-

Incubator temperature and humidity controller sintered porous metal stainless steel 316...

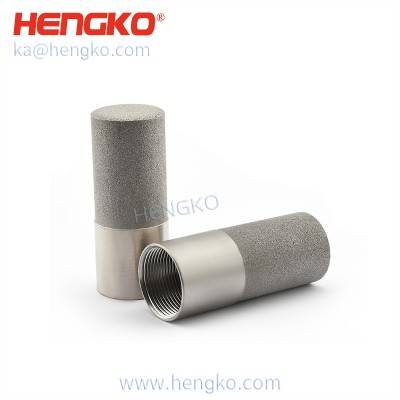

HENGKO stainless steel sensor shell is made by sintering 316L powder material in high temperatures. They have been widely used in environmental protection, p...

View Detail -

RHT35 sintered metal powder protected weather-proof temperature humidity sensor probe h...

HENGKO stainless steel sensor shells are made by sintering 316L powder material at high temperatures. They have been widely used in environmental protection,...

View Detail -

I2C ±2%RH digital temperature and relative humidity probe for weather station

Relative humidity sensor probe equipped with a weatherproof metal mesh and a 1 m long cable. The measuring range for temperature is from -40 °C to 125 °C, an...

View Detail -

air temperature and humidity sensor with sintered metal humidity probe for egg incubato...

HENGKO temperature and humidity probe detectors can be applied in various fields: telepoint base stations, electronic control cabinets, production sites, s...

View Detail -

Wholesale custom dustproof waterproof RHT20 digital high temperature and relative humid...

HENGKO temperature and relative humidity sensor based on RHT-H series sensor which gives good accuracy and covers a great range of temperature and humidity. ...

View Detail -

RHT31 protection wireless resistance I2c digital temperature and humidity sensor probe

HENGKO stainless steel sensor shells are made by sintering 316L powder material at high temperatures. They have been widely used in environmental protection,...

View Detail -

RHTX Series mesh-protected weather-proof humidity sensor probe housing

HENGKO stainless steel sensor shells are made by sintering 316L powder material at high temperatures. They have been widely used in environmental protection,...

View Detail -

HENGKO waterproof grain moisture humidity sensor, sintered stainless steel metal sensor...

HENGKO stainless steel sensor shells are made by sintering 316L powder material at high temperatures. They have been widely used in environmental protection,...

View Detail -

IP66 air temperature and humidity probe for greenhouse

HENGKO temperature and humidity probe detectors can be applied in various fields: telepoint base stations, electronic control cabinets, production sites, sto...

View Detail -

Sintered stainless steel sensor probe housing for digital egg incubator temperature hum...

HENGKO temperature and humidity probe consist of high precision RHTx series sensor module, one meter 4-pin cable, sintered metal filter cap, cable gland, etc...

View Detail -

IP65 IP66 waterproof sintered metal stainless steel HVAC relative temperature and humid...

HENGKO stainless steel sensor housing is made by sintering 316L powder material at high temperatures. They have been widely used in environmental protection,...

View Detail -

HK66MCN 30um weatherproof temperature and humidity sensor probe housing

HENGKO stainless steel sensor shells are made by sintering 316L powder material at high temperatures. They have been widely used in environmental protection,...

View Detail -

Excellent Long-term Stability Temperature And Humidity Sensor With Stainless Steel Prot...

HENGKO high temperature and humidity probe adopt high precision RHT series sensor equipped with a sintered metal filter shell for large air permeability, fa...

View Detail -

Waterproof IP66 humidity sensor housing to protect temperature humidity probe RHT30

HENGKO humidity sensor housing is made by sintering 316L powder material at high temperatures. They have been widely used in environmental protection, petrol...

View Detail -

Wall-mounted digital temperature and humidity probe series – sintered stainless s...

HENGKO stainless steel sensor shells are made by sintering 316L powder material at high temperatures. They have been widely used in environmental protection,...

