-

Tace Mai Tagulla Mai Inganci

Bayanin Samfurin Gabatar da Tacewar Man Fetur na saman-layi tare da Sintered Bronze Fuel Element - cikakkiyar mafita ga duk wanda ke buƙatar babban darajar ...

Duba Dalla-dalla -

Farantin Tagulla na Sintered Copper

Yana hana Electrolysis da Galvanic Corrosion Rage Tsangwamar RF da Inganta Ayyukan Lantarki Mafi kyawun liyafar ga na'urorin GPS ku, yanayin ...

Duba Dalla-dalla -

Ƙarfe Mai Ƙarfe Mini Silinda

Ƙarfe mai ƙyalli ɗaya ne daga cikin abubuwa da yawa da suka dace don kera bearings. Fa'idodin Sintered Mini Silinda foda karafa suna da adadi mai yawa ...

Duba Dalla-dalla -

Acid da Alkali Resistant More Dorewar 316L Bakin Karfe Tace Tace Tace...

Bayanin Samfuran HENGKO tacewar biomedical an yi shi da foda na ƙarfe na 316L wanda aka sanya shi a babban zafin jiki, tare da porosity iri ɗaya na 0.2-0.5 um, lalata resista ...

Duba Dalla-dalla -

CEMS Kan layi Mai Binciken Hayaki Na Binciken Gas 44.5mm*121mm Ƙirar Bincike Na Musamman

Kwatanta samfur * Rarraba ƙura a cikin tsari * Don ƙurar ƙura sama da 3g / m3 * Babban fage mai aiki * Tsawon rayuwa * ƙarancin matsin lamba ...

Duba Dalla-dalla -

Bututun matattarar ƙarfe mai ƙarfi don sarrafa zafin jiki da tacewa da sinadarai na musamman | HENGKO

HENGKO bakin karfe tace bututu ana yin su ta hanyar sintar da kayan foda na 316L ko ragin bakin karfe da yawa a cikin yanayin zafi. An yi w...

Duba Dalla-dalla -

316L SS bakin karfe sintered tacewa, Musamman microporous nickel monel inco ...

Ana samar da kayan ƙarfe na ƙarfe na HENGKO ta hanyar tsananin zafi na jiyya na bakin karfe na waya mai yawa ko foda 316L a yanayin zafi mai girma. Ku...

Duba Dalla-dalla -

Nau'in kyandir Sintered 316L bakin karfe raga tace sake amfani da harsashi

HENGKO yana ba da ɗimbin tarin gwanon matatun bakin karfe waɗanda aka keɓance don amfani da su a cikin masana'antu da yawa, gami da sinadarai na petrochemicals ...

Duba Dalla-dalla -

Anti-lalata Microns Foda Porous Sintered Karfe Tace Harsashi Don Tsarin Tacewa

HENGKO yana ƙirƙira bututun tacewa wanda ke ba da juzu'i a cikin ƙira saboda suna iya zama m ko makafi tare da ƙaramin kauri na bango na 1mm. Waɗannan samfuran sune c...

Duba Dalla-dalla -

sintered porous karfe tace abu kafofin watsa labarai, porosity 0.2 μm ~ 100 micron titanium mon ...

A HENGKO, tsarin ƙirƙirar kayan ƙarfe na su ya haɗa da zafi da zalunta kayan foda na 316L ko ragin bakin karfe da yawa a babban t ...

Duba Dalla-dalla -

porous karfe bakin karfe harsashi tace for high matsa lamba iska tsarkakewa m ...

HENGKO yana ƙera kayan ƙarfen sa na ƙarfe ta hanyar zafi yana kula da kayan foda na 316L ko ragin bakin karfe da yawa a yanayin zafi mai tsayi. Su...

Duba Dalla-dalla -

Kwarewar 0.2 zuwa 120 microns micro porosity brass inconel monel 316 316L bakin karfe ...

Ƙarfe mai ɓarna ana ƙirƙira shi ta hanyar damfara ƙarfen foda zuwa siffofi daban-daban, waɗanda sai a haɗa su da juna don ƙirƙirar tsari mai ƙarfi da rashin aiki. Wannan m ...

Duba Dalla-dalla -

Matatun Tagulla na Sintered tare da takamaiman Siffar OEM don Tacewa

HENGKO na iya ba abokan ciniki yuwuwar masana'anta masu tacewa da abubuwan haɗin tagulla tare da takamaiman siffofi. Kowane ɗayan waɗannan aikace-aikacen musamman r ...

Duba Dalla-dalla -

5 10 20 90 120 microns sintered porous karfe tagulla bakin karfe 316L Multi-manufa ...

HENGKO yana kera abubuwan tacewa a cikin kewayon kayan, girma, da kayan aiki don a iya bayyana su cikin sauƙi tare da halaye da daidaitawa.

Duba Dalla-dalla -

Uniform ƙarfi sintered porous karfe micron tace fluidizers tagulla tagulla jan fil...

Ana amfani da zanen gado mai zurfi don cire barbashi daga ruwa. Wannan yana nufin cewa ruwa zai iya zama mai tsabta-, mai kyau- ko kuma bakararre-tace. Tace zanen gado sun dace don ...

Duba Dalla-dalla -

sintered iska tace matsakaici mai siffar tagulla tace kashi

Ana shafawa HENGKO SINTERED BRONZE OIL FILTER a cikin sparging, kariyar firikwensin, iskar gas, da tace ruwa, dampening, sarrafa girma da sauransu wanda don solu ...

Duba Dalla-dalla -

Gudanar da gudana da rarraba ruwa sintered tace farantin / takardar, foda sintered porous ...

Ana amfani da zanen gado mai zurfi don cire barbashi daga ruwa. Wannan yana nufin cewa ruwa zai iya zama mai tsabta-, mai kyau- ko kuma bakararre-tace. Tace zanen gado sun dace don ...

Duba Dalla-dalla -

Ƙarfe mai ƙyalƙyali na tagulla tagulla tace uniaxial cylinders tare da rufaffiyar ƙarshen tare da hex.

Bayanin Samfura HENGKO yana kera abubuwan tacewa a cikin kewayon kayan, girma, da kayan aiki don a iya bayyana su cikin sauƙi tare da haruffan ...

Duba Dalla-dalla -

Ƙarfe mai ƙyalƙyali mai ƙyalƙyali na tagulla mai tace faranti/ takarda don gudana da sarrafa sauti

Ana amfani da zanen gado mai zurfi don cire barbashi daga ruwa. Wannan yana nufin cewa ruwa zai iya zama mai tsabta-, mai kyau- ko kuma bakararre-tace. Tace zanen gado sun dace don ...

Duba Dalla-dalla -

Medical sinadaran ruwa mai da gas 3um-90 microns foda porous duk-karfe tururi sint ...

HENGKO bututun tacewa na iya zama m ko makaho kuma suna da ƙaramin kauri na bango na 1 mm. An yi su ne ta hanyar isostatic compaction na foda a cikin m mo ...

Duba Dalla-dalla

Menene Sintered Powder Metal Filter da Babban Features

Fitar karfen da aka yi da foda wani nau'in tacewa ne da aka yi ta hanyar sintiri, ko dumama, cakuda foda na karfe

har sai sun haɗu tare don samar da tsayayyen tsari. Wannan tsari yana haifar da wani abu mara ƙarfi wanda zai iya kamawa

gurɓataccen abu da sauran ƙazanta, yana mai da shi ingantaccen tacewa don aikace-aikace daban-daban.

1.Hda Porosity

Ɗaya daga cikin mahimman fa'idodin ma'aunin ƙarfe na sintered foda shine suhigh porosity. Pores a cikin tace

ƙananan ƙananan ne, yawanci suna girma daga 0.2 zuwa 10 microns, wanda ke ba su damar cirewa yadda ya kamata.

yawan gurɓatattun abubuwa daga ruwa da iskar gas. Yana sa su dace don amfani a cikin mota,

sararin samaniya, da masana'antun likitanci, inda tsabta da tsabta suke da mahimmanci.

2. Dorewa

Wani fa'idar sintered foda karfe tace su nekarko. Tsarin sintiri yana haifar da a

karfi, m tsarin resistant zuwa lalacewa da tsagewa, kyale tace jure high matsa lamba da

yanayin zafi ba tare da nakasa ko karyewa ba. Yana sa su dace don amfani a cikin wuraren da ake buƙata,

kamar a cikin injuna ko wasu injuna masu inganci.

3. Sauƙaƙe Tsabta

Ɗaya daga cikin ƙalubalen yin amfani da ma'aunin ƙarfe na sintered foda shine cewa suna iya zamamai wahalar tsaftacewa da sake amfani da shi.

Saboda ramukan suna da ƙanƙanta, cire gurɓataccen gurɓataccen abu daga tacewa zai iya zama da wahala, yin shi

wajibi ne don maye gurbin tace maimakon tsaftace shi. Yana iya zama tsada, musamman ga aikace-aikace inda da

ana amfani da tace akai-akai. tabbas kuma kuna da wasu hanyoyin tsaftacewa.

Duk da wannan iyakance, sintered foda karfe tace ana amfani da ko'ina saboda tasiri da karko.

Su ne wani muhimmin sashi a yawancin masana'antu da masana'antu tafiyar matakai, wanda taimaka tabbatar da

tsarki da ingancin ruwa da iskar gas. Tare da ikon su na kama nau'ikan gurɓataccen abu da jurewa

wuraren da ake buƙata, sintered foda karfe tace kayan aiki ne mai mahimmanci don kiyaye aikin

da amincin injuna da kayan aiki.

Me yasa HENGKO Sintered Powder Metal Filters

Samar da Fitattun Maganin Tacewa

Irin mu na sintered foda karfe tace mafita ne fice a cikin wani m iri-iri na bukatar aikace-aikace;

porous sinterkarfe ta musamman Properties ana amfani da daban-daban high-matsi sparging kayan aiki ga tarar da

uniform rarraba iskar gas cikin ruwaye.

Matsalolin ƙarfe mai ƙura da ƙura, sau da yawa tare da ƙwanƙwasa-ingantattun masu haɗin yanki, ana amfani da su don raba

daskararru daga rafukan iskar gas a cikimatakai daban-daban. Babban fasali sune kamar haka:

1. High-zazzabi juriya, Thermal kwanciyar hankali har zuwa 950 ° C

2. Ya dace da babban matsin lamba

3. Babban juriya na lalata

4. Keɓaɓɓen haɗin haɗin sinta

5. Tsarin tallafi na kai tare da ƙarfin injiniya mai girma

6. Kyakkyawan aikin bugun bugun jini

7. Babu walda na m kafofin watsa labarai

8. Zane sassauci, Daban-daban siffofi samuwa, da kuma siffanta

9. Sama da 10,000 iri-iri na ma'auni da al'ada masu girma / siffofi suna samuwa

10. Main Don daidaitaccen gas / rarraba ruwa

11. Adopt Food-class 316L da 304L bakin karfe ko tagulla

12. Sauƙaƙe Tsabtace da Kayayyakin Maimaituwa

Fasahar mu

A matsayin ƙwararrun masana'anta na sabbin samfuran tace ƙarfe na ƙarfe, HENGKO yana ba da mafita na fasaha na zamani.

don yanayin zafi mai zafi da lalata.

A al'ada sintered foda karfe tace abubuwa ana yin su da bakin karfe, tagulla, nickel tushen gami, da titanium kuma iya

a haɗa su ba tare da wani lahani ba tare da wasu gami na musamman don keɓancewa zuwa wata siffa daban tare da haɗin zaren zaren ko bututun iska.

Ƙayyadadden tacewa ta daidaitaccen girman girman pore.

Zabin Kayayyaki

HENGKO yana samuwa a cikin kewayon kayan aiki.

A foda karfe bayani sa tela zane da bukatun zuwamutum tsari bukatun sauki.

