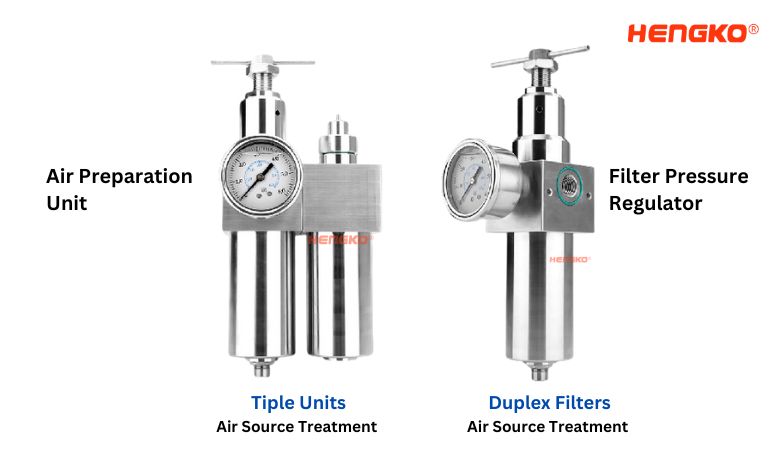

FRL Air Pressure Regulator Complete Filter Regulator Lubricator Assembly

Features of Stainless Steel Air Preparation Unit

Durable Construction

1.Corrosion Resistance: Made from high-quality stainless steel to withstand harsh environments and resist rust and chemical corrosion.

2.Robust Design: Ideal for industrial applications requiring long-term durability under high pressure and temperature.

Versatility and Compatibility

1.Wide Operating Range: Suitable for various pneumatic systems and compatible with multiple air compressor types.

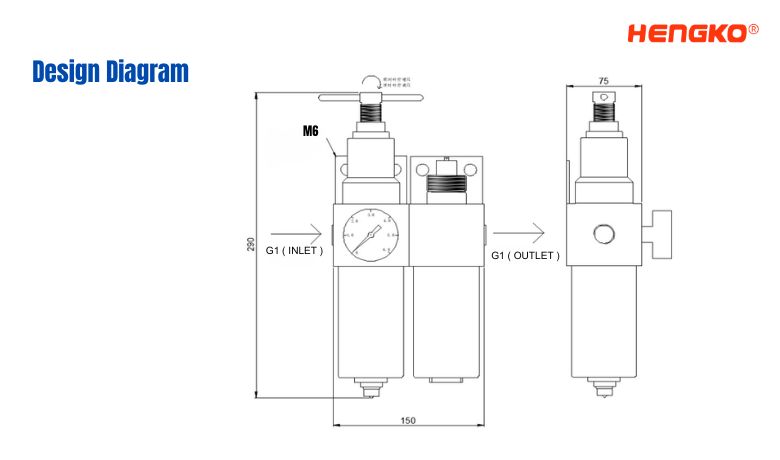

2.Compact Design: Space-saving structure for easy integration into compact systems.

High-Performance Components

1.Efficient Filtration: Advanced filtration mechanism to remove contaminants, moisture, and particles, ensuring clean air supply.

2.Accurate Regulation: Integrated pressure regulator ensures precise air pressure control.

3.Lubrication System: Built-in lubricator provides consistent lubrication to downstream equipment, increasing system efficiency and lifespan.

Safety and Maintenance

1.Leak-Free Seals: High-quality seals prevent air leaks and maintain system performance.

2.Easy Maintenance: Modular design for quick disassembly and cleaning.

3.High Temperature and Pressure Tolerance: Designed for demanding applications in extreme conditions.

Specialized Features

1.Customizable Options: Adjustable pressure ranges, filtration levels, and port sizes to suit different industrial needs.

2.Hygienic Design: Suitable for applications in food and beverage, pharmaceuticals, and other cleanroom environments.

Specification

Here’s a table based on the data in the image:

| Model | Port Size | Max Flow Rate | Weight (Standard Drain) | Lubricator Bowl Capacity | Filter Bowl Capacity |

|---|---|---|---|---|---|

| H-400-SFRL-03 | 3/8 | 2200 l/min | 3840 g | 110 cc | 130 cc |

| H-400-SFRL-04 | 1/2 | 2500 l/min | 3830 g |

Product Features

Here’s a neatly organized table based on the product features you provided:

| Feature | Description |

|---|---|

| Drain Port with G1/8 Thread | Equipped with an internal G1/8 thread for the drain port, includes a manual drain device. |

| Barbed Fitting for Plastic Tubes | Includes a barbed connector for linking to plastic tubes. |

| Manual Drain, G1/8 Thread | Drain port with internal G1/8 thread and manual drainage functionality. |

| Low-Pressure Visible Oil Window | Features an oil window for visibility under low-pressure conditions. |

| High-Pressure Non-Visible Oil Window | Designed with a non-visible oil window for high-pressure conditions. |

| Manual Drain, G Thread | G-threaded connection with manual drainage, supports up to 16 kg of pressure. |

| Auto Drain, G Thread (16 kg) | G-threaded connection with automatic drainage; supports up to 16 kg but cannot drain above 8 kg. |

| Auto Drain, G Thread (40 kg) | G-threaded connection with automatic drainage; supports up to 40 kg but cannot drain above 8 kg. |

Full Series Specification

| Item | Details |

|---|---|

| Model | H-200-SFRL / H-400-SFRL / H-600-SFRL |

| Pipe Size | 1/4” / 3/8” / 1/2” / 3/4” / 1” |

| Working Fluid | Compressed Air |

| Body Material | Stainless Steel 316L |

| Cup Material | Stainless Steel 316L |

| Gauge Material | Stainless Steel 316L (Casing) |

| Filter Material | Stainless Steel 316L |

| Filtration Accuracy | 5μm (Standard) / 40μm (Optional) |

| Operating Pressure | Regular: 0.5-16 kgf/cm² / High Pressure: 5-30 kgf/cm² |

| Max Inlet Pressure | 40 kgf/cm² |

| Ambient Temperature | Normal: -5℃ to 100℃ / Low: -40℃ to 55℃ / Ultra Low: -60℃ to 100℃ |

| Standard Drainage | Semi-automatic (drains when below 0.5 kgf/cm²) |

| Included Accessories | Pressure Gauge (0-16 kg), Plugs, Mounting Bracket Set |

| Optional Accessories | Pressure Gauge (0-16 kg / 0-60 kg) |

Model and Connection type

| Model | Connection Size |

|---|---|

| H-200-SFRL-02 | 1/4 |

| H-400-SFRL-03 | 3/8 |

| H-400-SFRL-04 | 1/2 |

| H-600-SFRL-06 | 3/4 |

| H-600-SFRL-10 | 1 |

Application

Applications of Porous Stainless Steel VCR Gasket Filter

1. Food and Beverage Industry

*Ensures clean and moisture-free air for pneumatic systems in processing, packaging, and bottling.

*Maintains hygiene standards in highly regulated environments.

2. Pharmaceutical and Medical Industry

*Provides sterile and contaminant-free air for sensitive equipment and cleanroom operations.

*Ideal for tablet manufacturing, medical device production, and laboratory applications.

3. Chemical and Petrochemical Industry

*Handles corrosive environments and ensures safe air preparation for pneumatic systems.

*Suitable for processes involving aggressive chemicals or high pressures.

4. Water Treatment Plants

*Controls pneumatic actuators and valves in filtration, purification, and desalination systems.

*Stainless steel construction resists rust and ensures durability in moisture-rich settings.

5. Marine and Offshore Applications

*Withstands saline and humid environments, making it ideal for ships and offshore platforms.

*Powers pneumatic systems for reliable operation in harsh conditions.

6. Industrial Manufacturing

*Supports pneumatic tools and machinery like drills, presses, and robotic systems.

*Enhances efficiency and reduces downtime in high-demand manufacturing environments.

Ready to optimize your gas distribution system with a high-performance Stainless Steel Air Preparation Units ?

Contact HENGKO today to discuss your specific requirements.

Our expert team is here to provide customized OEM solutions tailored to your industry needs.

Reach out via email at ka@hengko.com to get started on designing your special air preparation units or your applications!

Send your message to us: