-

Kiekie Sintered Bronze Fuel kānana

Nā kikoʻī Huahana Ke hoʻolauna nei i kā mākou kānana wahie top-of-the-line me Sintered Bronze Fuel Element - ka hopena kūpono loa no kēlā me kēia mea e pono ai i kahi kiʻekiʻe ...

Nānā Nānā -

Pāpaʻa keleawe keleawe i hoʻopaʻa ʻia

Hoʻopau i ka Electrolysis a me Galvanic CorrosionE hōʻemi i ka hoʻopili RF a hoʻomaikaʻi i ka hana uila ʻoi aku ka maikaʻi o ka hoʻokipa ʻana no kāu mau polokalamu GPS, ka wā ...

Nānā Nānā -

Poha metala Sintered Mini Cylinder

ʻO nā metala porous kekahi o nā mea kūpono no ka hana ʻana i nā bearings. Loaʻa nā pōmaikaʻi o ka Sintered Mini Cylinder Powdered metala i ka helu nui ...

Nānā Nānā -

ʻOi aku ka lōʻihi 316L Porous Stainless Steel Filter Sintered Filt...

Huahana E wehewehe ʻo HENGKO biomedical kānana i hana ʻia me 316L metala pauka i hoʻopaʻa ʻia i ka wela kiʻekiʻe, me kahi porosity kūlike o 0.2-0.5 um, pale i ka corrosion ...

Nānā Nānā -

CEMS Online Smoke Analyzer Gas Sampling Probe 44.5mm*121mm a Unique Probe Design

Huahana E wehewehe * Hoʻokaʻawale i ka lepo i ke kaʻina hana * No ka nui o ka lepo ma luna o 3g/m3 * Ka ʻili ʻeleʻele nui * Ke ola lōʻihi * ʻO ke kaomi ʻokoʻa haʻahaʻa...

Nānā Nānā -

ʻO ka paipu kānana metala porous no ka hoʻomaʻemaʻe ʻana i ka wela a me nā kemika kūikawā | HENGKO

Hana ʻia nā paipu kānana stainless steel HENGKO e ka sintering 316L mea pauka a i ʻole multilayer stainless steel wire mesh ma nā wela kiʻekiʻe. Ua w...

Nānā Nānā -

316L SS kuhiliʻole kila metala sintered kānana, Customized microporous nickel monel inco...

Hana ʻia nā mea metala porous o HENGKO ma o ka hoʻomaʻamaʻa ʻana i ka wela o ka uea kila kila multilayer a i ʻole ka pauka 316L i nā wela kiʻekiʻe. Cus...

Nānā Nānā -

Candle type Sintered 316L stainless steel mesh filter hiki ke hoohana hou ia

Hāʻawi ʻo HENGKO i kahi hōʻiliʻili nui o nā pahu kānana stainless steel i hoʻohālikelike ʻia no ka hoʻohana ʻana i kahi ākea o nā ʻoihana, me nā petrochemical...

Nānā Nānā -

Anti-corrosion Microns Powder Porous Sintered Metal Filter Cartridge No ka ʻōnaehana kānana

Hoʻokumu ʻo HENGKO i nā paipu kānana porous e hāʻawi i ka versatility i ka hoʻolālā ʻana no ka mea hiki iā lākou ke puka a makapō paha me ka liʻiliʻi o ka mānoanoa pā o 1mm. ʻO kēia mau huahana c...

Nānā Nānā -

i hoʻopaʻa ʻia i ka porous metala kānana mea media, porosity 0.2 μm ~ 100 micron titanium mon...

Ma HENGKO, ʻo ke kaʻina hana o ka hana ʻana i kā lākou mau mea metala porous e pili ana i ka wela e mālama ana i ka 316L pauka mea a i ʻole multilayer stainless steel mesh ma ke kiʻekiʻe ...

Nānā Nānā -

porous metala kuhiliʻole pahu pahu kānana no kiʻekiʻe puʻe ea hoʻomaʻemaʻe paʻa ...

Hana ʻo HENGKO i kāna mau mea metala porous ma ka mālama ʻana i ka wela 316L mea pauka a i ʻole multilayer stainless steel mesh ma nā wela kiʻekiʻe. ʻO kā lākou ...

Nānā Nānā -

Maikaʻi 0.2 i 120 microns micro porosity keleawe inconel monel 316 316L kila kila ...

Hoʻokumu ʻia ka metala porous e ka hoʻopili ʻana i ka metala pauka i nā ʻano ʻano like ʻole, a laila hoʻopaʻa ʻia ka sinter e hana i kahi ʻano ikaika a inert. ʻO kēia hiʻohiʻona ...

Nānā Nānā -

Nā kānana Bronze Sintered me ke ʻano kikoʻī OEM no ka kānana

Hiki iā HENGKO ke hāʻawi aku i nā mea kūʻai aku i ka hiki ke hana i nā kānana a me nā ʻāpana keleawe porous me nā ʻano kikoʻī. ʻO kēlā me kēia o kēia mau noi kūikawā r ...

Nānā Nānā -

5 10 20 90 120 microns sintered porous metala keleawe keleawe kilakila 316L multi-purpose ...

Hana ʻo HENGKO i nā mea kānana ma kahi ākea o nā mea, ka nui, a me nā mea pono e hiki ke maʻalahi iā lākou me nā hiʻohiʻona a me ka configura...

Nānā Nānā -

ʻO ka ikaika kūlike i hoʻopaʻa ʻia i ka porous metala micron kānana fluidizers keleawe keleawe keleawe fil...

Hoʻohana ʻia nā ʻāpana kānana hohonu e wehe i nā ʻāpana mai nā wai. 'O ia ho'i, hiki i ka wai ke ho'oma'ema'e, maika'i a i'ole sterile- kānana. He kūpono nā pepa kānana no ...

Nānā Nānā -

kānana ea i hoʻopaʻa ʻia ma waena o nā mea kānana keleawe spheric

Hoʻohana ʻia ʻo HENGKO SINTERED BRONZE OIL FILTER i ka sparging, ka pale sensor, ke kinoea, a me ka kānana wai, ka dampening, ka mālama nui ʻana a me nā mea ʻē aʻe no ka solu ...

Nānā Nānā -

Ka hoʻomalu kahe a me ka hāʻawi ʻana i ka wai i hoʻopaʻa ʻia i ka pā kānana sintered/pepa, pauda sintered porous...

Hoʻohana ʻia nā ʻāpana kānana hohonu e wehe i nā ʻāpana mai nā wai. 'O ia ho'i, hiki i ka wai ke ho'oma'ema'e, maika'i a i'ole sterile- kānana. He kūpono nā pepa kānana no ...

Nānā Nānā -

Poha metala sintered keleawe keleawe kānana uniaxial cylinders me hoʻokahi pani pani me hex.

Hōʻike Huahana Hana ʻo HENGKO i nā mea kānana ma kahi ākea o nā mea, nā nui, a me nā mea pono e hiki ke maʻalahi me ke ʻano ...

Nānā Nānā -

Porous metala sintered porous keleawe kānana papa/pepa no ke kahe a me ke kani

Hoʻohana ʻia nā ʻāpana kānana hohonu e wehe i nā ʻāpana mai nā wai. 'O ia ho'i, hiki i ka wai ke ho'oma'ema'e, maika'i a i'ole sterile- kānana. He kūpono nā pepa kānana no ...

Nānā Nānā -

ʻO ka aila wai wai lāʻau lapaʻau a me nā kinoea 3um-90 microns pauka porous all-metal steam sint...

Hiki i nā paipu kānana porous HENGKO ke puka a makapō paha a he 1 mm ka mānoanoa o ka pā. Hana ʻia lākou e ka isostatic compaction o ka pauka i loko o kahi moʻo maʻalahi ...