Abubuwan da ake samu:

1. Bakin Karfe (misali 316L),

2. Hastelloy,

3. Inconel,

4. Ma'ana,

5. Tagulla,

6. Titanium

7. Alloys na musamman akan buƙata.

Aikace-aikace

1. Tace Gas

Muna ba da samfura da yawa da mafita don tace iskar gas mai zafi a aikace-aikacen masana'antu, da yanayin yanayin aiki

yawanci wuce 750 ° C na dogon lokaci. Waɗannan masu tacewa galibi suna aiki a cikin tsarin sanye take da tsaftace kai ta atomatik

iyawa, kuma abubuwan tacewa dole ne su kasance masu iya cikakkiyar sabuntawa akan kowane zagayowar. hakada sintered foda karfe tace

sune mafi kyawun zaɓi, kuma duk fasalulluka na iya haɗuwa; ta wannan hanyar, ana ƙara amfani da filtattun narkewar mu a yawancin iskar gas

masana'antun tacewa.

2. Zazzagewa

Yawancin kayan aiki masu ƙarfi suna buƙatar abubuwan tacewa, kamar tuntuɓar ruwan gas da ake buƙata don amsawa: tsiri, haɗawa,

ko yadawa. A cikin sauran aikace-aikacen da yawa, muna taimaka muku haɓaka ingantaccen tsari ta hanyar ba da shawara da ƙira mafi kyau

mafita mai dacewa bisa babban nau'in raka'a sparger da ake samu.

3. Tace Ruwa

Hakanan muna ba da abubuwan tacewa na yau da kullun da masu tallafawa kai tsaye zuwa ingantaccen tacewa na 0.1µm a cikin ruwa. The

Za a iya ƙera matatun ƙarfe na sintered foda tare da sanwici biyu, kuma ana ba da maki foda mai haɗin haɗin gwiwa guda biyu.

Saki mai daidaituwa da kamanni da haɓaka kwararar ruwa idan aka kwatanta da abubuwan tacewa na al'ada. The sintered

faifan porous shine cikakkiyar tacewa don tafiyar matakai da suka haɗa da mai kara kuzari. Abubuwan abubuwan tace foda ɗin mu suna da a

tsawon rayuwa wanda ya zarce mafi yawan mafita masu gasa saboda babu ƙirar walda tare da haɗin "tsauri mai ƙarfi".

4. Ruwan ruwa

Muna ba da kyauta don keɓance kayan aikin ruwa don sababbin tsarin masana'antu da na yanzu ta hanyar sarrafa nau'ikan daban-daban

ƙira na masana'anta tace don tabbatar da mafi kyawun rarraba iskar gas wanda ke haifar da cikakkiyar kwararar taro ko haɗuwa ga mutane da yawa

kafofin watsa labarai daban-daban, gami da tagulla, bakin karfe, da polyethylene. Bugu da kari, saboda fluidizing Cones sanya daga

barga sintered karfe kayan yawanci goyan bayan kai, za mu iya yawanci samar da tacewa tare da haɗa flanges

kamar yadda ake bukata.

Abokin Hulba

Har yanzu HENGKO suna da aiki dubu na kamfanoni daga masana'antu da yawa sun haɗa da sunadarai da mai, abinci, likitanci da sauransu

Har ila yau, ƙwararrun kamfanoni da jami'a da yawa don masu samar da abokin tarayya na dogon lokaci. Da fatan za ku kasance cikinsu.

tuntube mu a yau idan sha'awar.

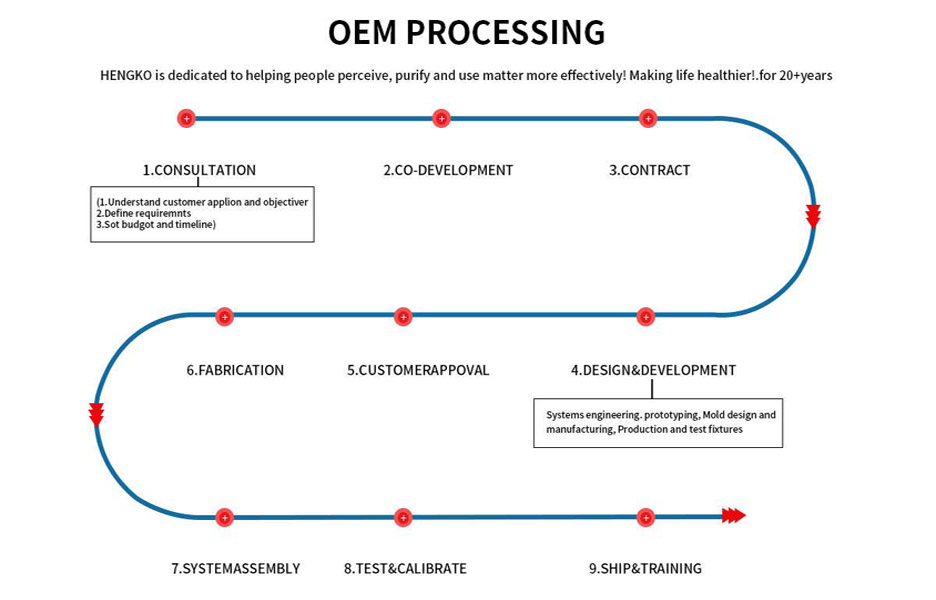

Yadda za a Keɓance Abubuwan Tacewar Ruwa na Sintered Foda Daga HENGKO

Lokacin da Kuna da wasuZane na Musamman Sintered Melt Tacedon ayyukanku kuma ba za ku iya samun Tace iri ɗaya ko makamancin haka ba

kayayyakin, Marabadon tuntuɓar HENGKO don yin aiki tare don nemo mafita mafi kyau, kuma ga tsarin

OEM Porous Melt TaceDa fatan za a duba kumaTuntube mumagana ƙarin bayani.

HENGKO ya sadaukar da kai don Taimakawa Mutane Hane, Tsarkakewa da Amfani da Al'amarin Mafi Inganci! Samun Lafiyar Rayuwa Sama da Shekaru 20.

1.Tuntuɓi HENGKO

2.Haɗin kai

3.Yi Kwangila

4.Zane & Ci gaba

5.Abokin ciniki ya amince

6. Ƙirƙirar Ƙira / Mass Production

7. Tsarin Tsarin

8. Gwaji & Daidaita

9. Jirgin ruwa

To menene masana'antar ku? kuma kuna da wasu tambayoyi game da matatun ƙarfe kuma kuna buƙatar mu magance ko keɓancewa

na musamman porous karfe tacedon na'urar ku da injin ku? Da fatan za a ji daɗin aiko mana da tambaya, ƙungiyar R&D ɗinmu za ta yi

iya samar muku da amsoshi masu sauri da gamsarwa.

FAQ

1. Menene sintering a foda karafa?

Ana amfani da Sintering a cikin ƙarfe na ƙarfe don juyar da foda na ƙarfe zuwa wani abu mai ƙarfi. Wannan tsari ya ƙunshi

dumama foda na karfe zuwa yanayin zafi kusa da inda suke narkewa, wanda ke sa barbashi su hade

tare da samar da tsayayyen tsari.

Ana amfani da tsarin sintering akai-akai wajen kera sassan ƙarfe da abubuwan haɗin gwiwa, kamar bearings, gears,

da tacewa. Yana ba da fa'idodi da yawa akan sauran hanyoyin masana'antu, kamar simintin gyare-gyare ko ƙirƙira, gami da

ƙananan farashi, mafi girman sassaucin ƙira, da ikon ƙirƙirar sifofi masu rikitarwa da sifofi.

A lokacin aikin sintiri, ana sanya foda na karfe a cikin wani mold ko mutu, wanda ke ƙayyade siffar

gama part. Daga nan sai a sanya gyambon a cikin tanderun wuta, inda za a yi zafi da shi zuwa yanayin zafi da ke ƙasa da narkewa

pmai na karfe. Yayin da foda na karfe suna zafi, sun fara haɗuwa tare kuma suna samar da tsari mai ƙarfi.

