-

Stainless Steel Sintered Porous Metal Filter Tubes Porosity Down to 0.2 µm – In F...

Pore size:0.2-100microns Materials: SS Metal Porosity:30%~45% Working Pressure:3MPa Operating Temperature:600℃ Applications for sintered porous metal ...

View Detail -

IoT Temperature and Huimidirty Sensor Monitoring for Food Quality Service Control ̵...

IoT Temperature and Huimidirty Sensor Restaurants, bars, food production and hospitality companies worldwide are responsible for executin...

View Detail -

Remote Temperature and Relative Iot humidity monitoring system for Food and Beverage Co...

Temperature and Humidity monitoring is an ideal solution for industries/businesses where temperature and humidity maintenance is of utmost importance. With t...

View Detail -

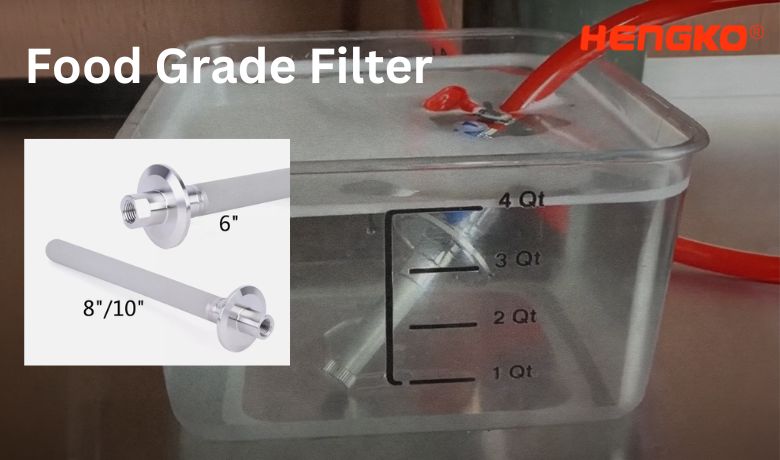

hydrogen water machines accessories food grade sintered porous stainless steel filter h...

Sintered air stone diffusers are often used for porous gas injecting. They have different pore sizes(0.5um to 100um) allowing tiny bubbles to flow. They can ...

View Detail -

Stainless steel harsh environment filter (male thread sintered porous metal filter) for...

Product Features Remove liquids and solids from gas samples Remove solids and gas bubbles from liquid samples Coalesce and separate two liquid phases Filer s...

View Detail -

3 stage sterile stainless steel high pressure compressed air filters assemblies for foo...

HENGKO manufactures filter elements in a broad range of materials, sizes, and fittings so they can be easily specified with the characteristics and configura...

View Detail -

Food grade microns 316L stainless steel powder sintered porous metal elements filter me...

Product Describe The Candle Filters are installed for clarification and recovery applications from liquids with low solids content ranging from 5% to PPM lev...

View Detail -

Preferential supply 0.2-120um sintered 316 stainless steel porous metal backwash strain...

Introducing the HENGKO Stainless Steel Filter Disc, the ultimate solution for all your environmental protection, petroleum, natural gas, chemical, environme...

View Detail -

Long service life sintered stainless steel filter disc parts – pure water treatme...

Sintered Mesh filter disc uses a five-layer sintered composite mesh structure to make a filter that combines filtration efficiency with strength. Typical mes...

View Detail

Types of Food Grade Porous Stainless Steel Filters

Food grade porous stainless steel filters are essential in various industries, particularly in food and beverage processing,

due to their durability, high filtration efficiency, and resistance to corrosion.

Here are some common types of these filters:

1. Plain Sintered Stainless Steel Mesh Filters

*Description: Constructed from layers of woven stainless steel mesh that are sintered together.

*Function: Filters based on mesh size, trapping specific particle sizes while allowing the desired medium to pass through.

*Characteristics: Reliable structural integrity and consistent pore sizes make them suitable for general filtration tasks.

2. Sintered Powder Stainless Steel Filters

*Description: Made entirely from stainless steel powder that is compressed and sintered into shape.

*Function: Offers a gradient structure for multi-level filtration, capturing particles at various depths.

*Characteristics: High strength and versatility in filtration applications, suitable for both liquid and gas processes.

3. Multi-layer Sintered Mesh Filters

*Description: Composed of multiple layers of stainless steel mesh with varying mesh sizes, sintered together.

*Function: Provides detailed filtration by trapping particles at different depths, ensuring both surface and depth filtration.

*Characteristics: Combines strength with precision, ideal for applications requiring high filtration performance.

4. Porous Metal Filter Cartridges

*Description: Made from fine stainless-steel powders sintered into rugged cartridges with controlled pore sizes.

*Function: Designed for high flow rates and pressure resistance; suitable for steam service and various liquid or gas applications.

*Characteristics: High durability, cleanability, and resistance to high temperatures and corrosive environments, making them versatile for food processing.

Summary Table

| Filter Type | Key Features | Applications |

|---|---|---|

| Plain Sintered Stainless Steel Mesh | - Reliable structure - Consistent pore sizes |

General filtration |

| Sintered Powder Stainless Steel | - Gradient structure - Multi-level filtration |

Liquid and gas processes |

| Multi-layer Sintered Mesh | - Varying mesh sizes - Surface and depth filtration |

High-performance applications |

| Porous Metal Filter Cartridges | - High flow rates - Pressure resistant |

Food processing, pharmaceuticals |

These various types of food grade porous stainless steel filters provide essential solutions for ensuring

product quality and safety in the food and beverage industry while also being applicable in other sectors

such as pharmaceuticals and chemical processing.

What are the advantages of using 316L stainless steel for food-grade filters

The use of 316L stainless steel for food-grade filters offers several significant advantages,

making it a preferred material in the food and beverage industry.

Here are the key benefits:

1. Corrosion Resistance

316L stainless steel exhibits superior resistance to corrosion compared to other stainless steel grades,

particularly in environments exposed to chlorides and acidic substances.

This makes it ideal for food processing applications where exposure to salty or acidic foods is common,

such as in the processing of tomato products or seafood

2. Non-Reactivity

This grade of stainless steel is non-reactive with food substances, ensuring that there is no leaching

of harmful chemicals into food products. This property is crucial for maintaining the integrity and

safety of food and beverages during processing and storage

3. Hygiene and Cleanability

316L stainless steel is easy to clean and sanitize, which is essential in food processing environments

where hygiene is paramount. Its smooth surface minimizes the risk of bacterial growth, making it

compliant with health regulations and standards set by agencies like the FDA

4. Durability and Strength

316L stainless steel has excellent mechanical properties, allowing it to withstand high pressures and

temperatures without compromising its structural integrity.

This durability ensures longevity in applications where equipment is frequently exposed to harsh conditions

5. Weldability

The lower carbon content in 316L (maximum 0.03%) enhances its weldability compared to standard

316 stainless steel. This feature allows for easier fabrication and repair of equipment used in

food processing, contributing to overall efficiency in manufacturing processes

6. Cost-Effectiveness

Although 316L stainless steel may have a higher initial cost than some other materials, its longevity

and reduced maintenance needs often result in lower overall costs over time.

Its resistance to corrosion means less frequent replacements and repairs

Summary

In summary, 316L stainless steel is favored for food-grade filters due to its exceptional corrosion

resistance, non-reactivity, ease of cleaning, durability, weldability, and long-term cost-effectiveness.

These attributes make it an ideal choice for ensuring the safety and quality of food products

throughout processing and storage.

Ready to Customize Your Food-Grade Filters?

Contact HENGKO Today!

Partner with HENGKO, your trusted OEM factory for high-quality food-grade porous metal filters.

Whether you need customized designs, reliable performance, or compliance with strict hygiene standards,

we’ve got you covered.