Nānā Nānā

He aha ka Sintered Powder Metal Filter a me nā hiʻohiʻona nui

ʻO nā kānana metala pauka Sintered he ʻano kānana i hana ʻia e ka sintering, a i ʻole ka hoʻomehana ʻana, kahi hui ʻana o nā pauka metala.

a hiki i ka hoʻopaʻa ʻana a lilo i hale paʻa. Hoʻokumu kēia kaʻina i kahi mea porous e hiki ke pahele

nā mea haumia a me nā mea haumia ʻē aʻe, e lilo ia i kānana kūpono no nā noi like ʻole.

1.High Porosity

ʻO kekahi o nā pōmaikaʻi nui o nā kānana metala pauka sintered ko lākouporosity kiʻekiʻe. ʻO nā pores i loko o ka kānana

liʻiliʻi loa, maʻamau ka nui mai 0.2 a 10 microns, e hiki ai iā lākou ke wehe pono.

ka nui o nā mea haumia mai nā wai a me nā kinoea. He mea kūpono ia no ka hoʻohana ʻana i ka automotive,

aerospace, a me nā ʻoihana lapaʻau, kahi e pono ai ka maʻemaʻe a me ka maʻemaʻe.

2.Durability

ʻO kekahi pono o nā kānana metala pauka sintered ko lākouka lōʻihi. Hoʻokumu ka hana sintering i kahi

paʻa paʻa paʻa i ka ʻaʻahu a me ka waimaka, hiki i ka kānana ke kū i nā kaomi kiʻekiʻe a

nā mahana me ka ʻole o ka hoʻoheheʻe ʻana a me ka haki ʻole. He mea kūpono ia no ka hoʻohana ʻana i nā wahi koi,

e like me nā mīkini a i ʻole nā mīkini hana kiʻekiʻe.

3. Maʻemaʻe maʻalahi

ʻO kekahi o nā paʻakikī o ka hoʻohana ʻana i nā kānana metala pauka sintered hiki iā lākoupaʻakikī e hoʻomaʻemaʻe a hoʻohana hou.

Ma muli o ka liʻiliʻi o nā pores, hiki ke paʻakikī ka wehe ʻana i nā mea ʻino mai ka kānana

pono e pani i ka kānana ma mua o ka hoʻomaʻemaʻe. Hiki ke kūʻai ʻia, ʻoi aku ka nui o nā noi i kahi o ka

hoʻohana pinepine ʻia ka kānana. ʻoiaʻiʻo nō hoʻi kekahi ala e hoʻomaʻemaʻe ai.

ʻOiai kēia palena, hoʻohana nui ʻia nā kānana metala pauka sintered ma muli o ko lākou pono a me ka lōʻihi.

He mea koʻikoʻi lākou i nā kaʻina hana ʻoihana a me nā hana hana, e kōkua i ka hōʻoia ʻana i ka

ka maʻemaʻe a me ka maikaʻi o nā wai a me nā kinoea. Me ko lākou hiki ke hoʻopaʻa i kahi ākea o nā mea haumia a kūpaʻa

koi 'ia nā kaiapuni, sintered pauda metala kānana he mea koʻikoʻi no ka mālama ʻana i ka hana

a me ka hilinaʻi o nā mīkini a me nā mea hana.

No ke aha ʻo HENGKO Sintered Powder Metal Filters

Hoʻolako i nā mea hoʻoponopono kānana maikaʻi loa

ʻO kā mākou ʻano o nā ʻano kānana kānana pauka sintered he mea kupaianaha i nā ʻano noi noi nui;

porous sinterHoʻohana ʻia nā waiwai kūʻokoʻa o ka metala i nā mea hana sparging kiʻekiʻe no ka maikaʻi a

ka hāʻawi like ʻana o nā kinoea i loko o nā wai.

ʻO nā kānana metala pauka sintered porous, Hoʻohana pinepine ʻia me nā mea hoʻohui wahi nui i hoʻokaʻawale ʻia, e hoʻokaʻawale

paʻa mai nā kahawai kinoea i lokonā hana like ʻole. ʻO nā hiʻohiʻona nui e like me kēia:

1. Ke kūpaʻa wela kiʻekiʻe, Thermal stability a hiki i 950 ° C

2. He kūpono no ke kaomi ʻokoʻa kiʻekiʻe

3. Kiʻekiʻe corrosion kū'ē

4. Unique sinter hoʻopaʻa hoʻohui

5. ʻO ke kākoʻo pilikino me ka ikaika mechanical kiʻekiʻe

6. Hana maikaʻi loa i ka pulse hope

7. ʻAʻohe welding o ka media porous

8. Hoʻolālā hoʻololi, Loaʻa nā ʻano like ʻole, a hoʻopilikino

9. Aia ma luna o 10,000 mau ʻano maʻamau a me nā ʻano maʻamau

10. Main No ka like kinoea / wai mahele

11. Adopt Food-papa 316L a me 304L kuhiliʻole kila a keleawe paha

12. Maʻalahi hiki ke hoʻomaʻemaʻe a hoʻohana hou

KO MAKOU HANA

Ma ke ʻano he mea hana kiʻekiʻe o nā huahana kānana metala porous hou, hāʻawi ʻo HENGKO i nā ʻenehana loea hou.

no ka wela kiʻekiʻe a me ka corrosive kaiapuni.

Hana ʻia nā mea kānana metala pauka maʻamau me ke kila kuhili ʻole, keleawe, nā ʻāpana nickel-based, a me ka titanium a hiki.

e wiliwili ʻia me kekahi mau huila kūikawā e hoʻopilikino i kahi ʻano ʻē aʻe me kahi mea hoʻohui threaded a i ʻole nozzle ea.

Hoʻokaʻawale ʻia ka kānana ma o ka puʻunaue ʻana i ka nui o ka pore.

Koho Materials

Loaʻa ka HENGKO ma nā ʻano mea.

ʻO ka hopena metala pauka e hana i ka hoʻolālā a me nā koi imaʻalahi kaʻina hana pono.

Nā mea i loaʻa:

1. Ke kila kila (maʻamau 316L),

2. Ka wikiwiki,

3. Inconel,

4. Monel,

5. keleawe,

6. Titanium

7. Nā Alloys Kūikawā ma ke noi.

Nā noi

1. Hoʻopili kinoea

Hāʻawi mākou i nā huahana he nui a me nā hopena no ka kānana ʻana i nā kinoea wela i nā noi ʻoihana, a me nā mahana hana

maʻa mau ma mua o 750°C no ka manawa lōʻihi. Hana pinepine kēia mau kānana i nā ʻōnaehana i hoʻolako ʻia me ka hoʻomaʻemaʻe ponoʻī

nā mea hiki, a pono e hiki i nā mea kānana ke hana hou i kēlā me kēia pōʻai. pelanā kānana metala pauda sintered

ʻo ka koho maikaʻi loa, a hiki i nā hiʻohiʻona āpau ke hui; ʻO ia ala, hoʻohana nui ʻia kā mākou porous melt filters i nā kinoea he nui

ʻoihana kānana.

2. Sparging

Pono nā mea hoʻoheheʻe kiʻekiʻe i nā mea kānana, e like me ka hoʻopili ʻana i ke kinoea-wai e pono ai no ka pane ʻana: wehe, hui ʻana,

a i ʻole ka hoʻopuehu ʻana. Ma nā noi ʻē aʻe he nui, kōkua mākou iā ʻoe e hoʻonui i ka maikaʻi o ke kaʻina hana ma ka paipai ʻana a me ka hoʻolālā ʻana i ka mea maikaʻi loa

ʻO ka hopena kūpono e pili ana i kahi ʻano nui o nā ʻāpana sparger i loaʻa.

3. Hoʻoheheʻe wai

Hāʻawi pū mākou i nā mea kānana hoʻoheheʻe i hoʻolālā ʻia a kākoʻo ponoʻī i lalo i kahi kānana pono o 0.1µm i ka wai. ʻO ka

hiki ke hoʻolālā ʻia nā kānana metala pauda i hoʻopaʻa ʻia me kahi sanwīwī ʻelua, a hāʻawi ʻia ʻelua mau māka pauka pili i ka sinter

Hoʻokuʻu kūlike a homogeneous a hoʻomaikaʻi i ke kahe e hoʻohālikelike ʻia me nā kānana i hoʻolālā ʻia. ʻO ka sintered

ʻO ka porous disc ka kānana kūpono no nā kaʻina hana e pili ana i kahi catalyst. Loaʻa i kā mākou mau mea kānana pauda pauda metala a

ʻOi aku ka nui o nā hoʻonā hoʻokūkū ma muli o ka hoʻolālā ʻole ʻana me ka pilina "paʻa-paʻa".

4. Ka hoʻoheheʻe wai

Hāʻawi mākou i ka hoʻopilikino ʻana i nā mea hoʻoheheʻe wai no nā ʻōnaehana ʻoihana hou a i kēia manawa ma o ka hoʻomalu ʻana i nā ʻano like ʻole

nā hoʻolālā o ka hana kānana e hōʻoia i ka hāʻawi ʻana i ke kinoea maikaʻi loa e hopena i ka kahe nui a i ʻole ka hui ʻana no nā mea he nui

nā pāpaho like ʻole, me ke keleawe, ke kila kila, a me ka polyethylene. Eia hou, no ka fluidizing cones i hanaia

ʻO nā mea metala paʻa paʻa paʻa ke kākoʻo maʻamau iā mākou iho, hiki iā mākou ke hāʻawi i nā kānana me nā flanges pili

e like me ka makemake.

KO MAKOU Hoa

A hiki i kēia manawa he mau kaukani ʻoihana ʻo HENGKO mai nā ʻoihana he nui e komo pū me ke kemika a me ka aila, ka meaʻai, ka lāʻau lapaʻau etc

Nui pū kekahi o nā ʻoihana a me ke kulanui no ka mea hoʻolako hoa hana lōʻihi. Manaʻolana e lilo ʻoe i kekahi o lākou,

e leka uila iā mākou i kēia lā inā makemake.

Pehea e hoʻopilikino ai i nā kānana metala pauda Sintered mai HENGKO

Ke loaʻa iā ʻoe kekahiHoʻolālā Kūikawā Sintered Melt Filterno kāu mau papahana a ʻaʻole hiki ke loaʻa ka kānana like a like paha

huahana, Welina maie hoʻokaʻaʻike iā HENGKO e hana pū e ʻimi i ka hopena maikaʻi loa, a eia ke kaʻina o

ʻO OEM Porous Melt FilterE ʻoluʻolu e nānā aKāhea iā mā˚oukamaʻilio hou aku.

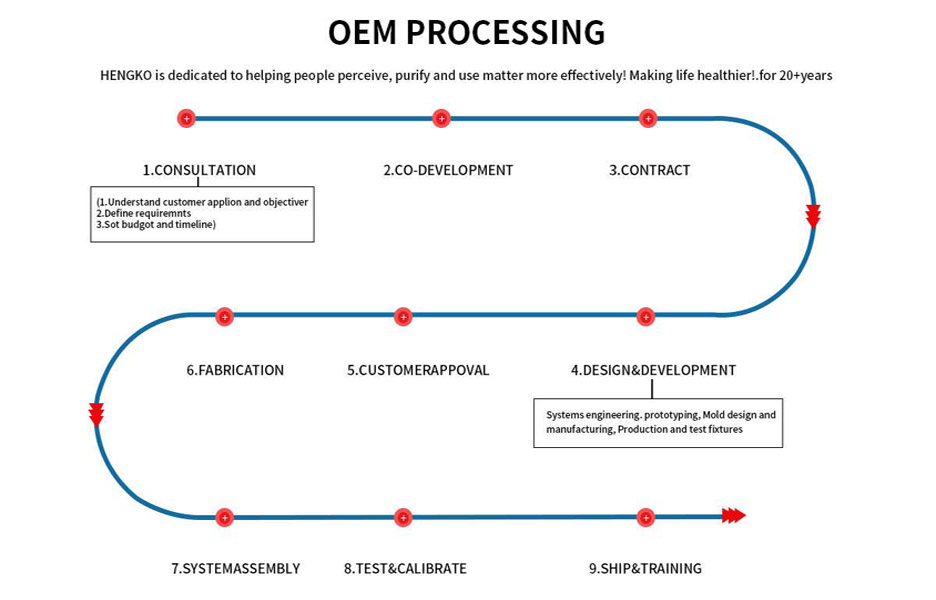

Hoʻolaʻa ʻia ʻo HENGKO i ke kōkua ʻana i ka poʻe e ʻike, hoʻomaʻemaʻe a hoʻohana i ka mea i ʻoi aku ka maikaʻi! Hoʻoikaika i ke ola ma mua o 20 mau makahiki.

1.Kūkākūkā a Hoʻokaʻaʻike iā HENGKO

2.Hoʻomohala hui

3.Hana i ʻaelike

4.Hoʻolālā & Hoʻomohala

5.Ua ʻae ʻia ka mea kūʻai aku

6. Hana Hana / Hana Nui

7. Hui Pūnaehana

8. Ho'āʻo & Hoʻokali

9. Hoʻouna

No laila he aha kāu ʻoihana? a he mau nīnau kāu e pili ana i nā kānana metala a pono mākou e hana a hana paha

nā kānana metala porous kūikawāno kāu mīkini a me kāu mīkini? E ʻoluʻolu e ʻoluʻolu e hoʻouna iā mākou i ka nīnau, ʻo kā mākou hui R&D

hiki iā ʻoe ke hāʻawi iā ʻoe i nā pane wikiwiki a ʻoluʻolu.

FAQ

1. He aha ka sintering i ka pauda metallurgy?

Hoʻohana ʻia ʻo Sintering i ka pauka metala e hoʻololi i nā pauka metala i mea paʻa, porous. Pili kēia kaʻina hana

ka hoʻomehana ʻana i nā pauka metala i kahi mahana ma lalo iho o ko lākou wahi heheʻe, kahi e hoʻopaʻa ai nā ʻāpana

hui pū ʻia a hana i kahi ʻano paʻa.

Hoʻohana pinepine ʻia ke kaʻina sintering i ka hana ʻana i nā ʻāpana metala a me nā ʻāpana, e like me nā bearings, gears,

a me nā kānana. Hāʻawi ia i nā mea maikaʻi ma mua o nā ʻano hana hana ʻē aʻe, e like me ka hoʻolei ʻana a i ʻole forging, me

nā kumukūʻai haʻahaʻa, ʻoi aku ka maʻalahi o ka hoʻolālā ʻana, a me ka hiki ke hana i nā ʻano paʻakikī a me nā hale.

I ka wā o ke kaʻina hana sintering, hoʻokomo ʻia nā pauka metala i loko o kahi mol a make paha, kahi e hoʻoholo ai i ke ʻano o ka

ʻāpana pau. Hoʻokomo ʻia ka ʻōpala i loko o ka umu ahi, kahi e wela ai i kahi mahana ma lalo iho o ka hoʻoheheʻe ʻana

pʻaila o ka metala. Ke hoʻomehana ʻia nā pauka metala, hoʻomaka lākou e hoʻopaʻa a hana i kahi ʻano paʻa.

Ke hoʻoheheʻe ʻia nā pauka metala, liʻiliʻi a liʻiliʻi nā pores ma waena o nā ʻāpana. Hoʻokumu ia i kahi porous

mea ikaika a paʻa hoʻi akā he ili kiʻekiʻe nō hoʻi, kahi e kūpono ai no nā noi like

e like me ka kānana a me ke kākoʻo catalyst. Hiki iā ia ke hoʻomalu i ka nui a me ka hāʻawi ʻana i nā pores ma ka hoʻoponopono ʻana i ka sintering

ka mahana a me ka manawa a me ke ʻano o nā pauka metala.

Ke hoʻopau ʻia ke kaʻina hana sintering, hoʻoneʻe ʻia ka mea paʻa, porous mai ka ʻōpala a ʻae ʻia

anu. Hiki ke hana ʻia ka ʻāpana i hoʻopau ʻia e hana i ke ʻano a me ka nui i makemake ʻia.

He hana maʻalahi ka Sintering e hiki ke hana i nā ʻāpana metala a me nā ʻāpana. Hāʻawi ia i nā pono he nui,

me nā kumu kūʻai haʻahaʻa, ka maʻalahi o ka hoʻolālā, a me ka hiki ke hana i nā ʻano paʻakikī a me nā hale. Ma ka hopena,

Hoʻohana nui ʻia ka sintering i ka hana ʻana i nā ʻāpana metala a me nā ʻāpana i ka automotive, aerospace, a

ʻoihana lapaʻau.

2. No ke aha he mea nui ka sintering i ka pauda metallurgy?

He hana koʻikoʻi ka sintering i ka pauda metala no ka mea e hoʻopaʻa i nā ʻāpana i loko o ka pauda metala

hana i mea paʻa, hui pū. Hana ʻia ia ma ka hoʻomehana ʻana i ka pauda i kahi mahana ma lalo o kona wahi hoʻoheheʻe.

ʻo ia ka mea e hoʻopaʻa ai nā ʻāpana ma o ka laha ʻana.

He mea nui ka sintering no kekahi mau kumu:

1. Hiki iā ia ke hana i nā ʻāpana me nā ʻano paʻakikī e paʻakikī a hiki ʻole ke hana

hoʻohana i nā ʻenehana hana ʻē aʻe.

2. Hiki iā ia ke hoʻohana i ka hana ʻana i nā ʻāpana me nā waiwai mechanical i hoʻomaikaʻi ʻia, e like me ka ikaika nui

a me ka paakiki.

3. Hiki i ka Sintering ke hana i nā mea porous me kahi porosity i hoʻomaluʻia, kahi kūpono no nā noi

e like me nā kānana a me nā catalysts.

ʻO ke kaʻina hana sintering e pili ana i ka hoʻomehana ʻana i ka pauka i kahi mahana ma kahi o 80-90%

o kona wahi hehee malalo o na kulana o ke kaomi ki'eki'e a me ka lewa i hoomaluia. Ke kumu o ka

e laha ana kekahi i kekahi, e hana ana i ka nuipa paa. Hiki ke mālama ʻia ke kaʻina hana sintering

e hana i kahi ākea o nā microstructures a me nā waiwai mechanical, e pili ana i ka noi kikoʻī.

ʻO kekahi o nā pōmaikaʻi nui o ka pauka metallurgy ʻo ia ka mea e hiki ai ke hana i nā ʻāpana me nā ʻano paʻakikī

a me nā hoʻomanawanui pololei. No ka mea hiki ke hana ʻia ka pauda metala i kekahi ʻano me ka hoʻohana ʻana i nā ʻenehana like ʻole,

e like me ke kaomi a me ka sintering. Hāʻawi kēia maʻalahi i nā mea hana e hana i nā ʻāpana me ke geometry paʻakikī

a me nā ana kūpono, ʻaʻole hiki ke hana me nā ʻenehana hana ʻē aʻe.

I ka hopena, he hana koʻikoʻi ka sintering i ka pauka metallurgy no ka mea hiki ke hana i nā ʻāpana

me nā ʻano paʻakikī, nā waiwai mechanical i hoʻomaikaʻi ʻia, a me ka porosity kaohi. He paepae nui ia i ka pauda

ka hana metallurgy a hiki i nā mea hana ke hana i nā ʻāpana kiʻekiʻe no nā noi like ʻole.

No laila inā he mau nīnau a makemake paha no ka Sintered Powder Metal Filters, ʻoluʻolu ʻoe

e leka uila iā mākouka@hengko.com a hiki iā ʻoe ke hoʻouna i ka nīnau ma ka hahai ʻana i ka palapala noiʻi, e hoʻouna mākou

hoʻi i loko o 24-Hora.