View Detail -

HK20MCN sintered porous stainless steel RHT-30 humidity sensor probe housing for plant ...

HENGKO stainless steel sensor shell are made by sintering 316L powder material in high temperature. They have been widely used in environmental protection, p...

View Detail -

HK97MCN Waterproof RHT30 35 40 temperature humidity sensor probe shell cover stainless ...

HENGKO stainless steel sensor shell are made by sintering 316L powder material in high temperature. They have been widely used in environmental protection, p...

View Detail -

HK78MCN digital humidity sensor probe filter housing 316 stainless steel M19*1.0

HENGKO stainless steel sensor shell are made by sintering 316L powder material in high temperature. They have been widely used in environmental protection, p...

View Detail -

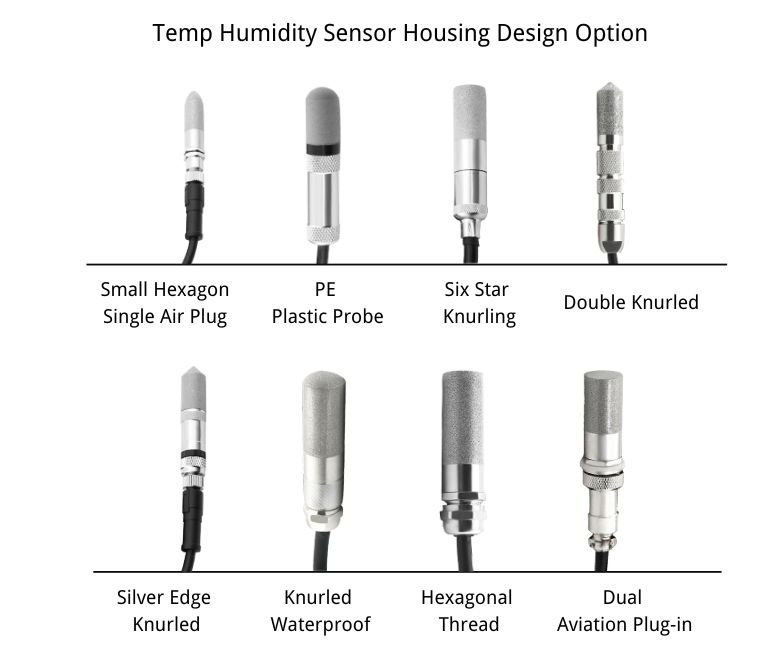

HENGKO Real-time monitoring relative humidity sensor probe with flange for industrial H...

Air ducts are an unfriendly environment for control sensors. You need an air duct humidity sensor strong enough to withstand these dangers and sensitive enou...

View Detail -

Digital I2C RHT-H85 temperature & relative humidity sensor probe for HVAC Incubato...

HENGKO RHT-85 sensor is a robust, high-accuracy, digital probe, the product adopts a capacitive digital sensor as the temperature and humidity measurement c...

View Detail

Main Features Humidity Probe

1. Humidity measurement:

Humidity probe is designed to measure the humidity or the amount of moisture in the air. It is typically done through the use of a sensor that is sensitive to changes in humidity.

2. Temperature measurement:

Our Humidity probes also include a temperature sensor, which allows them to measure the temperature in addition to humidity. It can be useful for applications where temperature and humidity are closely related, such as HVAC systems or greenhouses.

3. Data logging:

HENGKO's humidity sensor probe can log and store data over time. It can be useful for recording long-term trends or for data analysis.

4. Display:

Our humidity sensor probe include a display that shows the current humidity and temperature readings in real-time. It can be useful for quick and easy reference without connecting to a computer or other device.

5. Connectivity:

Our humidity probe are equipped with connectivity options, such as Bluetooth or Wi-Fi, which allow them to transmit data wirelessly to a nearby device. It can be useful for remote monitoring or integrating the probe into a larger system.

6. Durability:

Our Humidity probe are often used in harsh environments, such as industrial settings or outdoor locations. As a result, they are often designed to be rugged and durable, with features such as water-resistant or weatherproof housings.

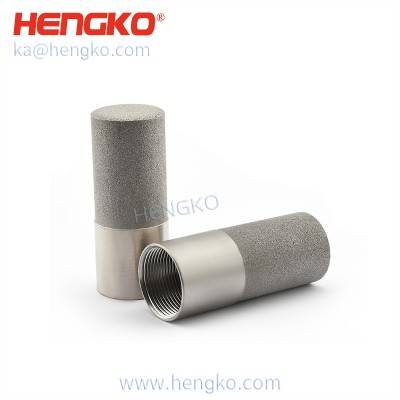

Types of Humidity Sensor Probe Housing

There are several types of humidity sensor probe housings, including:

1. Plastic housings

Plastic housings are the most common type of humidity sensor probe housing. They are lightweight, inexpensive, and easy to install. However, plastic housings are not as durable as metal housings and can be damaged by extreme temperatures or harsh chemicals.

2. Metal Housings

Metal housings are more durable than plastic housings and can withstand extreme temperatures and harsh chemicals. However, metal housings are more expensive and can be difficult to install.

3. Waterproof Housings

Waterproof housings are designed to protect humidity sensor probes from water and moisture. They are often used in outdoor applications or in applications where there is a risk of water damage.

4. Specialty Housings

There are a number of specialty humidity sensor probe housings available, such as housings for high-temperature applications, housings for low-pressure applications, and housings for use in hazardous environments.

The choice of humidity sensor probe housing depends on the application and the specific requirements of the user.

Some factors to consider when choosing a humidity sensor probe housing include:

* Durability

* Cost

* Ease of installation

* Protection from water and moisture

* Suitability for the specific application

| Type | Description | Advantages | Disadvantages |

|---|---|---|---|

| Plastic | Lightweight, inexpensive, and easy to install | Lightweight, inexpensive, and easy to install | Not as durable as metal housings and can be damaged by extreme temperatures or harsh chemicals |

| Metal | Durable and can withstand extreme temperatures and harsh chemicals | Durable and can withstand extreme temperatures and harsh chemicals | More expensive and can be difficult to install |

| Waterproof | Designed to protect humidity sensor probes from water and moisture | Protects humidity sensor probes from water and moisture | More expensive than plastic housings |

| Specialty | Available for specific applications, such as high-temperature, low-pressure, and hazardous environments | Suitable for specific applications | Limited availability |

What You Should Care When Custom Humidity Probe

When OEM/customizing a humidity probe, there are several factors to consider:

1. Sensitivity:

The sensitivity of the humidity sensor is important, as it determines the probe's ability to measure small changes in humidity accurately.

2. Range:

The range of the probe should be appropriate for the specific application, as well as the operating environment.

3. Accuracy:

The accuracy of the probe is critical, as it determines the reliability of the measurements.

4. Response time:

The response time of the probe should be fast enough to track changes in humidity in real-time accurately.

5. Size and form factor:

The size and form factor of the probe should be suitable for the specific application and installation requirements.

6. Durability:

The probe should withstand the operating environment, including any harsh or extreme conditions.

7. Connectivity:

If the probe is connected to a computer or other device, it should be equipped with the necessary connectivity options.

8. Data logging:

If the probe is used for data logging or analysis, it should be equipped with the necessary storage and processing capabilities.

9. Cost:

The cost of the probe should be considered, as well as any ongoing maintenance or replacement costs.

It is important to carefully assess the application's specific needs and choose a humidity probe that meets those requirements. It is also helpful to consult with a manufacturer or supplier to discuss custom options and ensure that the probe meets the desired specifications.

For Humidity Sensor, HENGKO have many design based on different application, please check as following.

Choose What You Interested in to Use.

Advantage of the Humidity Probe

1. Accurate measurement:

Humidity probes are designed to provide accurate and reliable humidity and temperature measurements. This can be important for various applications, such as ensuring proper humidity levels in a greenhouse or monitoring indoor air quality.

