available in both A and B versions,

providing a total of 12 probes for various application options.

Probe Option

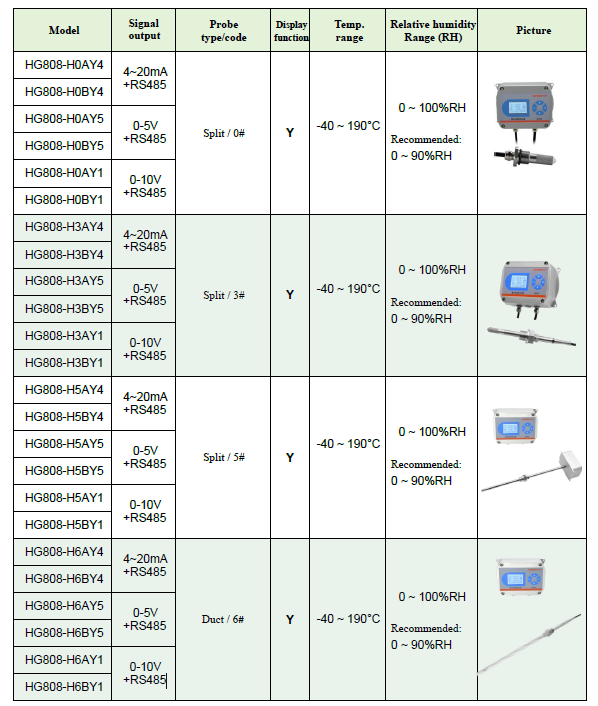

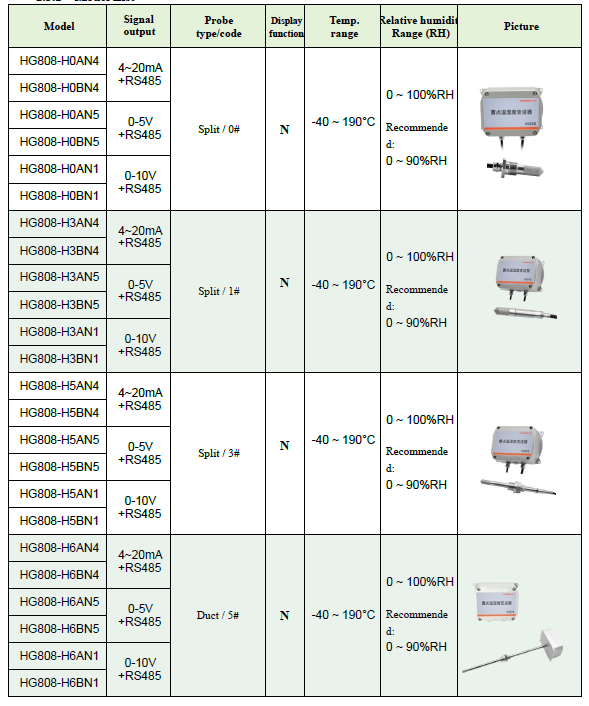

HG808-H Series Products List and Order Number:

1.) With Display

2.) Without Display

Applications for Extreme Environments

Industrial processes often involve extreme temperatures and humidity levels. Regular transmitters can’t handle these harsh conditions. Here’s a breakdown of applications where high-temperature and humidity transmitters (operating over 200°C and down to -50°C) are crucial:

High-Temperature Applications (Over 200°C):

*Industrial Ovens and Furnaces: Monitoring temperature and humidity is vital in curing processes like painting, drying ceramics, and heat treating metals. Precise control ensures product quality and prevents defects.

*Power Generation: Humidity measurement in power plants helps prevent corrosion in turbines and other equipment exposed to high temperatures and steam.

*Chemical Processing: Accurate temperature and humidity data is essential for safe and efficient chemical reactions in reactors, dryers, and pipelines. Deviations can lead to hazardous situations or product contamination.

*Semiconductor Manufacturing: Creating microchips involves tightly controlled environments with high temperatures and low humidity. Transmitters ensure proper conditions for sensitive processes like photolithography and etching.

*Glass Manufacturing: Glass production requires precise temperature and humidity control during melting, blowing, and annealing. Transmitters help maintain consistent glass quality and prevent defects.

Low-Temperature Applications (Down to -50°C):

*Cold Storage Facilities: Monitoring temperature and humidity in freezers and cold warehouses helps maintain optimal conditions for food preservation and prevent spoilage.

*Cryogenic Applications: Extremely low temperatures are used in research and industrial processes like superconductivity and liquefied natural gas (LNG) storage. Transmitters ensure safe handling and prevent equipment damage from ice formation.

*Climate Monitoring: These transmitters are valuable tools for weather stations in extreme cold environments like the Arctic or high mountain regions. They provide accurate data for climate research and weather forecasting.

*Aerospace Industry: Testing aircraft components for functionality in frigid conditions requires precise temperature and humidity control. Transmitters simulate real-world scenarios and ensure aircraft safety.

*Wind Turbine Icing: Detecting and measuring ice formation on wind turbine blades is crucial for safe operation. Transmitters help prevent blade damage and power generation loss in cold climates.

Send your message to us: