Filter Regulator for Diaphragm Pump Accessories

Filter Regulator for Diaphragm Pump Accessories

Here to give you my two cen tech tip using a filter regulator with the pneumatic actuator values it's a small investment that can significant extent the life of your pneumatic instrument the primary function of the regulator is to provide the instrument with a supply of stable air pressure it also prevents the actuator for over pressurizing by limiting how much pressure you will be able to deliver to your positioner it is important because your actuator will malfunction if it's over pressurized the seconed thing that makes the filter regulate a good option is that it helps prevent water and dabris from getting into small air passages in the instrument many people in the process industry assume that the instrumrnt our system delivers clean dry air but unfortunately that's not the case the number one case of premature instrument failure is poor air quality make a small investment of time and periodically drain any water that may have accumulated in the drip will by simply open the drain valve and allowing the water todrain out remember to close the valve also check the filter every time you do maintenance or calibration on your instrument and replace the filter if needed you'll save time and money in the long run that's my two cents.

Air filter regulators: do you really need them?

Technically, no, you don’t. However, using air filter regulators with pneumatically actuated valves can increase the lifespan of your devices.

Purchasing an air filter regulator is a small investment, but a worthy one. Here’s why.

Air filter regulators:

Provide the instrument with a supply of stable air pressure

Prevent actuators from over-pressuring (over-pressuring can lead to instrument malfunctions)

Prevent water and debris from entering small air passages within the instrument

Tip #1: Drain the water in the drip well

It’s a common misconception that instrument air supply systems deliver clean, dry air. In fact, poor air quality is the leading cause of premature instrument failure. You can prevent device failure by periodically draining any water that accumulates in the drip well. The process is simple. Open the drain valve, allow any water to drain out, and close the valve again.

Tip #2: Check the filters

Every time you perform routine maintenance or calibrate your instrument, take a look at the filter. If it’s in poor condition, replace it — in the long run, this will save you time and money!

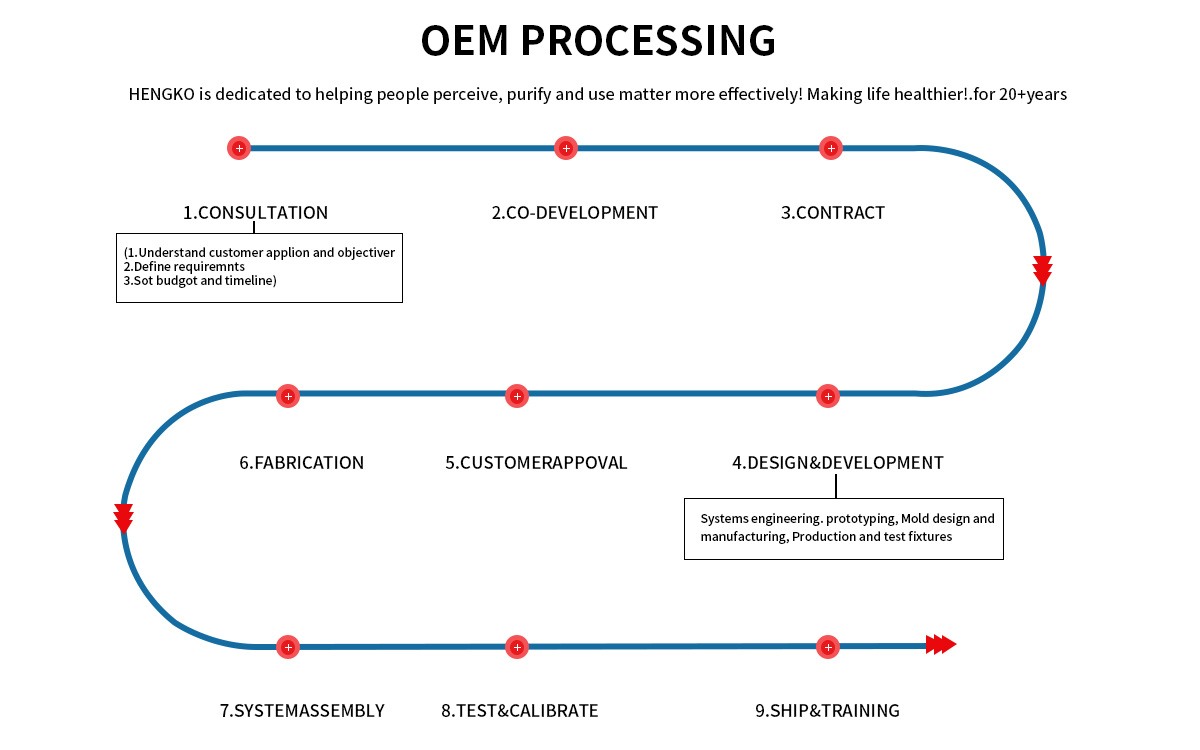

Can't find a product that meets your needs? Contact our sales staff for OEM/ODM customization services!