2. Easy to use:

Humidity probes, with simple controls and user-friendly interfaces, are typically easy to use. It is suitable for people with a wide range of technical expertise.

3. Versatility:

Humidity probes can be used in many settings, including homes, offices, warehouses, factories, and outdoor locations. So it is a flexible tool for a variety of applications.

4. Compact size:

Humidity probes are often small and portable, making them easy to carry and use in various locations.

5. Long battery life:

Many humidity probes have a long battery life, allowing them to be used for extended periods without requiring frequent battery replacements.

6. Low maintenance:

Humidity probes require minimal maintenance, with no need for regular calibration or other upkeep. It makes them a convenient and hassle-free choice for monitoring humidity and temperature.

For harsh environments such as strong acid and strong alkali, remote installation of temperature and humidity probes

Application

1. Indoor air quality monitoring:

Humidity probes can monitor humidity levels in homes, offices, and other indoor locations, ensuring that the air is comfortable and healthy for occupants.

2. HVAC system control:

Humidity probes can help control humidity levels in heating, ventilation, and air conditioning (HVAC) systems, improving energy efficiency and comfort.

3. Greenhouse management:

Humidity probes can help regulate humidity levels in greenhouses, improving the growth and health of plants.

4. Industrial process control:

Humidity probes can help monitor and control humidity levels in industrial processes, such as manufacturing or chemical processing.

5. Food storage:

Humidity probes can help monitor humidity levels in food storage facilities, ensuring that products are stored in optimal conditions.

6. Museums and art galleries:

Humidity probes can help control humidity levels in museums and art galleries, preserving sensitive artefacts and works of art.

7. Agriculture:

Humidity probes can be used in agricultural settings to help monitor and control humidity levels in fields, greenhouses, and other locations.

8. Shipping and logistics:

Humidity probes can help monitor humidity levels during shipping and storage, ensuring that goods are not damaged by excess moisture.

9. Laboratories:

Humidity probes can be used in laboratories to help monitor and control humidity levels, improving the accuracy and reliability of experiments.

10. Weather forecasting:

Humidity probes can help measure the atmosphere's humidity levels, providing important data for weather forecasting and climate research.

Frequently Asked Questions (FAQ )

1. How Does a Humidity Sensor Probe Housing Work?

A humidity sensor probe housing is a protective enclosure that houses a humidity sensor probe.

It protects the probe from the elements and ensures that it can operate accurately in a variety of environments.

The housing is typically made of plastic or metal and has a small opening that allows the probe to sense the humidity in the air.

The housing also has a number of features that help to protect the probe from damage, such as a watertight seal and a filter

to prevent dust and debris from entering the housing.

Benefits of using a humidity sensor probe housing:

* Protects the probe from the elements

* Ensures that the probe can operate accurately in a variety of environments

* Extends the life of the probe

* Makes the probe easier to install and maintain

Features of a humidity sensor probe housing:

* Made of plastic or metal

* Has a small opening that allows the probe to sense the humidity in the air

* Has a watertight seal

* Has a filter to prevent dust and debris from entering the housing

Applications of a humidity sensor probe housing:

* HVAC systems

* Industrial process control

* Meteorology

* Agriculture

* Environmental monitoring

2. What is the Range of a Humidity Probe?

The range of a humidity probe is the range of humidity values that the probe can accurately measure.

The range is typically expressed as a percentage of relative humidity (RH), such as 0-100% RH.

The range of a humidity probe depends on the type of probe. Capacitive and resistive probes typically

have a range of 0-100% RH, while thermal conductivity probes typically have a range of 0-20% RH.

The range of a humidity probe is also affected by the operating temperature. Probes that are designed

for use in high-temperature environments typically have a narrower range than probes that are designed

for use in low-temperature environments.

Here is a table of the typical ranges of different types of humidity probes:

| Type of Probe | Typical Range |

|---|---|

| Capacitive | 0-100% RH |

| Resistive | 0-100% RH |

| Thermal conductivity | 0-20% RH |

The actual range of a humidity probe will be specified by the manufacturer. It is important to use

a probe that has a range that is appropriate for the application. Using a probe with a too-narrow

range will result in inaccurate measurements, while using a probe with a too-wide range will

result in unnecessary cost.

3. How Accurate is a Humidity Probe?

The accuracy of a humidity probe is the degree to which the probe's measurements agree with the actual humidity of the air. Accuracy is typically expressed as a percentage of relative humidity (RH), such as ±2% RH.

The accuracy of a humidity probe depends on the type of probe, the operating temperature, and the humidity level. Capacitive and resistive probes are typically more accurate than thermal conductivity probes. Probes that are designed for use in low-humidity environments are typically more accurate than probes that are designed for use in high-humidity environments.

Here is a table of the typical accuracies of different types of humidity probes:

| Type of Probe | Typical Accuracy |

|---|---|

| Capacitive | ±2% RH |

| Resistive | ±3% RH |

| Thermal conductivity | ±5% RH |

The actual accuracy of a humidity probe will be specified by the manufacturer. It is important to use a probe that has an accuracy that is appropriate for the application. Using a probe with a too-low accuracy will result in inaccurate measurements, while using a probe with a too-high accuracy will result in unnecessary cost.

Here are some factors that can affect the accuracy of a humidity probe:

* Type of probe: Capacitive and resistive probes are typically more accurate than thermal conductivity probes.

* Operating temperature: Probes that are designed for use in low-temperature environments are typically more accurate than probes that are designed for use in high-temperature environments.

* Humidity level: Probes that are designed for use in low-humidity environments are typically more accurate than probes that are designed for use in high-humidity environments.

* Calibration: Probes should be calibrated regularly to ensure that they are measuring humidity accurately.

* Contamination: Probes can become contaminated with dirt, dust, or other pollutants, which can affect their accuracy.

By taking these factors into account, you can choose a humidity probe that will provide you with accurate measurements for your application.

4. Can Humidity Probes be Calibrated?

Yes, many humidity probes are calibrated to ensure that they provide accurate and reliable measurements. Calibration involves comparing the probe's readings to a known standard and adjusting the probe's output to match the standard. Calibration may be performed by the manufacturer or by the user, depending on the specific probe and its capabilities.

5. How Often Should a Humidity Probe be Calibrated?

The frequency of calibration for a humidity probe depends on the type of probe, the operating environment, and the desired accuracy of the measurements. In general, humidity probes should be calibrated at least once a year. However, more frequent calibration may be necessary if the probe is used in a harsh environment or if it is critical to the application.

Some factors to consider when determining how often to calibrate a humidity probe:

* Type of probe: Capacitive and resistive probes typically require more frequent calibration than thermal conductivity probes.

* Operating environment: Probes that are used in harsh environments, such as high-temperature or high-humidity environments, should be calibrated more frequently.

* Desired accuracy of measurements: If the accuracy of the measurements is critical to the application, the probe should be calibrated more frequently.

* History of the probe: If the probe has a history of drift or instability, it should be calibrated more frequently.

The recommended calibration intervals for different types of humidity probes:

| Type of Probe | Recommended Calibration Interval |

|---|---|

| Capacitive | 6-12 months |

| Resistive | 6-12 months |

| Thermal conductivity | 1-2 years |

It is important to note that these are just general guidelines. The actual calibration interval for a humidity probe

may be longer or shorter depending on the specific application.

Some signs that a humidity probe may need to be calibrated:

* The probe's readings are drifting or unstable.

* The probe's readings are inaccurate.

* The probe has been exposed to a harsh environment.

* The probe has been damaged.

If you notice any of these signs, it is recommended that you calibrate the probe as soon as possible. Calibrating a humidity probe is a relatively simple process that can be done by a qualified technician.

By calibrating your humidity probe regularly, you can ensure that it is providing you with accurate measurements. This will help you to make informed decisions about your application.

6. Can Humidity Probes be Used Outdoors?

Yes, some humidity probes are designed for outdoor use and are equipped with waterproof or

weatherproof housing features. Selecting a humidity probe suitable for the specific application and operating environment is important.

7. Can Humidity Probes be Connected to a Computer or Other Device?

Yes, some humidity probes are equipped with connectivity options, such as Bluetooth or Wi-Fi,

which allow them to transmit data wirelessly to a nearby device. It is useful for remote monitoring or integrating the probe into a larger system.

8. What Are the Main Factors that Can Affect the Accuracy of a Humidity Probe?

* Type of probe:

Different types of humidity probes have different levels of accuracy, and some types are more sensitive to certain environmental conditions than others. For example, capacitive and resistive probes are typically more accurate than thermal conductivity probes, but they are also more sensitive to temperature and humidity changes.

* Operating temperature:

The accuracy of a humidity probe can be affected by the temperature of the environment in which it is used, and some probes are designed for use in specific temperature ranges. For example, probes that are designed for use in high-temperature environments may not be as accurate in low-temperature environments.

* Humidity level:

The accuracy of a humidity probe can also be affected by the humidity level of the environment in which it is used. For example, probes that are designed for use in low-humidity environments may not be as accurate in high-humidity environments.

* Calibration:

Humidity probes should be calibrated regularly to ensure that they are measuring humidity accurately. Calibration is the process of comparing the probe's readings to a known standard, and adjusting the probe's output accordingly.

* Contamination:

Humidity probes can become contaminated with dirt, dust, or other pollutants, which can affect their accuracy. It is important to clean humidity probes regularly to prevent contamination.

* Damage:

Humidity probes can be damaged by physical shock, vibration, or exposure to extreme temperatures or chemicals. Damage to a probe can affect its accuracy, and it is important to handle probes with care to prevent damage.

* Electromagnetic interference (EMI):

Humidity probes can be affected by EMI from nearby electronic devices. If you are using a humidity probe in an environment with a lot of EMI, you may need to take steps to shield the probe from interference.

* Airflow:

The accuracy of a humidity probe can be affected by the airflow around the probe. If the probe is in a still environment, it may not be able to accurately measure the humidity of the air. It is important to position humidity probes in areas with good airflow to ensure accurate measurements.

* Barometric pressure:

The accuracy of a humidity probe can be affected by changes in barometric pressure. If you are using a humidity probe in an area with fluctuating barometric pressure, you may need to take steps to compensate for these changes.

By taking these factors into account, you can choose a humidity probe that will provide you with accurate measurements for your application and take steps to maintain its accuracy over time.

Here are some additional tips for using humidity probes accurately:

* Install the probe in a location where it will be exposed to the air that you want to measure.

* Avoid placing the probe near sources of heat or humidity.

* Keep the probe clean and free of contamination.

* Calibrate the probe regularly.

* Monitor the probe's readings and check for signs of drift or instability.

By following these tips, you can ensure that your humidity probe is providing you with accurate measurements that you can rely on.

9. How Do I Choose the Right Humidity Probe for My Application?

There are several factors to consider when selecting a humidity probe, including the required level of accuracy, the operating range, the type of sensor, and the connectivity and data logging capabilities. It is important to carefully assess the application's specific needs and choose a humidity probe that meets those requirements.

10. Can Humidity Probes be Used with a Humidity Controller?

Yes, humidity probes can be used with a humidity controller, which is a device that automatically adjusts humidity levels based on input from the probe. It can be useful for applications where it is important to maintain a consistent humidity level, such as in HVAC systems or greenhouses.

11. How Do I Clean and Maintain a Humidity Probe?

It is important to keep a humidity probe clean and in good.

If you're interested in our humidity probe, don't hesitate to contact us by email at ka@hengko.com for a

quotation or to learn more about how it can help with temperature and humidity detection. Our team will

respond to your inquiry within 24 hours and provide personalized suggestions and solutions.

Contact us now to get started!