-

Stainless Steel 316 Micro Spargers and Filter in Bioreactors and Fermentors

Product Describe The function of the bioreactor is to provide a suitable environment in which an organism can efficiently produce a target product. * Cell b...

View Detail -

In-tank porous metal spargers or multiple sparger assembly for a large tank, increase g...

Attaches to the tip of the sparger tube, this 316L stainless steel sintered tip is available in a variety of pore sizes. The 5 10 15 50 100 pore frit is the ...

View Detail -

Single Use Bioreactor diffuser sparger for cell culture

In the initial stage of upstream processing in bioprocessing, fermentation is commonly used. Fermentation is defined as the chemical changes caused by microo...

View Detail -

multi – bioreactor sparger for the fermenter sartorius

The Stainless Steel Fermenter|Bioreactor for Your Laboratory A bioreactor is a type of fermentation vessel that is used for the production of various chemica...

View Detail -

HENGKO OEM Sintered Steel Filter and Sparger

OEM Sintered stainless steel diffuser / sparger, for aerating in liquid. HENGKO’s sintered sparger are unsurpassed in strength, precision and uniformity. The...

View Detail -

Sintered Stainless Steel Sparger Porous Metal Diffuser for Gas Applications

OEM Sintered stainless steel diffuser / sparger, for aerating in liquid. HENGKO’s sintered sparger are unsurpassed in strength, precision and uniformity. Th...

View Detail -

Sintered Microsparger in Bioreactor System for Green chemistry industry

The importance of aeration and gas dispersion to achieve good oxygen mass transfer cannot be understated. This is at the heart of the ability of mic...

View Detail -

Replacement Micro-Bubble Porous Sparger Tips for Fermentation / Bioreactor Air Aeration...

Advantages of HENGKO Porous Metal Micro Spargers Due to the low solubility of oxygen in many cell culture mediums, optimizing this critical nutrient can be ...

View Detail -

Sintered Micro Porous Sparger in Benchtop for Bioreactors and Laboratory Fermenter

Every bioreactor sparging system is designed for the introduction of oxygen to feed cell cultures. Meanwhile, the system must remove carbon dioxide to preven...

View Detail -

Quick Change Sparger System for Bioreactors and Fermentors Air Sparger Accessories- Mic...

Stainless steel sparger is to supply enough oxygen to the microbes in submerge culture technique for proper metabolism. Each fermentation process requires a ...

View Detail -

316 L Powder Stainless Steel Metal Frit Spargers Building A Stainless Steel Filtering S...

Product Description This device is particularly good for fermentations that require a large population of yeast. Pilsners (or other beers fermented at low te...

View Detail -

HENGKO sintered porous carbonation stone air sparger bubble diffuser nano oxygen genera...

In bioreactor systems, optimal mass transfer of gases like oxygen or carbon dioxide is difficult to accomplish. Oxygen, in particular, is poorly soluble in w...

View Detail -

Sintered Sparger Tube with Porous Metal Stainless Steel Tank and In-line Spargers Used ...

Introducing the exceptional HENGKO sintered spargers, the ultimate solution to introducing gases into liquids. This innovative product utilizes thousands of...

View Detail -

HENGKO micron small bubble air sparger oxygenation carbanation stone used in acrylic wa...

Product Describe HENGKO air sparger bubble stone is stainless steel 316/316L, food grade, with a beautiful appearance, suitable for hotels, fine dining and o...

View Detail -

Sintered Sparger Stainless Steel Material Quick Change for Bioreactor Systems

In bioreactor systems, optimal mass transfer of gases like oxygen or carbon dioxide is difficult to accomplish. Oxygen, in particular, is poorly soluble in w...

View Detail -

Aeration Stone 20um Sintered Stainless Steel 316L Micro sparger Diffusion Stone Supplier

Hydrogen water is clean, powerful, and with hydron. It helps to purify the blood and gets blood moving. It can prevent many kinds of diseases and improve peo...

View Detail -

Sintered 316l stainless steel bubble hydrogen-rich water generator air sparger

Product Description Hydrogen water is clean, powerful, and with hydron. It helps to purify the blood and gets blood moving. It can prevent many kinds of di...

View Detail -

Stainless Steel Ozone Diffuser Stone Fine Air Sparger for Hydrogen Generator

Hydrogen water is clean, powerful, and with hydron. It helps to purify the blood and gets blood moving. It can prevent many kinds of diseases and improve peo...

View Detail -

Stainless Steel Aeration/Oxygen CO2 Diffusion Stone Micro Sparger for Microalgae Cultiv...

Micro-diffuser for Microalgae Cultivation, Photobioreactors & sintered sparger for microalgae cultivation is used in laboratories for growing algae. HEN...

View Detail -

Biotech Removable Porous Frit Micro Sparger for Mini Bioreactor System and Fermentors

Stainless steel sparger used as a cell retention device. The device consists of a metal tube and a sintered metal filter with a pore size of 0.5 – 40 µm. The...

View Detail

5-Main Features of Porous Metal Gas Sparger ?

The main features of a porous metal gas sparger are:

1. Efficient Gas Distribution:

The tiny pores ensure a uniform and efficient distribution of gas throughout the liquid.

This is achieved because the gas bubbles are forced to break up into smaller sizes as

they pass through the many

small pores of the sparger. Drilled tubes, for instance,

cannot achieve this even distribution and produce larger bubbles.

2. Increased Surface Area:

Smaller bubbles mean a larger surface area for gas-liquid interaction.

This is important because it improves the efficiency of processes that rely on mass transfer

between the gas and liquid,

such as oxygenation in fermentation or aeration in wastewater treatment.

3. High Durability:

Porous metal spargers are typically made from sintered stainless steel,

which makes them resistant to high temperatures,

corrosion, and wear.

This makes them suitable for use in a wide range of demanding industrial applications.

4. Customizable Pore Size:

The size of the pores in a sparger can be controlled during the manufacturing process.

This allows users to select a sparger that will produce bubbles of the desired size for their specific application.

5. Clog Resistance:

The even distribution of pores throughout the metal spargers makes them less prone to

clogging compared to other spargers with larger openings.

Types of Sintered Porous Gas Sparger

*End Fitting Types:

Sintered porous gas spargers come with various end fittings, including hexagonal heads, barbed fittings, MFL,

NPT threads, Tri-Clamp fittings, and other welding heads.

These fittings allow flexibility in installation based on the system's specific requirements. For optimal durability

and performance, 316L stainless steel is recommended for most gas sparging applications.

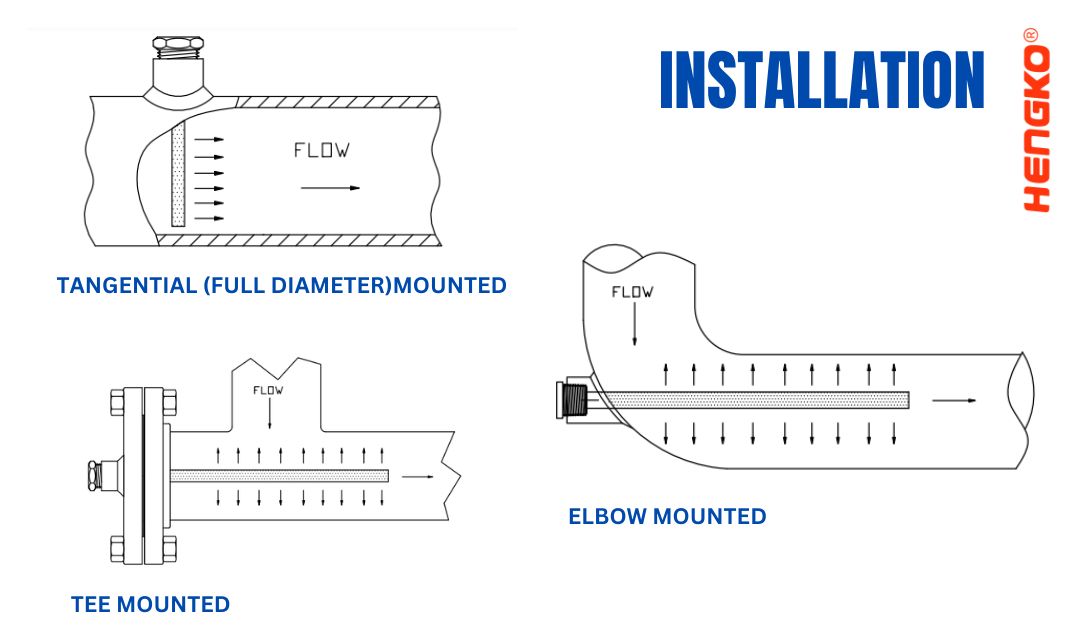

*Multi-Sparger Systems:

When a single sparger cannot achieve the desired gas absorption, multiple spargers can be combined to enhance

gas diffusion and mass transfer. These multi-sparger systems can be arranged in different configurations,

such as rings, frames, plates, or grids, to maximize efficiency. Additionally, these spargers can be mounted in various

ways, from unit-side mounting to cross-tank flange-side mounting, providing flexibility for different process requirements.

Why use Porous Metal Gas Sparger for Your Sparger System ?

Porous metal gas spargers are an excellent choice for sparger systems due to several key advantages:

1.Maximum Surface Area for Mass Transfer:

Sintered metal gas spargers are designed to produce fine bubbles, which significantly increase the

gas-liquid contact area.

The fine bubble propagation enhances the efficiency of mass transfer, making these spargers ideal

for applications requiring effective gas dispersion and absorption.

2.Rugged Construction:

The sintered metal structure provides superior mechanical strength, allowing the sparger to withstand

harsh conditions. This durability ensures reliable performance even under challenging operational environments.

3.Temperature and Corrosion Resistance:

Sintered metal spargers are temperature and corrosion resistant, making them suitable for a wide range of

industrial processes, including those involving corrosive media or elevated temperatures.

This resilience contributes to a longer lifespan and reduced maintenance costs.

4.Consistent and Even Gas Dispersion:

Porous metal spargers are engineered to provide consistent, evenly dispersed gas throughout the liquid.

This uniform dispersion optimizes the sparging process, resulting in higher efficiency and effectiveness for

various gas-liquid operations.

By utilizing porous metal gas spargers, you can achieve high efficiency in sparging with enhanced durability

and performance, leading to better process outcomes and reduced operational costs.

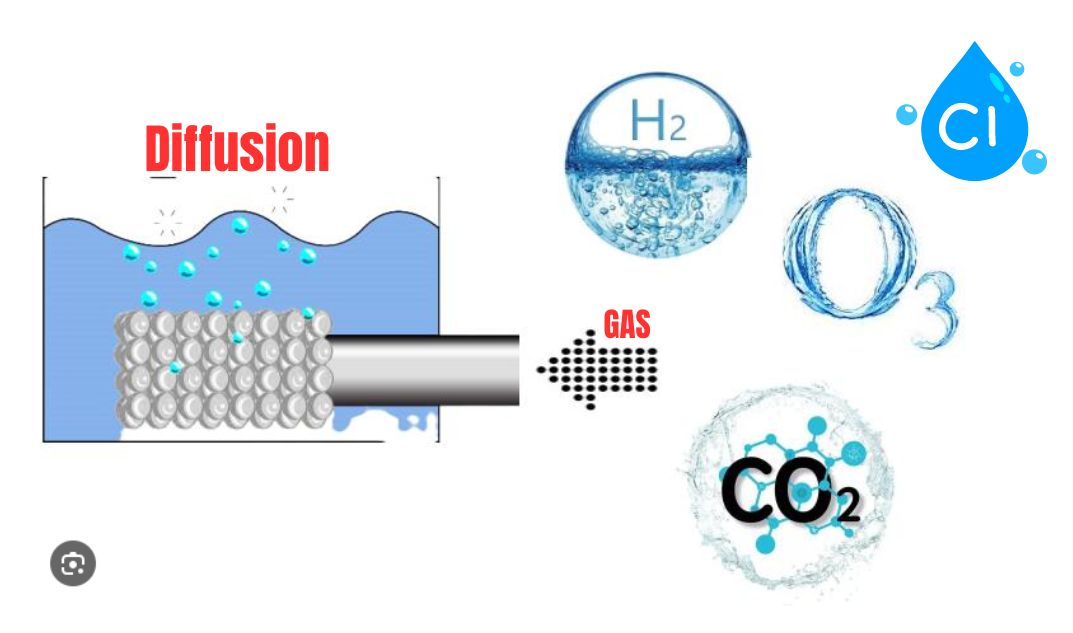

What Kind of Gas is good to use Porous Metal Gas Sparger ?

Porous metal gas spargers are actually quite versatile and can be used with a wide variety of gases. Here's why:

*Material Compatibility:

The key factor is the compatibility of the gas with the metal the sparger is made from. Typically, porous metal spargers

are constructed from sintered stainless steel (like 316L grade) which is resistant to a broad range of gases.

*Focus on Sparger Design and Process Needs:

As long as the gas isn't highly corrosive to the metal, the sparger itself will likely function well.

The main focus when choosing a gas for a porous metal sparger should be on the specific application

and the desired outcome.

Here are some examples:

*Common Gases:

Air, oxygen, nitrogen, carbon dioxide, and hydrogen are all commonly used with porous metal spargers in

various industries like fermentation, wastewater treatment, and chemical processing.

*Process Focus:

The choice of gas depends on the process. For instance, oxygen is used for aeration in fermentation tanks,

while nitrogen might be used for sparging inert gas to prevent unwanted reactions.

So If you're unsure about a specific gas, it's always best to consult the manufacturer of the sparger or a chemical

engineer to ensure compatibility and optimal performance for your application.

Frequently Asked Questions (FAQ)

Porous gas spargers are becoming increasingly popular in various industrial processes due to their efficiency in transferring gas into liquids.

Here are some commonly asked questions about porous gas spargers, along with detailed answers:

1. What is a Porous Gas Sparger?

A porous gas sparger is a device used to introduce gas into a liquid. It's typically made of a metal powder, such as stainless steel, that undergoes a sintering process to create a rigid structure with a network of tiny pores throughout. These pores allow the gas to flow through the sparger and disperse into the liquid as very small bubbles. Porous gas spargers are also known as sintered spargers or in-line spargers.

2. How Does a Porous Gas Sparger Work?

The key to a porous gas sparger's function lies in its design. The gas pressurizes and travels through the sparger's numerous microscopic pores. As the gas exits these pores, it shears into the liquid, forming a large number of very fine bubbles. The smaller the bubble size, the greater the gas-liquid contact area. This increased surface area significantly enhances the mass transfer rate, meaning the gas dissolves into the liquid more efficiently.

3. What are the Benefits of Using a Porous Gas Sparger?

There are several advantages to using porous gas spargers compared to traditional sparging methods:

*Increased Gas Absorption:

The creation of finer bubbles leads to a larger gas-liquid contact area, promoting faster and more

efficient gas dissolution into the liquid.

*Reduced Gas Consumption:

Due to the improved mass transfer rate, less gas is required to achieve the desired level of saturation

in the liquid. This translates to cost savings and reduced environmental impact.

*Improved Mixing:

The fine bubbles generated by the sparger can induce turbulence and improve mixing within the liquid,

leading to a more uniform process.

*Versatility:

Porous gas spargers can be used with a wide range of gases and liquids, making them

suitable for various applications.

*Durability:

The materials used to construct porous gas spargers, such as stainless steel, offer excellent

chemical resistance and mechanical strength, ensuring long service life.

4. What are the Applications of Porous Gas Sparger?

Porous gas spargers are employed in a diverse range of industries and processes, including:

*Fermentation:

Sparging oxygen into fermentation broths to promote cell growth and product yield in biopharmaceutical and biofuel production.

*Wastewater Treatment:

Aeration of wastewater using oxygen or air to facilitate the growth of microorganisms that break down organic pollutants.

*Chemical Processing:

Sparging various gases for reactions, stripping operations, and inserting vessels.

*Food and Beverage Industry:

Carbonation of beverages by sparging CO2, and oxygen sparging for processes like fish farming.

*Pharmaceutical Industry:

Sparging to control dissolved oxygen levels in bioreactors for cell cultures and drug production.

5. How to Choose the Right Porous Gas Sparger?

Several factors need to be considered when selecting a porous gas sparger for your specific application:

*Material of Construction:

The material should be compatible with the gas and liquid being used and resistant to any corrosive chemicals present.

Stainless steel is a common choice due to its durability and chemical resistance.

*Porosity and Pore Size:

The porosity determines the gas flow rate through the sparger, while the pore size influences the bubble size.

Smaller pore sizes generate finer bubbles and increase the gas-liquid contact area,

but can also lead to higher pressure drop.

*Sparger Size and Shape:

The size and shape of the sparger should be appropriate for the tank or vessel it will be placed in,

ensuring proper gas distribution throughout the liquid.

*Connection Type:

Consider the type of fitting or connection required to integrate the sparger into your existing piping system.

Consulting with a supplier who can provide technical guidance and offer various porous gas sparger options

based on your specific requirements is recommended.