High Pressure High Purify Gas Filter for the Semiconductor Industry HF series by HENGKO

Description

The high-pressure gas filter is specially designed for use in high-pressure, high-purity gas delivery systems and ultra-high-purity

gas cabinets in semiconductor manufacturing processes. Crafted from durable 316L stainless steel, it offers a robust structure

with a design pressure of up to 50 MPa, while maintaining a relatively lightweight profile.

Key features include:

*High Strength and Durability:

With excellent resistance to high pressure and temperature.

*Corrosion Resistance:

Ideal for handling corrosive gases in demanding environments.

*Exceptional Filtration Efficiency:

Effectively removes dust, rust, oil mist, and hydrocarbons from compressed

air, ensuring gas purity and protecting systems from contamination.

*High Permeability and Long Service Life:

Ensures efficient gas flow and extended operational longevity.

*Easy Maintenance:

Replaceable filter elements make upkeep simple and cost-effective.

This filter enhances gas quality and ensures the efficient operation of semiconductor equipment,

making it a reliable solution for high-purity gas systems.

Product Feature

Product Features

▶ All 316L Stainless Steel Construction

▶ Lightweight and Compact Design: Saves installation space.

▶ Threaded Connections: Ensures complete sealing of the high-pressure gas filter.

▶ Compatible with C-Type and W-Type Sealing Standards

▶ High Temperature, Pressure, and Corrosion Resistance

▶ High Filtration Efficiency: Resistant to clogging.

▶ Easy and Efficient Installation and Maintenance

▶ 100% Integrity Tested and Approved

▶ 100% Helium Leak Detection Tested and Approved

Datasheet

Technical Parameters

| Parameter | Specification |

|---|---|

| Filter Element Material | 316L Stainless Steel Powder Sintered |

| Housing Material | 316L Stainless Steel |

| Surface Finish | - Exterior: Ra <1.6 μm |

| - Interior: Electropolished, Ra ≤0.13 μm | |

| Filtration Efficiency | ≥0.003 μm |

| Maximum Operating Pressure | 500 bar |

| Maximum Differential Pressure | 5 bar |

| Maximum Operating Temperature | 600°C |

| Downstream Cleanliness | ≤0.03 particles/liter @ >0.01 μm rated flow |

| Helium Leak Validation | 1 × 10⁻¹¹ cc/min |

| Helium Leak Testing | 1 × 10⁻⁹ cc/min |

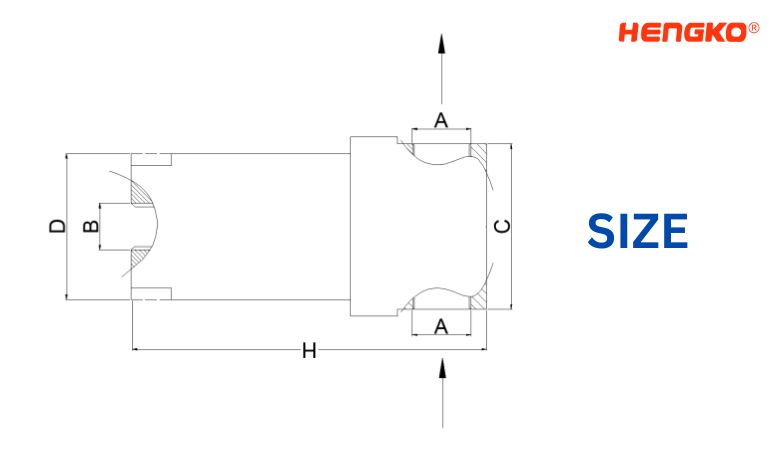

Size

Here’s the part number you can order and size details :

Product Information Table for Disc filter type

| Product Model | Inlet Specification | Outlet Specification | Total Length (A) | Filter Element OD (φB) | Housing OD (φC) |

|---|---|---|---|---|---|

| Z01B-00639 | 1/4’’ VCR | ISO NW40 Vacuum Flange | 42mm (1.64’’) | Φ39mm (1.53’’) | Φ55mm (2.16’’) |

| Z01B-00695 | 1/4’’ VCR | ISO NW50 Vacuum Flange | 42mm (1.64’’) | Φ52mm (2.05’’) | Φ75mm (2.95’’) |

Product Information Table for Cartridge filter type

| Product Model | A | B | C (mm) | D (mm) | Height H (mm) | Filtration Precision | Cleaning Grade |

|---|---|---|---|---|---|---|---|

| Z01G-00001 | NPT1/8 | NPT1/4 | 37 | 31.5 | 96 | ≤0.003 μm | C |

| Z01G-00002 | NPT3/8 | NPT3/8 | 56 | 45 | 198 | ≤0.003 μm | C |

| Z01G-00003 | G1/2 | M10*1.5 | 100 | 88 | 346 | ≤0.003 μm | C |

| Z01G-00004 | NPT3/8 | / | 45 | 42 | 149 | ≤0.003 μm | C |

| Z01G-00005 | G1-1/2 | G1/2 | 125 | 113 | 440 | ≤0.003 μm | C |

| Z01G-00006 | G1 | G1/4 | 92 | 75 | 280 | ≤0.003 μm | C |

| Z01G-00007 | G1 | G1/4 | 92 | 75 | 220 | ≤0.003 μm | C |

Typical Applications

Ideal for use in:

*Vacuum chambers requiring rapid and precise gas venting.

*High-sensitivity semiconductor manufacturing environments.

*Processes where turbulence minimization and particle control are critical.

With its advanced design and outstanding performance, the Diffuser Filter is the perfect choice for

optimizing filtration and flow control in semiconductor applications.

Contact us today to learn how this innovative product can elevate your production

*Filters high-pressure gases for cooling and process applications, especially in high-temperature settings.

*Enhances efficiency and reduces equipment wear by preventing contamination in gas cooling and flow systems.

These filters are essential in any application requiring clean, consistent gas flow, enhancing equipment protection,

process efficiency, and final product quality across industries.

![]()

Send your message to us: