-

Corrosion-Resistant Explosion Proof Filter Cap for Industrial Gas Sensors for sale

Gas sensor housing for use in high-temperature gas environments An apparatus and method for packaging and operating a gas sensor for use in high-temperature ...

View Detail -

Explosion-Proof Stainless Steel Cap for Industrial Gas Sensor Probe Protection for sale

Gas sensor housing for use in high-temperature gas environments An apparatus and method for packaging and operating a gas sensor for use in high-temperature ...

View Detail -

Industrial flameproof single toxic gas leak detector sintered metal housing with porous...

Gas sensor housing for use in high-temperature gas environments An apparatus and method for packaging and operating a gas sensor for use in high-temperature ...

View Detail -

Explosion-proof sintered porous water proof stainless steel probe housing with maximum ...

HENGKO explosion-proof sensor housing is made of 316L stainless steel and aluminum for maximum corrosion protection. A sinter-bonded flame arrestor provides ...

View Detail -

Sintered stainless steel metal catalytic bead accessories gas sensor explosion proof pr...

The HENGKO gas sensor housing can pass the explosion-proof certification stainless-steel enclosure complete with sensors and electronics, designed to be used...

View Detail -

Sintered 316L stainless steel Isolation sparks flame-proof protective filter housing Co...

HENGKO explosion-proof sensor housing is made of 316L stainless steel and aluminum for maximum corrosion protection. A sinter-bonded flame arrestor provides ...

View Detail -

Anti-explosion stainless steel 316L porosity gas sensor protection housing equipped wit...

HENGKO explosion-proof sensor housing is made of 316L stainless steel and aluminum for maximum corrosion protection. A sinter-bonded flame arrestor provides ...

View Detail -

Sintered stainless steel/wire mesh explosion-proof filter housing for carbon monoxide l...

HENGKO explosion-proof sensor housing is made of 316L stainless steel and aluminum for maximum corrosion protection. A sinter-bonded flame arrestor provides ...

View Detail -

Sintered 316L stainless steel fixed multi combustible gas leak detector monitor sensor ...

HENGKO explosion-proof sensor housing is made of 316L stainless steel and aluminum for maximum corrosion protection. A sinter-bonded flame arrestor provides ...

View Detail -

Waterproof porous sintered stainless steel 316L/316 explosion-proof probe gas analyzer ...

HENGKO explosion-proof sensor housing is made of 316L stainless steel and aluminum for maximum corrosion protection. A sinter-bonded flame arrestor provides ...

View Detail -

Waterproof stainless steel porous anti-explosion co2 ethylene nitrogen oxygen gas senso...

HENGKO explosion proof sensor housing are made of 316L stainless steel and aluminium for maximum corrosion protection. A sinter bonded flame arrestor provide...

View Detail -

Flame CO2 carbon dioxide arrestors – Combustible gas sensor housing

HENGKO explosion-proof sensor housing is made of 316L stainless steel and aluminum for maximum corrosion protection. A sinter-bonded flame arrestor provides ...

View Detail -

Stainless Steel Explosion Proof Sensor Housing for LPG gas leak detector

HENGKO explosion-proof sensor housing is made of 316L stainless steel and aluminum for maximum corrosion protection. A sinter-bonded flame arrestor provides ...

View Detail -

SS 316L stainless steel probe breathable protective filter housing Carbon Dioxide Infra...

HENGKO explosion proof sensor housing are made of 316L stainless steel and aluminium for maximum corrosion protection. A sinter bonded flame arrestor provide...

View Detail -

Sintered SS 316L stainless steel flame-proof protective probe filter housing industrial...

Explosion-proof sensor assemblies are made of 316 stainless steel for maximum corrosion protection. A sinter-bonded flame arrestor provides the gas diffusion...

View Detail -

Custom Gas Sensor protective covers with sintered powder metal stainless steel filter disc

Explosion proof sensor assemblies are made of 316 stainless steel for maximum corrosion protection. A sinter bonded flame arrestor provides the gas diffusion...

View Detail -

Explosion proof Stainless Steel Probe Filter Caps Protection Caps Industrial Analog Pla...

Explosion proof sensor assemblies are made of 316 stainless steel for maximum corrosion protection. A sinter bonded flame arrestor provides the gas diffusion...

View Detail -

Porous sintered stainless steel 304/316 waterproof and explosion-proof gas sensor prob...

Experience Uncompromising Corrosion Protection with our 316 Stainless Steel Explosion-Proof Sensor Assemblies! Introducing our cutting-edge explosion...

View Detail -

0~100% LEL Combustible Gas Detector Multi Gas Analyzer Sensor Housing

Explosion proof sensor assemblies are made of 316 stainless steel for maximum corrosion protection. A sinter bonded flame arrestor provides the gas diffusion...

View Detail -

Highly-Engineered Custom Sintered Porous Metal Flame Arrestors For Combustible Gas Anal...

Explosion proof sensor assemblies are made of 316 stainless steel for maximum corrosion protection. A sinter bonded flame arrestor provides the gas diffusion...

View Detail

Main Features of Gas Detector Probe or Protector Cover Accessories

1. Compact, low-cost design.

2. No field gas calibration is required.

3. Intrinsically safe & explosion-proof.

4. Standalone gas detector with 4-20 mA output.

5. Universal control board.

6. Long-life electrochemical sensors

Advantage:

1. High sensitivity to combustible gas in a wide range

2. Fast response

3. Wide detection range

4. Stable performance, long life, low cost

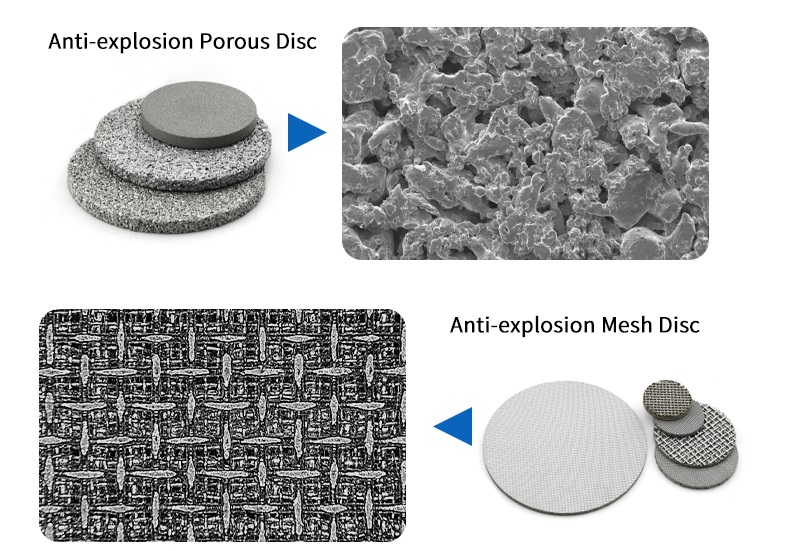

Sintered Porous Stainless Steel Filter or Sintered Wire Filter Better for Gas Detector ?

When choosing between a sintered porous stainless steel filter and a sintered wire filter for a gas detector, both options offer unique benefits, so the decision depends on your specific requirements. Here’s a breakdown to help you determine which might be better for a gas detector application:

1. Filtration Efficiency

*Sintered Porous Stainless Steel Filter:

Offers high filtration efficiency due to its uniform pore structure, capturing very fine particles and contaminants. It’s well-suited for sensitive gas detectors where high filtration accuracy is crucial.

*Sintered Wire Filter:

Typically has slightly larger gaps due to the woven wire design, making it better for applications that require lower filtration efficiency or where larger particles are expected.

2. Strength and Durability

*Sintered Porous Stainless Steel Filter:

Extremely durable and corrosion-resistant, making it ideal for harsh environments. Its structure is robust and can withstand high pressure and temperature, which benefits gas detectors used in industrial or outdoor settings.

*Sintered Wire Filter:

Also durable but may not be as strong under high-pressure environments. The layered wire structure can wear down faster in comparison to sintered porous stainless steel in extreme conditions.

3. Flow Rate

*Sintered Porous Stainless Steel Filter:

While offering excellent filtration, its dense structure may reduce the flow rate slightly more than a wire filter. However, flow rate can often be adjusted by selecting an appropriate pore size.

*Sintered Wire Filter:

Provides a higher flow rate due to the larger openings between the woven wires, which can be beneficial if the gas detector requires a quick response time.

4. Maintenance and Longevity

*Sintered Porous Stainless Steel Filter:

Easy to clean and maintain. It supports various cleaning methods like backflushing and ultrasonic cleaning, prolonging the filter's lifespan in continuous use.

*Sintered Wire Filter:

May be less resistant to aggressive cleaning methods due to its layered design and can clog more quickly in some applications, requiring more frequent replacement.

5. Cost Consideration

*Sintered Porous Stainless Steel Filter:

Generally has a higher upfront cost but may save money over time due to its longevity and lower maintenance needs.

*Sintered Wire Filter:

Typically less expensive initially, but the need for more frequent replacement in heavy-duty applications could offset this cost advantage over time.

Recommendation

For gas detectors, sintered porous stainless steel filters are generally the preferred choice due to their higher filtration efficiency, durability, and ability to operate reliably in extreme conditions. However, if a higher flow rate is essential and the environment is less demanding, a sintered wire filter could be a suitable option, especially in applications with lower contamination levels.

Here we make a comparison table to help you got a visualize the differences between sintered porous stainless steel filters and sintered wire filters for gas detector applications:

| Feature | Sintered Porous Stainless Steel Filter | Sintered Wire Filter |

|---|---|---|

| Filtration Efficiency | High, uniform pore structure captures fine particles | Moderate, larger gaps; suitable for larger particles |

| Strength & Durability | Very durable, withstands high pressure and temperature | Durable but less robust in extreme conditions |

| Flow Rate | Moderate; can be adjusted by pore size selection | High, due to larger openings in woven design |

| Maintenance & Longevity | Easy to clean with methods like backflush and ultrasonic; long lifespan | More prone to clogging, may need frequent replacements |

| Cost | Higher upfront cost but cost-effective over time | Lower initial cost; may incur more frequent replacement costs |

| Recommended Use | Ideal for sensitive, high-precision gas detectors, industrial or harsh environments | Suitable for applications with lower contamination, requiring faster flow |

Some Industrial Gas Detector Application Popular to use Porous Sintered Filter

so you can have idea to choose or OEM for your gas detector instrument

As following are some gas detector applications where sintered porous filters are especially beneficial for sensor housing:

1. Methane (CH₄) Detection

*Applications: Oil and gas facilities, landfills, and mining.

*Why Sintered Porous Filters?

Methane detection requires filters that protect sensors from contaminants while allowing steady gas flow.

Sintered porous filters provide high durability and are effective in preventing particulate contamination, ensuring accurate readings in challenging environments.

2. Hydrogen Sulfide (H₂S) Detection

*Applications: Wastewater treatment plants, oil refineries, and confined spaces.

*Why Sintered Porous Filters? H₂S is corrosive, so housings with sintered porous filters offer enhanced protection.

These filters resist corrosion, allowing sensors to maintain accuracy in environments with high moisture and corrosive gases.

3. Oxygen (O₂) Monitoring

*Applications: Confined spaces, industrial sites, and laboratories.

*Why Sintered Porous Filters?

In oxygen-deficient or inert gas environments, sintered porous filters protect sensors from dust and particulates without impeding gas diffusion, ensuring reliable oxygen level detection in confined spaces or industrial areas.

4. Ammonia (NH₃) Detection

*Applications: Agriculture (livestock housing), refrigeration systems, and chemical processing.

*Why Sintered Porous Filters?

Ammonia detection requires a robust filter due to its corrosive nature. Sintered porous filters offer a barrier against corrosive gases and environmental contaminants, protecting the sensor and enhancing its lifespan in agricultural and industrial settings.

5. Volatile Organic Compounds (VOCs) Detection

*Applications: Manufacturing plants, indoor air quality control, and laboratories.

*Why Sintered Porous Filters?

For VOC detection, sintered porous filters offer excellent protection against particulates, allowing sensitive sensors to measure VOC concentrations accurately. The filter structure maintains airflow while safeguarding the sensor from contaminants.

6. Hydrogen (H₂) Detection

*Applications: Battery storage rooms, fuel cell technology, and power generation.

*Why Sintered Porous Filters?

Hydrogen is flammable, and sintered porous filters provide explosion-proof qualities. They protect the sensor from dust and particulates while allowing efficient gas diffusion, essential for accurate hydrogen monitoring in power applications.

7. Chlorine (Cl₂) Detection

*Applications: Water treatment facilities and chemical plants.

*Why Sintered Porous Filters?

Chlorine is highly corrosive, making sintered porous filters an ideal choice. They protect the sensor from particulates and corrosion while enabling effective gas diffusion, ensuring accuracy in detecting this toxic gas.

8. Carbon Dioxide (CO₂) Monitoring

*Applications: Greenhouses, HVAC systems, and storage facilities.

*Why Sintered Porous Filters?

For CO₂ detection, sintered porous filters offer protection against dust and moisture, especially in HVAC systems and greenhouses. Their structure ensures a steady gas flow, allowing accurate CO₂ level readings for air quality and plant growth control.

Sintered porous filters excel in these applications due to their durability, corrosion resistance, and ability to filter particulates while permitting efficient gas diffusion. They enhance sensor protection and accuracy, making them ideal for environments where contamination or corrosive gases are present.

FAQ for Gas Detector Assembly

1. What is a gas detector assembly?

A gas detector assembly is a device that is used to detect and measure the concentration of gases in an environment. It typically consists of a sensor or sensors, a control unit, and an alarm or warning system. This device is particularly useful in applications where the presence of certain gases can pose a safety hazard.

2. How does a gas detector assembly work?

A gas detector assembly works by utilizing sensors that are designed to detect specific gases in an environment. These sensors then convert the measurements into an electrical signal that can be transmitted to a control unit. The control unit then processes the data and activates an alarm or warning system if the concentration of gases exceeds a certain threshold.