Yayin da ƙorafin ƙarfe ya ɓata, ramukan da ke tsakanin barbashi ya zama ƙarami kuma ƙarami. Yana haifar da porous

kayan da ke da ƙarfi da ɗorewa amma kuma yana da babban yanki, wanda ya sa ya dace da aikace-aikacen irin wannan

a matsayin tacewa da tallafin mai kara kuzari. Yana iya sarrafa girman da rarraba pores ta hanyar daidaita ma'auni

zafin jiki da lokaci da abun da ke ciki na foda na karfe.

Da zarar an gama aikin sintering, ana cire ƙaƙƙarfan abu mara ƙarfi daga ƙera kuma a bar shi

sanyi. Sa'an nan kuma za a iya sarrafa ɓangaren da aka gama ko a sarrafa shi don ƙirƙirar siffar da girman da ake so.

Sintering tsari ne mai ma'ana wanda zai iya ƙirƙirar sassa da yawa na ƙarfe da abubuwan haɗin gwiwa. Yana bayar da fa'idodi da yawa,

ciki har da ƙananan farashi, ƙirar ƙira, da ikon ƙirƙirar sifofi masu rikitarwa da sifofi. Saboda,

sintering ne yadu amfani a masana'anta karfe sassa da aka gyara a cikin mota, aerospace, da

masana'antun likitanci.

2. Me yasa sintering ke da mahimmanci a cikin ƙarfe na foda?

Sintering wani muhimmin tsari ne a cikin ƙarfe na foda saboda yana haɗa barbashi a cikin foda na ƙarfe zuwa

samar da m, kayan haɗin gwiwa. Ana yin ta ne ta hanyar dumama foda zuwa yanayin zafi ƙasa da inda yake narkewa.

wanda ke sa ɓangarorin su haɗu ta hanyar yaduwa.

Sintering yana da mahimmanci don dalilai da yawa:

1. Yana ba da damar ƙirƙirar sassa tare da sifofi masu rikitarwa waɗanda zasu zama da wahala ko ba za a iya samarwa ba

ta amfani da wasu fasahohin masana'antu.

2. Yana iya amfani da shi don samar da sassa tare da ingantattun kayan aikin injiniya, kamar ƙarfin ƙarfi

da taurin.

3. Sintering na iya haifar da kayan aiki mai laushi tare da porosity mai sarrafawa, wanda ke da amfani ga aikace-aikace

kamar masu tacewa da masu kara kuzari.

Tsarin sintering yawanci ya ƙunshi dumama foda zuwa zafin jiki na kusan 80-90%

na narkewar wurinsa a ƙarƙashin yanayin matsanancin matsin lamba da yanayi mai sarrafawa. Yana haifar da

barbashi don yaduwa a cikin juna, forming wani m taro. Ana iya sarrafa tsarin sintiri

don samar da nau'i-nau'i na microstructures da kayan aikin injiniya, dangane da takamaiman aikace-aikacen.

Ɗaya daga cikin mahimman fa'idodin ƙarfe na foda shine cewa yana ba da izinin ƙirƙirar sassa tare da siffofi masu rikitarwa

da kuma madaidaicin haƙuri. Domin kuwa ana iya samar da foda na ƙarfe zuwa kowace siga ta amfani da dabaru daban-daban,

kamar latsawa da sintiri. Wannan sassauci yana bawa masana'antun damar samar da sassa tare da hadadden lissafi

da madaidaicin ma'auni, wanda ba zai yiwu ba tare da wasu fasahohin masana'antu.

A ƙarshe, sintering wani muhimmin tsari ne a cikin ƙwayar foda saboda yana ba da damar ƙirƙirar sassa

tare da hadaddun siffofi, ingantattun kaddarorin injiniyoyi, da porosity mai sarrafawa. Mataki ne mai mahimmanci a cikin foda

tsarin karafa kuma yana bawa masana'antun damar samar da sassa masu inganci don aikace-aikace daban-daban.

Don haka idan har yanzu kuna da Tambayoyi da Sha'awar Abubuwan Tacewar Ruwa na Sintered Powder Metal, Kuna maraba da ku

tuntube mu ta imelka@hengko.com sannan kuma zaku iya aiko da tambaya ta hanyar bibiyar tambaya, zamu aiko

dawo cikin sa'o'i 24.