3. What gases can a gas detector assembly detect?

The specific gases that a gas detector assembly can detect will depend on the type of sensors that are used. Some gas detector assemblies are designed to detect a wide range of gases, while others are designed to detect only specific gases, such as carbon monoxide or methane.

4. What is the operating temperature range for a gas detector assembly?

The operating temperature range for a gas detector assembly varies depending on the specific model and manufacturer. It is important to carefully review the specifications of the device before use to ensure it is suitable for the intended environment. Some models may be designed for use in extreme temperatures or harsh environments.

5. How accurate are gas detector assemblies?

The accuracy of gas detector assemblies can also vary depending on the model and manufacturer. It is important to review the accuracy specifications of the device before use. Factors such as sensor quality, calibration, and environmental conditions can all affect the accuracy of the measurements.

6. What is the typical response time for a gas detector assembly?

The response time for a gas detector assembly also varies depending on the specific model and manufacturer. This can range from a few seconds to several minutes. The response time is a critical factor in some applications where rapid changes in gas concentration need to be detected and acted upon quickly.

7. Can gas detector assemblies be calibrated?

Yes, gas detector assemblies can be calibrated. It is recommended to calibrate the device periodically to ensure accurate measurements. Calibration involves adjusting the device to match a known standard, which can be done either manually or automatically depending on the device.

8. How are gas detector assemblies powered?

Gas detector assemblies can be powered by batteries or an external power source. The choice of power source will depend on the specific model of the device and the application for which it is being used. In some cases, a device may have the ability to use both battery and external power sources.

9. Can gas detector assemblies be used in outdoor environments?

Yes, gas detector assemblies can be used in outdoor environments. However, it is important to choose a model that is specifically designed for outdoor use and can withstand the environmental conditions. Outdoor environments can be harsh, and the device may be exposed to factors such as temperature extremes, moisture, and UV radiation.

10. What is the lifespan of a gas detector assembly?

The lifespan of a gas detector assembly can vary depending on the specific model and manufacturer, as well as the frequency and conditions of use. It is important to review the device specifications to determine the expected lifespan, and to follow proper maintenance and calibration procedures to prolong the lifespan of the device.

11. Which sensor is used in gas detection?

The specific sensor used in gas detection will depend on the type of gas being detected. Some common types of sensors include electrochemical sensors, infrared sensors, and catalytic sensors. Each type of sensor has its own strengths and weaknesses, and the choice of sensor will depend on the specific application and the properties of the gas being detected.

12. Which gas detector is best?

The best gas detector for a specific application will depend on a variety of factors, including the type of gas being detected, the environment in which the detector will be used, and the required sensitivity and accuracy of the measurements. It is important to carefully review the specifications of different gas detectors before selecting one for use in a specific application.

13. How accurate are gas detectors?

The accuracy of gas detectors can vary depending on the specific model and manufacturer. It is important to review the accuracy specifications of the device before use. Factors such as sensor quality, calibration, and environmental conditions can all affect the accuracy of the measurements. In general, gas detectors are designed to provide accurate and reliable measurements of gas concentrations.

14. Where should I place my natural gas detector?

Natural gas detectors should be placed in areas where natural gas is likely to accumulate, such as near gas appliances, gas lines, or gas meters. It is also recommended to place detectors in areas where gas leaks are likely to occur, such as near windows, doors, or other openings. It is important to follow the manufacturer's recommendations for placement and to regularly test and maintain the detector to ensure proper functionality.

15. How many gas detectors do I need?

The number of gas detectors needed will depend on the size and layout of the area being monitored, as well as the potential sources of gas leaks. In general, it is recommended to have at least one detector installed on each level of a building, and to place additional detectors near potential sources of gas leaks. It is important to follow the manufacturer's recommendations for placement and to regularly test and maintain the detectors to ensure proper functionality.

16. Does natural gas fall or rise?

Natural gas is lighter than air and will tend to rise when released into the environment. This is an important factor to consider when placing gas detectors, as they should be installed at a height where gas is likely to accumulate.

17. At what height should a natural gas detector be placed?

Natural gas detectors should be placed at a height where gas is likely to accumulate. This will vary depending on the specific location and potential sources of gas leaks. In general, it is recommended to place detectors at a height of around six inches from the ceiling, as natural gas tends to rise and accumulate near the ceiling.

18. Should natural gas detectors be high or low?

Natural gas detectors should be placed at a height where gas is likely to accumulate. In general, it is recommended to place detectors at a height of around six inches from the ceiling, as natural gas tends to rise and accumulate near the ceiling. However, it is important to follow the manufacturer's recommendations for placement and to consider the specific location and potential sources of gas leaks.